Rolled pipes made from polymer materials are actively replacing similar metal products. Polypropylene products are popular due to their simple installation and appearance.

Moreover, in terms of operational parameters, systems made from reinforced plastic products are practically not inferior to communications made from rolled metal pipes. Polymer networks made from reinforced products are characterized by increased reliability and durability, but only if the installation technology is followed.

Therefore, you need to know the specifics of stripping reinforced polypropylene pipes so that the engineering system created from them can operate without failure for decades.

Why is reinforcement needed?

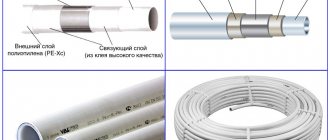

A pipe with internal reinforcement is a three-layer product. The product consists of two PP and one reinforcing layer. Thanks to the reinforcement, the strength of the rolled pipe does not deteriorate when the temperature changes sharply.

Types of PP rental

Reinforced products also have a lower thermal expansion coefficient. This characteristic for products with aluminum reinforcement is 6% lower compared to pipe products made from polypropylene alone.

Thanks to the additional reinforcing layer in the rolled pipe, the engineering systems created from it are able to move hot water. In this case, there is no rupture of networks made of reinforced pipe products. The flexibility of the reinforcing material allows it to compensate for temperature changes.

Reinforcement of polypropylene pipes is carried out using:

- fiberglass;

- aluminum foil.

Manufacturers produce tubular products reinforced with solid or perforated foil. In the second option, polypropylene penetrates through an aluminum mesh.

This allows the inner and outer polymer layers to be securely connected. Therefore, the reliability of such pipes increases with increasing temperature loads.

How it works?

If the aluminum foil is outside, then it is removed before welding the elements. Inside the product, aluminum is also removed, since it is necessary to prevent contact of water with the metal. If this is not done, then electrical potentials may arise in the system, which during operation will destroy the reinforcing film. This will change the properties of the product, which will negatively affect the operation of the system as a whole - polypropylene pipes delaminate and leaks appear.

If the product is reinforced with fiberglass, then stripping will not be required. The mesh is located in the inner part, so that from the outside it does not come into contact with the fitting, and it is not afraid of water.

When cleaning is required

The ends of polymer pipes with fiberglass reinforcement do not need to be pre-cleaned. However, for products with aluminum reinforcement, it is necessary to remove the metal inner layer and strip the ends. Only then is a reliable connection established.

After all, molten aluminum prevents the formation of a hermetically sealed joint. Moreover, it is necessary to exclude the possibility of corrosion resulting from the interaction of the metal with the aquatic environment. The preparation process also allows you to remove various contaminants from the joined areas.

Technical description

Modern technologies have made it possible to create a durable, lightweight material that is not susceptible to corrosion, has good strength characteristics, and does not react with aggressive environments.

Low price , light weight, ease of installation determine the widespread use of polypropylene pipes (what are pipeline fittings).

The industry produces several types of products, some of which contain a reinforcing layer outside or inside the pipe.

High-quality soldering of such models is only possible if the ends are cleared of aluminum foil.

Two types of shaver are used in the work:

- manual,

- automatic.

The first ones are used when performing one-time operations, the second one is capable of cleaning pipes in large volumes, which is typical for large construction companies (supports and fastening of process pipelines).

What do you know about the operating principle of a sewage pumping station? A detailed technical description of industrial and household equipment is published in a useful article.

Read about the effectiveness of aeration columns for deferrizing water on this page.

Tools for work

The installation process of a reinforced pipeline begins with the preparation of the tool. Stripping for polypropylene pipes can be purchased as a property, rented, or from familiar installers.

Tool for stripping polypropylene reinforced pipes

Manufacturers produce manual and mechanical trimmers. It is recommended to select a device taking into account the scope of work and the skills of the installer.

A hand-held tool is best used by inexperienced people. Such end-cutters for polypropylene pipes allow for highly precise and controlled operations. Mechanical tools will help you quickly complete a large number of jobs.

It is better to use stainless shaver for polypropylene pipes. These devices allow you to make cuts without burrs.

When manually processing, it is best to use a double-sided tool, which allows you to strip two tubular products of different diameters. These devices are usually equipped with removable handles in the form of two rods.

Recommended set

To install reinforced polymer systems, you will need the following devices:

- pencil or marker to mark the depth of the layer to be removed;

- cutter or special scissors for cutting part of the PP pipe;

- a gauge for restoring geometry and a countersink for removing chamfers and burrs from cakes;

- pipe bender or conductor, when the project requires bending pipes at certain angles and with radii not exceeding permissible values;

- trimmers for polypropylene pipes in the form of stripping couplings, trimmers or shaver for removing the metal layer.

A tool in the form of a trimmer for polypropylene pipes is selected depending on the characteristics of the reinforcement of the products and the financial capabilities of the contractor.

Stripping couplings have blades located in the middle. The devices are put on the ends of the pipe and rotated in a clockwise direction. They allow you to carefully and quickly remove the outer layer of aluminum.

Trimmers with internal blades allow you to make an even cut after 2-3 turns. This type of tool removes aluminum located in the middle of the pipe wall to a depth of 1 to 2 mm. If necessary, trimmers can be used to process non-reinforced polymer pipelines.

Shavers are available for pipes of various round sections. The tool is often used as an attachment for an electric drill. With this application, it is imperative to control the speed of the electric tool.

Shavers are manufactured to remove the aluminum layer located outside and inside the pipe wall.

What else is needed?

The full list of tools is as follows:

- pencil,

- roulette,

- trimming scissors,

- stripping tool,

- welding soldering iron.

It is better to cut polypropylene pipes with special scissors. A hacksaw or turbine does not allow you to make the cut as even as possible. However, trimming shears are used in cases where installation work on products is carried out regularly. If you need to install a home water supply (this means a single case, for example, the work is done for yourself during repairs), then you can refuse special scissors.

Stripping methods

The type of reinforcement of a polymer product affects the method of stripping the products. The option is selected depending on the location of the reinforcing layer in the wall of the pipe product.

Reinforcement

After all, polypropylene pipes are produced not only with internal, but also with external reinforcement. Therefore, various devices are used to process the ends.

Outer layer

When the reinforcing layer is located outside, high-quality soldering can be created only after melting and stripping the reinforcing material. There is no need to neglect the process of pre-treatment of the ends of the pipes, since even after heating the aluminum foil will not be able to bond with the polymer layer.

Therefore, the joint will not be airtight. The top layer is cleaned to a depth sufficient for reliable adhesion of the plastic. Often done using couplings.

Inner layer

Stripping of aluminum foil inside the pipe wall is carried out to prevent interaction of the metal layer with the aqueous environment. The operation is performed to exclude the formation of electrochemical processes. Therefore, the aluminum layer is not destroyed in areas where soldering is performed.

Stripping process

It is recommended that inexperienced people perform stripping using hand-held devices. The process is carried out easily and quickly even without special skills. The main thing is to follow the recommendations of specialists.

Before stripping, you first need to select a coupling of a suitable diameter in accordance with the cross-section of the reinforced pipe. Then the tool is put on the end of the pipe product. Then 2-4 turns of the device are performed.

Simple steps in most cases allow you to get an even cut, the depth of which will be approximately 2 mm. The work is usually carried out by one person. There is no need to use expensive tools.

Do-it-yourself pipe trimmer

In mass production of shaped pipes (for example, in sports car and motorcycle workshops, or in plumbing repair shops), a manual pipe ender can be made independently. To do this, the initial diagram of the trimmer, which is shown in the figure, is made according to the workpieces available to the home craftsman.

The design consists of the following parts:

- A base in which milled grooves are made for mounting a clamping device. In turn, the shape of the base can be adapted to an existing workbench, work table, etc.

- An L-shaped bracket with three longitudinal grooves, the presence of which allows pipes of different diameters to be fixed in the fixture.

- Sliders with adjusting and clamping screw.

- Replaceable presser foot.

- A bracket that presses the foot to the slide with screws.

- Bearing unit.

- A swing arm that serves as a supporting surface for the bearing assembly.

- A shaft that is structurally no different from a similar part of industrial facing machines.

To make a shaft, you can use the front shock absorber strut of a passenger car (for example, a VAZ - they are easier to get at a car service center). In addition, the steel grade of the shock absorber strut, in terms of its strength and performance characteristics, fully complies with the rigidity requirements for high-quality trimming of steel (and, especially, aluminum) pipes. The guides of the rack itself are suitable for guiding the shaft: they have a wear-resistant surface coating based on antifriction alloys. The ends of the stand are naturally subject to additional processing - for mounting in a drill chuck, and for installing a core cutter.

Needle bearings should be pressed into the guides, the size of which is selected according to the dimensions of the guides. Two bearings installed in the guide from the return cylinders of a decommissioned hydraulic press will ensure the necessary rigidity and parallelism of the main working unit of the trimmer. Bearings are installed simultaneously at both ends of the housing.

The existing advice regarding the installation of fluoroplastic guides should be treated with skepticism, since the load-bearing capacity of fluoroplastic is much lower than that of bearings.

To make other elements of a homemade pipe trimmer, you can use rolled profiles - angles or channels of the appropriate size. It is better to perform profiling and production of grooves on a coordinate milling machine, thereby guaranteeing their accuracy and parallelism. It will not be difficult to make a clamping device, for which a new clamp with the required diameter and length is suitable.

The rotary lever must have sufficient rigidity, so for its manufacture it is necessary to use a strip with a thickness of at least 12...16 mm. On the part of the body where the rotary lever is installed, it is worth putting angular marks along which it is easier to position the pipe.

Common questions and answers about soldering polypropylene

Is it possible to solder pipes from one manufacturer and fittings from another? Of course it is possible, but I would like to warn you that both couplings and pipes should be used of proper quality. You should not use parts from unnamed manufacturers. In unprofessional stores they often sell pipes from different companies, but the fittings are the same, from an unnamed manufacturer. I don't recommend using this combination. In general, nothing prevents you from soldering pipes and fittings from different manufacturers, with or without different reinforcement on different sides of the coupling.

Is it possible to bend polypropylene pipes? They cannot be bent, either during installation or after. If there is a need to bend the pipe during installation, then you should use contours or combinations of corners. To be fair, it is worth noting that the weak point of the bending pipeline is the junction of the pipe and the fitting. This mating point breaks off at some breaking force. To make sure of this, just solder a test structure from a corner and two 50 cm pipe sections, and try to break this “poker” with your hands.

How to solder pipes if the faucet does not hold it? It is strictly forbidden to weld if there is water in the area to be soldered. If for some reason it is not possible to completely shut off the water, you need to stop it while welding. On the Internet they advise plugging the pipe with bread crumbs, but the problem is that the crumb is immediately squeezed out by the newly created pressure in the pipe. Therefore, the method will only work when it is possible to open the area up to the soldering point for air to escape. And when the pipes are soldered, the crumb easily pops out when pressure is applied.

Advice: if during welding you could hear the hissing of water on the nozzle, it is better to cut out the assembly and redo it! It’s better to spend extra time during installation than to fix and eliminate leaks in the future, with a bunch of problems that pop up!

In this photo you can see that the plug on the filter is unscrewed and excess water flows down the cloth from there. And in the place of soldering the bread crumb is plugged. Thanks to the open filter, we had a little over a minute to do the soldering before the water squeezed out the crumb.

Actually, this is where I propose to end the presentation of information. Over time, I plan to expand the list of common questions about soldering polypropylene pipes.

Rate this publication:

- Currently 3.75

Rating: 3.8 (16 votes)