Many products are produced from rolled metal, but the most popular denomination is thin-walled, galvanized or steel pipe. Their multifunctional purpose is due to their versatility and excellent performance. These products are produced using different technologies, from different steels, but their quality remains impeccable thanks to standardization. However, when choosing products, it is important to navigate their range.

Thin-walled pipe is a popular material for the installation of various networks and highways

Thin-walled stainless steel pipe

A specific building material in the form of thin-walled stainless pipes is characterized by minimal wall thickness and resistance to various types of high-temperature, aggressive mechanical and chemical influences.

Scope of application

The unique performance properties of thin-walled pipes are highly appreciated in many industrial and commercial areas. They serve as an important link in various engineering networks. The limited scope of use is due only to the high cost of the product. For example, when installing heating and plumbing systems and creating decorative fences, the use of thin-walled stainless steel samples is not recommended due to unprofitability. Seamless models are in demand in the aviation, automotive, aerospace, medicine, construction, dry cleaning and food industries. Thin-walled elements are used to make stair railings, canopies, and small canopies. In the furniture segment, electric-welded analogues are in predominant demand.

Standards

The family of thin-walled pipes is represented by solid (seamless) and welded products. When producing thin-walled pipes, manufacturers are guided by regulatory technical documentation that meets international requirements, in particular:

- GOST 10498-82, developed for seamless samples;

- GOST 11068-81 - for electric welded options,

- GOST 9941-81 – for cold- and heat-deformed products.

Transforming steel sleeve blanks into seamless thin-walled pipes requires powerful piercing presses, complex rolling mills and furnaces. The formation of electric welded products is carried out from cut strips (steel strips) connected using induction, laser or plasma welding. At the final stage, the shape and parameters are calibrated.

The range of seamless stainless steel is represented by corrosion-resistant elements with an outer diameter to thickness ratio of more than 40. Samples with a diameter of up to 80 mm are subject to heat treatment. If there are flaws, the surface is ground or bored.

Basic information about pipes can be gleaned from the markings. For example, the designation “Pipe 70 inx0.5 ovx4000 - 08Х18Н10Т GOST 10498-82” contains the pipe diameter, manufacturing accuracy (especially high), metal grade 08Х18Н10Т, GOST and length in mm for measured products. The measured size is expressed in numbers 5.6, 7 m, unmeasured - 0.75-12.5 m. The precision of pipe manufacturing can be increased, high or normal, differing in the deviation index, curvature and ovality. The color of the products is determined by the grade of steel and varies from light to matte gray. Mirror shine is achieved through electrochemical and mechanical processing.

Electric-welded stainless steel pipes have an outer diameter ranging from 8... 76 mm (up to 102 mm) and a thickness of 0.8... 1.8 mm (up to 4 mm). The dimensional parameter is limited to values of 5-9 m, non-dimensional - 1.5...9 m. The magnitude of deviations is limited to 15 mm. All deviations and tolerances are specified in the regulations.

Advantages of thin-walled pipes

The product demonstrates its trouble-free operation for a long time, due to the following features:

- increased internal space,

- aesthetics,

- reliability of welds,

- vibration resistance,

- strength and flexibility, allowing you to go around any obstacles with a minimum of connecting fittings;

- safety for health,

- possibility of using pipes of smaller cross-section,

- ensuring the viability of systems for a long time.

Polished products attract consumer attention

functionality, presentability, durability, decorative characteristics and the absence of toxic emissions. The popularity of the products is due to their exceptionally smooth surface, which prevents the formation of deposits and the growth of bacteria, as well as their strength and anti-corrosion resistance.

Source

Areas of product use

The use of thin-walled pipes - black, from any other type of steel or metal - although limited due to the lower mechanical stability of the product, is nevertheless widespread in many areas of industry.

Areas of application of products:

- hydraulic or pneumatic drive units for automotive, aviation and shipping products;

- construction of residential buildings and industrial buildings;

- servicing residents, arrangement of communication systems;

- production of furniture and other household items;

- energy enterprises that have working boilers;

- in everyday life, for example, for electrical wiring.

Thin-walled stainless steel pipe: characteristics, application, GOST

Stainless steel pipes occupy a significant part of the pipe rolling market. They combine strength and fire resistance at a relative low cost, which neither expensive copper pipes nor fire-hazardous plastic can boast of. Large volumes of manufactured products have made it possible to bring technological processes to near perfection, so in most cases the finished products are distinguished by high quality and a wide range of applications.

The production of stainless steel pipes is based on the requirements of GOST and technical specifications. Standards determine production technology, assortment, tolerances, acceptance rules, test methods and other factors that must be taken into account when manufacturing stainless steel pipes. Let's take a closer look at the types of pipes and their areas of application, as well as the factors that determine the market price for this type of product.

Seamless cold-formed pipe production process

These products must comply with the requirements of GOST 8734-75.

In general, the manufacturing process of such pipes is identical to that described above, however, two important technological features are provided:

- The sleeve obtained by piercing is pre-cooled before passing through the rollers, after which, at a reduced temperature, it is fed to the rollers. As a result of this requirement, stresses are generated in the metal.

- To relieve stress, additional heat treatment of the metal is performed at the end of all stages of the process. As a result of this, the steel again becomes sufficiently ductile and tough. After completion of the heat treatment, another calibration is carried out on the rollers.

Production points: bending with your own hands or round from the factory

Stainless steel seamless pipe is made through a complex and expensive process that shapes the blank on sophisticated rolling machines to turn it into a finished product.

- Flat blanks are rolled into pipes;

- Each edge is welded using inductive current, plasma or laser;

- Welds undergo a cleaning process;

- Then it’s time to calibrate the required sizes and shapes;

- Eddy currents control the seams.

After the procedure, the workpiece is cut into pieces of the required length, and they are sent to warehouses.

The welding method is used in the manufacture of thin-walled stainless steel pipes; this process seems complex at first glance, but it is much simpler than the alternative.

Advice: when buying products, pay attention to thin-walled ones, their cost is 20-40% higher, but the quality is much higher than electric welded ones.

Types of thin-walled products

The grade of stainless steel is different, in order to figure this out, let’s find out what types of seamless stainless products exist:

- Round electric welded. It is used in areas ranging from mechanical engineering and water or heating supply systems; for the drainage system; for production purposes for household kitchen and bathroom accessories; for interior decoration. External surfaces are polished or mirrored, they can vary from 600 cm, and are made to order.

- Seamless thin-walled hot and cold production. They have high strength, are used for water supply systems, and do not leak. The size varies from 0.6*1 cm to 0.54*11 cm.

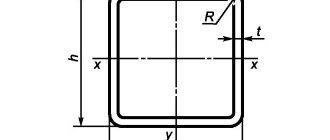

- Profile rectangular or square. These are used in various fields due to their ability to withstand significant loads and the ability to bend without losing their unique properties. The size varies from 600 cm. They can be produced in oval shape with mirror or polished surfaces.

Advice: before purchasing, decide for what purpose you are buying it; if you choose incorrectly, you will have to change or redo the design.

Electric-welded thin-walled

In this section we will talk about welded pipes, which are manufactured in production with a wall thickness of 0.8 to 4 millimeters, and their diameter is 0.8-10.2 cm.

- The measured length of such a pipe is made from 4.5 to 9 meters.

- Pieces that are multiples of this size are produced with allowances for every 4-6 mm.

- Measured and multiple measured lengths, 11% of the total weight with a length of 1.5-10 meters.

A stainless thin-walled pipe, which was produced by electric welding, meets GOST standards with a permissible deviation (exceeding) of the dimensional dimensions of no more than 1.5 cm.

Special Moments

As mentioned above, seamless pipes with thin walls are produced, and often. This is not a theoretical probability, but production points:

- The production of seamless pipes with thin walls is possible;

- Thin-walled pipes are manufactured in accordance with GOST 9941-81, which provides for the production of pipes with thin walls of at least 0.02 cm, meaning cold-deformed pipe;

- Production of thin-walled steel pipes in accordance with GOST 10498-82, the product standard is hot-deformed with a thickness of at least 0.012 cm.

- From 500 to 3000 cm with a diameter from 0.4 to 0.6 cm;

- From 500 to 5000 cm with a diameter from 0.6 to 2.5 cm;

- From 500 to 4000 cm with a diameter of more than 2.5 cm.

A thin-walled stainless steel pipe has certain standard dimensions.

Seamless hot-formed pipe production process

These products on the territory of the Russian Federation must meet the requirements of GOST 8732-78. Of course, you can purchase not only products made in accordance with GOST, but also foreign ones, which are subject to the standards of the manufacturing country.

Product production algorithm:

- The pre-fabricated rod (cylinder-shaped blank) is fed into the furnace. There it is heated to a temperature at which recrystallization of the alloy or metal begins.

- Next, the workpiece is moved to a piercing press, where it is shaped into a hollow cylinder - the so-called sleeve.

- The resulting workpiece is gradually passed through a series of rollers (rollers). During the process, the liner acquires uniform thickness of the material and the diameter required by the assortment. When rolling, there must be a mandrel inside the sleeve.

- After the calibration process is completed, the finished product is cut into pieces of the required length, after which they are packaged and sent to the warehouse.

Dimensions of seamless corrosion-resistant steel alloy pipes 12Х18Н10Т according to GOST 9941-81

Depending on the thickness and diameter, the maximum length of stainless steel pipes prescribed in the standard is in the range from 4 to 7 m. The enterprises of the ChTPZ group produce corrosion-resistant pipes of the following lengths in accordance with GOST 9941-81:

- unmeasured from 0.75 m to max. standard length - for products with thickness. walls up to 0.5 mm;

- unmeasured from 1 m to max. standard length - for products with a thickness index of 0.5-1 mm;

- undimensional in the range from 1.5 to 12.5 m - for products with a thickness ≥ 1;

- dimensional - within the limits of non-dimensional and at the same time no more than max. standard size with max. permissible error +15 mm;

- multiple dimensional - within the dimensional limits with an allowance of 5 mm for the cut and max. total length error +15 mm. Min. multiple length – 300 mm.

By prior agreement with the client, the enterprises of the ChelPipe Group produce rolled pipes whose measured length exceeds the standard maximum prescribed by the described GOST.

It is also allowed to produce products longer than 12.5 m and pipes with a diameter of 15 mm and a wall GOST 9941 - Cold-deformed stainless steel pipes

The interstate standard GOST 9941-81 regulates the range, technical requirements, acceptance rules, test methods, marking, packaging, transportation and storage of seamless cold- and heat-deformed pipes made of corrosion-resistant steel for general use.

Assortment

According to GOST 9941-81, seamless stainless steel pipes are manufactured with a diameter from 5 to 273 mm with a wall thickness from 0.2 to 22 mm . The table below shows the maximum possible length for each size. The first column indicates the outer diameter, the header indicates the wall thickness.

See table. (opens in a new window)

There are a number of notes to this table:

If the ratio of diameter to thickness is greater than or equal to 40, the pipe is considered thin-walled . The requirements for such a pipe in terms of technical characteristics and maximum dimensional deviations are established by regulatory and technical documentation.

There are restrictions on the range depending on the steel used for production. If the product is made of steel grades 12Х17, 08Х17Т, 15Х25Т, the outer diameter should not be less than 21 mm. For alloy 06ХН28МДТ, the outer diameter should be in the range from 14 to 85 mm and the wall thickness from 1 to 5 mm.

Limit deviations

The process of producing pipes on a rolling machine is technologically complex.

The blank has to be molded to the size of a hollow sleeve and therefore often the nominal dimensions stated in the documentation do not correspond to the actual ones. GOST 9941-81 determines which deviations are acceptable. They are: Pipe dimensions, mm

| Limit deviations for manufacturing accuracy | |||

| ordinary | increased | high | |

| By outer diameter | |||

| with a diameter from 5 to 10 | ±0.3 mm | ±0.2 mm | ±0.15 mm |

| with a diameter of St. 10 to 30 | ±0.4 mm | ±0.3 mm | ±0.2 mm |

| with a diameter of St. 30 to 95 | ±1,2% | ±1,0% | ±0,8% |

| with a diameter of St. 95 | ±1,0% | ±1,0% | ±0,8% |

| According to wall thickness | |||

| at wall 0.2 | ±0.05 mm | ±0.03 mm | – |

| with a wall from 0.3 to 0.4 | ±0.07 mm | ±0.05 mm | – |

| with a wall from 0.5 to 0.6 | ±0.10 mm | ±0.07 mm | – |

| with a wall from 0.7 to 1 | ±0.15 mm | ±0.10 mm | – |

| at the wall of St. 1 to 3 | +12,5% -15% | ±12,5% | +12,5% -10% |

| at the wall of St. 3 to 7 | ±12,5% | +12,5% -10% | ±10% |

| at the wall of St. 7 | +12,5% -10% | ±10% | – |

Pipes, highlighted in dark yellow in the table , are produced in only two accuracy categories: normal and high. Other maximum deviations are established for them:

| Pipe sizes, mm | Limit deviations for manufacturing accuracy | |

| ordinary | high | |

| By outer diameter | ±1,2% | ±1% |

| According to wall thickness | ||

| with a wall from 1.5 to 2.5 | ±15% | 12,5% -15% |

| at the wall of St. 2.5 to 4 | 12,5% -15% | ±12,5% |

Also, unique maximum deviations are established for pipes made from steel 06ХН28МДТ . They are listed in the table below.

| Pipe sizes, mm | Limit deviations for manufacturing accuracy | |

| ordinary | high | |

| By outer diameter | ||

| with diameter up to 30 | ±0.45 mm | – |

| with a diameter of St. thirty | ±1,2% | – |

| According to wall thickness | ||

| at wall up to 3 | ±15,0% | – |

| at the wall of St. 3 | ±12,5% | – |

Typically, pipes are manufactured based on outer diameter and wall thickness. But if the consumer wishes, GOST allows manufacturing according to the internal diameter and thickness. In this case, permissible deviations are specified separately.

If the product turns out to be slightly oval, the ovality should not bring the diameter beyond the maximum deviations in the outer diameter.

Deviations in curvature are also established. The curvature on any section 1 m long should not exceed:

- 1 mm – with a diameter of 5 mm or more, with a wall thickness of 0.5 mm or more;

- 2 mm – with a diameter of 15 mm or more, with a wall thickness of less than 0.5 mm.

- not regulated - with a diameter of less than 15 mm, with a wall thickness of less than 0.5 mm. These pipes should not have sharp bends.

Classification of stainless steel pipes

- By manufacturing method: stainless steel electric-welded pipes;

- hot- and cold-formed seamless stainless steel pipes;

- For surface treatment:

matte stainless steel pipes;

- round;

- ordinary;

All supplied types of stainless steel pipes (12Х18Н10Т, 08Х18Н12T, AISI 304, 50×25 pipes, etc.) are certified and manufactured in accordance with DIN and GOST standards.

Buy aluminum round pipe

You can buy round aluminum pipes at retail and wholesale at the most affordable prices. To do this, you can contact our managers at the phone numbers listed on the website or place an online order. Aluminum pipes can be picked up from the company’s warehouse in the Moscow region or ordered delivered to any region of Russia and the CIS countries. The company has its own fleet of vehicles to deliver orders throughout Moscow, Moscow Region and the largest regions of Russia; we also cooperate with leading transport companies in the Russian Federation.

Combination of corrosion resistance, heat resistance and heat resistance of pipes made of 12Х18Н10Т

The heat resistance of pipes made of stainless steel 12Х18Н10Т ensures that their surface is resistant to chemical erosion in gas environments with temperatures exceeding 550°C when operating in low-load or unloaded modes. For this alloy, the maximum operating temperature of metal products is 800°C (up to 10 thousand hours). At 850°C in an air environment, intense scale formation begins on the surface of the pipe. Steel alloy 12Х18Н10Т is unstable in a sulfur environment.

In accordance with the characteristics of heat resistance, corrosion-resistant pipes are used in heat exchangers, body elements, spark plug electrodes, and functional elements of exhaust systems. They are also used when it is impossible to use pipes made of nickel-free steel alloys.

Corrosion-resistant seamless pipes in accordance with GOST 9941-81 are used in vessels, units and pipelines under pressure used in the temperature range –196...+600°C, and with an aggressive working environment – up to +350°C.

You can place an order in the catalog

or by phone

8 800 2345 005

Pipe weight calculation

Often the consumer is faced with the need to calculate the weight of a linear meter of pipe . This can be done using special rolled metal calculators, which can be found on our website or on many other specialized sites on the Internet. The standard specifies the following formula for calculating weight:

Weight=3.14/1000*((Diameter – Thickness)*Thickness*Density)

The mass of a meter is usually measured in kilograms. For calculations, the steel density must be taken from the following table.

| steel grade | Temporary resistance | Relative extension | Density |

| no less | |||

| 08Х17Т | 372 (38) | 17 | 7,70 |

| 08Х13 | 372 (38) | 22 | 7,70 |

| 12Х13 | 392 (40) | 22 | 7,70 |

| 12Х17 | 441 (45) | 17 | 7,70 |

| 15Х25Т | 461 (47) | 17 | 7,60 |

| 04Х18Н10 | 490 (50) | 45 | 7,90 |

| 08Х20Н14С2 | 510 (52) | 35 | 7,70 |

| 10Х17Н13М2Т | 529 (54) | 35 | 8,00 |

| 08Х18Н12Б | 529 (54) | 37 | 7,90 |

| 10Х23Н18 | 529 (54) | 35 | 7,95 |

| 08Х18Н10 | 529 (54) | 37 | 7,90 |

| 08Х18Н10Т | 549 (56) | 37 | 7,90 |

| 08Х18Н12Т | 549 (56) | 37 | 7,95 |

| 08Х17Н15М3Т | 549 (56) | 35 | 8,10 |

| 12Х18Н10Т | 549 (56) | 35 | 7,95 |

| 12Х18Н12Т | 549 (56) | 35 | 7,90 |

| 12Х18Н9 | 549 (56) | 37 | 7,90 |

| 17Х18Н9 | 568 (58) | 35 | 7,90 |

| 08Х22Н6Т | 588 (60) | 20 | 7,60 |

| 06ХН28МДТ | 490 (50) | 30 | 7,96 |

All calculated values for stainless steel seamless pipes in our database are made taking into account these requirements using the above formula! The steel density for basic calculations was taken equal to 7.85, which corresponds to GOST standards.

Length

Often the buyer has a question regarding length . The standard on this matter states that the production of pipes is allowed:

- Measured length - within unmeasured length. In this case, the length should not exceed the values specified in Table 1 of GOST. The deviation in length should not exceed +15 mm. It is allowed to manufacture pipes with a length exceeding the specified values, but only with appropriate agreement between the manufacturer and the consumer.

- Length that is a multiple of the measured length – within the measured length. In this case, allowances of 5 mm are allowed for each cut. The deviation in length should not be more than 15 mm

- of unmeasured length with a wall thickness of up to 0.5 - it is allowed to manufacture pipes with a length of 0.75 meters up to the value indicated in Table 1. In this case, no more than 6% of products with a length of 0.5 to 0.75 meters are allowed in a batch.

- of unmeasured length with a wall thickness of 0.5 to 1 mm – it is allowed to manufacture pipes with a length of 1 meter up to the size indicated in Table 1. In this case, no more than 6% of products with a length of 0.75 to 1 meter are allowed in a batch.

- of unmeasured length with a wall thickness of more than 1 mm - minimum length 1.5 meters, maximum length 12.5 meters. At the same time, no more than 6% of products with a length of 0.75 to 1.5 meters are allowed in a batch.

It is possible to produce pipes longer than 12.5 meters, but only if agreed upon by the manufacturer and the buyer.

In case of approval for the production of pipes with a length exceeding those established in Table 1, it must be remembered that pipes with a diameter of up to 25 mm cannot be longer than 16 meters.

Difference from hot-deformed

In accordance with this standard, pipes are produced by cold or warm deformation. As you know, there are stainless steel seamless pipes manufactured according to GOST 9940-81 by hot rolling. The difference from cold-deformed ones is in the manufacturing method. In cold forming, the workpiece is formed without preheating to a high temperature. Since there is no heating, the resulting pipe is not subject to temperature deformation and, as a result, comes out more accurate and uniform.

The actual dimensions of pipes produced in accordance with GOST 9941-81 are much more accurate than with hot forming. Permissible deviations in size are usually smaller. Therefore, if the project requires increased manufacturing accuracy, choose cold-rolled products.

The main disadvantage of such pipes is their higher price. They are usually more expensive than hot rolled ones. However, some projects require just such products. Therefore, if manufacturing accuracy is not a critical factor for the project, it is more advisable to give preference to hot-deformed ones due to their lower price.

Specifications

There are three methods for producing stainless thin-wall pipe:

- By the electric welding method (electric arc in an inert gas environment, or high-frequency induction currents), in this case, the production of stainless steel pipes is regulated by GOST 11068 - 81. The range of electric welded pipes includes products with an outer diameter from 8 mm to 102 mm, and wall thickness from 0.8 mm to 4 mm, according to the diameter. An electric-welded pipe is manufactured in pieces of measured length from five to nine meters and unmeasured lengths from one and a half to nine meters;

- Cold deformation (hot-deformed pipes are used as blanks), in this case the production of stainless steel pipes is regulated by GOST 9941-81. The range of stainless steel pipes includes products with diameters from 5 mm to 273 mm, and wall thicknesses from 0.2 mm to 22 mm. Measured and unmeasured lengths of products are determined according to the table specified in the guest document, based on the diameter of the product and wall thickness.

- Hot deformation (from a cylinder-shaped steel monolith heated to the recrystallization temperature, a sleeve is made using a special press, which then takes on the required shape and parameters using rollers, is calibrated and cut into pieces of the required length). In this case, the parameters of manufactured stainless steel pipes are regulated by GOST 8732-78, according to which the range of stainless steel pipes includes products with a diameter from 20 mm to 530 mm and a wall thickness from 2.5 mm to 75 mm. The pipe is made in pieces of unmeasured length in the range from four meters to twelve and a half meters, with measured lengths within the unmeasured range.

Thin-walled products for electrical wiring

When choosing electrical thin-walled steel pipes, first of all you need to be aware of whether the cross-section of the product will ensure the laying of all the necessary wires and cables without damaging the electrical insulation. For such purposes, electrical corrugated pipes remain popular because they are reliable in operation.

In addition, it is extremely important that the inner surface is as smooth as possible, without any defects (welding seams, burrs, foreign inclusions, etc.), otherwise the threat of damage to the wire insulation and, as a result, short circuit and harm also increases health of residents.

Production technologies

There are seamless thin-walled pipes and products made using a welded joint. Seamless technology for the production of thin-walled stainless steel pipes involves the use of powerful presses, with the help of which a cylindrical stainless steel blank is transformed into a pipe with geometric parameters that meet all the requirements of the regulatory document.

Welded thin-walled pipes using stainless steel are produced as follows.

- The stainless steel blank, which initially has a flat shape, is rolled into a pipe.

- The edges of the pipe blank, forming the joint of the product, are welded using induction, plasma or laser technology.

- The weld formed on the surface of the pipe is cleaned.

- In order for a thin-walled pipe manufactured using this technology to acquire the required geometric parameters, it is calibrated using special equipment.

- To check how tight the formed weld is, it is subjected to an eddy current test.

- Formed and welded stainless steel pipes are cut into specific lengths and sent to warehouse.

Production of electric-welded pipes from stainless strips

It should be noted that the technology for the production of thin-walled steel pipes from stainless steel, which involves the use of welding, allows us to reduce the cost of such products by 30–50% when compared with the seamless method. In this regard, such pipe products are produced mainly using welding.

Welding sequence

- After cutting the chamfers, the end parts of the pipes are cleaned. The lower part is welded with a ceiling seam. The electrode is placed perpendicular to the surface. The side surfaces are treated with a vertical seam. The electrode is directed upward. The first seam is completed at the top of the pipe. After cleaning from slag, the procedure is repeated; two passes are necessary to obtain a high-quality seam.

When welding galvanized products, HLS-B flux is used, and the treatment area is pre-wiped with acid. While working, the welder wears a respirator; when the zinc is heated, harmful gases are released.

To bend the pipe, use a hydraulic or electric pipe bender. Hydraulic bending is performed using the extrusion method, in this case a crease is formed, and if the force is too great, the pipe breaks. An electric device creates a rounding radius when the segment rotates, resulting in a smooth and high-quality bend.

Production

In accordance with the requirement of GOST 28 548−90, a seamless pipe must be produced by rolling, forging, drawing or pressing without welds along the entire length, since the highest quality seam cannot eliminate leakage. The most commonly used steel is 10Х17Н13М2Т (AISI 316Ti). The analogue is 08Х17Н13М2Т. According to the ratio of wall thickness and outer diameter, all steel round pipes are divided into thick-walled and thin-walled.

| Name | Ratio of pipe thickness and outer diameter |

| Thin-walled stainless steel pipe | 0,025 — 0,05 |

| Extra thin-walled stainless steel pipe | less than 0.025. |

A ratio of 0.05 means wall thickness = 1/20 diameter

With a ratio of 0.025, wall thickness = 1/40 diameter

Assortment

If the value of the ratio of the outer diameter to the wall thickness of the product is in the range of numbers from 12.5 mm to 40 mm, or the wall thickness of the product is less than 1.5 mm, then such a steel pipe is defined as thin-walled.

In the case when the ratio of the outer diameter to the wall thickness of the product is more than 40 mm, then the steel pipe is defined as extra-thin-walled.

Stainless steel thin-walled pipe is defined by a separate standard GOST 10498-82. The range of extra-thin-walled stainless steel pipes includes products with a diameter from 4 mm to 120 mm, with a wall thickness from 0.2 mm to 1 mm, according to the diameter.

A stainless thin-walled steel pipe is made in sections:

- measured length, from half a meter to three meters, with a product diameter of 4 - 6 mm;

- measured length, from half a meter to five meters, with a product diameter of 6 - 25 mm;

- measured length, from half a meter to four meters, with a product diameter of more than 25 mm;

- of unmeasured length, from half a meter to eight meters.