What fittings are needed to connect a heating radiator made of cast iron or aluminum? Is it necessary to equip the heating device with any shut-off or control valves? In our article we will try to give the reader advice on choosing the optimal set of equipment and its installation.

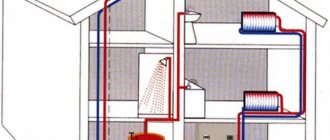

One of the options for connecting a heating device.

Purpose

The instructions assume the use of fittings to solve the following problems:

- Transition of the main line to another diameter. This situation occurs especially often when connecting new wiring to old wiring.

- Creating a system branch. Allows you to direct the coolant to different circuits.

- Connecting pipes to the battery. Creates a reliable removable or non-removable connection.

Connecting the radiator yourself

- Connecting pipes to each other. Assembles the pipeline into a single whole.

Connecting copper pipes with a coupling

The radiator connection itself looks like this:

- We mount the brackets on the wall using a hammer drill and hang the battery on them.

- We install fittings on the radiator.

Advice: supply the heated coolant from below. Otherwise, due to the fact that hot water rises upward, the lower part of the device simply will not warm up.

- We connect the pipes.

So, we’ve figured out the functions, now let’s figure out what fittings are needed to connect a heating radiator.

Installation

Sgony

Here are instructions for connecting a cast-iron battery to squeegees.

- We push the locknuts and the passage plug onto the long threads of the liner until they stop.

- We hang the radiator by inserting the liner threads into the first section by 1-3 centimeters.

Please note: the heating device is hung strictly horizontally, level. When tilted towards the liner, air will collect in it.

- We wind the plug along the thread with a bunch of plumbing flax with paint or silicone pipe sealant.

- We wrap it into the radiator until it stops with moderate force.

- We drive the locknut to the plug, leaving a gap of 5 - 10 mm between them.

- We wind a bunch of flax into the remaining gap along the thread (again with paint or sealant).

- Tighten the locknut.

The cast iron battery is connected to the leads.

American women

Here the procedure is much simpler:

- Let's look at the Americans;

- We screw the parts of the fittings with the union nut into the coupling, tap or throttle, and the elements with the gasket into the radiator plugs. For winding we use the same flax with paint or a polymer thread - sealant.

- We hang the radiator on the brackets.

- We screw on the American union nuts by hand and carefully, without unnecessary effort, tighten them with an open-end or adjustable wrench.

Excessive force will tear the gasket or crush the American nut.

Type No. 7: plugs

Stub Example

A simple and much-needed component for assembling a heating system. It seals the end of the pipeline, which is very often located right on the last radiator of the heating circuit.

Advice: instead of conventional plugs, you can install Mayevsky taps. Although they are more expensive, they make it easy to bleed air from the radiator, which interferes with its uniform heating.

The Mayevsky tap simplifies the maintenance of the heating system

Which fittings are best for connecting a heating radiator?

For steel batteries the set includes:

- Traffic jams.

- Flushing tap.

- Lock nut.

- Sgony.

On the upper floors of high-rise buildings you will need a Mayevsky crane.

Currently, American ones are used instead of radiators: two are enough for one radiator. It is more profitable to purchase these fittings combined with taps and throttles.

The fittings in the radiator piping include ball valves, chokes, and a thermal head.

For a heating system, it is better to select connecting elements made of bronze or brass.

Ready-made sets of fittings are produced for radiators in polypropylene networks. They include 4 adapters from one thread size to another, a Mayevsky tap, a key for it, and fasteners. Threaded connectors are equipped with seals.

Installation features

The main difference in this case is polypropylene fittings, which are either screwed or easily soldered with a special soldering iron. This is possible due to the low melting point of plastic.

Step-by-step progress of work when soldering plastic pipes

But fittings for cast iron, steel or aluminum radiators are installed depending on what type of installation is provided for in their design:

- Welded. They are made of stainless steel and connected with a strong, sealed seam using welding. Disadvantages: difficulty in dismantling and the need for expensive equipment.

Welded connections made of stainless steel

- For soldering. Can be made of copper or bronze. Fixed with a torch. They are used exclusively for installing heating pipelines made of steel.

Assortment of solder connection parts

- Crimping. They do not require expensive devices; all installation is carried out using an open-end wrench thanks to a special crimp ring.

Crimp models

- Compression. Often used to connect plastic and metal pipes, as they can interact with any materials. But they are also not cheap.

Compression connection product

- Press fittings. They guarantee an increased level of tightness thanks to the sealing ring inside the ridge. But at the same time they require the use of an expensive tool - a press machine.

Professional equipment for installing press fittings

- Self-locking. Copper products allow the connection of heating elements from any materials without the use of special tools. They are as easy to remove as they are to install.

Self-fixing samples

Sgons and Americans

What it is

Let's start with a short excursion into history.

Quite recently, by historical standards - some twenty to twenty-five years ago - only three types of heating devices were massively sold and used in our country:

- Convectors, which were a coil made of a steel pipe with steel plates pressed onto it to increase heat transfer.

Domestic design, meaningless and merciless.

Let us clarify: optionally, their design could include a decorative screen and blinds to regulate heat transfer.

- Plate radiators are two stamped steel plates welded around the perimeter. The coolant moved through a labyrinth of grooves between them.

- Cast iron sectional radiators. They, it seems, do not need any introduction, since they are now installed in most apartments.

There were only two methods of fastening:

- Welding . They were welded to the convector connections exclusively: their mechanical strength and service life, at least not inferior to the service life of the risers and connections, did not require dismantling for repair or replacement.

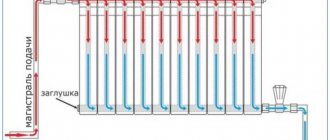

- Sgony . The coupling (in the case of a convector or plate-type device) or the radiator plug (in the case of a sectional radiator) was driven along the long thread on the connection, simultaneously screwing onto the thread of the device or screwing into it. The connection was then sealed with a wound locknut.

The first aluminum radiators were mounted the old fashioned way - on saddles. However, after a few years, simple fittings - American ones, which included detachable connections with a union nut and a rubber seal - became widespread. Their main advantage was the simple and quick dismantling of the device: an operation that previously took up to half an hour now took no more than a minute and did not require much effort.

The aluminum heating device is connected with modern fittings.

Help: a cast iron radiator cap from a new radiator can be unscrewed with a gas wrench number 2. To deal with an old stuck cap, you have to lengthen it with a lever or use a wrench number 4. In this case, the cap often does not unscrew, but is literally torn in half, losing the thread .

Does the American woman have any disadvantages? In essence, there is only one drawback: the strength of the connection is limited by the quality of the rubber seal and the tightness of its pressure. With high pressure in the circuit (for example, during water hammer), it is the seal and the relatively thin American union nut that turn out to be the weak link.

Recommendations

The conclusions that the author made for himself will certainly be challenged by many other experts; however, they are quite unambiguous.

- In central heating systems with a high probability of exceeding the standard pressure, it is better to use the usual threaded fittings.

The cast-iron radiator in the central heating system is connected via leads.

- It is advisable to use American ones in autonomous systems.

Polypropylene pipes: which fittings to choose?

Construction stores offer a variety of fittings for polypropylene heating pipes. Choosing the right model is not so difficult - thanks to the large selection of connecting elements of different sizes. They are divided into parts without threads and with threads, which, in turn, can be solid or collapsible.

Installing fittings to a heating radiator

You need to choose the type of element you need based on what functions it will perform. For example, it is convenient to connect a hose using a one-piece fitting, while for a meter it is better to use a detachable threaded mount.

When installing a polypropylene pipeline, it is very important to take into account thermal expansion. This is important when it comes to installing a radiator with hot water supply. For these purposes, a compensator is installed. Its main function is to absorb temperature changes and stabilize pressure surges in the heating system.

The polypropylene pipeline and fittings together create one system. Accordingly, in this case polypropylene heating fittings are used.

There are also cases when it is necessary to connect metal pipelines, then a fitting with a brass threaded insert is taken.

Fittings are different

There are different types of heating fittings.

It is worth considering the types of connection elements depending on their purpose.

They are divided into the following types:

- coupling - a fitting that resembles a barrel with a hole inside.

It refers to simple elements. They are necessary in order to connect pipes of the same diameter in a straight section; Fittings for heating radiators - adapters are a type of fittings that have different diameters at the ends. This means that they are used to connect pipes of different sections. This also includes drives and nipples;

- corners, bends - connection elements necessary to create the desired angle of direction of the pipe.

- Tees and manifolds are designed to connect several pipelines at a distribution point. These elements have different diameters. It is possible to choose plastic fittings for heating - they are suitable for various pipelines, including for connecting dissimilar pipes;

- crosses are elements that are used to connect pipes of the same diameter at the joints where they branch.

- fittings - are connecting elements that are necessary to connect a flexible hose to a pump.

- plugs - fittings that are used to ensure a tight seal at the ends of the pipeline.

Copper fittings: installation features

The building materials market also offers a huge selection of copper pipelines and related parts. This frees up the hands of craftsmen, allowing them to carry out installation work of varying complexity.

Fittings for copper pipes have their advantages:

Copper and steel fittings

- weigh little;

- resistant to high temperatures;

- do not deform under the influence of sunlight.

Craftsmen use connecting elements to build up the highway, create the required number of branches, form the necessary bends, form new angles and turns.

Copper fittings for heating are presented in a fairly wide range, which makes it possible to select exactly what is required in each specific situation. For example, on display cases you can find a large selection of fittings for installing pipelines of different sizes. Particularly popular are simple elements - doubles, couplings, crosses, corners and others.

Heating system options

An autonomous heating system (in a private house, small cottage) allows you to choose from two possible options for installing a heating system.

- Single-circuit (single-pipe) - classic, which has been used for a long time and everywhere.

- Double-circuit (two-pipe) - more efficient in operation, with the ability to regulate heat transfer.

Note! When choosing polypropylene as a material for installation, metal pipes should be completely abandoned. A high-quality heating system requires only polypropylene pipes. Combining is prohibited here.

Single-circuit heating system

The radiator is connected to polypropylene pipes in a single-circuit system in series.

Shut-off control valves for heating radiators

Radiator fittings, regardless of whether they are automatic or manual, are designed to regulate heat flow in heating devices. The radiator valves used in the heating system will allow you to set and maintain a certain temperature in the rooms. Also quite important in the system are radiator taps, which allow you to smoothly regulate the coolant in the radiator.

Mainly two types are used: thermostatic radiator valve and manual radiator valve (ball). The use of taps in the design of the system avoids water hammer if the hollow radiator fills. Fittings for connecting products should be installed at the approaches to heating devices.

Shut-off valves for radiators are designed to regulate the flow of heat into heating devices by regulating the intensity of the coolant flow. The heat output of a heating device can be adjusted in two ways: manually (with a manual tap) and automatically (thermal valve and thermostat). In the case of a manual method of regulating the heat output of a heating device, only the amount of water that enters the device changes. The automatic method only controls the temperature of the water, which leaves the boiler along the outgoing line to a greater or lesser extent, depending on the set temperature and the current one in the room.

The radiator fittings include:

- Radiator connection kits;

- Radiator and control valves;

- thermostats, temperature regulators (thermostatic valves);

- bottom connection units, which allow you to connect a heating device to the pipeline;

- drain and shut-off valves, which allow you to turn off an individual heating device without having to drain water from the entire heating system;

- various accessories for connecting radiators (fittings, fastenings, brackets, fittings).

Shut-off and control valves are used to dose the coolant flow into the radiator to create comfortable conditions. Shut-off valves are used to completely block their flow area. They are in the “open” or “closed” position. Thermal heads are used on radiator thermostatic valves to automatically regulate room temperature. A type of shut-off and control valves for radiators for additional ability to regulate temperature conditions in the room. Air vents are designed to automatically remove air from the heating system.

Information on the topic: WiFi control of radiators | Connecting radiators | The best aluminum radiators

Nowadays, when the price of heating is high, correctly selected fittings will help reduce heating costs as much as possible. To do this, we recommend getting advice from the manager of any company that specializes in this technology.

For which radiators is it necessary?

- For aluminum and bimetallic radiators. Always sold without complete set, additionally required are fittings, fasteners, installation kit and connection kit (radiator taps and thermal head)

- For steel radiators. The kit includes a wall mount and a built-in thermostatic valve. Additionally, a connection kit is required (radiator taps and thermal head) and, in the case of pipes being supplied from the floor, a lower connection unit is also required.

- For cast iron radiators. Fittings and a set of radiator valves, as well as a plug and an air vent.

Radiators and components for them are offered by many manufacturers of fittings and manufacturers of heating batteries themselves. We recommend, whenever possible, using the original equipment, or equipment from time-tested manufacturers, with a mandatory warranty. Don’t chase the cheapest connection fittings, it will cost you more!

Bottom radiator connection unit - advantages of use

Radiator fittings, which are used to connect from below, are intended for use in steel panel heat exchangers and are not suitable for aluminum radiator sections - due to this, steel types are highly competitive with them. Bottom inclusion compared to other types has the following advantages of using fittings:

- Saving pipe materials and outlets - in the floor structure or on the wall there are only two short outlets for connecting the radiator; the pipes do not go to its upper inlet.

- The connection at the bottom is aesthetically pleasing, and if the pipeline comes out of the wall, it is practically invisible under the body and does not interfere with cleaning the floor covering.

- Shut-off control valves (ball valves or valves) in the “binoculars” allow you to control the intensity of the liquid entering the heat exchanger, and when it is completely shut off, remove the batteries for maintenance or repair.

- The bottom connection unit with a vertical bypass evenly distributes water throughout the radiator with heating of its coldest upper corners, which is observed with the bottom connection. Also, with single-pipe wiring, the bypass helps to equalize the temperatures of the incoming and return flows, which in turn leads to uniform heating of the devices built into the line.

Rice. 2 Straight and elbow 3/4" bottom fittings installed

Accessories for mounting radiators

The most suitable method of installing heating radiators to the surface of the walls is selected taking into account their technical parameters - weight, dimensions - as well as taking into account the place where they are supposed to be installed.

The most acceptable scheme is where the heating radiators are mounted under the window sill, but there are situations when the heating device must be installed on the floor surface. Taking into account the method of fastening the heating battery, the type of fasteners required is selected. The catalog of our online store has a wide selection of fastening systems and elements for various types of radiator installations.

To install the radiator, elements corresponding to the type of metal from which the heating device is made are used. Modern manufacturers produce radiators made of aluminum, cast iron or steel. Such radiators have good heat transfer and a long service life.

Accessories for radiators and convectors in Moscow - Santekhkomplekt | Sale of plumbing

Installation of radiators made of aluminum alloys is the simplest, since they have the least weight. For this purpose, brackets are used for installing aluminum radiators. These brackets are produced in fixed lengths.

The installation of steel radiators is characterized by the fact that they must be secured with a high degree of reliability, since with a large number of sections they create a fairly noticeable load on the wall structure.

Cast iron radiators have the heaviest weight among all heating devices, so for their fastening special parts are used that can withstand sufficient weight without deformation. In addition, fasteners for such radiators make it possible to adjust the distance between the battery and the wall.

The installation of a heating radiator to the floor surface may be related to the structural or planning features of the building. Such fastening is also carried out in cases where the size of the windows is large enough, then the radiator is installed on a special pedestal or on legs.

With this installation method, aluminum radiators are most often used. Because they are light in weight and look beautiful.