With the onset of cold weather, the issue of home heating becomes more pressing. In the chilly off-season, centralized systems are often not turned on until the last minute, and then alternative heating systems come to the aid of freezing residents.

One of the simple solutions are considered to be heating elements for heating radiators, which can become an effective addition to the heating system. In some situations, the device can easily cope with the role of the main heat source, for example, in seasonal premises.

Before you decide to buy a device, you need to find out more information about it, don’t you agree? We have prepared a review article about the design of radiator heating elements, their classification, advantages and disadvantages. The material identifies the main criteria for choosing an electrical appliance and describes the features of its installation.

Why do you need a heating element for heating radiators?

A heating element is a tubular electric heater that converts electricity into thermal energy.

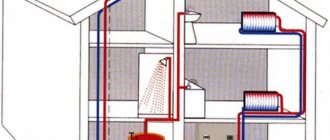

A heating element installed in radiators can be the main source of heat in homes with an autonomous heating system, or an additional water heating device in centralized systems. The heating element is mounted in a cast iron battery in cases where:

- Switching to autonomous heating.

- There is not enough radiator heat for comfortable living.

- There is a need to install an emergency coolant (if there is a possibility of central heating being turned off).

Heating elements have their advantages:

- High efficiency, in a closed space there is nowhere for heat to go.

- Simple installation that every adult man can handle.

- If installed correctly, the service life is unlimited.

- It has control sensors, so the heating element for radiators is safe.

- Low cost of the device itself, variable prices for thermostats (which, as a rule, are not included in the heating element kit)

- Makes it possible to adjust heat transfer and helps save energy resources.

At the same time, the device also has vulnerabilities:

- When used as the main means of heating, it requires large electricity consumption.

- It is not recommended to use in conditions of frequently changing network voltage (or greatly reduced).

Main functions and design of the heating element

The main functions of a heating element mounted in a battery: heating the coolant and, if the heating element is equipped with a thermostat, temperature control.

The heating element for radiators itself is so simple that even a schoolchild can understand its design. An insulated conductive thread is inserted into a metal tube. Most often this is a nichrome spiral. During the galvanization process, a metal tube is coated with chromium or nickel, which gives the metal special protection from the aggressive effects of water and guarantees no human contact with electricity. In addition, the housing of the heating element is equipped with control sensors that prevent the device from overheating.

As for the coolant heating function, there are no other options except one: the device is plugged in and the water (or other coolant) is heated. The principle is the same for all electric heating devices.

The thermostat functions are carried out by a heating element equipped with a thermostat. This allows you to set the heating element for radiators to a certain temperature. In addition, there are regulation modes that are simply necessary in certain conditions:

- “Anti-freeze” - maintains a constant coolant temperature of +10 ° C, which does not allow the heating system to freeze.

- “Turbo” is necessary for instant heating of the coolant in an autonomous heating system at maximum power. After reaching the required temperature, the mode automatically turns off and the device operates in accordance with the parameters set by the thermostat.

As for the coolant itself, there is an opinion that the most suitable for batteries equipped with heating elements is transformer oil. It heats up in a short time and gives off heat for a long time.

When is a heating element used for a battery?

Electric heaters for a heating system battery are devices designed to convert electricity into heat; thanks to this property, the coolant inside the heating devices is heated. These units, when immersed in a coolant tank, begin to heat it up. This type of device includes a heater for the heating system and the familiar boiler.

Typically, such devices are installed in radiators either as the main heat source in homes with an autonomous heating system, or as an additional heat source to increase heat transfer and automate the entire process. Thanks to these properties, these devices make it possible to turn an ordinary radiator into an electric heater.

As a rule, heating elements are installed in heating batteries in cases where:

- It is necessary to switch to an autonomous heating system.

- Central heating cannot cope with heating the rooms, and they remain cold; in these cases, these devices are used as additional heat sources.

- Installation of a heating element in a radiator as an emergency heat source. It will help prevent freezing of the heating circuit if it is disconnected from the heating network. You just need to close the heating taps and plug the electric heater into the power supply.

As a rule, these devices are installed together with thermostats, which allow you to automate the heating process.

The usual conversion of electricity into heat using a heating element, which is integrated into the radiator, allows you to increase the heat transfer of central heating radiators by heating the coolant in them. This is a fairly inexpensive and very effective method of heating homes with an autonomous heating system, which is becoming increasingly popular among consumers.

Types of heating elements

You can find various models of tubular electric heaters on sale. They differ in the structure of the body and the material of manufacture. Devices are also divided according to power and purpose:

- from 2.5 to 4 kilowatts - household;

- from 4 to 6 kilowatts - industrial.

There are both single heating elements and devices with two heating coils. Such devices are also made with right-hand or left-hand threads. Many models are equipped with additional options:

- Antifreeze. The function protects the heating system from possible defrosting at low temperatures. At the same time, the permissible minimum temperature is automatically maintained. During this operating mode, a completely insignificant amount of electrical energy is consumed.

- Turbo heating. This option will allow you to maximize the temperature in the room. For turbo heating to work, a thermostat is required, which makes it possible to change the heating mode.

Heating elements for radiators are produced in various lengths and with distinctive design characteristics.

Types of heating elements

A copper heating element for a cast iron radiator lasts longer due to the properties of the metal.

A heating element for a heating radiator can be manufactured in several modifications. Each of them has individual technical characteristics and design features.

The power of heating elements for a heating battery varies from 0.3 to 6 kW.

According to the design of the housing, the heating element for the battery can be with right-handed or left-handed threads. Such design solutions allow them to be installed in batteries of various configurations.

Based on the diameter, the heating element in the heating radiator is divided into two types. The devices are designed for cast iron or aluminum radiators. In the first case, the diameter of the device is 1.25 inches, and in the second - only 1 inch.

Manufacturers can equip electrical appliances with additional functions:

- Turbo heating. This option allows you to force an increase in the temperature in the room. This was achieved because the built-in thermostat is capable of changing the heating intensity. It is recommended to install such modifications in rooms with periodic traffic or outbuildings.

- Antifreeze. This option allows you to prevent possible freezing of heating devices with the arrival of cold weather. When the heating element operates in this mode, electricity consumption is minimal.

When purchasing a heating element, it is recommended to familiarize yourself with the product quality certificates, otherwise you can purchase a low-quality and fire-hazardous fake.

Application of heating elements

Tubular heaters

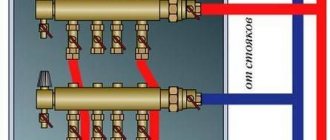

Installation of heating elements is so simple that any home craftsman can perform all the required work. As a rule, the heating element comes complete with everything necessary for installation, protection, connection and automation. Thanks to this, it is enough to screw a heating element equipped with a thermostat into the radiator socket and connect it to the power supply. The system must be filled with coolant. After such simple work, the heating element can be used for its intended purpose. When installing, you must ensure that the mounted heater is in a strictly horizontal position.

There are models of different capacities on the market. They are suitable not only for household but also for industrial use. The basis of the design is a stainless steel pipe with a spiral of nichrome wire placed inside. Using a brass nut with a right or left thread, the heating element is screwed into the pipeline. Such units can be used with any radiators that have a 1-inch mounting thread.

The heating element for radiators is a collapsible design, so the housing can be detached if necessary, even during operation. One of the most important issues that arise when using electric heating is safety. Among all electrical appliances, heating elements are the safest. To protect against overheating, dual control is used due to the main and additional temperature sensors. The main sensor is located inside the housing, and the additional one is in a special tube.

Differences depending on model and type of radiator

The heating element for the battery can operate in two modes. When used as the main source of heating, the heating element is turned on at full power. Thanks to this, it quickly warms up the room to a comfortable temperature and maintains it at a given level. In houses with irregular occupancy, heating elements can be used to protect the autonomous heating system from freezing. In this case, the device will operate with minimal power, maintaining the temperature of the coolant in the pipes at a level that does not allow it to freeze.

The power of the heating element is one of the main parameters when choosing a model. Low-power products will not be able to cope with the tasks assigned to them. After all, you can’t heat water in the bathroom with a small boiler—you’ll need a more powerful one. In the same way, when installing a low-power heating element, the water in the system will cool faster than it will heat up to the set temperature.

Important! Before buying this or that model, it is necessary to make calculations that allow you to use the heating device with maximum efficiency. . When calculating power, it is necessary to take into account not only the volume of water in the radiator where the heating element will be installed, but also the initial and final temperature of the coolant and the time spent by the device on heating it

To perform the most correct calculations, special formulas are used. For the average person, they can be difficult, so a full calculation is ordered from heating specialists. A simpler calculation is that the coolant temperature in a cast iron radiator should be within +70 degrees.

When calculating power, it is necessary to take into account not only the volume of water in the radiator where the heating element will be installed, but also the initial and final temperature of the coolant and the time spent by the device on heating it. To perform the most correct calculations, special formulas are used. For the average person, they can be difficult, so a full calculation is ordered from heating specialists. A simpler calculation is that the coolant temperature in a cast iron radiator should be within +70 degrees.

Modern radiator

In addition to power, it is necessary to take into account other technical parameters of the unit. The main ones are:

- Shape and diameter of the heating element tube.

- Heating tube length.

- Overall length of the device.

- Insulator dimensions.

- Mounting type.

- Type of connection to the radiator.

Radiator power calculation

What power should the heating element be?

Mistake #5

There is no need to proceed from the principle - the more, the better.

First of all, you need to ensure smooth operation of the heating element. It should not turn off and on too often.

If you choose a heating element that is too powerful, when it reaches operating temperature, it will work in the following mode: 1 minute off – click – less than a minute on – click – 1 minute off, etc.

With proper selection of power and good insulation of the room, the battery will “rest” 2/3 of the time, releasing heat to the environment, and only 1/3 of the time will work, consuming electrical energy.

Based on this, you can approximately calculate your electricity consumption per month.

In addition to clicking, a powerful battery will make a lot of noise and gurgle. Adding vinegar or citric acid to soften the liquid does not help much.

Here the effect is similar to that of an electric kettle. With a power of 2 kW we have very small vessel sizes, plus the presence of voids.

As a result of the sudden release of heat into the water, a similar noise occurs. The less water in the kettle, the louder it makes.

The same goes for the battery. When the heating element is too powerful, the heating rate is an order of magnitude higher than the rate of heat removal, plus the low circulation rate of the coolant affects it.

Mistake #6

Often, strong noise during operation occurs due to inaccurate screwing or a crooked heating element and accidental contact of the tube with the nipple partition.

To solve this problem, try turning the heating element slightly clockwise or counterclockwise, changing its position. Noisy operation at the limit and constant clicks are not only annoying, but also directly affect the service life of the relay contacts.

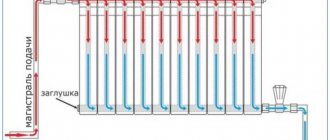

Therefore, when choosing the power of the heating element, proceed from the rule:

- maximum 0.5 kW – for every 4 sections

- 0.7 kW – 6 sections

- 1kW – 8 sections

- 1.2 kW – 10 sections

- 1.5 kW – 12 sections

Install a heating element of lower power, and it will not turn off at all, since it will not be able to heat the water to the desired temperature.

On the one hand, this is good, the battery will never overheat, even if the thermal relay malfunctions. For example, for cast iron (4 sections 500mm high), a heating element with a power of 300W, some even manage to screw it in directly without a thermostat.

Another advantage of low power is the absence of annoying clicks. However, despite this, if there is a lack of kilowatts, you significantly lose in heat transfer.

So we have to look for the ideal formula.

When the battery is too long (12 sections), it is better to screw in two instead of one 1.5 kW heating element. At the bottom of the radiator, on one side there is 1 kW, and on the other another 0.5 kW.

Or two, 0.7 kW each. Thus, the heating of the sections will be more uniform.

Mistake #7

Just don't forget to check the threads on the heating elements.

It is different on both sides of the battery. When purchasing a heating element, pay attention to the letter, which indicates a right-handed or left-handed thread (1.1/4R or 1.1/4L).

Rules of operation and maintenance

In order for the heating element installed in the heating battery to serve as long as possible, the following rules are observed:

- The heater turns on only if there is water in the battery. If liquid gets on the already heated tube of the device, a small thermal explosion may occur. As a result, not only the heating element will fail: the heating battery may be damaged.

- During operation of the device, scale will form on its surface, which must be cleaned off periodically. The recommended maintenance schedule is once every three months. If the thickness of scale on the heating tube exceeds 2 millimeters, heat transfer will decrease and the device may fail.

- To eliminate possible voltage surges, it is recommended to connect the heating element through an uninterruptible power supply or stabilizer. When installed, the heater is grounded.

- Manufacturers recommend using only distilled water as a coolant. In apartment buildings with a common riser, it is unrealistic to comply with this requirement, so it is necessary to clean the heating elements from scale more often.

Which heating element for a radiator should I choose?

Since there is no great variety in the design and technical features of radiator heating elements, problems in choosing usually do not arise.

When purchasing, you should pay attention to the following:

Power - if there is no information about thermal standards for a specific area, you can select a device based on average indicators for central Russia, adjusting them in accordance with the weather conditions of the region. Thus, a heating element with a power of 1 kW is capable of heating the air in a room with an area of 10 m2, provided that there is an autonomous heating system. From this calculation the choice should be made.

Material - there are no particular differences in materials between radiator heating elements from different manufacturers. Their designs are also identical. The difference may be in diameter, that is, in the size of the plug plug. In addition, there are single and double heating elements.

Size - since a heating battery can consist of a certain number of sections, the length of the heating element must correspond to the length of the battery. Experts recommend purchasing a heating structure whose rod is 6-10 cm shorter than the length of the battery. If the heating element is shorter than the required length, it will not be able to provide complete and uniform heating of the coolant.

Availability of additional equipment - if you plan to install an autonomous heating system, then it is better to install models with a thermostat. This will allow you to regulate the temperature in the rooms and reduce electricity costs.

Price is the main thing, do not purchase a heating element for a radiator, putting its cost at the forefront. First of all, you need to be guided by the technical characteristics specified in the product passport. And always remember, cheap doesn’t mean good!

Calculations of the required power of the heating element

When you plan to install an autonomous heating system in a permanent home, it is especially important to correctly calculate the required power of the device. How to do it?

The technical documentation for radiators indicates the exact heat transfer values, say, for one cast iron section it will be 140 W. These values must be multiplied by the number of sections. Thus, the required power of the heating element will be obtained.

How to choose the right heating element for a cast iron radiator

For a heating element to truly become an effective assistant, you need to select it according to the following parameters:

- First of all, you should focus on the power of the heating device. To select the power of a heating element for a cast iron battery, you need to calculate what it should be. If we focus on SNiP indicators, then 1 kW of power will be required to heat 10 m2, but this is not the only indicator that should be taken into account.

- Of considerable importance is what metal it is made of and how the heating radiator works. There is a difference between heating elements for cast iron batteries and aluminum or bimetallic ones. For the former, heating elements of a different shape and with a larger plug diameter are produced.

When purchasing a heater, you need to clarify what type of radiators it is suitable for.

- To choose the correct heating element length, you need to focus on the number of sections in the radiator . As a rule, the optimal length of the device is 10 cm shorter than the battery. This will allow it to heat the coolant in the device evenly and quickly.

- You can install a heating element in a heating radiator with a thermostat if it will be used as an additional heat source. When its function is to heat a house or apartment, additional external electronics will be required to automate the heating process. This makes the device itself somewhat more expensive, but helps save on energy resources during its operation.

- The pressure in the central heating batteries should also be taken into account. If it tends to increase, then you should periodically bleed the air using a Mayevsky tap.

Important: when purchasing a high-quality heating element, you should approach it not from the standpoint of price, country of origin and quality, but according to the technical characteristics specified in the data sheet

As a rule, inexpensive Chinese models immediately attract attention, but you should not rely on cost when the heating element should become the main source of heat. In this case, you will need a reliable and powerful device, and it cannot be cheap

How not to make a mistake in choosing

Radiators for heating elements are quite simple to choose, since they do not require a special variety of designs and technical characteristics. Please consider the following points before purchasing.

Electric heating element power calculation

In order to correctly determine the required power of the device, it is advisable to know the thermal standards in force in the given area. As a last resort, you can use the average indicator, which can be used in central Russia and make some adjustments if necessary.

Based on this, for 10 sq. meters of heated area, provided that the heating element will be used as the main heating, 1 kW of its power is required.

If heating elements for radiators are chosen as the main heating for the home, it is highly advisable to purchase models with a thermostat. In this way, it will be possible to regulate the power of the device and thereby reduce energy costs

If the device is used as additional heating, the required power will be 3-4 times lower. In addition, when choosing a device, you should take into account the specifics of the radiator heating element.

Due to its design features, it will be able to operate uninterruptedly only at 75% of the heat transfer from the radiator. With higher power, the device will overheat and it will constantly turn off.

Based on this, the power of the device is calculated. The exact heat transfer values of a particular radiator can be found in its technical documentation. However, on average, one section of an aluminum battery has a heat output of 180 W, and a cast iron battery has a heat output of 140 W.

Let us calculate, as an example, which heating element is suitable for a 10-section radiator. We multiply the data by 10 and we get that for an aluminum battery it is worth taking a heating element with a power of up to 1.35 kW, for a cast iron battery - up to 1 kW.

Design features of the device

For each radiator, you should select a heating element that is suitable for it in size and thread direction. The equipment has different shaft lengths, which may affect its performance.

If the length of the heating element is insufficient, the equipment is not able to provide a sufficiently high circulation rate of the coolant, as a result of which the heating of the radiator will be uneven and insufficient.

The length of the device is perhaps one of its most important characteristics, which directly affects its efficiency. Before purchasing, you should measure the radiator and calculate the required length of the built-in heating element

The optimal option is when the heating element rod does not reach the inner wall of the opposite edge of the radiator by 60-100 mm. It is also important to choose the right body shape and diameter of the device.

The material of the plug may vary between models. To make the right choice, you should study the manufacturer’s recommendations, where he describes the types of heating devices suitable for using a particular heating element.

Availability of automatic control

Devices are available for sale with or without built-in automatic control. The first variation is as convenient as possible and does not require the purchase of additional equipment. In this case, a thermostat with a sensor that measures the temperature of the coolant is built into the lower part of the heating element housing.

If there is no built-in automation, the electrical appliance does not have a thermostat. In this case, it is advisable to connect using a detector that measures the air temperature in the room.

It must be admitted that this equipment is not so popular and in demand for large European companies to start producing it.

In stores you can find radiator heating elements made by Turkish, Polish and Ukrainian brands. In terms of quality and functionality, they are approximately similar.

It is difficult to say which company's products should be preferred. But you need to be wary of Chinese heating elements, since you can often get a low-quality product.

Additional information on choosing a heating element for heating is provided in this article.

Features of choice

Electric heaters designed for radiators may differ in several parameters. Therefore, you should approach the choice wisely

Below we will consider what you should pay attention to when choosing a heating element.

Power is one of the most important parameters, since the heat transfer of the device depends on it. Therefore, first of all, you need to calculate the required power for comfortable heating of the room.

On average, 1 kW of power is required for every 10 m2. For a more accurate calculation, it is necessary to take into account the region and heat loss of the room. However, if the heaters are used as an additional heating element, then half the power is sufficient.

Note! It makes no sense to use a heater more powerful than 75 percent of the heat output of the radiator itself, since its capabilities will not be fully used.

Bimetallic radiator with electric heating element

Radiator type

Heating elements for aluminum heating radiators and bimetallic batteries are structurally no different from heating elements for cast iron appliances.

However, the differences are in the following points:

- The shape of the outer part of the body.

- Plug material.

The heating element for an aluminum radiator has a plug with a diameter of one inch. The diameter of the plug for standard cast iron batteries is 1¼ inches.

Therefore, before purchasing a heater, you should pay attention to what types of batteries it is intended for. This information is usually contained in the instructions included in the kit.

Heating element length

An important selection parameter is the length of the heating element. As you might guess, the uniform heating of the battery and the circulation of liquid depend on this. Accordingly, the length is selected depending on the number of sections of the device.

Ideally, the heating element should be 10 cm shorter than the battery. In this case, the liquid will be heated as evenly as possible.

Automation

Automation can be built-in or external. It should be noted that a radiator heating element with a built-in thermostat is cheaper than the components separately. However, outdoor electronics tend to be more functional.

The choice depends on the purpose of the heater. If it is to be used as the main heat source, external electronics can be installed to ensure maximum heating comfort. If the device is planned to be used as an additional one, a heating element for heating radiators with a thermostat in one housing is also suitable.

Inexpensive heating element with thermostat for cast iron radiator

Manufacturer

As for the manufacturer, in this case the choice is not so important. The fact is that well-known European companies do not produce this equipment. Therefore, as a rule, you can find products of Polish, Ukrainian and Turkish origin on the market.

All these heating elements are quite similar in quality, so more attention should be paid to their characteristics. The only thing is that it is better to refrain from purchasing Chinese products, since suppliers often import the cheapest, low-quality models. However, even among them sometimes there are decent heaters.

These are, perhaps, all the main points that are important when choosing heating elements for batteries.

The use of heating elements for radiators does not provide any benefits compared to other types of electric heating. However, these heaters are an excellent option for heating all kinds of utility rooms. In addition, they can be used as an additional or emergency heat source.

What are the advantages and disadvantages?

These units have their pros and cons. The advantages include:

- Quite high rates of efficiency and operational efficiency. This comes from the fact that electricity is converted into thermal energy with virtually no losses.

- Installation is simple, and even a beginner can handle it after reading the instructions that come with each device.

- If installed correctly, this device can last for quite a long time.

- Heating elements for heating batteries are compact and almost invisible.

- High level of security due to the fact that they are equipped with control sensors.

- The price is quite low, but if the device is not equipped with a thermostat, then purchasing it can cost quite a large amount depending on its design.

- Heating elements for heating radiators can not only regulate the heating of the coolant, but also save energy resources.

The disadvantages of the unit include:

- Decent electricity consumption if the heating element in the heating battery is the main and only source of heat.

- It is prohibited to use these devices in homes where the power supply is unstable.

If you use a heating element with a thermostat in a room with irregular occupancy, the anti-freeze mode will protect the heating system from cracks and rupture of the pipeline. The device can maintain the specified minimum water temperature. This mode of operation does not require the consumption of a large amount of electricity, but at the same time does not allow the coolant to freeze.

Advantages and disadvantages

You can reduce heating costs by purchasing a heating element with temperature control

A tubular thermostat can be used to create an efficient heating system used as additional or main heating.

Main advantages:

- Easy to install. Even an inexperienced person can cope with the task.

- Possibility of automatic control if the system is equipped with additional equipment.

- Acceptable cost of construction.

- Compared to oil radiators, the system is more reliable. The batteries are repairable.

Among the disadvantages, it is worth highlighting the impressive operating costs due to the high cost of electricity. It is possible to reduce consumption, but to do this you will have to additionally purchase an automated control system.

Pros and cons of radiator heating elements

Tubular-type electric heaters make it possible to assemble a practical and fairly efficient heating system for main or additional heating.

The advantages of the devices include:

- Extreme ease of installation . Every novice master can handle this job.

- The low cost of the device , however, refers to the price of one heating element, without additional equipment.

- Greater reliability compared to oil radiators. In addition, batteries with heating elements are repairable. If the equipment fails, it will be enough to replace the heater.

- Availability of additional options and functionality.

- Possibility of automatic control of the heating system, but this will require additional equipment.

We have listed the main advantages of radiator heating elements; we will consider their significant disadvantages. There are quite a lot of them. First of all, these are impressive operating costs, which is explained by the high cost of electricity. They can be reduced if the heating system control is fully automated.

In this case, the heating elements will be switched on only after the room temperature drops to a certain minimum value. And turn off when the temperature defined as comfortable is reached. Working in this mode is as economical as possible.

The simplest radiator heating elements in design are not equipped with automatic control. To automate such a system, you will need to purchase additional equipment

However, automation equipment will require financial investment. If we consider purchasing a heating element complete with a radiator and automation, the cost of such a kit will be much higher than the price of an electric convector or an oil radiator.

But at the same time, in terms of the level of comfort provided, the latter are in no way inferior, and in some ways even superior to radiators with heating elements. For example, the latter require permanent installation, while electric convectors and oil radiators are more mobile and compact.

In addition, like any other electrical device, heating elements generate a magnetic field during operation. Its danger to the body has not been proven, nor has its safety. Therefore, it is worth attributing the presence of such a field to the negative qualities of devices, because they are mounted in radiators, that is, they are in close proximity to people.

In other heating systems powered by electricity, this disadvantage is to some extent leveled out. For example, electric boilers are located in non-residential premises where human presence is short-term.

One of the most significant disadvantages of radiator heating elements is their relatively low efficiency. If we compare it with the efficiency of traditional systems operating with liquid coolant, it will be significantly lower.

This is due to the fact that in the first case the coolant moves at a fairly high speed. Thanks to this, the radiator warms up quickly and completely.

To increase the heat transfer of radiators equipped with heating elements, you can cover the wall on which the device is mounted with a reflective screen made of foil. Thermal radiation will only move into the room

The functioning of the heating element is not able to provide such a high speed. As a result, the heating of the battery case will be uneven. The temperature at the bottom will be much higher than at the top.

Considering that, for safety reasons, the battery should not be allowed to heat up above +70ºС, such a temperature will only be present in the lower part of the radiator, where the heating element is located. Consequently, in order to prevent overheating of the equipment, it will be necessary to reduce its power by about a third.

Features of self-installation of heating elements in the battery

The ease of installation of the device corresponds to the simplicity of its design. You should also check the package contents in the store; ideally, everything needed for connection should be packed in the box. If something is missing, you need to buy it immediately.

Installation of the heating element is carried out in the following sequence:

- Free the system from water;

- Remove the bottom plug from the radiator;

- Install the heating element instead of the plug - treat the joint area with sealant or wrap flax around the threads, rubber gasket, and install the heating element strictly horizontally;

- Fill the radiator with coolant;

- Connect the device to the network. Important! To connect the heating element to the network, it is prohibited to use a socket without grounding!

Over time, during operation, the heating element becomes covered with scale, which can lead to breakdown. It is easier to regularly monitor the condition of the heater and clean it in a timely manner. For these purposes, the heating element is removed from the radiator, and scale is removed from it in one of two possible ways.

Mechanically - the surface is wiped with sandpaper or a wire brush. To avoid damage to the surface, this operation should be carried out very carefully. Chemical - the surface of the heating element body must be treated with an appropriate composition. This must also be done carefully, and in no case should the cleaning solution come into contact with the rubber gasket.

Recommendations for the safe operation of a radiator equipped with a heating element

You can use an electric heater installed in batteries if the following conditions are met:

- Availability of adequate ventilation in the room;

- Do not place flammable objects and substances close to a working heating element;

- Before installing the heating element, you need to make sure that there is no damage to the electrical wiring and that it has sufficient power;

- You cannot dry clothes or shoes on a battery with a heating element.

Radiator heating elements can be either the main or additional source of heating. But such a heating system is still more suitable for small rooms that are used periodically: utility rooms, garages, closed verandas, and, of course, country houses that are rarely visited in winter.

Rules for installing a heating element in a battery with your own hands

Before installing the heating element, it is necessary to drain the water from the system

To install a heating element into a battery, you do not need specific knowledge and skills. The main thing is to strictly follow the instructions and comply with safety requirements.

- It is imperative to stop the water supply to the radiators and drain the remaining water from the system.

- Remove the bottom plug and install an electric heating element in its place.

- After tightening the plug, the electronics are installed and water is again supplied to the system to check the tightness.

Safe installation rules:

- It is prohibited to use heating elements if the room is not equipped with a proper ventilation system.

- There should be no flammable objects near the device connected to electricity.

- Before you begin designing and installing a heating element, you need to make sure that the electrical wiring can withstand the additional load.

- It is prohibited to dry shoes and clothes on radiators connected to the network.

Modern electric heating elements combine a large number of advantages, due to which the demand for them is growing.

Heating elements for heating batteries: pros and cons, device, principle of operation

Installing a heating element in a heating radiator allows you to maintain optimal temperature conditions in any room. In stores you can see them in a large assortment, but before making a purchase you must make power calculations in order to purchase the most suitable option.

Design and principle of operation of heating elements

The heating element for the battery is used as a heating element and the temperature sensor

The heating element in the cast iron and aluminum battery has a rather primitive design. It is a cylinder made of metal, the internal cavity of which is equipped with a spiral of copper/steel strong wire. Since the heating element is equipped with a temperature regulator, it is used to adjust the temperature of the medium, and not just as a heating element.

The cylinder with a spiral is located in a sealed housing, which is equipped with a control sensor. Its main task is to prevent the device from overheating. Thanks to the galvanization process, additional reliability of the device is ensured. Nickel and chrome plating increase the strength of the heating element and also form an additional protective barrier.

Types of heating elements

Copper heating element for a cast iron radiator lasts longer due to the properties of the metal

The heating element for a heating radiator can be manufactured in several modifications. Each of them has individual technical characteristics and design features.

The power of heating elements for a heating battery varies from 0.3 to 6 kW.

According to the design of the housing, the heating element for the battery can be with right-handed or left-handed threads. Such design solutions allow them to be installed in batteries of various configurations.

Based on the diameter, the heating element in the heating radiator is divided into two types. The devices are designed for cast iron or aluminum radiators. In the first case, the diameter of the device is 1.25 inches, and in the second - only 1 inch.

Manufacturers can equip electrical appliances with additional functions:

- Turbo heating. This option allows you to force an increase in the temperature in the room. This was achieved because the built-in thermostat is capable of changing the heating intensity. It is recommended to install such modifications in rooms with periodic traffic or outbuildings.

- Antifreeze. This option allows you to prevent possible freezing of heating devices with the arrival of cold weather. When the heating element operates in this mode, electricity consumption is minimal.

When purchasing a heating element, it is recommended to familiarize yourself with the product quality certificates, otherwise you can purchase a low-quality and fire-hazardous fake.

Advantages and disadvantages

You can reduce heating costs by purchasing a heating element with temperature control

A tubular thermostat can be used to create an efficient heating system used as additional or main heating.

Main advantages:

- Easy to install. Even an inexperienced person can cope with the task.

- Possibility of automatic control if the system is equipped with additional equipment.

- Acceptable cost of construction.

- Compared to oil radiators, the system is more reliable. The batteries are repairable.

Among the disadvantages, it is worth highlighting the impressive operating costs due to the high cost of electricity. It is possible to reduce consumption, but to do this you will have to additionally purchase an automated control system.

Selection options

The heating element should be 10 cm shorter than the heating radiator

When choosing an electrical appliance, it is necessary to take into account the technical characteristics of radiators. The main criteria that influence the choice:

- Automatic control. Not all models are equipped with this option, but for convenience it is better to give preference to these.

- Battery Type. To ensure that the thermostat is optimally suited to the heating system, you need to study its technical data sheet.

- Length of the electric heating tube. The optimal parameter is 10 cm shorter than the length of the battery. Thanks to the correct selection, it is possible to heat all sections evenly.

Correctly selected power plays a big role when choosing. Heaters can be installed up to 203 kilowatts.

For aluminum radiators

A heating element for an aluminum radiator with a thermostat is no different from heating elements for cast iron appliances. The differences lie in the material used to make the plug and the shape of the outer part of the housing. The radiator has a 1-inch diameter plug. The plug diameter of standard cast iron batteries is 1.25 inches.

When purchasing a heating element, it is important to read the information on the packaging.

Power calculations

In order for the battery to fully warm up, it is necessary to check the amount of coolant

To select an electric heater of optimal power, you need to carry out preliminary calculations.

- The power of an electrical appliance is determined by the amount of heat that is required to heat the room. To heat 1 square meter of a room you need to spend 100 V. It is important to consider that the power and length of the heating elements must correspond to the needs of the radiators.

- You will need to calculate the volume of coolant in the structure. Even the most powerful heating elements will not be efficient enough if there is not enough coolant (liquid) in the batteries. The volume of a cast iron battery ranges from 0.6-1.5 liters depending on the model; in aluminum radiators it is only 0.2 liters.

Approximately for every 1 kW of heater power, 15 liters of coolant are taken. Based on these data, the required number of sections and the power of the electrical device are calculated.

Rules for installing a heating element in a battery with your own hands

Before installing the heating element, it is necessary to drain the water from the system

To install a heating element into a battery, you do not need specific knowledge and skills. The main thing is to strictly follow the instructions and comply with safety requirements.

- It is imperative to stop the water supply to the radiators and drain the remaining water from the system.

- Remove the bottom plug and install an electric heating element in its place.

- After tightening the plug, the electronics are installed and water is again supplied to the system to check the tightness.

Safe installation rules:

- It is prohibited to use heating elements if the room is not equipped with a proper ventilation system.

- There should be no flammable objects near the device connected to electricity.

- Before you begin designing and installing a heating element, you need to make sure that the electrical wiring can withstand the additional load.

- It is prohibited to dry shoes and clothes on radiators connected to the network.

Modern electric heating elements combine a large number of advantages, due to which the demand for them is growing.

Installing a heating element: important features

The heating element is installed according to the following scheme: one of the battery plugs is unscrewed, and a heating element is installed in its place using a threaded connection. To ensure the tightness of the joint, a rubber gasket is used.

Mr. Build recommends: it is best to screw in heating elements instead of the bottom plug. There is a logical explanation for this: heated water will rise and cold water will fall, which will ensure efficient operation of the heating element.

This procedure is repeated in each room of the apartment. We remind you that installation is carried out before the start of the heating season.

It is important! Shut-off valves and a bypass must be installed near the radiator to which the electric heater is planned to be connected. If there are no valves, all the heat will go to the neighbors. In the absence of a bypass, the general building heating system will be disrupted.

A few more important points:

- Do not use excessive force during the installation process. There is no need to forcefully tighten the contact nuts and the heating element fasteners themselves. Brittle material may burst.

- It is strongly recommended that after the shut-off valve, install a safety valve or a small expansion tank with a volume equal to 10% of the battery volume. This is due to the fact that when the coolant in a closed system is heated, it expands and increases the pressure in it.

Safety precautions and operational points

A heating element is a mains-powered heater. When using the device, it is quite important to follow some rules that will ensure safe use and significantly extend its service life:

- In order for the device to operate for a long time with full heat transfer, the scale that forms on its surface should be cleaned once every three months. If a large layer of white deposits forms, it can damage the device. The intensity of scale formation can be reduced by using distilled water as a coolant.

- Do not allow the electric heater to overheat. The temperature of the radiator in the place where the electric heater is installed should not reach seventy degrees above zero. Therefore, it is quite important to choose the correct power of the heating element.

- The heater can only be turned on in a battery filled with coolant. If water enters an already heated electrical appliance, it can lead to a thermal explosion. As a result, not only the radiator, but the entire heating system may be damaged.

- If static electricity appears on the surface of a tubular device, it must be immediately turned off and all connections and the device itself checked for leaks.

- The heater power should not be higher than the thermal rated power of the battery. A load of no more than 3.5 kilowatts is allowed in one outlet.

The temperature of the heating element for the radiator must not reach 70 degrees.

Installation of the heating element in the heating radiator is carried out only using grounding. To avoid voltage drops, it is best to connect the electric heater to the network through a stabilizing device.

Design and principle of operation

The design of an electric heating element is quite primitive. It looks like a metal cylinder, inside of which a copper or steel strong wire spiral is placed in a special insulator. Since the heating element for heating batteries is mounted together with a thermostat, in addition to the heating function, it is also used to adjust the temperature of the coolant.

The cylinder with a spiral is protected by a housing, which is equipped with control sensors. Their task is to monitor the device against overheating. In addition, the device is galvanized for additional reliability. Chrome plating and nickel plating can increase the strength of the heating element and thereby create additional protection that prevents human contact with electricity.

In addition to the main tasks of heating and thermoregulation, modern heating elements for heating radiators perform additional tasks:

- In the “anti-freeze” mode, a constant temperature of the coolant is maintained at +10°C, this is quite enough to ensure that the coolant does not freeze in the pipes. After the water is heated to the required temperature, the heating elements are turned off until its temperature drops below the set point.

- When equipping an autonomous heating system in a private house with batteries with integrated heating elements, the most successful would be to use the “Turbo” mode. The device operates at full power, due to which the system and the air in the room heat up almost instantly. In the future, the task of the heating elements is to maintain the established level of temperature in the system, which allows significant savings in energy resources during heating.

Among the majority of consumers, there is an opinion that the best option as a coolant for radiators with a built-in heating element is technical oil, due to its properties of rapid heating and slow cooling. But this does not mean that such radiators cannot be used in a water heating system.

Efficiency mark

A heating element for a radiator is not a heating device that can be constantly used to heat a large area. One kilowatt of electrical appliance power is converted into one kilowatt of thermal energy, which is completely used to heat the room.

When using cast iron batteries, a heating element equipped with a thermostat with a heating power of 100 Watt/m² can heat no more than 25 m² of space. Electrical energy consumption for twenty-four hours will be 36 kW/h, which approximately corresponds to 167 rubles. This takes into account the average power consumption of 1.5 kW. If the heating system is well organized, installing a tubular type electric heater does not make sense.

A heating element for a radiator is most effectively used as an emergency device. If the heating system is unstable, such a device will allow you to maintain the required level of heat in the room even in severe frosts. Installing a tubular heater makes sense if its power is correctly selected and all safety rules are observed.