When carrying out modern repair work, builders are increasingly faced with the installation of polymer pipelines. An irreplaceable part of such structures is a plastic tap or even several shut-off devices. But in order to install them efficiently, you need to understand their types, the nuances of installation and operation.

Advantages and disadvantages

Plastic valves have their pros and cons.

Experts note the following advantages of these products:

- do not rust, are not subject to fungal deposits, sedimentation, which allows them to be used in drinking water containers;

- easy to install and transport;

- are light in weight;

- have a long period of stable and reliable operation;

- Some types can be installed in the heating system.

Significant disadvantages include restrictions on use on networks made of other materials.

Criterias of choice

To choose the right faucet for an existing heating, plumbing, gas, etc. system, you need to determine:

- its variety;

- technical parameters of shut-off valves;

- manufacturer of the fitting, which determines the quality and service life of the device.

Types of ball valves with drive

American ball valves can be classified according to the following criteria:

- Depending on the design of the installation site, the following are distinguished:

- direct - installation is carried out on a straight section of the pipeline system (figure above);

- angular - installed if it is necessary to rotate the pipeline by 90°;

Ball angle valve with drive

- Depending on the type of handle that drives the locking element, there are:

- with butterfly handle;

- with a handle in the form of a lever;

Types of products depending on the type of control handle

On small-diameter household pipelines, faucets with butterfly handles are predominantly installed, since the devices are compact and more aesthetically pleasing. Products with a lever handle are installed on industrial pipelines, since this type allows you to quickly shut off a large pipe in case of an emergency.

- Depending on the type of fastening, there are:

- with a cylindrical (flat) mount. In this situation, the tightness of the connection is achieved by installing a rubber gasket and additional sealing with FUM tape (linen thread, etc.);

- with conical fastening. This coupling valve provides sealing without gasket. However, for maximum results when installing the device, the use of some kind of sealing material is still required.

Types of fastening cranes with squeegee

Determination of technical parameters

A full bore American crane is also selected according to technical parameters. Of significant importance are:

- purpose. Manufacturers produce products intended for gas supply, cold and hot water supply, and heating systems. All taps differ in pressure and maximum temperature of the flowing medium;

Novice workers can distinguish faucets by the color of the installed handle. For example, fittings with a red handle are made for hot water supply systems, and with a blue handle for cold water supply.

Taps with flow for cold and hot water

- nominal diameter (valve diameter), which must correspond to the diameter of the pipes;

- type, pitch and length of the threaded connection. There are taps with right, left, external and internal threads and pitches of ½, ¾ and 1 inch.

Manufacturer's choice

At the final stage, it is important to select a manufacturer of shut-off valves, since indicators such as the reliability and durability of the device depend on this factor. Experts recommend purchasing faucets manufactured by the following companies:

Experts recommend purchasing faucets manufactured by the following companies:

- Bugatti (Italy). Manufacturers use only high-quality materials, conduct constant monitoring at all stages of production, and constantly improve the design of fittings depending on consumer preferences. The average cost of a crane with a squeegee is 850 rubles;

- Valtec (joint production of Russia and Italy). The most significant advantage is the low cost of shut-off valves, on average 300 rubles, with normal quality of the products;

- Itap (Italy). The products are distinguished by a variety of models, high quality and reasonable cost, 350 - 400 rubles.

Differences between a faucet and a valve

Valves are practically not used in autonomous water supply and heating systems. Due to their design, taps are more convenient to operate: to shut off the main line, it is enough to turn the handle of the device 90 degrees. In the valve you have to turn the valve wheel, which takes much more time.

Unlike valves, they require constant maintenance and repair and are subject to frequent breakdowns.

What key is needed for the “American”

You can install “American” in plumbing without loss of quality and convenience using different tools. But this cannot be said that there are no restrictions in their choice. The most suitable and often used for installing the “American” is an adjustable wrench.

To install this fitting in plumbing, you should avoid using gas wrenches at all costs.

Recently, a universal tool has appeared that is most suitable for installing pipes in plumbing, including “American” ones. This wrench is used for a wide variety of jobs, which clearly proves its convenience and practicality.

The most common “American” sizes in plumbing are ¾ inches and ½ inches. This generally does not mean that you will not have a need for other types of this fitting. In this case, you need to purchase a key of the appropriate size or use an adjustable one. The main thing is not to use a gas wrench under any circumstances.

If you know how to work with metal and have the necessary tools, then you can make a cone wrench of the required size yourself. The taper is needed to fit into the recesses.

The shape of the key will be L-shaped, the handle will be about 150 mm long. The dimensions of the key for the “American” in ½ inch plumbing will be 12x12 mm and 10x10 mm. As a rule, such keys are made from scraps of profile reinforcement.

A good alternative when a plumber works with ½-inch “American” would be pliers, which, as a rule, everyone has. They are a great replacement for a set of keys.

Read material on the topic: Engineering plumbing wholesale: range and prices

Types and designs

Different plastic materials dictate different methods of connection to the pipeline and areas of application.

- PVC and polypropylene fittings are designed to work with pipes of the corresponding material. Can withstand heating system conditions (temperatures up to 95° and pressures up to 20 bar). Mounted by soldering using a special soldering iron.

There are one-sided devices, which on one side are welded to the pipe, on the other - installed on a thread or using an American coupling.

- Gates made of low-density polyethylene (HDPE) are used at an ambient temperature of no more than 45º and a pressure of no more than 15 bar. These are mainly cold water supply and country irrigation systems.

Among them, compression devices are distinguished, characterized by simple and easy installation using a collet and a crimp nut (pictured).

Compression ball valve:

There are also HDPE valves connected to pipes with threads in various combinations (internal-internal, external-internal, etc.).

Along with them, valves with flanged and welding connection methods are used.

Kitchen and shower faucets are made from special, very dense and hard, stable thermoplastic.

Plastic three-way valves are also produced.

Advantages of plastic products

There are almost no disadvantages to plastic locking fittings:

- the ability to use the tap only to stop and resume the supply of the working medium, since when the product is used to regulate the flow, it quickly becomes unusable;

- instability to high temperatures and pressure;

- impossibility of repair in case of failure.

However, plastic taps have significantly more advantages:

- the cost of materials is low, and processing polymers is easier than working with metal, so plastic fittings are cheaper than metal ones;

- the chemical and biological inertness of polymers makes products made from them resistant to corrosion and the formation of deposits on the walls and environmentally friendly - no toxic substances enter the working environment, harmful microorganisms do not settle in the interior of the fittings;

- The service life of ball valves with proper operation is at least 50 years;

- polymer fittings are suitable both for connecting plastic pipes and for connecting pipeline elements made of different materials;

- due to the simplicity of the device, ball valves are easy to install and do not require further maintenance: the seals do not lose their sealing properties, the metal ball of the locking mechanism does not stick to the plastic body;

- the full bore ball element does not reduce the pipeline capacity;

- lightweight plastic does not require effort during transportation and installation, and does not put stress on the pipeline and fasteners.

We recommend that you read: How to make a machine for rolling a metal profile pipe with your own hands

approximate price

The cost of the shutter is determined by the material, workmanship, technical characteristics and manufacturer.

A polyethylene tap (PND) for irrigation can be purchased for 35 rubles. A polypropylene device for the heating system costs 290 rubles, branded ones will cost 2 times more.

Rules for installation and operation of the crane

Before installation, it is important to make sure that the selected product is suitable for the given pipeline system according to all the above parameters.

The thread pitch on the pipe and the valve device must match.

The location for installing the locking product is chosen so that it provides free access to the handle control.

The device does not require constant maintenance.

Required tools and materials

The installation kit includes a set of keys and a welding machine.

The materials you need to purchase are the valve itself, fum tape or tow, and plumbing paste.

Work progress

Determine the location for installing the device. It should make it possible to easily operate the crane.

The valve is attached to the pipe, usually by welding. Before soldering, everything is carefully marked.

The second side is connected through a coupling with an American one.

Compression devices will attach more easily. You just need to clean and chamfer the end of the pipe that fits onto the collet. Then it is inserted all the way and the crimp nut is screwed on.

Metal-plastic or polypropylene

Connection of polypropylene pipes

Modern plumbing equipment is, first of all, five-layer pipes made of metal-plastic, which have gained particular popularity due to their many advantages over other types of pipes:

- compacted inner layer of polyethylene;

- elastic aluminum layer of the pipe, preserving the shape and configuration specified during installation;

- connecting the inner and outer layers of polyethylene pipe with its aluminum layer using glue;

- durable layer of anti-corrosion polymer;

- It is not necessary to comply with exact calculated dimensions when installing metal-plastic pipes.

When installing plumbing equipment, another type of pipe is used - polypropylene pipes. Their advantages over metal-plastic ones are economic benefits (polypropylene pipes are at least three times cheaper), as well as ease of installation. They can be connected even to metal pipes without much difficulty.

Features of operation

The plastic ball valve must be turned monthly so that the ball does not stick to the walls of the housing.

Hinged valves are designed for locking functions only. If you start regulating the water flow with them, they will quickly break. To regulate the flow, valves or devices with control functions are purchased and installed.

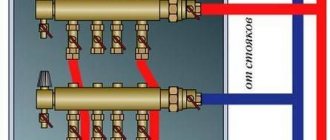

For the convenience of connecting the valve to heating devices, a special detachable unit has been developed - a coupling with a union nut, called an American.

Types of American connections

This shut-off and control device began to be called American because of the machines that began to arrive from America to the USSR in the 40-50s of the last century.

The design of the supplied equipment included similar connections. The devices quickly came into use in other areas of industry and in everyday life. Among specialists, the device began to be called “American”, just as the angle grinder was called “grinder”.

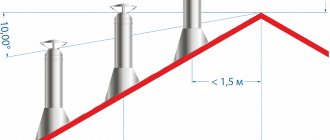

The classification of shut-off valves is based on the internal design and modification of external elements. Based on the shape of the body, devices are divided into straight and angular:

- The first are the simplest devices that are installed on a straight section of the water supply. Corner models are designed for installation in cramped conditions, for example, in places where a pipe turns at a right angle near a wall or other obstacle.

- The type of rotary mechanism - valve - allows you to divide American taps into lever and petal. Levers as a turning mechanism are installed on small-diameter pipes and reduce the physical effort when turning the valve. Lobe devices have a butterfly-shaped working element, which are usually installed in areas with a large pipeline diameter. According to its design, the American one is divided into devices with internal thread (IV) and external thread (EM).

By size, American type taps are divided into inch (1”) and three quarters (3/4”) - these are the most common types of products for household use. The industry uses larger closures - 1/2 and 2 inches. These valves correspond to typical sizes of pipe fittings used for plumbing installations.