A huge range of sewer pipes made of different materials often leads the end user to a dead end. Products made from polyvinyl chloride (PVC) are in greatest demand, but you can often see the abbreviation UPVC in pipe markings.

It is the extra letter “N” that makes many people think. So how do pipes made from the familiar PVC differ from uPVC, and what kind of material is it? Let’s look into this article.

What is uPVC

This type of polymer is obtained from raw materials consisting mainly of polyvinyl chloride, food resins and various additives. Moreover, polyvinyl chloride (PVC) is used without the plasticizers inherent in it under normal conditions. This is where the name of the material comes from – unplasticized polyvinyl chloride.

Decoding the abbreviation

Polyvinyl chloride is abbreviated in the Russian version as PVC, in the international version - PVC (English: polyvinyl chloride).

Accordingly, unplasticized, or as it is also called, unmodified polyvinyl chloride, is given the designation PVC-U. In international standards - PVC-U.

Installation

Knowing certain features of the installation of PVC-U pipes, you can safely begin laying an internal sewer pipeline yourself. To perform such work efficiently, you will need to adhere to the following algorithm of actions:

- At the first stage, a selection of all necessary parts (fittings, bends) is made. In order not to get confused, it is recommended to first draw up a plan diagram on which you need to indicate all the necessary details and footage;

- As a rule, on pipes for internal sewerage, a sealing gasket is installed in the socket. If it is not there, then an adhesive connection is performed, the procedure is as follows:

- you need to make sure that the counter part fits approximately 2/3 into the socket;

- glue is applied to the part inserted into the socket (for a high-quality connection, it is recommended to first create roughness, for example, by scratching the surface);

- make the connection.

The assembled system must undergo a leak test, which must last at least one hour.

Performance characteristics

The material allows you to create products with high performance characteristics:

- Smooth external and internal surface, which gives pipe products greater throughput.

- Complete absence of corrosion phenomena.

- Wide range of operating temperatures - from -50 to 78 degrees.

- Excellent strength and rigidity to withstand pressures up to 25 bar.

- Light weight.

The bottlenecks of uPVC products are:

- Restrictions on use at sub-zero and high temperatures (at -50 the material begins to break down, at +90 it loses its qualities). For this reason, they are not used in heating systems.

- Instability when interacting with nitrobenzene, acetone, dichloroethane.

Sewer pipes for external sewerage – types: red, white and waste uPVC

The system responsible for drainage is a complex engineering communication. Owners of apartments in multi-storey buildings should only worry about internal pipelines, but owners of private properties also have to think about external systems.

Sewer pipes for external sewerage must be selected carefully, since the durability and reliability of communication will depend on the choice. What products there are, what their features are, and how to choose them - we will consider below.

Requirements for external pipes

It is necessary to understand that external pipes operate in difficult conditions, for this reason high demands are placed on them.

The material from which they are made plays a significant role. It must have the following properties:

- strength;

- resistance to various aggressive environments;

- the ability to withstand seasonal temperature changes without changing its qualities;

- wear resistance.

Sewage pipes for external sewerage are made of various materials, such as plastic, steel, cast iron, ceramics and asbestos cement. All of them meet the above requirements. As a rule, we are talking about external communications, then additional requirements are added to them:

- they must withstand heavy loads (filling with soil, traffic of pedestrians and cars);

- static and dynamic effects should not affect pipes for underground installation;

- resistance to the effects of groundwater, which can lead to displacement of key components of the system and, as a result, to its complete depressurization.

Differences from PVC pipes

To produce polyvinyl chloride, plasticizers are added to the feedstock, which impart softness and plasticity to the material. This greatly simplifies the processing and installation of PVC products.

Eliminating plasticization from the production process makes the resulting product more rigid and durable. Therefore, uPVC pipes are superior in strength to their PVC counterparts.

According to GOST, the color of external PVC-U sewer outlets is orange-brown. PVC bends are used for internal wiring and are supplied in gray color.

Advantages of uPVC products

Products made from uPVC are very different from pipes made from other materials, with a large number of advantages that mechanics and ordinary people could appreciate.

Here are the main advantages:

- Light weight makes loading and delivery easier.

- Resistant to harsh chemicals

- Wear-resistant and can be used for drainage of wastewater that includes mechanical particles.

- Easily cuts if necessary.

- Long service life. 50 years and even longer.

FLAWS:

- Performance at -5 to +50

- Mice, rats and other small rodents can damage the line

- Do not store in direct sunlight, performance will suffer.

It should be noted that manufacturers offer not only uPVC products for arranging an external drainage system.

Pipes are made from

- Cast iron

- Metal

- Cement-asbestos

- Ceramics

Each material has its pros and cons.

Advantages and disadvantages of unplasticized polyvinyl chloride

Consumers include the following advantages of NVVC pipes:

- Simplicity and ease of installation, due to its light weight and simple connection method.

- Long service life - 50 years.

- High strength, ability not to deform under significant underground loads.

- Relatively low price.

- Resistance to chemically active substances.

- Good maintainability. Damaged parts of the pipeline can be easily replaced with new ones or restored using repair couplings.

The disadvantages of this type of product are significantly less than the advantages. These include:

- Poor frost resistance, the contents of the line begin to freeze at -15.

- Exceeding the temperature of the working environment over 45 for a long time significantly reduces the service life of products.

Cast iron

Pipes made of cast iron and ceramics can be called competitive. Cast iron has very high strength and durability. The service life of a cast iron main is at least 50 years, but the material is expensive and difficult to install.

Ceramic pipes have all the advantages. They do not rust, do not rot, are environmentally friendly, have a long service life, smooth walls prevent the occurrence of sediment sticking, but along with all the advantages they have significant disadvantages. High cost, fragility during transportation and short length, which significantly increases the number of joints in the sewer system.

Classification, types and range

PVC-U plastic pipes for non-pressure systems are produced in accordance with GOST 32413-2013 (with one wall) and R 54475-2011 (with a structured wall).

In sewer systems, pressure outlets are also used, made of uPVC in accordance with GOST R 51613-2000, designed mainly for water supply and wastewater disposal.

These products have a large number of parameters, so they have many different classifications.

They are usually distinguished by:

- Purpose.

- Strength classes.

- Wall thickness.

- Sizes.

Let's take a closer look at each division.

Standard sizes

For laying street sewerage, uPVC bends with a nominal outer cross-section of 110 mm or more are used.

In this case, its maximum values are for bends:

- Non-pressure single-layer according to GOST 32413-2013 – 1000 mm.

- Multilayer non-pressure according to GOST R 54475-2011 – 1200 mm.

- Pressure according to GOST 51613-2000 – up to 31.5 cm.

For internal wiring, the following sections are used:

- For bends from devices – 25-50mm.

- For a toilet – 110 mm.

- For risers – 110-160 mm.

The length is set by the manufacturer and ranges from one to 6 meters.

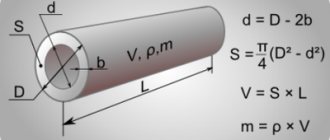

Wall thickness

The strength of the product, its ability to withstand soil loads during underground installation, and increased pressure in the channel depend on this parameter. Therefore, in external sewerage, bends with wall thicknesses from 3.2 mm to 24.5 mm are used.

In addition, multilayer pipes of various types are produced:

- Type A - with smooth external and internal walls, between which either a foamed polymer layer or hollow profiles are placed.

- Type B - with a smooth base and an outer profiled layer consisting of annular ribs or profiles of various shapes.

Strength classes

When choosing a product, it is important to know what loads the sewer line can withstand under soil pressure and traffic. Based on this indicator, uPVC pipes are divided into ring stiffness class. It is denoted by the abbreviation SN and powers of 2. It is measured in kilonewtons per m2:

- SN2 – rigidity up to 2 kN/m2 (the main can be laid to a depth not exceeding 1 meter).

- SN4 – up to 4 kN/m2 (placement depth up to 6 m).

- SN8 – up to 8 kN/m2 (canals can be laid under a road section with heavy traffic, maximum depth up to eight meters).

Corrugated bends, for example, belong to class SN8.

PVC-U pressure products are further subdivided according to the amount of internal pressure they can withstand. It is important to keep in mind that PN is not a pressure value, but rather a strength class for this parameter.

| Strength class | Nominal pressure (in MPa) |

| PN6 | 0,6 |

| PN10 | 1,0 |

| PN16 | 1,6 |

| PN20 | 2,0 |

Separation by purpose

According to their purpose, PVC-U pipes are divided into:

- Non-pressure, used in gravity pipelines.

- Pressure, suitable for systems with high operating pressure.

- Corrugated, with increased ring rigidity, used in deep underground areas.

For example, a uPVC pressure pipe with a socket for an adhesive joint is used in laying pressure sewer and water mains. The range includes products with the ability to withstand operating voltages from 0.5 to 16 atmospheres.

PVC pipes for sewerage: prices and sizes

Is it possible to install a sewer system in a private house on your own? You can, for this you need to purchase PVC plumbing pipes and adapters for sewerage, and also follow all the requirements of regulatory documents for the construction of sewerage.

Long before installing the sewer system, you need to select pipes. This is a very important point, because the performance and service life of the entire sewer system will directly depend on the quality of the pipes.

Sewer pipe sizes

Typically, the sizes of PVC sewer pipes for internal sewerage come in different diameters. The most popular pipes have diameters of 32 mm, 40 mm, 50 mm, 100 mm and 110 m. In this case, the thickness of the pipe walls is selected taking into account the expected operating pressure in the sewer system and the depth of the internal sewerage.

For example, a 50 mm PVC pipe for sewerage is resistant not only to the aggressive environment of wastewater, but also to high temperatures. And the price of a 50 mm PVC pipe for sewerage is quite low. In addition, PVC pipes can withstand short-term movement of wastewater heated to 95 degrees.

Sewage pipes for internal sewerage have less thickness and rigidity compared to external sewerage pipes.

To make the installation of internal sewerage as simple as possible, PVC pipe manufacturers offer customers all kinds of parts for connections. Such parts include: tees, adapters and elbows.

The sizes and prices of PVC pipes for sewerage are influenced by customer demand and the cost of materials for their manufacture.

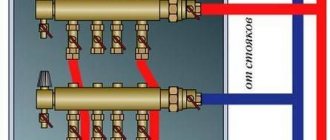

Plumbing connection

Before you begin installing an internal sewer system, you need to take into account the placement of all the main plumbing fixtures: toilet, shower, washing machine and dishwasher.

Taking this data into account, a pipe routing plan is drawn up, which will take into account not only the plumbing fixtures themselves, but also their dimensions and the diameter of the outlet pipes. This set of measures will greatly facilitate the installation of pipes and plumbing connections.

Of course, for connecting each type of plumbing fixture there are specific requirements, but there are also general standards that apply to all types of plumbing fixtures:

- Pipe height. At the extreme connection point relative to the riser, the height of the pipe should start at 0.8 m from the floor surface.

- Absolute coincidence of the diameter of the outlet pipe with the diameter of the sewer system pipe.

- A siphon must be installed, as it prevents the penetration of unpleasant odors from the pipe.

- The toilet must be connected exclusively directly to the riser, and the length of the pipe must be more than 1 m. In terms of installation level, it must be located at the lowest point in relation to other connections.

Absolutely all sewer joints must be sealed and be stable in the event of a powerful water hammer.

PVC pipes for internal sewerage

The purpose of the internal sewerage system is to collect contaminated water from all connected points and remove these wastewater from the premises.

What pipes are suitable for installing internal sewerage? The answer is simple, PVC pipes for sewerage have a number of advantages, due to which the choice should be in their favor.

Also, the price of PVC sewer pipes for internal sewerage is quite acceptable.

Qualitative characteristics of pipes for internal sewerage:

- Strength.

- Smooth surface allowing unhindered movement of contaminated water.

- Absolutely compatible with external sewerage pipes.

- Resistance to aggressive wastewater environments.

All of the above qualities are possessed by PVC pipes for internal sewerage, which, moreover, are very easy to install.

In general, prices for PVC pipes for internal sewerage depend on the diameter of the pipe. Therefore, before you buy PVC pipes for sewerage, you need to perform all the necessary calculations.

The production of PVC pipes is carried out from plastic compounds. PVC pipes consist of a fairly hard and very soft material. In general, the pipe has the shape of a cone, on one side of which there is a fastening socket with a rubber sealing ring. Thanks to this, no special tools are needed when performing installation work.

Step-by-step arrangement of internal sewerage

Installation of internal sewerage begins with the installation of sewer pipes in the basement, starting from the outlet pipe. Pipework needs to be done.

After the sewer pipes have been laid out, risers should be made in the basement, and its horizontal drain lines in the room.

Then installation work begins on arranging internal sewerage directly in the room.

The main rules for installing indoor sewage systems:

- You should try to install sewer pipes with a small number of connections and turns. This guarantees reliable and durable operation of the entire sewer system, because every connection is a potential site of leakage, and a turn is a site of possible clogging.

- The direction of risers and sockets of horizontal pipes should be towards the movement of contaminated water.

- The diameter of the pipes for the riser connection section is 100, 150 mm.

- To avoid repair work due to blockages, it is necessary to lay horizontal sewer pipes, maintaining an inclination angle of 4-7 cm per 1 meter.

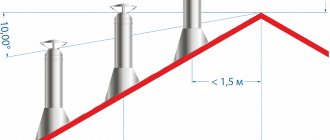

- There must be a ventilation pipe. It warns against the penetration of unpleasant odors into the room (if installed on the roof of the house).

- Use silicone non-acid sealant, it will protect against leaks.

Marking features

In the interests of consumers, manufacturers are required to label plastic pipe products. It is placed every meter of the product, applied either with special paint or with a heated tool.

State standards define the mandatory information to be displayed on the product:

- Product designation.

- Name of the material.

- Standard sizes.

- SDR.

- Hardness rating.

- Number and date of the corresponding GOST.

What do the symbols on the label mean?

For obvious reasons, information on products is written in abbreviated form and is designated:

- In Russian letters NPVC or Latin PVC-U - name of the material;

- The nominal values of the external section and wall thickness are simply numbers in millimeters;

- SDR – normalized ratio of section dimensions to wall thickness;

- SN – ring stiffness class;

- The standard is designated by the number and year of publication of GOST.

Sample product labeling

Bend with outer section 160 mm, wall 4.9 mm:

PVC-U pipe 160×4.7 SDR 34 SN 8 GOST 32413-2013

Strength classes

This parameter displays what load the sewer pipe can withstand; the corresponding GOST provides three categories:

- light group (marked “SN-2”) with a permissible load of 2 kN/m2. Laying in green areas, under sidewalks, flower beds, etc.;

- middle group (SN-4), for which the permissible load is 4 kN/m2. Scope of application: roads, where there is little traffic, parking lots, country houses;

- heavy group (SN-8), designed for a pressure of 8 kN/m2 (highways, industrial zones, etc.). The permissible depth for laying pipes of this type is eight meters.

Tips for choosing

Pipes are selected based on the characteristics of the future sewer main. Pay attention to the following parameters:

- Dimensions of external and internal sections.

- Wall thickness, strength classes and ring stiffness.

- Total pipeline length.

It is important to find a reliable supplier who will have a wide range of pipes from a reputable manufacturer. Fittings are purchased from the same materials and from the same manufacturer.

Estimated cost

The price for uPVC elbows is set per linear meter or pipe section and depends on the standard sizes and quantity of purchased products.

Thus, the cost of a 110×3 m HPVH pipe for external sewerage, with a wall thickness (3.2 mm) from the well-known Russian manufacturer Hemkor will be 546.33 rubles.

PVC-U pipes. Application area

Let us consider in more detail the use in external sewerage.

The pipes used for external sewerage differ from the pipes used for internal sewerage. Taking into account the difference in temperature, pressure and working volume. In order to easily distinguish the pipes, they were made of different colors. The external drainage system is installed from orange pipes.

Internal sewerage is assembled from gray hoses.

PVC-U pipes for external sewerage come in two types:

- Smooth

- Corrugated

About the smooth appearance of uPVC pipes for external sewerage

- They are used in a free-flow sewer system.

- Non-pressure is a system that operates by gravity.

- They are laid in places with the least pressure from the surface onto the pipes.

- It is advantageous to install the products in areas with pedestrian paths, in areas of vegetation, in garden plots, etc.

- Unlike corrugated pipes, smooth ones do not have high ring rigidity. Although they have long been used in laying external sewers.

Initially, hoses were imported from abroad, their cost was high, but over time, manufacturers, for greater demand, moved pipe production to Russia, which resulted in a reduction in price.

At the junctions of smooth pipes with each other and with fittings, a socket design is used. To ensure the reliability of the connecting seams of the pipeline, at the ends of the pipes, there are sealing rubber bands on the inside, which also facilitate installation and increase the speed of joining products by 5-6 times, unlike pipes made from other materials.

To change the direction and branch pipes, shaped parts are used; they are also made from uPVC.

About the corrugated type of PVC-U pipes for external sewerage

- Corrugated PVC-U pipes have recently begun to be used and are ideal for laying external sewerage systems.

- They are frost-resistant, have low thermal conductivity, and are neutral to chemically active substances. This prevents the system from freezing during low temperatures - this is their main feature.

- Due to these qualities, pipes are sometimes superior to plastic and even metal counterparts.

- It is also beneficial to use the products under high soil pressure.

- When laying in the ground, they can be concreted.

They can easily withstand pressure drops when pumping out a septic tank. Other plastic pipes burst due to this. Corrugated ones only deform without damage to themselves when the pressure changes and, after the pressure has stabilized, they return to their original shape.

The optimal area of application of products is in storm and drainage systems, in agriculture and in land reclamation systems, due to their lightness, durability and effortless installation.

PVC-U pipes for external drainage system

Differ by:

Purpose of the applied area- Directly along the thickness of the sleeve wall

- Difference in permissible load

- Size depending on application

What is the difference between external and internal sewerage

External sewerage is laid underground, at a depth below the freezing point. Therefore, products with greater strength are purchased for it than for the internal system. In this case, thick-walled orange pipes are used. Their cross section is 110-500 mm, the maximum value is 1000 mm. Wall thickness varies from 3.2 to 24.5 mm. In addition, products with two- and three-layer walls are used.

When assembling internal communications, gray thin-walled bends are used, the wall thickness of which does not exceed 3.5 mm, and the diameter is 50-250 mm.

Scope of application

PVC-U pipes of 110, 125, 160 and other diameters are widely used both in households and industrial facilities. They can be used in any pipelines designed to transport a working medium with temperatures up to 45 °C. Here are the most common types of these products and their areas of application:

- casing pipe, this PVC-U product is used when drilling wells; it has become an excellent alternative to steel products, since it is absolutely not subject to corrosion. A characteristic feature of these pipes is the presence of a trapezoidal thread (internal on one side, external on the other), which greatly simplifies installation;

Trapezoidal thread casing - domestic and industrial piping systems;

Water supply pressure PVC pipe with O-ring - when installing electrical wiring (corrugated and flat pipes), it is used as a protective sheath for cables;

Corrugated and flat pipe for electric cable - engineering drainage and sewer systems, we will consider this area of application in more detail.

Photo: plastic socket-type free-flow pipe for sewerage systems

Features of installation and connection of uPVC pipes

Before you begin assembling the pipeline, draw up a diagram of its laying. They select the necessary material (pipes, fittings). To do this, you can use the calculation calculator on the websites of sellers of polymer products.

Laying of sewer channels is carried out with a slope and in the direction towards the drains.

PVC-U materials allow installation to be carried out easily and quickly, without the use of expensive welding equipment or threaded bends, as when installing casing columns.

Connections are made in the following ways:

- Using socket connections through rubber seals.

- By gluing the end and socket of the bends.

- With the use of fittings.

Adhesive connection of uPVC pipes without socket

This joining of the bends is made using a coupling. The parts to be joined are cut at right angles with a fine-toothed hacksaw.

Chamfer at an angle of 15 degrees.

The edges are cleaned of small particles, the depth of the coupling is measured and a mark is placed.

The ends of the pipes and fittings are cleaned with a special solvent and dried.

Glue is applied with a brush to the outer parts of the products and the inner surface of the coupling. To ensure that the glue is evenly distributed over the areas being joined, the parts are turned a quarter turn.

Important! Solvent adhesive is used only that recommended by the manufacturer of pipe products.

Similar connections are used when installing tees, crosses, and various adapters.

Pros and cons of uPVC pipes for pressure sewerage

The advantages and disadvantages of products made from unplasticized polyvinyl chloride are related to the properties of the material. They are definitely superior in durability and quality to cast iron, but are still not used everywhere, since renovation of old networks costs a lot of money. In new construction, preference is almost always given to uPVC.

Advantages

- Corrosion resistance - plastic does not oxidize or collapse, plus it does not create a breeding ground for bacteria and fungi.

- Immunity to stray currents, no cost for cathodic protection.

- Chemical resistance to acids and alkalis, unaffected by abrasives.

- Low coefficient of linear expansion.

- Guaranteed throughput due to the absence of overgrowing of the working section.

- A light weight.

- Durability - at least 50 years under the manufacturer's warranty; recent research extends the safe operation life to 75 and at least 100 years before complete wear (wall fracture).

- Easy installation, low requirements for the operator, self-installation is permissible with initial skills of home networks.

- Possibility of laying on difficult terrain.

- Stability of indicators at low temperatures, permissibility of installation in winter.

- Adaptability when connecting to equipment due to a wide range of shaped products.

- Hygienic and environmentally friendly - in a stable state they do not emit harmful substances and do not form rotting products.

Minuses

- Inability to use at high temperatures.

- Requires protection from rodents.

- When melted, they release toxins.

PVC sewer pressure pipe can be used without risks to health or damage to associated equipment to organize wastewater disposal at facilities where hot liquid is not discharged. For production facilities, it is recommended to consider a different type of sewage system in areas operating at elevated temperatures.

Nomenclature of external PVC-U sewer pipes

| Dn, mm | Din, mm | Draster, mm | E, mm | Lraster, mm | Length, mm |

| 110 | 103,6 | 132,5 | 3,2 | 116,0 | 2000 |

| 110 | 103,6 | 132,5 | 3,2 | 116,0 | 3000 |

| 110 | 103,6 | 132,5 | 3,2 | 116,0 | 4000 |

| 110 | 103,6 | 132,5 | 3,2 | 116,0 | 6060 |

| 160 | 152,0 | 186,0 | 4,0 | 134,5 | 2000 |

| 160 | 152,0 | 186,0 | 4,0 | 134,5 | 3000 |

| 160 | 152,0 | 186,0 | 4,0 | 134,5 | 4000 |

| 160 | 152,0 | 186,0 | 4,0 | 134,5 | 6080 |

| 200 | 190,2 | 228,9 | 4,9 | 146,5 | 2000 |

| 200 | 190,2 | 228,9 | 4,9 | 146,5 | 3000 |

| 200 | 190,2 | 228,9 | 4,9 | 146,5 | 4000 |

| 200 | 190,2 | 228,9 | 4,9 | 146,5 | 6100 |

| 250 | 237,6 | 281,9 | 6,2 | 162,2 | 6000 |

| 315 | 299,6 | 351,3 | 7,7 | 192,2 | 6140 |

| 400 | 380,4 | 443,1 | 9,8 | 220,0 | 6150 |

| 500 | 475,4 | 549,6 | 12,3 | 255,0 | 6160 |