Profiled pipes are not used for pipeline installation due to insufficient resistance to internal loads and lower throughput compared to round ones, but they are used in industry, the construction of buildings for various purposes and private development.

Metal profiles differ from conventional pipes not only in appearance, but also in purpose, technical characteristics and manufacturing technology.

Features of the bending process

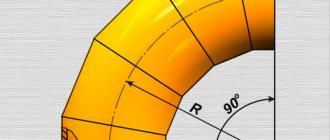

Each metal has its own characteristics; without taking them into account, it is impossible to give the pipe material a complex shape. The bent pipe is subject to radial and tangential forces. The former deform the section, and the latter contribute to the appearance of folds. The main requirement for the final result is that the cross-section of the pipe should remain unchanged, and there should be no corrugations on the walls.

Bending allows you to minimize the number of welds when laying pipelines with all kinds of bends.

Methods for bending pipes and profiles

The process of bending pipes is present in many production operations: in the laying of oil and gas routes, heating mains, in the installation of water supply and sewerage networks, industrial ventilation and air conditioning systems.

Bent pipes serve as branches, connecting sections, bends and fences in the designs of various mechanisms and rigid metal structures. In all cases, pipe bending is carried out using pipe bending machines

. Each technology for changing the direction of the pipe has its own characteristics and indications that should be taken into account when choosing equipment.

Pipe bending methods

Based on the required bend angle, material and diameter of the pipe, bending can be done manually or using special equipment. There are also hot and cold bending, with and without filling the pipe cavity.

Here is a diagram and recommendations for calculating pipe bending parameters, following which is a guarantee of a good result. After the load is removed, a phenomenon called springing occurs, which is directly proportional to the elastic modulus of the material. The amount of possible deformation also depends on the bending method used and the geometry of the object

Specifics of hot technology

This method is chosen when it is necessary to bend a pipe with a diameter of 10 cm or more. Pipes are deformed hot, both manually and using mechanisms. There is such a thing as a minimum bend radius. The length of the pipe zone that needs to be heated is determined based on the pipe diameter and bending angle. In this case, the rounding cannot be less than the pipe diameter multiplied by 3.

Find the length of the heated section using the formula:

L = α x d / 15

In the formula: L is the required length in mm, α is the bending angle in degrees, d is the outside diameter of the pipe in mm, 15 is the coefficient. Let's say a pipe with a diameter of 200 mm needs to be bent at an angle of 60⁰, then L = 60 x 200/15 = 800 mm, i.e. 4 diameters.

The minimum permissible bending radius for water and gas pipes in accordance with the requirements of GOST 3262-92 can be taken from the table

To bend the pipe, it must be heated to 900⁰. The optimal temperature for starting bending is 760⁰, and at the end - 720⁰C. When burned, the strength characteristics of the material deteriorate. The hot bending process includes several operations:

- making a template;

- sand packing;

- site marking;

- heat;

- bending.

To prevent the cross-section of the pipe from being deformed and sweet spots not forming on its inner part at the bend, the internal space is filled with quartz sand. It is first dried and calcined in order to remove organic impurities at a temperature of 150 to 500⁰, and then passed through a fine sieve with a cell size of 3.3 x 3.3 mm. Before you start stuffing the pipe, you need to plug one end of it.

Wooden or metal plugs with a hole for gases to escape are used as plugs. Fine and wet sand cannot be used, because... the first one is sintered under thermal influence and firmly adheres to the walls of the pipes. The second, as a result of the formation of steam, contributes to the development of high internal pressure, which can cause the plug to fly out. The presence of stones in the packing is unacceptable; they can push through the pipe wall.

The process of stuffing the pipe is very labor-intensive, so it is transported to the tower and given a slightly inclined or vertical position. Since the quality of the bend is directly dependent on the compaction of the packing, the pipe is continuously tapped throughout the process. A dull sound indicates that the workpiece is well filled.

Before proceeding directly to the main operation, areas of future bends are drawn on a pipe filled with sand, attaching a template. The pipes are heated in furnaces or furnaces. Bend both manually and mechanized.

In the latter case, special plates are used, equipped with thrust posts, with the help of which the heated section of the pipe is fixed, and clamps that serve to hold the end of the pipe on the plate. A cable is put on the opposite end of the pipe, the tension of which with the help of a winch or capstan causes the pipe to bend.

To prevent the pipe walls from deforming, gaskets - straight or curved - are placed in the space of the pipe stand. The free end with the cable attached to it is secured using a stand. During the process, the geometry of the pipe is monitored by periodically applying a template to it.

Having bent the pipe at the desired angle, the plugs are removed from it by burning or simply knocking them out. The sand is poured out, the pipe is cleaned and washed. Perform a final bend check using a template.

Cold bending

To change the configuration of pipes of small diameters, various manual devices are used; for large diameters, mechanized pipe benders are used. At home, bending of water pipes for the heating system is most often required. Bending a pipe at 90⁰ is called a bend, 180⁰ is a roll, with the formation of a ledge is a weft, and in the form of a loop is a bracket.

This device is used to bend pipes with a diameter of up to 2 cm. It is attached to the workbench using a plate (1) and a hub. The template roller (6) is fixed on the common axis of the plate and the hub. The movable roller (2) is fixed by a bracket (4) having a handle (3). The pipe is placed between the rollers so that its end fits into the clamp (7). The bracket is rotated around the template using the handle until the desired bend angle is obtained.

There are other devices for manual bending. At home, to make a coil for heating water, a stainless steel tube with a diameter of about 20 mm is simply wound onto a piece of large diameter pipe. First, a bracket is welded onto a large pipe, placed on supports and clamped.

The tube is tightly filled with sand and closed with plugs, then inserted into the bracket and winding begins. The pipe used as a template needs to be twisted, so it will require the efforts of at least two people. Having finished winding, the coil is leveled.

Using such a device, pipes with a diameter of up to 2 cm are bent. It is attached to the workbench using a plate (1) and a hub. The template roller (6) is fixed on the common axis of the plate and the hub. The movable roller (2) is fixed by a bracket (4) having a handle (3). The pipe is placed between the rollers so that its end fits into the clamp (7). The bracket is rotated around the template using the handle until the desired bend angle is obtained.

Bending a pipe made of stainless steel or other material at home can be done using the simplest device. It is advisable to use it for small volumes of work. To make a primitive pipe bending device, you need a concrete slab, metal pins and a hammer drill. The slab is divided into cells 40 x 40 or 50 x 50 mm. Using a puncher, holes are drilled in the corners of the cells and pins are inserted into them.

The tubular product is inserted between the pins and, applying force, is bent. The accuracy with this bending method is not ideal, but it is quite sufficient for using the workpiece at home. For bending with higher precision, you can use a device made on the basis of a jack.

To make such a device, you need a jack that can withstand a 5-ton load, a strong base and pins. The pipes are bent using shoes. The size of these elements must correspond to the parameters of the bent pipe

To prevent the internal lumen of the pipe from deforming, means are used to counteract this process from the inside. Sand is most often used as internal limiters. In this case, a plug is inserted into one end of the pipe, sand is poured through the other, and then it is plugged with a plug. Next, bending is performed.

Sometimes the limiter is a spring specially made for this purpose. For winding, wire with a diameter of 1 to 4 mm is used. The spring should fit freely into the pipe at the bend point; a portion of the wire is left outside. After the bend is completed, the spring is removed by pulling the wire. When working with a pipe with a square cross-section, wire with the same cross-section is selected to make a spring.

A bundle of wire consisting of separate segments, which are pushed inward one at a time to the point of future bending, is also suitable for this purpose. After the operation is completed, the segments are also removed one by one. You can manually bend a stainless pipe with a cross-section of up to 4 cm and a wall thickness of 0.3 cm.

The photo shows the existing methods of manual bending of pipes: with rolling, by winding, on two supports, by bending with drawing. The latter method is used for seamlessly drawn thin-walled pipe material. In this way, short pipes are bent at a small angle.

To work with large diameters, professional equipment is required. There are pipe bending machines equipped with a mandrel. This structural element is an ordinary metal rod.

Pipe bending machines can bend pipes with different cross-sectional geometries. This is universal equipment, because... It is possible to bend products with a wide range of diameters and from different materials, from carbon steel to pipes made of non-ferrous metals. The most complex machines are electronically controlled

Before starting the bending process, it is placed inside to prevent deformation of the pipe walls. The mandrels included in the kit have different sections, so you can choose the one you need for a specific diameter of pipe products.

Approximate price for bending metal pipes

| Workpiece length (mm) | Sheet thickness (mm) from 0.5 to 2.5 | Sheet thickness (mm) from 2.5 to 4.0 |

| from 0 to 1000 | 8,4 13,7 | *410 rubles for each batch of parts (equipment adjustment, programming) |

| Packing products with stretch film or tape | 5% of the order value |

| Packaging of products in cardboard, bubble polyethylene or other agreed upon method. Applying labels and stickers | by agreement |

| Urgency surcharge | 20% of the order value |

| Extra charge for product weight above 50 kg. | 0,5 |

| Repainting the product | 15% of the order value |

| Minimum order | 2000 rub. |

| Delivery | by agreement |

| Painting of products requiring the manufacture of additional devices. Drilling technological holes for hanging the product. | by agreement |

Pipe bending service in Moscow

offers a service called pipe bending in Moscow at an affordable cost. Work is carried out with profile and round products. The service is one of the extremely popular in the metal rolling industry. The cost of bending linear meters is quite acceptable and does not require extra costs.

Purchasing bent pipes as a finished product is fraught with numerous complications and is expensive. Finished products cannot always be made in exact accordance with certain parameters. An effective alternative is custom pipe bending in Moscow, which is carried out on an individual basis. During the work, the necessary bent metal profiles will be manufactured according to the specified parameters.

Online application

When ordering a mandrel pipe bending service in Moscow, you get a lot of advantages:

- reduction of production costs and optimization of business processes;

- receiving the necessary products promptly;

- saving money when purchasing finished rolled metal products;

- implementation of ideas in the creative, construction and architectural fields.

When ordering services related to flexible pipes in Moscow, the result is the following:

- the work is done accurately and efficiently and flawlessly;

- the order is completed as quickly as possible;

- the terms of cooperation are convenient for buyers;

- The service is completely customer-oriented.

Changing the configuration of pipes made of non-ferrous metals

Non-ferrous metals have a very useful property - high ductility. However, they are not strong enough. During the bending process, as a result of the application of compression and tension forces, the pipe may collapse or rupture. To prevent this from happening, you must strictly follow the technology.

How to bend copper and brass pipes

Both hot and cold methods are used for bending copper and brass pipes. When choosing the first, sand is chosen as the internal filler, and molten rosin is used as the second filler. The bending technology is the same as for steel pipes.

Tubular products made of copper and brass are subject to annealing and subsequent cooling before cold bending. The temperature range for both materials is the same - from 600 to 700⁰С. The difference is in the cooling medium - copper is placed in water, and brass is cooled in air.

Once the process is complete, the rosin is removed by smelting it. To prevent pipe rupture, the process should never be started from the middle of the pipe, only from the ends. Both simple tools and complex machine equipment are used as bending devices.

Manual pipe benders work due to human physical efforts, while hydraulic ones reduce these efforts to a minimum. Both are equipped with interchangeable nozzles to allow you to select the desired diameter.

The minimum radius for bending copper and brass pipes is regulated by GOST 617-90 and GOST 494-90, respectively. Experts do not recommend using this radius unless absolutely necessary. It's always better to use a larger value

It is much easier to work with copper and brass pipes than with steel ones, but metal deformation during bending occurs according to the same laws of physics. In the bending section, the outer surface experiences tension, as a result of which the walls become thinner.

Inside the pipe, reverse processes occur - the wall shrinks and becomes thicker. There is a risk of the round section turning into an oval and reducing the nominal diameter, so bending should not be started without taking measures to prevent these phenomena.

Aluminum pipe bending

The main methods for bending aluminum pipes are the same as for brass or copper:

- pushing between rollers;

- rolling;

- rollback;

- pressure.

Before making a decision about how and in what way to bend aluminum pipes of square section or any other, you need to familiarize yourself with each one. The first method is used for thin-walled pipes with a maximum diameter of 10 cm, when it is necessary to obtain a gentle bend with low accuracy requirements. The minimum radius is strictly regulated here. Its size is 5-6 pipe diameters.

The curvature of the section is determined by the position of the deflection roller. Interior decorative elements are most often made in this way. The second method is to bend large-diameter pipe material, for which 3-roller pipe benders are used. The pipe is pulled between drive rollers, the orientation of which determines the bending radius.

The photo shows a stationary electric 3-roller pipe bender, but there are also manual mobile models of the equipment. On it, the workpiece moves through rollers and is bent at a given angle along its entire length. On such a machine, you can change the configuration of the pipe by bending it into a ring, a spiral, or making an arc of large radius

The accuracy of this method is even lower than the previous one, but the part can be re-bent and the process repeated until the desired geometry is achieved. The rolling method does not provide for the presence of internal filler, so it is not used to obtain small radii. When choosing this method, it will not be possible to fulfill the strict requirements regarding the ovality of the section at the bend.

To deform an aluminum pipe by pressure, presses are used with stamps installed on them with a matrix of the desired shape. The given geometry is obtained as a result of the influence of pressure exerted from the outside. In some cases, the pressure can be internal, when the pipe is placed in a mold and liquid is supplied inside with a pressure sufficient to press it against the walls.

It is not easy to bend duralumin pipes, because... This material is quite hard and springy. To facilitate the process, they are fired immediately before bending at a temperature of 350 to 400⁰C, then wait until the pipes cool naturally in the air.

Hot pipe bending method

This method is used if it is impossible to bend a pipe cold using a pipe bending device. Its labor intensity is much higher. In addition, filler is used for the workpiece. This can be pre-sifted and dried river sand without small particles and organic matter that burn to the walls of the pipe when heated. Otherwise, high pressure steam may form when the pipe is heated.

The bending process occurs when the workpiece is heated to approximately +900 °C. To obtain a high-quality product, it is necessary to prevent overburning of the workpiece. The size of the heated area depends on the bending radius and cross-section of the pipe. After bending is completed, the sand is removed from the cavity, after removing the plugs holding it. The product is then cleaned and washed.

Methods for bending large diameter pipes

Relatively recently appeared methods are bending pipes using industrial and high frequency currents and bending with tension. In the first case, a high-performance high-frequency installation is used, in which a pipe with a diameter of 95 - 300 mm is heated, bent and cooled. It consists of two parts - a mechanical one in the form of a bending machine and an electrical one, which includes an electrical part and a high-frequency installation.

The pipe is deformed only in the heated area located in the inductor zone. The geometry changes to a given size under the influence of a deflecting roller. Using this method, you can obtain a bend with a small radius curvature.

Bending using the second method is carried out on bending and stretching machines, which include a rotary table. The pipe is subject to large tensile and bending forces. This is how steeply curved bends are obtained with a constant wall thickness along the entire circumference.

The method is used for bending large-diameter pipes used in the aviation, automotive, and shipbuilding industries, where high demands are placed on the pipeline. The advantage is the ability to bend pipes with a wall of 2 - 4 mm by 180⁰.

Capabilities of machines for bending stainless pipes

Stainless pipe bending along the radius is carried out on a three-roll profile bending machine. It allows you to bend products with a diameter of up to 214 mm, while the minimum radius depends on the wall thickness and can be equal to 4 to 6 pipe diameters (mm).

A mandrel machine makes a sharp bend of a stainless steel profile. The minimum radius, depending on the wall thickness of the product, is from 1.5 diameter (mm) of the pipe. The machine also carries out spatial bending of profile stainless steel products.

Features of bending profiled pipes

Profile pipe products have a more aesthetic appearance than their round counterparts, which is why they are often found in household structures. When bending, a compressive force acts on it from the inside, and a tensile force from the outside. You should carefully select the bending method before starting this operation.

The profile range includes pipes with a cross-section in the form of a square, oval, rectangle. There are several nuances and they should not be forgotten when bending profiled pipes at home without special equipment:

- The optimal length of the bending section for corrugated pipes with thin walls and a cross-section of up to 2 cm is the height of the pipe multiplied by 2.5.

- For thick-walled pipes, the length of the bending zone is determined by multiplying the cross-section by three. Otherwise, cracking of the material from the outside or deformation from the inside cannot be avoided.

- The minimum value of the radius of curvature is the bending section multiplied by 2.5.

Without taking these requirements into account, you can’t even hope for a good result. The bending methods do not differ from those used when working with products with a round cross-section. In addition, you can use the manual bending method with cross cuts, which are made on three sides of the pipe.

The length of the cuts and their number are determined by calculations. Let's say there is a pipe 40 x 90 mm. You need to perform a full turn, i.e. bend along the wall 40 mm at an angle of 180⁰ with a radius of 150 mm. First, calculate the length of the semicircle along the outer radius - L = (2π r: 2 = 2x 3.14 x 190): 2 = 596.6 mm.

For the inner radius, the calculations are the same: Lin. = (2 x 3.14 x 150) : 2 = 471 mm. The sum of the cut lengths on the inner radius is determined by the formula: Lout = L – Lin = 596.6 – 471 = 126 mm. If we take into account that a grinder can make a cut 5 mm wide, then on a bend plane 126 mm long you will get 25 slits, after which the pipe is bent until the edges of the cutouts touch. The slots are welded and the seams are cleaned.

Conventional pipe benders are not suitable for bending profile pipes. There are special pipe bending machines for this purpose, but even with such equipment, it is almost impossible to obtain a right angle. It is easier to use the welding method or use fittings

There is another way in which profiled and round pipes are bent, but it can only be used in winter. To do this, insert plugs into the ends of the tube, pour water inside and wait until it hardens. The pipe is bent, controlling the process with a template, then the plugs are removed and the liquid is removed.

Stages of metal profile production

The main stages of the full production cycle are as follows:

- strip processing,

- production of round blanks,

- pipe profiling,

- slicing,

- quality control,

- heat treatment.

Strip processing

Raw materials for profiled pipes are supplied to the production line from metallurgical plants in the form of rolls - strips.

The rolls are unwound and cut on a slitting machine into strips of the required width. The cut segments are then welded into a continuous strip, which is wound onto a drum.

This is done to ensure continuity of production - a technological reserve of material is created to prevent downtime in the operation of the rolling machine.

Making a blank

The metal strip is transferred to the forming mill, where it is formed into a blank with a round cross-section.

When passing through the stands and rollers of a forming machine, the tape produces a continuous pipe with an open seam.

At this stage, a cold strip of steel is passed through the forming mill or heat treatment is carried out immediately.

We recommend that you read: Seamless thick-walled pipes - types and applications

The pipe is transferred to a welding machine, where the seam is closed to form a blank. Welding is carried out using a furnace method, in shielding gas or with high-frequency currents. The seam can be straight or spiral.

During welding, the machine rollers compress the edges of the seam to increase the strength of the joint, resulting in the formation of flash - excess molten metal pressed into the pipe and onto its outer surface. The burr is removed with a cutter, after which the workpiece is cooled with an emulsion composition.

Important! The process of cooling the workpiece with the emulsion composition continues both at the profiling stage and during cutting.

Pipe profiling

Depending on the cross-sectional shape that needs to be obtained, pipe profiling takes place in one or two stages.

- The workpiece is passed through sizing rollers, which level the workpiece. After calibration, it has the same cross-section along its entire length. If a pipe of oval or flat-oval cross-section is required, then its profiling ends there.

- If a triangular, square, rectangular or polygonal cross-section is required, the workpiece is passed through a profiling machine. The rollers of this machine compress a round pipe to the desired shape.

Slicing

The finished continuous pipe is cut to specified dimensions without stopping the cooling process.

For additional protection of finished profile pipes, cold or hot galvanizing is used:

- The first method is to apply a layer of powder or polymer paint to the metal profile.

- The second method differs in that the finished pipe is pre-cleaned, dipped into a bath of molten zinc, and then cooled and dried.

Quality control

Strict requirements are imposed on profile pipes manufactured under full cycle conditions. An obligatory stage in the production of metal profiles is quality control.

The tightness of the seam is especially carefully controlled, since the weak point of welded pipes is the seam.

Two verification methods are used:

- visual inspection,

- eddy current flaw detection.

The specialist inspects the seam and identifies seam irregularities caused by welding defects and damage caused by improper operation of the rollers.

We recommend that you read: Novosverdlovsk Metallurgical Company

The second verification method is hardware. The operation of the flaw detector is based on comparing the electromagnetic characteristics of the metal in all areas of the seam.

These characteristics are affected by the chemical composition of the material and the presence of physical defects. The flaw detector helps to identify areas of lack of welding in the seam and shell that were not noticed during a visual inspection.

The production process is considered completed, and the product is allowed for sale only after quality control has been carried out.

Types of pipe bending equipment

All bending units can be divided into three groups according to the type of drive:

- Devices with rolling drive. Such devices are manually controlled. With their help, you can bend thin-walled metal or polymer pipes of small diameter. The advantages of such equipment: low cost of work, the ability to do everything yourself. Disadvantages - the need to use the physical strength of the master, a small range of pipe diameters, the inability to work with workpieces of non-standard sizes.

- Devices with mechanical (hydraulic) drive. The method of bending pipes using them is considered universal. Professional devices of this type are used in construction, industry and other fields. Advantages of hydraulic installations: higher productivity than the previous type of bending machines, a large number of workpieces are processed per unit of time, it is possible to work with large-section pipes. There is one minus, but a significant one: if a hydraulic cylinder fails, it cannot be repaired - only a complete replacement.

- Electrically driven devices. Electromechanical units can often be found at capital construction sites and industrial enterprises. Pipe bending methods using this type of equipment are distinguished by high accuracy, quality of finished products and high productivity. Today there are many models of electromechanical bending machines. Some of them even cope with large-diameter pipes, and the accuracy of such manipulation is very high. The disadvantage of this type of device is its low mobility, which is due to the weight of the machine and the need to connect to the power supply.

In accordance with the principle of operation, the equipment is divided into the following types:

- Automatic - the device is controlled by a CNC system, pre-configured by the master. Production control is carried out automatically using sensors.

- Lever - has manual control, the impact on the object occurs using the physical force of the master. When working with thin-walled workpieces, an angle of 180° can be achieved using this pipe bending method.

- Crossbow - gives the workpiece the shape of an angle of 90°. This device does not take up much space. It can be used to process workpieces made of polymers and non-ferrous metals.

- Hydraulic - the impact on the pipe occurs using a hydraulic cylinder machine.

- Arched - a manually operated device. Bending occurs by passing the pipe through a template segment.

- Three-roller (roller) - a manually driven unit that acts on the workpiece using a system of three rollers. Using this pipe bending method allows you to process hard metal workpieces and reduces the risk of cracks or deformations.

- Spring – made of spring steel. During work, a spring is placed in the pipe cavity, then the master applies physical force to change the shape of the workpiece. This processing method is suitable for seamless workpieces of small diameter.

Bending steel or plastic pipes: ways to implement the process

By and large, there are only two ways to deform rolled pipe:

- cold pipe bending

- deformation of heated products

The first method - “cold” bending - is possible only if the deformed pipe is made of a sufficiently plastic material that can change its shape under the influence of external forces.

Therefore, “cold” bending is usually practiced when deforming relatively small metal pipes (with the exception of cast iron pipes).

True, bending stainless steel pipes (or any other pipes with increased ring rigidity) forces us to use special machines in this process - pipe benders. Because with our own strength we can only bend very flexible pipes made of copper or aluminum.

However, “soft” plastic pipes cannot be bent using this method even on pipe benders. Indeed, despite the declared softness, plastic pipes either do not have sufficient ductility for this method of deformation, or they do not have ring rigidity sufficient to hold the product in a bent state (polyethylene products without a reinforcing frame).

An exception can be made only for combined materials based on polyethylene - bending of metal-plastic pipes is carried out only in a “cold” way. Inside such a pipe there is a reinforcing belt made of aluminum - during the deformation process it is this that is bent and it is this that holds the shape after bending.

Hot bending is possible in almost any case. Indeed, in a heated state, the plasticity of any material increases by an order of magnitude. For example, high-temperature bending of steel pipes (or products made of any other metal) is very simple: the pipe is simply heated at the point of deformation and bent by hand. That is, in this case, we will no longer need machines or mechanical pipe benders.

With plastic, in this case, problems arise again. Hot deformation is impossible in principle - polymer pipes lose their ring rigidity when heated above 250 degrees Celsius. That is, during the process of hot deformation, such a pipe will simply spread over the surface.

Well, now that we have become familiar with the methods of deformation, let's move from theory to practice and figure out how to bend pipes in a “cold” and “hot” way.