A pipe made of rigid material during installation will require changes to the original structure of the floor and roof. In such cases, the consumer’s costs for the purchase of special fastening devices, fittings and brackets increase. By using a flexible chimney for heating boilers, you can reduce financial losses without reducing efficiency.

Flexible chimney

Specifications

Corrugations for chimneys made of aluminum and stainless steel are similar in manufacturing properties, they differ only in strength and temperature values. Aluminum melts at 680°C, and stainless steel at 1400°C. In this regard, lightweight materials are not used in smoke exhaust systems, where readings up to 900°C are reached; stainless steel is used there.

To repair old chimney systems, durable steel material is used, and the pipe is pushed from above to the junction with the boiler. Soft material is not able to provide a stable ride without deformation of the product.

The design of corrugated pipes allows complex bends and turns of 90° in different planes. The length of horizontal sections should not exceed 3 m for new buildings, and 6 m when installed in old premises.

Production technology

In the process of making corrugations, two elements are used, such as a stainless steel spring and strips of metal. Aluminum and stainless steel are used as metals for strips. In pipe production, metal foil is wound onto a spring in strips and secured with locks. With the help of such devices, flexible chimneys are provided with stable flexibility. A meter-long product can increase in length three times, and also be turned 180°.

The stores provide a large selection of products. If necessary, the consumer can purchase corrugated chimneys of the required size, which simplifies the connection to the heating boiler. During the pipe production process, all connections are checked using a laser, then the internal surfaces are coated with a protective compound that prevents damage to the metal when exposed to aggressive environments. A flexible chimney can last up to 20 years.

The right choice Master Flush

To choose a roof sealant, it is not enough just to know its dimensions.

- Flexible seals with round and square bases are suitable for roofs that have a slope of up to 45 degrees. In addition, the roof can be made of bitumen shingles, roofing steel, profiled metal and so on. The seals are installed using silicone and then secured with self-tapping screws.

- Seals with a flange on an elastic base are used for roofs with a slope of up to 60 degrees.

- Flat roofs with a slope angle of more than 60 degrees are equipped with a seal, the base of which has an increased area.

- Flat roofs receive cuffs that are installed perpendicular to the base. To do this, use bitumen mastic or silicone.

- For tiled and slate roofs, seals that have a large metal base are suitable.

For the manufacture of Master Flash the following is used:

- High quality rubber that can withstand high temperatures. It is worth noting that rubber MF lasts longer.

- Silicone, which is also resistant to temperatures around 200 degrees.

Types of corrugation

Depending on the material from which the flexible chimney is made, there are two types of corrugations:

- aluminum;

- made of stainless steel.

Corrugated stainless steel chimney

Aluminum corrugation

Relatively recently, corrugated multilayer aluminum pipes were used for the manufacture of flexible chimneys. However, for heating boilers operating on solid fuel, aluminum chimney corrugation is not suitable because it cannot withstand high temperatures.

In some regions, the use of such pipes is strictly prohibited. As the temperature increases, aluminum undergoes deformation, which can result in the walls of the chimney system burning out, resulting in consumers suffocating from gas leaks.

Steel corrugation

The design of stainless steel chimneys is similar to aluminum ones, but steel pipes have improved technical characteristics. They are used in systems with heating boilers powered by liquid and solid fuels. They function effectively at temperatures up to 900°C without undergoing deformation.

How to install roof sealant?

The general principles of organizing roof passages using Master Flash were given above. In addition, manufacturers provide a detailed description of the installation process. However, there are differences in the installation and fixation algorithms of different models, which are best familiarized with before purchasing.

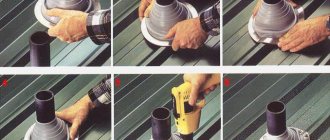

Installing a seal with a flexible flange

The sealing system with an elastic base is mainly used in the installation of chimneys crossing metal roofs.

Work algorithm:

- We determine the location of the groove on the cone for the upcoming cut. Do not forget that the Ø of the removed segment should be 20% less than the Ø of the pipe.

- Carefully cut off the excess with cable cutter's scissors, trying to make the cut as even as possible.

- We moisten the surface of the pipe to optimize sliding. We put the cuff on the chimney and pull it to the place of fixation, holding the cone and not the flange.

- Having reached the seal to its place, we draw a line around the edge of the flange.

- Slightly lift the cuff to apply adhesive around the perimeter of the flange according to the markings.

- We install the seal in place.

- Apply elastic sealant around the top cut and edge of the base.

The adhesive must match the type of coating. Rules and restrictions on selection are indicated in the instructions attached to the product. For example, gluing master flash with bitumen mastic to a roof with a polycarbonate coating or polymer membrane is prohibited, because the materials will begin to deteriorate and the connection will become unusable.

Master Flash Mount with Rigid Edge

The procedure for installing a seal with an aluminum strip along the edge follows a similar pattern. Before the fastening stage, all work is carried out in the same order. The difference is that during fitting, before outlining the outline of the flange, it must be profiled to ensure a tight fit to the surface of the coating.

Fastening is done with self-tapping screws with a hex head. The fasteners are screwed into the low profile flanges. If desired, for reliable fixation with self-tapping screws, you can buy a counter metal part installed on the back side of the roof.

For roof passages under large chimneys and on roofs steeper than 45º, it is recommended to place the square flange in the form of a diamond. In order to more effectively protect against leaks on roofs with a pronounced ribbed surface and steep slopes, it is recommended to purchase seals with an enlarged base.

The line of cuffs with a metal flange edging includes models with a porous seal located on the back side. To fix them, there is no need to treat the surface with an adhesive. The system is simply screwed to the roof without gluing or filling the seams with silicone. The porous material ensures perfect tightness without additional manipulation.

Insulation for repair operations

Roof seals with a cut are required where it is not possible to put insulation on the chimney from above. Most often they are in demand for repairing worn-out chimney insulation.

Installation algorithm:

- Using cable cutter's scissors, we cut off the top of the cone along the edge, the Ø of which is 20% smaller than the same size of the chimney.

- Remove the toothed fastener from the lock and wrap the cuff around the pipe.

- We connect the sides of the cuff cut and put the fastener back on, without fanaticism squeezing the teeth with pliers.

- Lifting the edge of the flange, we apply silicone sealant to the roof.

- We press the system and apply silicone glue to the fastener and all problem areas of the insulation.

On roofs with an increased likelihood of leaking, systems with an increased base area are installed.

Roll insulation device

For cutting large pipes, rolled material reinforced with aluminum strip is produced. It allows you to seal chimneys of round, square, rectangular configurations. Thanks to its elasticity, pipe bypass parts can be easily formed, and thanks to the built-in aluminum, the sealing system adheres flawlessly to the roofing surface. The method of installing roll insulation is similar to the technologies for installing brick pipes, which we presented in another article.

In order to seal a round chimney, you need to cut a piece of material 30 cm larger than the circumference of the pipe. This must be done so that the insulation is secured with an overlap. Before gluing, the section must be bent like a metal corner so that the vertical shelf is 17cm wide. This part will be glued to the vertical surface of the chimney. Before fixing, the horizontal shelf should be given the shape of a skirt by stretching. The edge of the roll seal can stretch up to 25%. After complete molding and a couple of fittings, the flexible roofing flashing is glued to the pipe and covering.

Square chimneys are covered in four steps in the following sequence:

- Cut out 4 parts of the apron, leaving 30cm allowances at the corners. We stretch the material before gluing, because after that its shape and dimensions cannot be changed.

- We fill the recesses of slate or coverings with a similar profile with silicone or sealant so that the cutting fits tightly. The sealing composition should be no more than 1 cm. There is no need to fill in the corners.

- Glue the top part of the insulation to the walls of the chimney without touching the corners. First we glue the bottom strip of the apron, then we put it on it and glue the two side parts. Then we apply the top strip so that its edges overlap the tops of the sides. As a result, atmospheric water will drain without getting into the butt seams.

- Flatten the apron and glue its lower part to the roof with silicone, not forgetting to glue the corners. We lay a metal strip around the perimeter and secure it with screws or rivets.

Roll insulation can be painted in any color that matches the roof.

Installation of cuffs on tiles and slates

For arranging penetrations through roofs, covering with bitumen and ceramic tiles, slate tiles and slate, sealing systems with a lead or aluminum base are produced. The cone is traditionally cut to fit the collar tightly around the chimney. The upper part of the metal flange must be placed under the covering; on the sides and bottom it is laid on top of the roof.

The upper edge of the base is bent to prevent atmospheric moisture from penetrating into the system. After installation, all problematic connections are filled with silicone compound.

Application of corrugation

Corrugated stainless steel chimney is used in devices with high operating temperatures. They can be installed in private homes to remove combustion products from kitchen gas water heaters. In them, the outlet gases are heated to 300°C. Steel pipes are used for chimneys of heating units, in which temperatures up to 900°C are reached.

This material can be used for repairing old chimneys, as well as as adapters when installing smooth steel pipes. Stainless steel corrugation is also used as a connection for household appliances in the house. In this case, it is necessary to install fittings made of brass and stainless steel with linings of dielectric material to avoid sparks. In stores you can find connecting devices covered with polyethylene and painted yellow. The internal diameter of the corrugation does not exceed 20 mm.

Advantages and disadvantages of corrugation

Advantages of flexible chimneys made of stainless steel and aluminum:

- used for heating systems and removal of waste combustion products of various levels of complexity;

- increased strength of the entire structure;

- easy installation;

- resistance to sudden temperature changes;

- the material used is not subject to destruction due to corrosion;

- the round shape of the pipe section does not allow combustion products to accumulate on the inner surface of the chimney, which simplifies maintenance;

- atmospheric phenomena and aggressive environments do not destroy the material;

- tightness of connections and transitions.

The disadvantage of corrugated chimneys is the use of insulation. At low temperatures, moisture forms on the inner surface. Insulation is carried out when installing the chimney along the wall and partially on the street, as well as when using thin single-layer modules.

Pipe cost

When choosing a particular corrugated chimney made of stainless steel or aluminum, the consumer should focus on the diameter and length of the pipe. When purchasing foreign components, the buyer will have to shell out a large sum. The price starts from 105 rubles and increases, depending on the length and diameter of the flexible pipe, to 1400 rubles per meter.

Selection in store

What to consider during work?

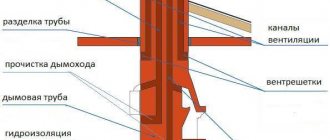

Finishing smoke exhaust ducts involves creating a flashing or apron from rectangular sheets of metal. The width of the products is 40 cm, and the length corresponds to the size of the pipe. The plates need to be bent, focusing on the angle of movement of the smoke. To calculate the length of the finish, it is worth considering:

- chimney size;

- the angle that the slope has;

- type of roofing.

Tiled roofs or structures covered with corrugated sheeting are connected using the standing seam technique. Pitched roof structures require a special “side” made of wooden beams, which prevents exposure to weather factors.

Rules for installing chimney systems made of corrugated pipes

When installing corrugated stainless steel pipes for chimneys, safety requirements must be observed. Manufacturers recommend following the following rules when installing:

- Installation of corrugated pipes begins with the selection of the internal diameter of the product; it must correspond to the size of the outlet hose from the heating boiler.

- The structural size of the chimney itself is calculated based on the rated power of the heating unit. The average value is considered to be 19 kW; a corrugation with a diameter of up to 110 mm is installed for it; with increasing power, the size reaches values of up to 130 mm.

- To ensure high efficiency of the system, when exiting the boiler, the vertical pipe should not be less than 1 m long. To achieve tightness, the upper part of the chimney is inserted into the lower part and secured with clamps. Sometimes metal tape is used for sealing.

- In new houses, for the sustainable removal of waste combustion products, a chimney should be installed on a horizontal section no more than 3 m long, and in old premises no more than 6 m long.

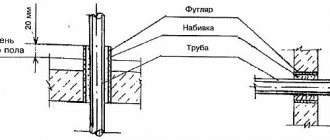

- In places where the corrugated pipe system passes through walls and ceilings, special adapters and materials that are not subject to ignition at high temperatures are made. The pipes are wrapped with mineral wool.

- It is prohibited to lay a corrugated chimney in residential premises, entrances, loggias and balconies. It is also not recommended to install pipes through walls with access to the street.

- When installing a flexible chimney from geysers, manufacturers advise installing the outlet with a right angle bend. Some designs use a condensate collection device.

Sometimes corrugation is used to modernize an old brick chimney that has failed over time. Also, when the axis of the riser of the exhaust gas removal system is displaced, steel pipes are installed.

Features of flexible chimneys

The flexible chimney is a round hollow profile. To make such a pipe, sheet metal rolled into a spiral is joined using a locking seam.

The structure of the product differs in that steel wire is inserted between the metal layers, thanks to which the pipes acquire properties such as flexibility and strength. They have different cross-sectional sizes, but the most common are pipes with a diameter of 110 - 300 mm.

Each part of the pipe is 65 centimeters long, but it can easily be extended to 3 meters. Flexibility allows you to install a chimney with various bends and many turns. The wall thickness varies from 0.25 to 1 mm.

A corrugated pipe can be used for arranging part of a chimney (passage through a wall or ceiling, as well as when reconstructing a chimney made of indirect brick construction) or for installing the entire chimney duct.

Note! It is recommended to install a corrugated chimney to a heating system operating on different fuels with flue gases of high or low temperature.

Reliability is ensured due to the following properties:

- cylindrical spiral shape with interlocking connecting seam;

- a reinforcing layer in the form of wire, making the body more resistant to mechanical damage, but maintaining the flexibility and elasticity of the product.

According to the type of strength, light, heavy and super-heavy pipes are distinguished.

We recommend that you read: Which fittings are best suited for drip irrigation