Any monolithic building, brick wall, metal structure collapses over time. Chimneys also become unusable. Without timely replacement of damaged parts of the smoke exhaust duct, a fire or smoke may occur in the premises. Chimney repairs must be carried out regularly. The stages of channel restoration depend on the degree of wear and the material of the structure.

Metal chimney repair

Causes and consequences of chimney destruction

The causes of chimney destruction can be artificial or natural. The first group includes poor-quality masonry (failure to comply with construction plans and rules), cheap materials, and violation of operating rules.

Because of this, for example, condensation can form in the chimney duct, which will accumulate, freeze in winter and destroy the pipes. The destruction of the masonry will worsen the draft and render the fireplace or stove completely unusable.

Natural causes of destruction include physical aging of the structure or a natural disaster, which a person cannot influence in any way.

Why do chimneys collapse?

During operation, even without errors, a constructed chimney is subjected to intense loads. The service life of a brick pipe is 20-30 years. For a steel chimney, the operating warranty is less and is 10-15 years. The given figures approximately show the service life without major repairs at an average load.

In real conditions, the integrity of the smoke exhaust duct depends on many factors, both natural and man-made. Natural causes of pipe destruction are aging and wear and tear of the material under the influence of external factors. Subject to the rules for chimney construction, natural factors act gently and over time. Errors, negligence or ignorance lead to rapid destruction of the chimney.

The following factors contribute to the destruction of chimneys:

- Errors at the design stage, when the constructed smoke exhaust duct initially works with the formation of a large amount of condensate and ash sediment on the inner surface.

- Stove-maker mistakes when laying a smoke exhaust duct or stove.

- Formation of chemically aggressive condensate on the inner surface of the channel. Occurs when construction technology is violated or when the stove is rarely used.

- Destruction of brickwork. The reason is poor-quality material, freezing of condensate in the pipe solution, frequent temperature changes with rare use of the furnace.

- Burnout of the steel inner pipe of a sandwich chimney. Occurs when low-quality steel is used in the manufacture of a pipe or when a chimney is installed on a boiler that does not comply with the recommendations of the manufacturer of this sandwich pipe.

- Violation of the chimney seal at the joints (for a steel pipe). Air leakage from the outside and burning of the brickwork or cracking of the bricks.

Note! The first sign of a problem with the chimney is a decrease in draft in the stove. This is expressed in the throwing of smoke into the room when the oven door is opened.

In what cases is repair necessary?

Repairs cannot be delayed if:

- there is obvious destruction of the outer part of the structure;

- numerous cracks in the masonry, cracks in the foundation;

- poor traction;

- blockage of the oven chamber with mortar or brick;

- severe blockage of the channel.

Repairs are required immediately so as not to worsen the situation.

Pipe condition assessment

The condition of the pipe is assessed after the inspection, when all possible defects are identified, the dimensions of the chimney are specified, if there are no drawings, the performance of the gas boiler, fireplace, etc. is checked.

In difficult cases, it is worth resorting to the help of experts, and in order to prevent this from happening, you should regularly conduct a visual examination yourself.

More details about assessment and diagnostics are written in the set of rules for construction and design SP 13-101-99.

Acts for Mosoblgaz

To officially register a gas boiler with the gas service, you must not only have a maintenance contract, but also a chimney certificate, and if you have a non-volatile boiler, then a grounding certificate. This package of documents is mandatory, as they fully confirm the safe operation of gas equipment in the house.

In our company you can order the entire package of documents for the gas service, which is needed either when re-registering the owner, or when putting a gas boiler back into operation.

Sample documents

The main malfunctions of brick chimneys and how to eliminate them

There are 4 types of main chimney faults:

- contamination of the channel with soot or other foreign objects;

- formation of condensation in the masonry;

- visible cracks on the surface of the pipe;

- blowing into the chimney channel.

Clogging

Clogging is likely due to the accumulation of soot, collapse of brick or plaster, or foreign objects entering the shaft. Due to the blockage, traction decreases. Strictly speaking, there is no need for repairs here. To correct the situation, a heavy metal weight is used to break through the resulting plug. A specialist (or you yourself), being on the roof, ties a weight to a rope and lets it into the shaft.

If this method does not work, you will have to disassemble the stove until the “thief” who “stole” your draft is found! If the cause of the blockage is soot, then, rolling up your sleeves, you need to clean it: with a brush on a long stick, with chemicals like “Chimney Sweep” or by burning potato peelings the old-fashioned way.

Condensate

The appearance of a burning smell in a heated room or tarry stains and excess moisture on the walls of the shaft indicates that condensation has appeared in the structure.

Its culprit is cracks in the masonry or freezing due to poor insulation of the chimney.

Insulation is usually necessary for buildings with a cold attic. In such cases, the pipe section is thermally insulated with basalt wool or other suitable material.

Cracks

Cracks, as I already said, are formed due to condensation. But the most common reasons for their appearance are:

- Significant temperature difference. Therefore, when the stove has not been heated for a long time, you need to heat it little by little with a gradual increase in the volume of firewood.

- Operating time. Make repairs on time!

To repair a chimney from small cracks use:

- clay – sold packaged in bags weighing from 1 kg;

- heat-resistant sealant;

- fireproof cement mortar.

To repair areas with large cracks, it will likely make more sense to replace the problem area entirely.

Blowing out

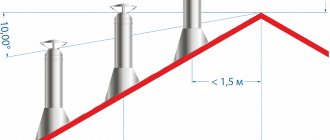

Backdraft, also known as blowing, occurs due to two reasons:

- Failure of the furnace head. Replacing the head solves the problem.

- Insufficient height of the chimney on the roof. In this case, you need to add a few rows and the traction will return.

Internal repair of chimneys and ventilation ducts

If during the inspection no obvious defects are found or minor ones are found, then it is best to carry out the so-called “preventive repair”. There are two well-proven methods for such repairs. These methods are intended to carry out internal repairs of chimneys and ventilation ducts:

Ventilation duct sleeve

The most common one now is the “liner” of the chimney duct.

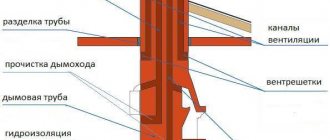

It is produced by selecting a stainless steel pipe (it may not necessarily be stainless steel, it may also be a ceramic pipe, if we are talking exclusively about a ventilation duct and not a chimney pipe for a solid fuel stove) of the required diameter and installing it inside the existing smoke or ventilation brick smoke duct . The chimney is thoroughly cleaned beforehand.

Lining of ventilation ducts

A method that appeared relatively recently and has not yet become widespread is lining or lining with special non-flammable mixtures, or, more simply, internal plaster. There are two types of mixtures for sale for this work - the Russian “Masan”, made on the basis of perlite, and the Finnish “Mordax”, based on granite chips. These mixtures have good adhesion and fit well on any brick surface.

First, the chimney duct is thoroughly cleaned. Then, the walls are moistened. And then the lining is carried out using a special brush that sprays the mixture along the walls. After such treatment, the inner surface of the chimney becomes smooth, without cracks or damage, and most importantly, it does not lead to a narrowing of the chimney.

This treatment makes repairing stove chimneys and fireplace chimney repairs much easier. Of course, not everyone has such equipment and therefore it is better to entrust this work to professionals who have the necessary tools and the skills to use them.

Basic malfunctions of metal chimneys and methods for their repair

The main malfunctions of a metal chimney include:

- Wall corrosion. Repair will not help - the problem area needs to be replaced.

- Top element broken. In such a situation, you should quickly replace the head to prevent back draft in the room.

- Channel deformation. If possible, align the course of the chimney pipes and make additional fastenings, strengthening problem areas.

Do not forget to clean the shaft, because soot negatively affects the operation of the system.

Prices for repairs and cleaning of ventilation

| Price per one. (rub) | ||

| CLEANING CHANNELS | ||

| Cleaning the internal surface of the flue and ventilation duct. | m2 | from 150 |

| Chimney cleaning | m2 | from 200 |

| Clearing a blockage in a channel | 1 channel | 3000 |

| Opening and sealing the technological hole in the channel to remove the blockage | 1 hole | 1000 |

| Cleaning of industrial ventilation systems, restaurant and cafe ventilation systems | 1 system | from 12000 |

| Disinfection of the ventilation system | 1 system | from 9000 |

| REPAIR OF CHIMNEYS AND VENTILATION CHANNELS (FIMING) | ||

| Lining with cement-sand composition | m2 | from 2500 |

| Lining with fire-resistant composition "Masan" | m2 | from 6000 |

| REPAIR OF CHIMNEYS AND VENTILATION CHANNELS WITH POLYMER LINERS “FuranFlex” | ||

| 7.1. Repair using FuranFlex technology | p.m. | from 7000 |

| REPAIR OF FORCED VENTILATION SYSTEM | 1 system | negotiable |

The final cost of design and installation work, as well as the cost of technical maintenance of the ventilation system. systems is determined by our specialists after inspecting the facility.

Prices shown are for informational purposes only, are not exhaustive and may differ from actual prices. Please check with our managers for the exact cost of services.

This is not a public offer.

If you want to order repairs or cleaning of the ventilation system, please contact us by phone or by mail [email protected]

Types of industrial chimney repairs

For industrial chimneys, the operating requirements are more stringent. Regular inspection of the chimney trunk and auxiliary systems (smoke removal systems and others) is carried out by company employees authorized for supervision. Based on the inspection, an act, a technical condition report and a map of defects are drawn up. After the inspection, a decision is made on repairs, which can be of two types:

- Current. It is usually carried out on its own, at least according to established standards. Repairs of this type do not involve heavy and complex work.

- Capital. Conducted by special companies.

Capital work includes: replacement, extension or strengthening of the trunk; foundation repair, replacement of worn-out elements.

Examination of chimney pipes

An examination of industrial pipes is appointed due to conservation, reconstruction, liquidation of the pipe or the enterprise itself, etc. With the help of an examination, you can establish its actual technical condition, draw up a repair plan and set a date for the next inspection.

According to safety rules for the operation of ventilation and industrial pipes PB 03-445-02, examination is required if:

- vertical cracks more than 10 mm thick;

- horizontal cracks of the wound 1/6 of the circumference of the pipe itself;

- destruction of masonry up to 2 cm deep;

- destruction of the solution up to 4 cm;

- peeling of the top finishing layer with an area of 1 m2.

When is repair required?

Before starting repair work on the smoke exhaust channel, you need to understand what actions need to be taken: minor replacement of some elements and complete dismantling of the structure.

Chimney repair in a multi-storey building (Photo: Instagram / sia_skyworker_riga)

Small

It is carried out in several if:

- at the joints of individual elements, the metal pipeline allows smoke to pass through;

- decorative finishes fell off from the brickwork;

- There is curvature of the metal pipeline due to improper installation or under the influence of high temperatures.

Simple repair work can be performed by anyone who knows how to use hand or power tools.

Capital

A major overhaul of the smoke duct is needed when the following situations occur:

- destruction of a pipe above the roof;

- the appearance of cracks in metal pipes or brickwork;

- worsening traction;

- penetration of smoke into premises.

Repair work must not begin until a complete inspection of the internal and external surfaces of the smoke duct has been carried out. This procedure includes photographing, studying the initial design diagram, and identifying defects.

Cracks in brickwork (Photo: Instagram / cleaning_surgut186)

How to repair a brick chimney

In case of local destruction in the upper street part of the chimney, it is dismantled and re-laid. During repairs, special solutions and high-quality bricks are used.

When the chimney shaft is damaged along its entire length, a metal, ceramic or polymer sleeve is inserted inside.

When the mortar cracks, the chimney channel is lined from the inside.

Restoration of masonry

Before restoring the masonry, it must be disassembled. Start at the top, gradually moving down. Having reached the desired place where the cracks end, a new trunk is erected from refractory bricks. It is very important that the inner surface after repair is smooth and does not interfere with smoke exhaust.

Installing the sleeve

If it is not possible to disassemble the channel, then it is restored using a sleeve that is inserted into the chimney. In such repairs, along with the installation itself, the preparatory stage is also extremely important.

Preparing for work

Before work on installing the liner begins, the shaft is cleared of soot, debris and other objects. The cross-sectional area of the sleeve is made smaller than the internal area of the channel in order to place thermal insulation in the resulting gap.

Installation

Initially, the masonry is partially dismantled. The sleeve that is going to be installed must correspond in height and cross-section to the shaft of the existing chimney. It should also have a cleaning door.

The sleeve is carefully lowered down in sections. At the junction of the parts, the masonry is dismantled to open access to the elements and reliably connect them together. This is how the whole structure is assembled.

After installation and thermal insulation of the sleeves, install an umbrella on the head of the pipe and seal the disassembled areas.

Lining of smoke channels

Lining a chimney is a quick and less labor-intensive process, unlike other methods. It consists of spraying a refractory solution with the addition of marble chips or perlite.

Apply, as a rule, in 3 layers with breaks, during which the previous layer must dry completely. The result is a smooth coating without roughness, which does not interfere with the free passage of combustion products.

Repair video

Now it’s worth taking a break and watching a few useful videos on the topic.

Minor repairs

To prevent the destruction of the chimney, regular monitoring of its condition is necessary. Minor repairs carried out in a timely manner can prevent the destruction of the smoke exhaust duct and save the owner from significant expenses. Visual inspection of the integrity of the outer side of the pipe is not difficult. To inspect the condition of the internal surface of the chimney, special equipment is used - industrial rigid or flexible endoscopes.

Note! The destruction of the brick pipe is clearly visible from the outside. To maintain it in working condition, annual minor repairs are required.

Minor repair work on a steel pipe is necessary when the tightness of the joints is broken, but the steel is in good condition. To restore the tightness of the pipe, a fireproof sealant is used, which is marked with resistance to temperatures of 800 degrees and above. When repairing, it is applied to the junction of the sandwich chimney segments and allowed to dry.

We recommend that you read: How to build a columnar foundation from asbestos pipes with your own hands

Minor repairs to the brickwork of a traditional chimney consist of restoring the mortar between the bricks, sealing small cracks, and replacing individual bricks. To do this, it is necessary to clean out the remains of the destroyed cement to a depth of 2 cm so that the adhesion of the new mixture is sufficient. For minor pipe repairs, use a solution consisting of Portland cement, sand and lime in a ratio of 1:7:2. An alternative to this solution may be clay and sand or fire-resistant masonry sealant.

Maintenance of brick chimneys

In order for the brick to serve for 50 years or more, it is necessary to carry out timely repairs of the chimney, as well as its maintenance. Such maintenance means cleaning the internal cavity of the channel, timely sealing of small cracks, potholes and cavities, maintaining the lining layer in proper condition, etc.

Dismantling

Chimney dismantling can be partial or complete. The brickwork is dismantled in order from top to bottom. The volume of bricks to be dismantled must be calculated in advance in order to plan the number of vehicles for its removal. The surrounding area is cleared of machinery and equipment to prevent damage to them.

With the sequential dismantling method, the bricks are dismantled and thrown into the chimney shaft. Downstairs, the bricks are received and stored in the boiler room, after which they are taken out for disposal by prepared transport.

To avoid injury and property damage, it is important to assess the condition of the chimney in advance and develop a plan for dismantling the chimney. In some cases, instead of serial disassembly, disassembly in parts is used. This method requires a lot of mechanization and a truck crane.

Reduced cravings

Reduced draft is the most common case that leads to pipe repair or reconstruction. As a result of operation, soot accumulates in the chimney or construction debris gets there, which impairs draft. To break through the clog, use clearing weights. If this method does not bring the desired result, then you have to completely or partially disassemble the chimney.

Today, in order to avoid troubles with soot, fire-retardant compositions are used, which are added to the stove along with the fuel.

Masonry

In the design and laying of chimneys, there are several rules that must be followed:

- The outer walls must be at least half a brick thick (125 mm).

- The size of the channel is directly affected by the heat transfer value.

- When installing exhaust ventilation in one pipe with a smoke duct, they are combined.

- The material consumption is overestimated in order to maintain ligation of the sutures.

Gas boiler chimney repair

Repair of gas chimneys has a number of features due to the fact that the temperatures of combustion products are not as high as in stoves operating on solid fuel. Recently, the most progressive method is the installation of polymer liners. First, a polymer shell of the liner is installed inside the chimney, which is pumped first with compressed air and then with hot steam. Under the influence of pressure and temperature, the liner takes the shape of the pipe channel, tightly fitting all irregularities.

As the steam cools, the shell hardens. Repairs of chimneys and ventilation ducts made in this way lead to the formation of an absolutely smooth surface that does not retain gas combustion products in the form of small soot particles. Currently, similar technologies are emerging for solid fuel stoves with elevated exhaust gas temperatures.

How to repair a reinforced concrete chimney

Reinforced concrete chimneys are usually repaired in the following situations:

- lining repair (protection of fire-resistant coating);

- anti-corrosion protection on the outside;

- replacement of bandage rings;

- strengthening of individual sections of the structure, etc.

Depending on the type of repair (simple or complex), the optimal method for eliminating defects is selected. Simple work includes repairing chips and cracks in concrete and protecting corroded reinforcement. Complex ones include restoration of pipe geometry with various repair compounds, protection of surfaces with special compounds from moisture and other aggressive environmental influences.

The protective material is applied using special equipment (spray gun, shotcrete machine, etc.)