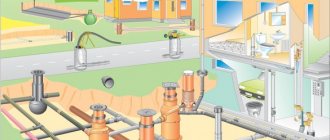

Drainage of rainwater away from the house is an important component that must be taken into account when planning and carrying out construction work. To do this, rainwater inlets for storm drainage are installed under the drainpipes, discharging water outside the site into drains or containers for further use for irrigation and other household needs.

If a rainwater drainage system was not installed during the construction of a house or cottage and the need arose for its construction, such a structure is quite easy to make with your own hands without the help of hired workers. To do this, you should know the main types of storm sewer systems, their materials of manufacture and design, as well as installation rules when carrying out installation work yourself.

Rice. 1 Storm drains - examples of use on the site

What is storm drainage and its components

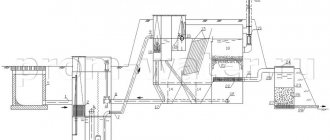

Storm sewers have a fairly simple design - water entering through its grate is filtered and flows down inclined pipes into a sewer well.

The main components of the stormwater sewer system are the following components:

- Lattice. Water enters the system through the element and serves to ensure safe passage and passage, screening out large objects and debris that clog the channel. Made from galvanized or stainless steel, cast iron, high-strength plastic.

- Sand trap. The main purpose of the sand filter is to collect sand and other heavy small debris that leads to clogging of the underground pipeline channel. Structurally, it is made in the form of a basket with a handle, onto the bottom of which heavy sand settles, and water enters the channel through a hole located above; according to the principle of operation, it resembles a siphon under a kitchen sink. The element is placed under the cover and does not carry a large load, so it is most often made of plastic; during operation it must be regularly cleaned of sand. In other similar models, garbage settles in a rectangular tray without a handle, which is also easily accessible after removing the top cover.

- Storm water inlet. The basis of the entire structure, the grate rests on it and a filter is installed inside, accumulates the collected water and directs it through the outlet holes into the pipeline channel. The element is made in the form of a square or cylindrical container; the materials used are high-strength polymers, cast iron, and concrete.

- Pipes. Water is drained from the storm drain body using smooth PVC sewer pipes that are resistant to low temperatures. Pipes made of asbestos cement, cast iron, and ceramics are used less frequently. The cross-section of the pipelines corresponds to the outlet openings in the rainwater inlet body. In popular inexpensive plastic models, the outlet usually has a size of 110 mm, but in the construction of, for example, parking lots, wells with a pipe outlet of 160, 200 mm can be used.

- Inspection manifolds. As in any sewer line, inspection taps are needed to monitor the performance and clear the pipeline of blockages.

Rice. 2 Storm water inlet device for storm drainage

What it is?

This is a special container into which liquid flows from pipes installed on the facade of the house. This tank must be made of durable material as it faces soil pressure, mechanical loads and water pressure. Storm sewer inlets should not be subject to corrosion.

A rainwater well with a grate can be round, square, oval, or rectangular. This fact does not affect the performance characteristics in any way. The choice of form may be influenced by the design features and style.

Purpose, classification and design

Water intakes used for drainage, when placed in the area of an individual residential building, perform the following functions:

- They protect the walls and foundation of the house from getting wet by water flowing from the roof.

- They protect basements and basements in cases where spring flooding may occur.

- They allow you to save water by collecting it in drainage wells for further use for household purposes.

- They protect landscape elements and the vegetable garden (paths, flower beds, beds) in the garden area from erosion by water, and help prevent puddles from forming on the site.

- When the runoff falls from the pipes, it destroys the material of the blind area; this can be avoided by protecting it from destruction while simultaneously draining the water by installing storm water inlets.

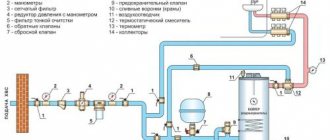

Rice. 3 Storm water inlets for the drainage system - installation diagram

The storm drainage system works as follows:

Through a high-strength decorative grille, which fulfills the main condition necessary for aesthetics - an attractive appearance, water enters the pre-cleaning element in the form of a basket for settling sand. Heavy dirt and sand remain at the bottom of the rainwater basket, and the liquid enters the channels and gutters through the holes located above in the housing that houses the filter device. The further path of the water lies through an underground pipeline laid with a slight slope; it enters a storage well, where it is collected for further use or disposal.

If there are abandoned silted wells or boreholes on the site, collection can be carried out in their shafts - this will save money on the installation of new drainage tanks.

The main differences between all systems are the design of the rainwater inlet, which has the following body designs:

- Rectangular. The rectangular design can be found on the streets of any city - such heavy cast iron gratings of standard size are located along city highways. Such a drainage system often has a large length and is assembled into a main line of several buildings, installed along certain sections of highways, streets, and pedestrian crossings. It is used in cases where the collected water flow has a large distribution area; sometimes devices are installed under sewer pipes to collect water from several points into one channel.

- Square. These devices are used when the area from which wastewater needs to be drained is small; they are usually located directly under the drainpipes of houses. Square models are widely used in individual households; due to the low loads on the lattice, their bodies are produced in a polymer version.

- With frame. Similar types are used in areas of high loads on surface lattice elements; they are mainly located on roads. When installed, their grid rests on a strong metal frame, which prevents deformation and destruction of the well, and its immersion under the road surface.

Rice. 4 Designs of storm water inlets with different grid shapes

Which one is better and why?

The best pipe is a two-layer corrugated or fiberglass pipe. Durable (corrugation is also plastic). If you have an earthquake-prone area or there is a danger of landslides, you will have to lay a steel, cast iron, or fiberglass pipeline. But if you need to lay a pipeline to the collector at a depth of less than 2 meters and there are no particular difficulties in geology and load on the soil surface, then it is better to choose inexpensive HDPE or PVC pipes and not bother. They will last for 50 years. And maybe more.

Calculation of pipeline diameter

To calculate the diameter, you first need to calculate the amount of liquid drained using the formula:

Q is the amount of water that the sewer system should remove when it rains;

q20 – intensity of precipitation for 20 minutes. This information is available from your local surveyor's office;

F – area of the plot or house. The area of the house is equal to the area of the horizontal projection of the house (taking into account the roof overhang). There is no need to calculate the area of the roof slopes;

φ – correction factor depending on the type of surface of the protected area. It depends inversely on the ability of the surface to absorb water. For asphalt – 0.95; for concrete – 0.85, for roofing – 1.0; for crushed stone – 0.4; for soil - 0.75, sand or gravel - 0.4.

The diameter is determined according to the Lukin tables. Knowing the water flow rate in l/s, you can determine the required pipe diameter. The ratio h/D (the height of the pipe filled with liquid to the internal diameter of the pipe) should be taken equal to 1. Tables and counters based on them are easily available on the Internet.

Approximate price (table)

In a standard urban area, pipes with an outer diameter of 110-160 mm are most often used. Prices for products of these diameters are shown in the table.

| Material | Diameter, mm, wall thickness, mm | Price 1 m |

| Steel | 108×4 | 550 |

| Steel | 159×4 | 810 |

| HDPE | 110×10 | 160 |

| HDPE | 160×14,6 | 330 |

| PVC | 110/4 | 190 |

| PVC | 160\4 | 320 |

| Double-layer corrugation | 110 | 130 |

| Double-layer corrugation | 160 | 200 |

Fiberglass pipes are produced with a diameter of 300 mm or more - they are not suitable for a private home.

Storm water inlets for storm drainage - types

All types of meltwater and sediment disposal systems are divided according to the materials used to manufacture their main element - a storm inlet, which is a round or rectangular body with outlets for gutters or pipe connections. The area of application of waste systems, their cost and installation methods depend on the material used to make the grille and body.

All rainwater gratings, depending on the load they can withstand, are marked with the following letter symbols:

- A - hold a weight of about 1500 kg, suitable for installing drainage systems in individual areas.

- B - the maximum load the device can withstand is no more than 12,500 kg, the grille carries the weight of vehicles and can be placed outside and inside garages.

- C - element supports weight up to 25,000 kg, installed on highways with heavy traffic.

- F - the product holds a weight of up to 90,000 kg, is located along the route of heavy special equipment, at airports and ship repair docks.

Rice. 5 Features of the design of rainwater inlets for storm drainage systems made of concrete

Drainage well: plastic, concrete

Most often, wells are made of two types of materials: concrete and plastic. You can order any for installation. Let's look at the advantages and disadvantages of each.

Features of drainage wells made of concrete rings

The concrete storm drainage well is quite strong. It consists of a concrete slab and a ring. This material is not expensive, but it will require lifting equipment. In addition, concrete is a fairly durable material, but it is destroyed by water over time. The prefabricated structure is quite difficult to install; it is especially difficult to drill holes in the pipeline. In addition, it is necessary to ensure high-quality waterproofing. However, by calling the experts, you can install a concrete structure without difficulty.

Drainage well made of concrete rings Source strojdvor.ru

Concrete structures

Traditional concrete catch basins are widely used in road construction; they can withstand high loads and are made from reinforced concrete or fiber-reinforced concrete. There are several types of products of this type, depending on the scope of application - light, heavy or long-haul.

Light types are a small model (no more than 400x400 mm), cubic in shape with a wall thickness of about 20 mm; for a greater depth of the outlet pipeline, they can be installed in a vertical position on top of each other. The products have low cost, long service life, and are resistant to temperature fluctuations over a wide range.

Characteristics and types

The flexible hose for connecting plumbing is a hose of different lengths made of non-toxic synthetic rubber. Thanks to the elasticity and softness of the material, it easily takes the desired position and allows installation in hard-to-reach places. To protect the flexible hose, there is an upper reinforcing layer in the form of a braid, which is made from the following materials:

- Aluminum. Such models can withstand no more than +80 °C and retain functionality for 3 years. At high humidity, aluminum braiding is prone to rust.

- Of stainless steel. Thanks to this reinforcing layer, the service life of the flexible water line is at least 10 years, and the maximum temperature of the transported medium is +95 °C.

- Nylon. This braid is used for the manufacture of reinforced models that can withstand temperatures up to +110 °C and are designed for intensive use for 15 years.

The fasteners used are nut-nut and nut-fitting pairs, which are made of brass or stainless steel. Devices with different permissible temperatures differ in the color of the braid. Blue ones are used to connect to a pipeline with cold water, and red ones for hot water.

When choosing a water line, you need to pay attention to its elasticity, reliability of fasteners and purpose. It is also mandatory to have a certificate that prevents the rubber from releasing toxic components during operation.

Cast iron storm water inlets

The types and parameters of rectangular rainwater inlets made of cast iron are regulated by GOST 3634-99, which divides all products into the following categories:

- D - small storm water inlets weighing no more than 30 kg. and a rated load of up to 15 kilonewtons (kN), which in kilograms is equal to 1500 kg.

- DB1, DB2 are large storm water inlets with a total weight of about 50 kg. and 80 kg. Accordingly, they are installed on city highways and vehicle parking lots, holding a load of up to 12,500 kg.

- DM1, DM2 - mainline type models with a rated load of up to 25,000 kg, have a mass of 60 and 100 kg. Accordingly, they are used on highways with heavy traffic.

- DS1, DS2 - super-heavy modifications, designed to hold a nominal weight of 40,000 kg, product weight of 80 and 130 kg. Accordingly, they are used in areas of high loads (airfields, ship docks).

In addition to the rectangular products specified in the standard, the industry produces round varieties marked DK weighing about 100 kg, withstanding a rated load of about 15,000 kg.

GOST 3634-99 does not stipulate the overall dimensions of the gratings, focusing on the length and width of the grooves depending on their location in relation to the traffic flow, for example, the standard dimensions of the DB2 grating are 400x810 mm.

Rice. 7 Cast iron drainage systems - examples of location

Cast iron structures have the following features:

- High drainage capacity due to the presence of wide cross-section grooves, ensuring the drainage of significant volumes of water.

- Durability to withstand significant loads of heavy vehicles.

- Long period of technical operation, which does not require frequent and complex maintenance of the drainage unit.

- High resistance to aqueous environments when the cast iron surface is coated with special corrosion-resistant components

- Environmental cleanliness and safety for people.

- Cost acceptable to the consumer.

- The large mass of the product makes its installation difficult, requiring the installation of a high-strength reinforced concrete well.

- Gratings and frames made from cheap, untreated cast iron are highly susceptible to corrosion.

- Due to widespread cases of theft of ferrous and non-ferrous metals, many devices are equipped with special fasteners consisting of elements that lock the grille.

In individual areas, such structures are rarely used due to their large dimensions and weight; for private areas, DB1 products with overall dimensions of 695x470x120 mm are most suitable.

Rice. 8 Plastic storm water inlets - modifications

Design and principle of operation

It must be taken into account that the structure of absolutely any storm sewer system contains such elements. How:

- gutters and pipes transporting liquid;

- receivers for sending liquid from the base where it has accumulated;

- drainage wells and drains - water is sent into them;

- filter barriers and grilles that prevent various types of debris from entering the system.

Using this system, it will be possible to water the plantings with melt water. In addition, with its use it will be possible to increase the service life of paths and sidewalks. Constructions located on the site will also not be subject to the harmful effects of increased moisture.

A traditional modern rainwater receiver consists of the following necessary elements.

Lattice. This component is designed to cover the structure from above. The grille plays the role of not only a decorative addition, but also protects people from various types of injuries. Today, similar components made from cast iron or plastic are often used. They are good because they additionally act as primary filter barriers (they do not allow large debris to enter the sewer system).

- Storm water inlet. The said structure usually has a round or square structure. It is necessary to direct the liquid directly into the waste system.

- Sand filter (sand traps). This is a component that is not available in all structures. It is needed so that pieces of earth, sandy inclusions and other similar debris do not penetrate into the sewer system along with the liquid. Said filter part is located slightly lower than the tray associated with the receiver. For this reason, any debris descends to its bottom, and the liquid rises up to the exit mark from the receiver itself.

Not every user knows that the garbage filter in such a system needs to be cleaned regularly. Otherwise, over time, a very unpleasant characteristic odor may form, which will be released as the liquid evaporates from the receiver tray.

Storm sewers are often confused with a drainage system. Its distinctive feature from drainage lies in the fact that the latter is mounted below the level of the foundation. As for storm drainage, it usually has a more modest depth. So, along the perimeter of the roof of the house, a structure of gutters, gutters and funnels is installed. Receivers are placed under all the pipes here. They are connected to a pipe structure through which liquid is removed from the area.

Along the paths located on the site, as well as before entering the garage, a special system of trays covered with gratings is installed. This structure is connected using single pipes and a single drainage system from the territory. A system of surface-type trays is usually very modest, but storm sewers contain inspection wells or special sand traps that catch large debris.

Plastic storm water inlets

Modern plastic storm water inlets have no competitors when used in households; they are made from frost-resistant polymers (special heat-resistant polypropylene) and have the following features:

- The plastic storm water inlet is lightweight and easy to install and assemble even by an unprepared homeowner. The device can be easily connected to a pipeline of any diameter thanks to the built-in cylindrical partitions.

- Standard modifications of an equilateral cubic storm inlet have edge lengths of 300, 400 and 500 mm.

- The manufacturing material is resistant to temperature changes in the range from -40 to +90 C., withstands the corrosive effects of most aggressive chemicals, and has a long service life.

- The device is easy to maintain and provides high-quality cleaning, thanks to the smooth, hard plastic surface with low hydraulic resistance and low absorbency.

- The design is made in such a way that it allows you to install rainwater inlets on top of each other, and to install pipes of any standard section at different levels.

- Depending on the expected load, gratings made of cast iron, galvanized steel, stainless steel, and plastic are installed in plastic boxes.

Rice. 9 Plastic drainage systems - design and correct installation diagram

A proper plastic storm inlet, unlike other types, has a more complex design, the main elements of which are:

- Lattice. Depending on the chosen model, it has a round or square shape; wastewater flows through its slots into the drainage system.

- Garbage bin. Prevents heavy debris and sand particles that collect on its bottom surface from entering the pipeline channel.

- Protective siphon. The rubber element prevents the spread of contaminated air from the baskets.

- Water seal. The partition is placed at the entrance to the pipeline and stops the movement of wastewater in the opposite direction.

- Protective cover. The element closes the rainwater inlet in winter, preventing it from clogging with snow and ice from frozen water.

- Extension. Allows you to increase the height of the structure and, accordingly, the depth of its immersion into the ground together with the pipeline system; it is used as a means of protecting pipes from freezing in winter.

- Luke. Installed instead of a grille if the device is used as an inspection or maintenance hatch.

Rice. 10 Stormwater drainage system from trays - layout diagram

What does it consist of?

If you compare storm drains, you will notice that they differ in weight, size and some other features. According to the standard, the depth of the device is 400 mm. As a rule, they are light in weight, except when cast iron is used as the material.

Please note! Reservoirs can be sold as a complete set or individual elements.

Consists of the following parts:

- The container itself.

- A basket that is installed inside the water intake.

- Partition or siphon.

- External grille.

In different types, these elements can be made of different materials, which affects the final quality of the product. As for the grille, it is necessary to choose a high-quality and durable one, since it encounters mechanical stress when pedestrians walk and even when hit by a car.

How to choose a rain inlet for storm drainage of a private house

In everyday life, storm drains made of concrete or cast iron are used quite rarely due to the complexity of installation and heavy weight; their use is ineffective due to the lack of high loads. Cast iron gratings of class D1, D2 are sometimes located in places where cars pass, at the entrance to the garage or on the access roads to the house.

The vast majority of houses are installed under drainpipes with plastic structures that are distinguished by their functionality, high technical characteristics and ease of installation. In addition, the price of such devices is quite affordable and affordable for any homeowner.

A small plastic model installed under the drainpipes of a house has an aesthetic appearance and modern design, and does an excellent job of filtering and draining stormwater into the pipeline and then into the storage well. In addition, the device is easy to maintain - periodic cleaning of the sand collection basket is done quite rarely and takes a minimum of time.

To cope with surface runoff throughout the entire site, drainage lines are used in everyday life, which are prefabricated trays or semicircular guides cast from concrete, located at the same level with the ground cover and covered with gratings. Such a system allows water to be drained from laid paving slabs or other covering over a large area, transporting it along underground concrete or plastic guides outside the site or into drainage tanks.

Rice. 11 Tool for installing storm drains

State standards

The technical characteristics of storm water inlets are regulated by the requirements and recommendations of current state standards:

- GOST 26008-83 Cast iron storm water inlets for wells. Technical specifications;

- GOST 3634-99 Manholes for inspection wells and storm water inlets for storm drainage wells. Technical specifications;

- GOST 1855-55 Gray cast iron castings. Permissible deviations in size and weight and allowances for machining.

Stormwater inlets, hatches and gratings for storm drainage must be manufactured in accordance with the requirements of State standards according to working drawings approved in the prescribed manner.

Plastic hatch DN600 with holes and polymer concrete base, load B125 N=140 mm

RUB 20,606

RUB 24,212

Order

Plastic hatch DN600 without holes with a polymer concrete base, load B125 N=140 mm

RUB 20,606

RUB 24,212

Order

Cast iron hatch DN600 load D400 without holes, anti-slip coating

RUR 64,822

Order

Cast iron hatch DN600 load D400 with holes, anti-slip coating

RUB 63,534

Order

Location rules

When installing rainwater inlets, the following rules must be observed:

- Surface drainage systems are installed in places where water accumulates on the site; when placing the drainage pipeline, a slope of at least 20 mm is maintained. for products with a standard diameter of 110 mm, the indicator increases with small diameters and heavily contaminated wastewater.

- Surface drainage is located 3 - 5 mm below the coating level, and point storm drainage is installed in the same way.

- The house's storm pipe should be placed in the center of the drainage grate and at such a height as to ensure unobstructed removal of the cover and lifting of the sand trap basket.

About each material separately

The technical characteristics of different materials cannot completely coincide, so the advantages and disadvantages of finished products are completely different. The elements are mainly made from cast iron, concrete or plastic. All of them are able to withstand different loads.

Correct location of the collection point relative to the drainpipe

Concrete structures

Almost every developer has the opportunity to buy a storm drainage inlet made of concrete. There are a great many options for such designs. Some owners of suburban areas make them themselves.

Drawing with dimensions of a concrete water collection tank

Concrete products are resistant to moisture, so they are ideal for collecting precipitation. They can be successfully operated for decades under high load. They should be chosen if heavy equipment will be regularly moving around the site.

Concrete structure with galvanized grating

Cast iron products

Most cast iron models are used in the construction of roads to drain sediment from roadways and sidewalks. DB2 rainwater inlets, which are widely used, are excellent for these purposes. In individual construction, less massive structures are used.

This is what the cast iron model db1 looks like

In suburban areas, models are usually installed with a width of 470 mm and a length of 695 mm. The products are characterized by a high level of wear resistance, which is why they attract many developers. Cast iron storm inlet grates are simply inserted into the inside of the block without additional fasteners.

Plastic elements

In current conditions, plastic products are most widespread. They allow not only to receive precipitation, but can also be used as inspection wells, since they can be placed on top of each other.

The structure is made of plastic

The advantages of plastic rainwater inlets are as follows:

- light weight greatly simplifies the installation of elements and transportation to the future installation site;

- plastic is a durable and weather-resistant material, so products made from it last a long time;

- thanks to the smooth surfaces, the process of cleaning structures does not cause difficulties;

- storm sewer pipelines can be installed without the use of additional fasteners;

- Installing the elements is relatively simple, so there are usually no problems when doing the work yourself.

Components for plastic products

The process of installing a plastic analogue under a drainpipe

Installation of rainwater inlets - installation features

If you choose a square design of a rain inlet made of plastic through which water will be drained, then the process of installing it under the drainpipes of the house will consist of the following steps:

- At the location of the rainwater inlet, a pit is dug to a depth of 30-40 cm greater than its height with a gap of 3 - 5 cm between the side walls and the surface of the pit.

- Prepare the body for installation of pipes by first cutting holes of the required diameter using a jigsaw according to a template; the standard cross-section of sewer pipes is 110 mm. It should be borne in mind that for outdoor work orange pipes are always used, which are designed for lower temperatures than gray indoor domestic pipelines.

- The bottom of the pit is filled with a layer of sand and compacted in such a way that 5 - 10 cm remains to the bottom surface of a properly installed rain inlet. After compaction, the hole is filled with a small layer of concrete 5 - 10 cm thick, fixing the rain inlet in the working position so that its bottom rested on the poured concrete layer. The element can be installed at the bottom of the pit even after the concrete pad has hardened; the main thing when solving this problem is to avoid the body subsiding into the ground over time.

- After installing the box, a pipeline located in pre-dug trenches with a slope of at least 2 cm per 1 linear meter is connected to it.

- After completing the installation of the last element, the system is checked for functionality with a stream of water from a watering hose and then buried; usually the next stage of work is the installation of a blind area and laying paving slabs.

During installation, you should take into account the fact that cleaning the sand collection basket every 2-3 months is a mandatory maintenance step, therefore the distance from the bottom edge of the drainpipe to the surface of the grate should ensure its unhindered removal.

Also, all plastic structures provide the possibility of connecting a drainage pipe underground to the inlet located in the side wall of the housing.

Rice. 13 Installation of a rainwater inlet for storm drainage from polymer concrete trays

Typical installation errors

often wants to save on small things.

In most cases, having once built a storm drain, people do not worry about its prevention and maintenance. And these procedures must be carried out consistently twice a year. Cleaning the sewer is not a complicated procedure. In order for a storm drain to last a long time, it is necessary to remove debris from the funnels, clear the wells of silt, wash the trays with water pressure from a hose and clean the sand traps and waste baskets from the storm inlet. Then you won’t have to spend money on system repairs.

If you follow all construction instructions and do the work efficiently, the storm drain will look quite aesthetically pleasing and neat and will last for many years.

Features of installation of surface drainage systems

Often, on an individual plot near a private house, it is necessary to collect water from paving slabs, if the slope does not allow it to be drained outside the plot, and direct it to a drainage well or outside the plot. For these purposes, surface systems are used, consisting of rainwater inlets and trays made by hand from concrete, or factory products made of plastic, concrete or polymer concrete.

It is easier and faster to assemble surface drainage from semicircular trays made of concrete or plastic; work is carried out in the following order:

- They draw up a drainage diagram linked to the site plan, indicating the slopes and direction of water movement along the trays.

- Prepare the necessary tools, the main ones of which are a building level, an angle grinder, a rubber hammer, a spatula, and a bayonet shovel.

- A drainage hole is made in the concrete polymer sand catcher and a place is prepared for installing trays, observing the required slopes. To do this, mark a line with a cord along which you dig a ditch of the required depth so that there is a free space of about 10 cm on the bottom and sides of the tray.

- The trays are laid out along dug channels, starting from the highest point of the drain and connecting to each other; if necessary, use a grinder for adjustment.

- Place a concrete pad at the bottom of the pit and lower the trays onto it, checking the slope with a level and the straightness of the direction with a previously stretched cord. The position is adjusted using a rubber hammer.

- The joints in concrete-polymer trays are sealed using the sealant included in the kit; in the last section, a plug is glued to the end.

- After the concrete has hardened, the system is covered with gratings, then the channels are lined with paving slabs; during installation, the depth of the grating should be maintained at 3 - 5 mm. below the surface level of the paving lining.

Rice. 14 Isoline map of precipitation intensity depending on the area

How to lay a storm drain with your own hands

The systems are placed in accessible places:

- near a residential premises;

- along the road;

- next to the front door;

- below water pipes;

- in areas where slopes converge - if the terrain is uneven or there are paths on a hill.

If you are lucky and precipitation is a rare occurrence for your climate, the site is not threatened by meltwater flows. In such a situation, the best place for a storm drain is near the house. Lay the rainwater inlet under the water supply.

To lay a storm drain with your own hands, follow the diagram:

- buy materials;

- prepare tools for work;

- select a location;

- cut a hole in the device;

- install a rainwater inlet in the blind area;

- connect the device and the drainage tray.

What materials and tools will be needed for installation?

During the installation process, you will have to work with hard materials - gravel, crushed stone, concrete. The volume of consumables determines the scale of the project:

- sewer size;

- storm drain capacity.

Using a plastic structure as an example, let’s look at the standard list of materials and tools:

- ready-made storm water inlet - buy it at any construction hypermarket;

- PVC pipe - for connecting to the sewer;

- connecting corners;

- set of seal couplings;

- tee.

Tools:

- Bulgarian;

- level;

- shovel;

- hammer;

- putty knife;

- drill or hammer drill.

Stormwater volume calculator

Usually, the determination of the volume of storm drains is carried out when designing storm sewers in public utilities; in individual housing construction, calculations are not relevant if water is drained outside the site. It is clear that the standard diameter of outlet pipes is 110 mm. in a set with industrially produced storm water inlets, will ensure the transportation of any water volumes that may appear on the site after a rainstorm or spring flood.

Calculating the amount of storm drains is important if they are discharged into a storage tank, the volume of which must be determined to avoid overflowing. The easiest way to make calculations is to use an online calculator; in this case, the amount of water collected from the entire site is calculated using the following formula:

Q = q x F x Y, where

Q is the total volume of storm water on an individual site;

q is a coefficient characterizing the intensity of precipitation in a given area. Determined from tabular data from metrological or design organizations, as well as from special maps and diagrams for a given area, measured in liters per second per unit area (hectare).

F is the surface area of the area from which water is collected; it can be the roofs of houses and outbuildings or a landscaped area around a private house. For the convenience of calculations on calculators, this parameter is entered in square meters.

Y is a tabular coefficient characterizing the absorbing properties of the surface from which drainage is carried out. The standard calculator for calculations, instead of this Y indicator, includes a list of various surfaces: roofing, asphalt, paving slabs, turf.

After entering the data, the desired value is obtained in liters per second, minute, or cubic meters per hour.

Rice. 15 Drainage maintenance - examples

Calculation of pipeline diameter

To calculate the diameter, you first need to calculate the amount of liquid drained using the formula:

Q=q20*F*φ, where

Q is the amount of water that the sewer system should remove when it rains;

q20 – intensity of precipitation for 20 minutes. This information is available from your local surveyor's office;

F – area of the plot or house. The area of the house is equal to the area of the horizontal projection of the house (taking into account the roof overhang). There is no need to calculate the area of the roof slopes;

φ – correction factor depending on the type of surface of the protected area. It depends inversely on the ability of the surface to absorb water. For asphalt – 0.95; for concrete – 0.85, for roofing – 1.0; for crushed stone – 0.4; for soil - 0.75, sand or gravel - 0.4.

The diameter is determined according to the Lukin tables. Knowing the water flow rate in l/s, you can determine the required pipe diameter. The ratio h/D (the height of the pipe filled with liquid to the internal diameter of the pipe) should be taken equal to 1. Tables and counters based on them are easily available on the Internet.

In a standard urban area, pipes with an outer diameter of 110-160 mm are most often used. Prices for products of these diameters are shown in the table.

| Material | Diameter, mm, wall thickness, mm | Price 1 m |

| Steel | 108×4 | 550 |

| Steel | 159×4 | 810 |

| HDPE | 110×10 | 160 |

| HDPE | 160×14,6 | 330 |

| PVC | 110/4 | 190 |

| PVC | 160\4 | 320 |

| Double-layer corrugation | 110 | 130 |

| Double-layer corrugation | 160 | 200 |

Fiberglass pipes are produced with a diameter of 300 mm or more - they are not suitable for a private home.

Structure care

Like the sewer system, storm drainage needs maintenance, and the following cleaning methods are used:

- The sand trap baskets located under the drainpipes of the house should be regularly cleaned of sand as they fill; the same operation is carried out with surface drainage baskets at a higher frequency (once every 2 - 3 months.)

- To clean the rain inlet, basket and trays, you also need to rinse with a stream of water under high pressure, using a hose connected to the water supply system, while all contaminants are washed off and discharged outside through the channel.

- To clean the drain from mold, plaque, algae, which are sources of microbes and unpleasant odors, you can use construction or gardening tools (trowels, scrapers) in combination with household chemicals for cleaning water pipes.

Typically, the design of a house and the surrounding area includes a storm drainage layout, which serves to drain rainwater from the roofs of houses and outbuildings, as well as from the sidewalk outside the site. In everyday life, when choosing the right rainwater inlet, they often give preference to a drain from a wide range of plastic models - the devices have a low cost, good physical parameters, an aesthetic appearance, and are easy to install and assemble with your own hands.

Maintenance, operation and care

So, all the work is done, the system is installed. To prevent the unpleasant smell of sewage from spreading throughout the area, the device must be maintained. Follow these rules:

- Do not allow debris to enter the system through the grille. Otherwise, rotting processes will begin inside the structure;

- If you have a personal water collection well, monitor its filling level. Overwatering will lead to structural failure;

- regularly - at least once a quarter, inspect storm drain filters. Lift the grill and remove the basket. Rinse it well under running water. Remove debris and dirt;

- repeat the manipulation with the siphons.

Advice! If persistent deposits of dirt and a pungent odor appear on the walls of the basket, use a spatula and remove the deposits.

A do-it-yourself rainwater inlet will solve a lot of problems related to water flow. The main thing is to think everything through in advance. Calculate the capacity of the structure, choose the appropriate model. Find the location where you will install the system. Buy materials, prepare tools. Follow the instructions we discussed in this article - and you will succeed.

Materials for production

The choice of material for the manufacture of a sewer storm inlet depends on factors such as installation location, operating conditions, and so on.

A plastic storm water inlet has the following advantages: light weight, ease of installation and resistance to environmental influences. The use of special stiffening ribs in plastic products increases resistance to loads. For manufacturing, special polymer materials are used that can withstand high loads and sudden temperature changes.

Such products have the shape of a cube with a side edge length of 300 mm or 400 mm. Each face is equipped with pipes for connecting to pipes of various diameters (from 110 to 200 mm). Connecting several chambers will increase the volume of the structure. Plastic rainwater inlets are usually installed on the territory of private houses.

Rainwater inlet made of plastic with metal grate

The main advantage of storm water inlets made of reinforced concrete is their high strength. They are able to withstand heavy loads. They have the shape of a cube or cylinder. The walls at the junctions with the pipes are thinner to make it easier to make holes.

The main disadvantage of reinforced concrete structures is their heavy weight. This makes the installation process more complicated. This structure is mounted on a bed of sand or gravel. Storm water inlets made of reinforced concrete are usually installed on the territory of industrial enterprises and on heavily congested roads.

Concrete rainwater inlet

Storm water inlets made of composites (polymer composites) are currently very popular. They are relatively light in weight (although heavier than plastic) and highly durable (like concrete).

Composite storm water inlet

Cast iron storm water inlets are widely used in urban infrastructure and industrial areas. They are also used in private housing construction. They are installed where large amounts of water need to be drained. According to their shape, such rainwater inlets are divided into round, square and rectangular. A round grille is installed on a concrete or plastic round well, a square one - on a square one. A rectangular rainwater inlet, accordingly, has a rectangular grille.

Cast iron storm grates

The popularity of rainwater inlets made of cast iron has currently decreased somewhat. This is due to their disadvantages such as heavy weight and vulnerability to corrosion. To combat the latter drawback, the surface of cast iron is treated with special compounds. Nowadays, products consisting of stainless steel or corrosion-resistant alloys are increasingly used.

Sometimes elements of rainwater inlets are made of different materials. For example, a plastic storm drain with a cast iron grate is lightweight and resistant to corrosion (this applies to the body itself) and can withstand heavy loads (thanks to the grate).

Design Features

The most popular type of rainwater inlet for storm drainage is a single-chamber design with a rectangular grid. If large surface loads are possible at the installation site, then in this case structures made of polymer concrete or reinforced concrete are used. In this case, the rainwater inlet consists of several sections located vertically. This is necessary to increase throughput.

Stormwater inlets in the form of curbs are sometimes used to remove water from highways. They fit perfectly into the road structure and are not subject to loads from passing traffic.

Cast iron storm grate on the road