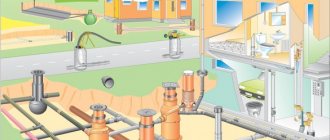

When installing sewerage in difficult areas: terrain with a large slope, connecting several pipelines located at different depths, etc., drop wells are used. The external sewage system of a private house is equipped with several types of wells, which not only help to monitor the performance of the system, but also, if necessary, carry out repairs.

The drop (overflow) well is one of the important elements. Such structures are installed on straight sections. Main purpose: reducing the speed of wastewater flow and changing the depth of the main line.

Purpose of drop wells

If there is a large difference in height between the sewer outlet from the house and the end point (cesspool, septic tank), the flow rate will be high. And this, in turn, threatens the formation of a blockage in the pipe, since the liquid will pass faster and heavy particles will settle on the surface of the pipe.

Purpose of these devices:

- decrease in flow rate;

- bypassing existing underground communications (gas, water, etc.);

- connection of outlets with different depths;

- aligning the level of sewage discharge with the level of discharge into the reservoir.

According to building codes, with a small drop of up to 0.5 m and a pipeline diameter of up to 600 mm, a manhole can perform the functions of a drop structure. There are several types of differential wells, which differ in design and functionality.

Products of the POLIPLASTIC Group

The structures sold by the company are made of plastic. Its advantages include low weight (ensuring low transportation costs and ease of installation of the structure), corrosion resistance, tightness, and long service life (up to 100 years). One of the product samples - a differential sewer well - has the following dimensions:

- diameter – 1600 mm;

- shaft height – 5750 mm;

- diameter of exits (inputs) – 1200 mm.

Inside there is a flow damper, which is required to reduce the speed of the medium. It also serves as an observation deck. The well is equipped with a ladder for ease of maintenance. Entrances and exits are made of polymer corrugated pipe.

It is possible to produce custom models according to Album No. 5 of the document “Chambers and wells of rainwater drainage. Standard materials for design 902-09-46.88.” Production is carried out according to designs that indicate the required height differences.

Construction of a drop well

Domestic, storm and industrial sewer wells are similar in design. A standard well consists of the following elements:

- support bottom;

- working shaft;

- neck;

- cover and hatch.

The differential devices include a bumper or overflows, which are the main distinguishing feature. The difference in drainage can be both internal and external.

How to make a well

It will be quite difficult to build a container with water traps yourself. The fact is that such structures are large in size and have design features. To construct such a well with a drop, it is necessary to develop appropriate design documentation. The easiest way is to install a ready-made prefabricated plastic frame or concrete rings, which are manufactured in factories.

Installation of the differential well is carried out in the following sequence:

- First of all, you need to dig a pit to a depth below the freezing level of the soil.

- A cushion of gravel or sand is placed at the bottom of the trench. Its thickness is 30 cm. The pillow must be carefully compacted.

- A concrete screed is placed on top of the pillow, which will serve as the bottom and support for the well.

- At the next stage, concrete rings or a finished plastic product are installed.

- A fender is installed inside the structure.

- Next, the inlet and outlet pipelines are connected to the tank. All joints are carefully sealed with bitumen mastic. In cases with concrete rings, cement mortar is used.

- A cover with an inspection hatch is installed on top.

- The space between the container and the ground is filled with crushed stone or sand and cement.

If necessary, additional inlet pipelines can be connected to the well. They can be placed either on top or level with the main highways. The main thing is that they do not interfere with the normal flow of water.

The well is an integral element of external sewerage and drainage. To build such a structure, a tremendous amount of work needs to be done. It is best to use ready-made plastic containers for this. In this case, it is worth taking into account the features of the system itself and the topography of the site. This is especially true for the design of a drainage system, which serves to remove excess moisture from the land.

Types of wells with drop

These structures are divided into four types:

- with inlet at the top and outlet at the bottom;

- a bumper in the form of a glass or pipe;

- with one vertical or angled damper;

- with a multi-stage fender system;

- chambers connected by a channel installed at an angle.

The first option is used only when the difference is no more than 3 m; in all other cases, options with bumpers are used. The latter option is used in places where it is necessary not to reduce the flow rate, but, on the contrary, to increase it.

Design features of wells

Installation of communications is accompanied by the installation of hydraulic structures made of various materials: brick, reinforced concrete, cast iron and plastic. Depending on the purpose, they are round and square, which are designed for large cross-section highways. The diameter of the structure depends on the size of the pipeline:

- for a main with a cross-section of up to 30 cm - a well of at least 70 cm;

- up to 60 cm – 100 cm;

- up to 100 cm – 150 cm.

Concrete wells

Due to their strength, speed of installation and standard sizes, wells made of reinforced concrete rings are very popular. Their components are:

- wall ring;

- cover with hatch;

- bottom.

To create a sealed structure, the rings are treated with waterproofing mastic. The elements are connected to each other with cement-sand mortar. Universal products are suitable for installing any type of well.

Components of a concrete structure

Attention. Well shafts are equipped with brackets or ladders for descent.

Polymer wells

Plastic structures are inferior in popularity to concrete structures, but they are often used when installing private communications for drainage of waste and storm water. Plastic wells are assembled from several parts:

- Luke;

- neck or telescopic extension;

- mine;

- sealing cuffs;

- tray part.

Plastic well

Among the advantages of plastic: tightness, lightness, lack of corrosion. But with all strength indicators, there is a risk of tank deformation.

Advice. The performance characteristics and service life of brick wells are inferior to structures made from other materials, so they are built very rarely.

Material for drop wells

When constructing this type of sewer wells, the following is used:

- concrete;

- brick;

- fiberglass;

- polymer materials.

The easiest to install are finished products made of polymers or fiberglass, but they are also the most expensive. It is cheaper to use reinforced concrete rings or brickwork. However, to install the rings you will need to use special equipment, and to lay bricks you need to have such skills.

Classification of hydraulic structures

Types of wells are distinguished according to several characteristics:

- Type of network on which installation is carried out:

- domestic and industrial - access to wastewater discharged from residential buildings and industrial enterprises is provided;

- drainage – ensuring an audit of the site’s drainage network;

- storm drains - structures for draining into a system that drains rain and melt water.

- Construction material:

- reinforced concrete;

- polymers: polyethylene, polypropylene, polyvinyl chloride;

- brick.

- Functional purpose:

- examination rooms;

- distribution;

- accumulative;

- differential;

- absorbing.

Attention. The placement points, dimensions and requirements for installation of various types of wells are determined by SNiP 2.04.03-85.

Installation of the structure

The construction of the most common concrete drop well includes the following stages of work:

- Preparatory activities : marking the territory, clearing debris and vegetation, arranging approaches, or better yet, an access road.

- Digging a pit for a mine . The depth is selected taking into account the parameters of the pipeline location and the need to form a cushion at the bottom.

- Filling with a cushion of sand and crushed stone (at least 15 cm thick), careful compaction, laying roofing felt waterproofing or filling with bitumen.

- Formation of the bottom part . The most rational option: laying a finished reinforced concrete slab. When pouring concrete, a reinforcing layer of steel rods with a diameter of 12-16 mm must be installed.

- Installation of concrete rings . The seams between the elements are sealed with concrete mortar. Bitumen waterproofing is applied to the outside of the walls.

- Installation of specific elements : riser with a receiving funnel, water trap. Construction of a bottom pit. A metal plate is placed at the bottom to protect the concrete from destruction by the jet.

- Installation of floor slab and hatch.

The water flow suppression system inside the well can be of 2 main types. Tubular dampers are made in the form of a riser from a pipe into which the sewage system is introduced. Second option: waterproof surface. A metal vertical or inclined plate is mounted in the well, onto which a stream of water is thrown. The profile of the entire well is selected taking into account the topography and flow volume.

Drop wells are necessary for difficult terrain of the site, because allow you to protect the sewer pipeline from rapid destruction.

To install them, it is better to use ready-made structures, which you just need to dig in at the right place and connect the pipeline. When making a well with your own hands, you should use standard designs, in particular a structure made of reinforced concrete rings.

Storm well calculation

Design mistakes are costly - it's easy to turn your yard into a pond.

How big should a storm sewer well be? It is logical to assume that, at a minimum, it should contain all the water that has accumulated after rain or during a thaw.

In other words, when making calculations, you need to take into account the volume of water drained from your site, for which you should make preliminary calculations using the following formula:

Q=q20×F×Ψ, where

- q20 - coefficient of average precipitation in your area (average norm - data is taken from SNiP);

- F is the area of the site on which the storm sewer will be installed;

- Ψ is a correction factor that takes into account the type of coverage and the degree of precipitation absorption in a given area.

Reference values of this coefficient are given in the table:

| Coverage type | Correction factor Ψ |

| Open ground | 0,35 |

| Concreted area | 0,85 |

| Paved area | 0,95 |

| Crushed stone filling | 0,40 |

After making calculations, you can use the table to select not only the diameter of the pipes, but also the slope angle.

The calculated value allows you to more accurately select the slope angle and diameter of the pipes for installation.