Polymer corrugated pipes for sewerage are used instead of concrete, steel and cast iron predecessors. Having the same high strength and long service life, a corrugated sewer pipe weighs several times less and is very easy to install.

Blue and white colors help quickly locate pipe damage in the ground

Description and application of corrugated sewer pipes

Corrugated pipes are used for stormwater, free-flow, sanitary, all-alloy industrial and domestic sewerage. The corrugated pipe has recesses located at the same distance from each other. These recesses are located along the entire length of the pipe. This corrugated profile provides the necessary ring rigidity. Compared to smooth pipes, corrugated pipes are many times superior in stability and strength. Corrugated pipes, depending on their properties, are divided into:

- lightweight corrugated pipes, which have low mechanical stability, are used for the construction of an external sewer system;

- heavy corrugated pipes, with an average level of mechanical resistance, are used for underground sewerage;

- extra-heavy corrugated pipes with high mechanical resistance are intended for laying sewers under railway tracks or highways.

A variety of types of corrugated pipes satisfy the requirements of various sewerage systems.

Table of the ratio of extra-morning and external diameters

Characteristics

Corrugated pipes are made from a special polymer, the features of which also affect the technical characteristics of such products:

- Nominal diameter DN – from 110 to 1200 mm.

- The color of the outer surface is black or orange-brown.

- Ring stiffness indicator - for pipes with DN less than 500 mm: SN4; SN8 or SN16; for products with DN more than 500 mm: SN2; SN4; SN8 or SN16.

- Impact strength - TIR≤10%.

- Ring flexibility at 30% deformation - no cracks, wall delaminations, kinks or warping.

- Installation temperature - up to -20ºС.

- Change in length and appearance after overheating - from 2 to 5%.

- The Vicat softening point is not less than 76ºС.

- Depth of occurrence (depending on the parameter of ring rigidity) - from 1 to 15 m.

- The warranty period is at least 50 years.

Classification of sewer pipes

Corrugated pipes come in single-layer and double-layer types. The double-layer structure is more durable and can easily withstand soil pressure when used in underground sewer installations. The division of two-layer corrugated pipes for sewerage into types occurs due to the use of different materials for their production:

- Corrugated pipes made of polyvinyl chloride (PVC) are used in industrial sewerage systems, central drainage systems, and for sewerage systems of country houses. They withstand strong mechanical loads, do not become clogged during operation, have an operating temperature from -40 to + 50 degrees Celsius, with a short time interval of up to +90. Double-layer PVC sewer pipes do not corrode, are environmentally friendly, can be installed to a depth of up to 15 meters, and have a shelf life of up to 50 years. The color of corrugated pipes for external sewerage can be orange, gray and yellow.

- Corrugated pipes made of polypropylene (PP). Ideal for chemically contaminated soil and used for drainage, external and storm sewer systems. They can withstand temperature changes from -20 to +95 degrees Celsius, have increased mechanical strength, suitable for soil with sand, gravel, etc. Not susceptible to the effects of chemical formations in liquid waste.

- Corrugated pipes made of low pressure polyethylene (HDPE). They have the same properties as PVC pipes. They are: environmentally friendly, withstand a wide range of temperature differences, increased tightness and ease of dismantling and repair.

Helpful advice! Professionals recommend installing double-layer pipes in surface, underground and storm sewer systems.

Installation of double-layer corrugated pipes

How is installation carried out?

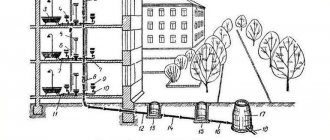

Any cylindrical element has a socket, so its installation does not require the use of any special tools or special construction skills. Since the use of such products is specific, it is necessary to stock up on additional materials for reliable installation. We are talking about silicone sealant or plumbing glue.

Polymer pipes for external sewerage should be laid only at positive temperatures. A cushion of crushed stone and fine sand is placed at the bottom of the trench, which allows the product to withstand soil pressure.

Before installing pipes, all dimensions are checked. The cylindrical elements are then placed in the trench. When arranging internal sewerage, they are laid at certain points.

The smooth end of the cylindrical structure is thickly coated with sealant and inserted into the receiving socket. The product must be squeezed tightly and held for several minutes.

The system should be checked after three hours. During this time, the sealant will completely harden.

Using double-layer corrugated pipes for storm drainage system

Storm drainage is a non-pressure system of channels and devices for collecting, filtering and draining precipitation and melt water. In most cases, these are grid-covered rain collectors - two-layer corrugated pipes through which precipitation is directed to a well or collector. It is better to select rain collectors with a hole for attaching pipes, which allows for faster movement of wastewater. It is preferable to lay a corrugated sewer pipe with a slope of 1%, that is, 1 cm per 1 m of pipe. To prevent sewer pipes from freezing, they are installed below the soil freezing level. The part of the pipe that is in the freezing zone is wrapped with insulation so that subzero temperatures do not arise inside. Depending on the amount of precipitation in the region, the size of corrugated pipes for storm drainage ranges from 110 mm to 210 mm.

Laying corrugated pipes in the ground on a sand bed

Tips for choosing

The sewer system will function uninterruptedly only if the work on its assembly and installation is carried out correctly, as well as the correct selection of all components. As for pipes, they must be selected according to the following parameters:

- Nominal diameter and wall thickness.

- Length of sections.

- The type of system is pressure and non-pressure.

- Estimated load on the system.

It is better to purchase such products in specialized stores, where the quality of the product is confirmed by an appropriate certificate describing the technical characteristics and a quality certificate. You should also check the integrity of the packaging and the presence of markings on each section of pipe, consisting of:

- Name or trademark of the manufacturer.

- Symbol.

- Dates of manufacture.

approximate cost

The cost of plastic corrugated pipes for sewerage depends on the size of the product, stiffness class, material of manufacture and manufacturer.

Average prices for the most popular two-layer corrugated HDPE pipe with a welded socket are shown in Table 2.

Table 2.

| No. | Outer/inner diameter, mm | Hardness class | Price 1 linear meter, rub. VAT included |

| 1 | 110/94 | SN 8 - SN 9 | 210 |

| 2 | 160/136 | 360 | |

| 3 | 250/216 | 758 | |

| 4 | 230/200 | SN 6 - SN 7 | 512 |

| 5 | 250/216 | 622 |

The best domestic and foreign manufacturing companies

The most famous manufacturers of plastic corrugation for sewerage are the following companies:

- Wawin (Holland).

- PIPELIFE International GmbH (Austria) - Pragma pipes.

- Polieco (Italy) - Corsis PRO sewer corrugation.

- Russian companies - FD-plast, Poliplastik, Politek.

The use of double-layer corrugated pipes for an external sewerage system

External sewerage is very important for the removal of sewage and other waste. There are a number of requirements for corrugated pipes for external sewerage:

- resistance to waste composition;

- strength, environmental friendliness, heat resistance;

- ease of maintenance.

When laying corrugated sewer pipes for external sewerage, the composition of the soil and the flow load are taken into account. Pipe sizes start from 110 mm and above. If the sewer pipe is laid in a green area, then choose a lightweight type; in an area with a small flow of moving traffic - severe; under highways and railway tracks - super-heavy type of pipes. Just when installing corrugated sewer pipes in homogeneous soil, one of their main advantages is visible: the soil fits tightly to the notches of the corrugated profile and the pipe takes a stable position.

Helpful advice! A corrugated pipe for external sewerage is chosen to be a two-layer pipe with a smooth inner surface, painted white or blue. This choice of color helps to quickly find damage and carry out repairs.

When a corrugated pipe is used in a sewerage system, it easily copes with the flow of wastewater and household waste.

Fittings for corrugated double-layer PVC pipes

Product Standards

Requirements for the technical characteristics and dimensions of corrugated pipes made of polymeric materials are established by GOST R 54475-2011 and TU 2248-001-96467180-2008.

Dimensions

Corrugated pipes are sold in lengths of 6 or 12 m and have the following cross-sectional dimensions (Table 1):

Table 1

| Outer diameter, mm | Inner diameter, mm | Wall thickness, mm | Corrugation protrusion width, mm |

| 110 | 91 | 1,0 | 8,6 |

| 125 | 107 | 1,1 | 8,6 |

| 160 | 138 | 1,2 | 9 |

| 200 | 176 | 1,4 | 12 |

| 250 | 216 | 1,7 | 23 |

| 315 | 271 | 1,9 | 27 |

| 400 | 343 | 2,3 | 30 |

| 500 | 427 | 2,8 | 38 |

| 630 | 535 | 3,3 | 47 |

| 800 | 678 | 4,1 | 56 |

| 1000 | 851 | 5,0 | 60 |

| 1200 | 1030 | 5,0 | 80 |

Advantages of corrugated pipes for sewerage

Corrugated sewer pipes have a high stability threshold compared to reinforced concrete and cast iron pipes and weigh very little. At the same time, the sewer corrugated double-layer pipes have rings, the rigidity of which allows them to withstand soil pressure at a depth of up to 20 meters. Some are simply installed using a special solvent that glues the pipe to the fitting. For other pipes, classical connection methods are used. Many manufacturers produce corrugated sewer pipes with a protruding, widened edge for joining with other parts of the sewer system, which ultimately provides greater tightness. The material from which the pipes are made does not corrode, be it PVC, HDPE or PP.

Interesting fact! Since corrugated double-layer sewer pipes are used quite often, manufacturers have made the lower price limit accessible to everyone, while the quality remains at a high level.

For stormwater, drainage and external sewage systems, the temperature regime that corrugated pipes can withstand is important. When using pipes in urban systems, and especially in manufacturing, resistance to the chemical composition of the waste is necessary to avoid deposits inside the pipe. With proper maintenance and proper operation, double-layer corrugated sewer pipes last 50 years or more.

How to choose

When purchasing polymer products, you must consider the following:

- Wall thickness. The thicker the product, the higher the reliability of the entire structure.

- Length. If the connection is very long, the pipe will sag and additional bends will appear. As a result, this leads to clogging and coating of the walls with a fatty film.

- Bell diameter. The product must have dimensions corresponding to the size of the receiving product, as well as the diameter of the drain hole in the toilet.

- Reinforcement. Products with reinforcement will last much longer due to increased strength.

- If there are rodents in the house , polymer products must be hidden in a special casing made of fiberglass.

- Installation of a plastic corrugated pipe to the toilet should only be carried out in an open area . This product is not suitable for wall installation.

Purpose

Double-walled corrugated pipes are a universal category of products that are used in almost all types of economic activities. They are widely used during electrical work during cable laying, as well as for the construction of reclamation systems, drainage wells, water supply, heating and drainage systems.

We recommend that you read: How to install pipes for heating systems

The corrugated structure can have any diameter - small (16 to 32 mm), medium (39-50 mm), and large (up to 63 mm or more).

Thin and medium-sized pipes are used in the electrical and telecommunications fields:

- for laying electrical cables above and below ground;

- to protect fiber optic cables when laying telephone lines and connecting the Internet.

For ease of installation and cable laying, the products are equipped with a flexible internal cable with a hook, which allows you to pull the wire through the pipe manually without outside help.