A high-quality and durable sewer network is a necessary condition for a person to live as comfortably as possible in a house or apartment.

When installing sewer systems, plastic is the leader compared to other types of materials.

Plastic has a number of advantages that its closest analogues do not have. Products such as plumbing pipes and PVC adapters for sewerage also have these advantages.

What technical characteristics do the structures have?

PVC - this is the designation for any type of polyvinyl chloride. It is obtained when vinyl chloride is polymerized. The new material has the following advantages:

- Resistance to corrosive processes.

- Ultraviolet resistance.

- The ability to withstand the negative effects of various substances.

- Long service life.

- They have great strength. It also has a 50 mm PVC pipe for sewerage.

Plumbing products measuring 250 mm, which are made from this material, also have positive qualities. They are lightweight, making installation and transportation much easier.

Low price attracts buyers the most. Compared to cast iron and steel analogues, products made from this material are the cheapest.

Installation is simple and can be done by the owner himself without additional assistance. It is enough to use suitable fittings. But it is not without its drawbacks, just like other materials.

Plastic is very susceptible to negative temperatures. It can also be deformed at high temperatures - from 70 degrees or more. Water flows through such a pipeline quite noisily.

Replacing a cast iron riser with a plastic one - why is this done?

It would seem that cast iron is a metal and, by definition, should inspire more confidence than plastic. This is not always the case with sewer systems. Cast iron has a porous and lumpy structure, and therefore pollution quickly builds up inside cast iron sewer pipes.

Cast iron sewer riser - joint with a plastic pipe

Its internal diameter decreases, permeability decreases, and the likelihood of blockages increases many times over.

Cast iron pipes that have served for more than 20 years can become completely overgrown with plaque from the inside.

During dismantling, there were cases when, under the blows of a sledgehammer, cast iron risers were broken into pieces, and the fossilized column of plaque remained in place.

Plastic sewer pipes are smooth and, when installed correctly, significantly exceed cast iron pipes in terms of throughput parameters. The positive effect of replacing with plastic ones will be immediately obvious.

Sewer plastic riser

The reason for replacement may also be the presence of cracks, fistulas, breaks in the existing sewer system or its general deterioration. Replacement of cast iron riser pipes in an apartment should be done after 25 years of operation. It makes sense to change sewer risers simultaneously along the entire riser. Replacing a sewer riser in one apartment will cause a number of inconveniences to neighbors, but will not increase the efficiency of wastewater flow at all. More likely, there will be an additional cause of blockage at the joints connecting cast iron and plastic.

Varieties. Features of the structure

Most often, a special extension, the so-called socket, is installed on one side of the pipe. Without this element it is impossible to create a high-quality connection. The end with a smooth surface is connected to the socket and inserted inside.

The type of product determines the composition and subtleties of the structure, possible color design. PVC plumbing pipes for sewerage are no exception, where GOST 51613 2000 defines clear requirements for them. For more information about what GOST 51613 2000 is, see here.

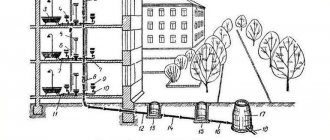

About the construction of the pipeline, the use of adapters

Products in gray color are most often used by those who install risers and wiring inside the house. They are made from unplasticized polyvinyl chloride.

This is a smooth-walled type of pipes and fittings. Its sizes can be any. 5, 11 centimeters are the most widely used sections.

When it comes to internal sewerage, fittings equipped with rubber seals are most often purchased. Here they help arrange turns in the pipeline and connect elements to each other.

Adapters are divided into several types according to their functions:

- Compensation pipes. They become indispensable assistants when performing repair work. They will help connect PVC pipes with a diameter of 250 mm for external sewerage.

- Rotary bends. Sold at 90, 30 and 45 degree angles.

- Tees with different angles - from 45 to 90 degrees. To connect several pipes with a diameter of 50 mm, crosses are also used; they usually have a slope of 45, 90 degrees.

- Inspection hatch. These types of equipment are necessary when specialists are checking the system and performing diagnostics.

- Elements with different diameters are connected using reduction.

- Couplings are used where it is not possible to use a socket connection. Or they help perform installation where there is a PVC plumbing pipe, where the diameter does not matter.

PVC sewer pipe size chart

The dimensions of PVC sewer pipes must be known for high-quality installation and proper operation of the system. They are enshrined in the state standard for each type, which is marked GOST 32413-2013.

The measurements are based on 2 main characteristics: the nominal outer diameter of PVC sewer pipes and the thickness of their walls in millimeters. The length that manufacturers set independently is also taken into account.

Dimensions for internal systems can be presented in table form.

| Nominal diameter, inch | External diameter, mm | Minimum wall thickness, mm | Design internal diameter, mm | Weight, kg |

| 1/2 | 21,3 | 2,8 | 15,7 | 0,238 |

| 3/4 | 26,7 | 2,9 | 20,9 | 0,313 |

| 1 | 33,4 | 3,4 | 26,6 | 0,476 |

| 11/4 | 42,2 | 3,6 | 35,0 | 0,640 |

| 11/2 | 48,3 | 3,7 | 40,9 | 0,759 |

| 2 | 60,3 | 3,9 | 52,5 | 1,012 |

| 21/2 | 73,0 | 5,2 | 62,6 | 1,592 |

| 3 | 88,9 | 5,5 | 77,9 | 2,098 |

| 4 | 114,3 | 6,0 | 102,3 | 2,991 |

| 5 | 141,3 | 6,6 | 128,1 | 4,062 |

| 6 | 158,8 | 7,1 | 144,6 | 5,253 |

| 8 | 219,0 | 8,2 | 202,6 | 8,020 |

| 10 | 273,1 | 9,3 | 254,5 | 11,234 |

| 12 | 318,8 | 10,3 | 298,2 | 14,895 |

| 14 | 355,6 | 11,1 | 333,4 | 17,558 |

| 16 | 406,4 | 12,7 | 381,0 | 22,960 |

How is the external sewage system arranged?

Yellow or orange colors indicate plumbing elements that are used for laying external sewers, where the diameter size is 50 mm.

Their walls can be different: with one layer and a smooth surface, or with three layers and corrugated. These options fully comply with GOST 51613 2000.

Wall thickness and strength become the most important parameters for representatives of this group. According to these characteristics, smooth structures can be divided into three more categories.

- SN8. Plumbing products with the greatest strength. They can be laid even under busy highways, at great depths.

- SN4. It is better to lay them under roads without much traffic.

- SN2. Can't withstand heavy loads.

1.1-6.3 centimeters is the most common diameter for external sewerage.

When installing outdoor external networks, specialists use the following types of connecting elements.

- Single-plane cross with right angle. Or - a tee that supports angles of 45, 67 and 90 degrees. This rule corresponds to GOST 51613 2000.

- Right angle tee, three-socket type.

- Reduction.

- Plumbing inspection hatches for structures measuring 50 mm.

- Siphons equipped with two elbows.

- Check valves.

- Bends with two sockets, rectangular in shape.

- Plumbing bends with a large number of possible angles: 15, 30, 45, 67 and 90 degrees.

- Clutch. The main thing is that it complies with GOST 51613 2000.

Dependence of the scope of application on appearance and color

Corrugated products are distinguished by their versatility. They can be one- or two-layer (the outer layer is corrugated, the inner layer is smooth). The corrugated material used to produce pipes is much cheaper than metal.

Corrugated products are also relatively cheap.

If the system is laid open, a black corrugated PVC pipe is used, and if it is hidden, a smooth version of the risers is used. For such purposes, they often use a socketed PVC sewer pipe with a nominal bore of dn32, dn40, dn50 and more, the price of which depends on the material of manufacture, the manufacturer, and the batch of supplies. Plastic pipes come in different colors. If the riser is gray, then it can only be used indoors.

Blue and white analogs provide reliable well casing.

Orange thick-walled PVC pipe is used in a gravity-flow external sewage system. A structure with such elements can be laid to a depth of 7-8 meters.

Transparent polyvinyl chloride is used for the production of transparent risers with a wall thickness of 0.5 mm - 5 mm, a diameter of 3 mm - 14 mm. Such structures are able to fully function in the temperature range from -30 to +80 degrees Celsius. Thanks to its transparency, the liquid that moves inside it is visible in the pipeline. This significant advantage provides the ability to fully control the transportation process.

Pipelines mounted from transparent risers can:

- transport drinking, distilled, sea water;

- transport cooling drinks, dairy products, carbonated and mineral water, juices, wines, strong alcoholic drinks, vinegar, vegetable oils.

They are also used in freezers and water supply systems.

Forced drainage

A special category of products made from PVC. The main requirement is the ability to withstand high pressure.

Such plumbing pipes and adapters are available in three varieties, depending on the pressure they are designed for. Typically, products are designed for 6, 10 and 12.5 kg/cm2.

Based on the type of assembly, structures are divided into two main categories.

- For the adhesive method, allowing the use of special fittings

- For a classic bell.

What is uPVC

Very often you can hear the name “PVC sewer pressure pipe” without the prefix “N” (unplasticized). In professional terms, this is acceptable, since experts know that pressure pipes are not made from modified polyvinyl chloride. The material used for these systems is uPVC (unplasticized polyvinyl chloride) - a vinyl chloride polymer that does not contain plasticizers. Plasticizers are introduced to increase the fluidity and elasticity of the material, which contradicts the objectives of pressure pipes. The wall of the product must be as rigid as possible, designed to withstand pressure changes, especially when passing solid masses; its deformation can lead to a rupture, which is unacceptable in a sewer network.

Tips for choosing

An important point when installing a sewer system, regardless of whether it is internal or external, is where the installation is taking place and the expected operating conditions. No less attention is paid to the size and quality of the pipeline.

It is quite difficult to independently calculate the appropriate diameter for external sewerage in certain conditions, but there are general recommendations that will help solve the problem.

- A 5-centimeter diameter is quite enough for a shower, drainage from a sink and similar elements.

- From the toilet, drains are discharged into 11-centimeter structures.

- To equip a full-fledged bathroom in apartments and private houses, the minimum size is also 11 cm. If the house is multi-story, then craftsmen often choose vertical systems with a diameter of up to 15 cm. If they are made in accordance with GOST 51613 2000.

- 20 centimeters should be equal to the cross-section of the pipeline, if we are talking about a pipeline in a horizontal plane, which collects and discharges wastewater from the entire house.

- The branch through which drains flow from plumbing fixtures to the pipe vertically should not be smaller than the riser.

Video

Pipes for external and internal sewerage. Recommendations from experts // FORUMHOUSE

PVC plumbing pipes with pressure

Such 50 mm pipes differ from others in that they can withstand pressure of up to 10 atmospheres.

They are relevant for systems in which pumps are responsible for forced circulation of liquid. This creates artificial pressure, and then the flow becomes continuous.

The installation of pumps will be especially relevant where there are many apartments and large premises.

The wall of a pipe with a size of 50 mm increases in thickness, otherwise they will not be able to withstand the increased load. The use of multilayer products is allowed. And here the characteristics are regulated by GOST 51613 2000.

Pressure external pipe materials with a diameter of 50 mm are installed even where the pump will not operate on a permanent basis.

Non-pressure type of PVC pipes

They are most often used in modern sewer systems. Their design is standard. They are not recommended for use in systems with artificially created pressure.

It is possible to install pressure pipes along the entire length of the external sewer system, but this solution is too expensive. Similar non-pressure materials are 25 percent cheaper than pressure materials.

Watch the video

About corrugated varieties

They have the most unusual appearance. The walls look like an accordion. This allows installation even in places where access is difficult.

The structure has an inner and outer layer. A smoother material is used to make the inside so that blockages do not appear inside. The outer layer is standard PVC.

How to connect plastic pipes to cast iron?

Adapter sleeves and fittings will help connect any external pipes. Even if part of the branch is made of cast iron, part remains plastic.

A regular rubber adapter will suffice if you need to connect a system that has a socket. Plastic external adapters are needed where there is no socket.

When using rubber cuffs, replacement is carried out as follows.

- We clean the 250 mm bell from plaque and dirt if they appear on the surface.

- Apply a layer of sealant to the outer surface of the socket. After which the part is inserted.

- A plastic pipe for the sewer system is connected to a cuff.

Plastic connecting elements require a slightly different procedure.

- We level the edge of the pipeline by 250 mm using a grinder if part of it bursts during operation.

- We put a 250 mm rubber cuff on the structure. Its surface is pre-coated with a composition for high-quality sealing.

- A plastic adapter is placed on top.

Video

Material Definition

Red pipes are made from cross-linked polyethylene. Previously, there was a skeptical attitude towards this definition. Now what remains in my memory is also not exactly what these products mean now. Cross-linked polyethylene is presented as a pipe product with a longitudinal seam, which has the advantage of low cost. However, the quality leaves much to be desired.

But this is not true at all. A modern red HDPE pipe is a high-tech invention that, in terms of its performance properties, competes well with other types. Modern construction and renovation work rarely goes without this type. In addition, red pipes are increasingly used for heated floors.

So why is it called “cross-linked polyethylene”? Everything happens at the molecular level. It is the polymer molecules that are cross-linked using special equipment, which ultimately produces a strong and durable material for making pipes. Special physical and chemical processes are involved in production.

Red pipes are made from several types of derivatives of the material obtained in different ways, namely:

- PE-Ha – formed during heat treatment using peroxides;

- PE-Xb - obtained as a result of moisture treatment using implanted silane and catalytic substances;

- PE-Xs - produced by exposing molecules to electrons;

- PE-Хd – obtained when exposed to nitrogen.

The main technical properties are precisely laid down at the molecular level. Thanks to strong bonds, it is almost impossible to break the material.