Home/Types of heated floors/Water heated floor. Installation of a warm water floor./Calculation of a pipe for a heated floor: online calculator and formulas

Every year new technologies are created for the arrangement and comfort of housing. Thus, not long ago a new innovative design was created for insulating water heated floors. This model has gained great popularity in use in a short time, as it can serve as the main or additional source of heat supply to the room. This system is very easy to use and has many advantages compared to other heating designs. But before installing this equipment, you need to know how to calculate pipes for heated floors and other materials.

General recommendations before installing the system

Before purchasing a water heating system, you need to create a heat map of your home with the help of a specialist. Such a map will help identify heat loss in the room. Thus, if they amount to more than 100 watts per square meter, then before calculating the length of the pipe, you need to insulate the building.

You can calculate a warm water floor yourself using a calculator. But the important point here is that the heating system cannot be placed under large furniture and stationary equipment. Otherwise, the heating system will quickly fail. But at the same time, the water structure must still occupy at least 70% of the floor area, otherwise the room will be poorly heated.

Also, the efficiency of heating will depend on the requirements for the premises.

Basic calculations

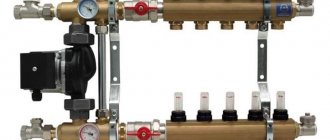

Determining the required power of the system will help you calculate the pipe for the heated floor, select a pump and collector for the cottage heating system.

Heat loss calculation

The required power of thermal circuits (M) depends on heat loss (Q) and is determined by the formula:

M = Q×1.2

Heat escapes through external walls, ceilings, and windows.

On a note! Since in our case the floor will be heated, heat loss through it is not taken into account.

Proportion of heat loss through different house designs Source domekonom.su

See also: Catalog of house projects with a boiler room

To determine losses, you need to know the thermal resistance (R) values of all structures. They are easy to calculate if you divide the thickness of a wall or other structure by the thermal conductivity coefficient, which is different for each material. It is found in the table:

| Materials | Thermal conductivity coefficient, W/(m°*C) |

| Reinforced concrete | 1,7 |

| Sand-lime brick | 0,7 |

| Ceramic brick | 0,44 |

| Aerated concrete and foam concrete | 0,26 |

| Expanded clay concrete | 0,4 |

| Tree | 0,18 |

| Mineral wool | 0,055 |

| Expanded polystyrene | 0,038 |

For example, if a house is built from timber 20 cm thick, then the thermal resistance of the external walls is calculated as follows:

0.2/0.18 = 1.11 m²°C/W

If the walls are insulated with mineral wool, calculations must be performed both for it and for the façade finishing material. The complexity of the calculations also lies in the fact that heat losses are calculated individually for each structure: the area of openings is subtracted from the area of the walls, the thermal resistance of double-glazed windows and window profiles is determined, the power required to heat the air entering through ventilation ducts is taken into account, etc.

The thermal resistance of a wall is the sum of the resistances of all its layers Source www.bazalt-most.ru

See also: Catalog of companies that specialize in the installation of internal engineering systems

That is why it would be better to trust the specialists. But particularly thrifty and time-poor homeowners can use the following formula:

Q = 1/R x (Tv - Tn) x S,

where S is the area of the structure, and Tv and Tn are the indoor and outdoor temperatures (minimum).

Let's show with an example how to calculate a warm floor. Let’s assume that the area of the external walls in the room of our house made of timber is 50 m², the minimum winter temperature outside is -30°, and inside should be +24°. Then:

Q = 1/1.11 x (24 – (-30)) x 50 = 2432 W

But that’s not all, you should take into account the orientation of the room according to the cardinal direction. If it faces south, leave the value unchanged; if it faces north, multiply it by a factor of 1.1; if it faces west or east, multiply it by 1.05.

Then, using the same formula, we separately calculate heat loss through windows, adding up their area, through the front door, ceiling, ventilation system (by air volume per unit time). And we summarize all the results. And so on for each room, especially if they are supposed to be maintained at different temperatures.

A detailed house plan with dimensions will simplify the task Source 2.bp.blogspot.com

Let's assume that we end up with 12500 watts. We multiply by 1.2 and get the required system power of 15,000 W or 15 kW.

What room requirements must be met when installing the system?

During installation work, the most correct decision would be when the pipeline is installed at the initial stage of construction of the floors. This method is 30–40% more economical than the radiator method. It is also possible to install a water heating structure in a ready-made room, but to save the family budget, you should pay attention to the following requirements:

- The height of the ceilings should allow the installation of heated floors with a thickness of 8 to 20 centimeters.

- The height of doorways should not be less than 210 centimeters.

- To install a cement-sand screed, the floor must be more durable.

- To avoid airiness of the contours and high hydraulic resistance, the surface for the base of the structure must be flat and clean. The permissible level of unevenness is no more than 5 millimeters.

And also in the building itself or in individual rooms where the heating system will be installed, plastering work must be done and all windows must be installed.

Water floor power calculation

Calculations of the heating water system must be made extremely carefully. Any mistakes in the future can lead to additional costs, since they can be corrected only with complete or partial dismantling of the screed, and this can damage the interior decoration of the room.

Before you start calculating the amount of power you need to know several parameters .

Parameters for a water floor

The power of the heating system is influenced by several factors, such as:

- diameter of pipelines;

- pump power;

- room area;

- type of flooring.

These parameters also help to calculate the length of pipes for underfloor heating and their branches for heating rooms.

But how is power calculated?

Power calculation method

It is very difficult to independently calculate power, since it requires skill and experience. For these reasons, it is better to order it from the appropriate organization where process engineers work. If, however, the calculation is made independently, then the average value is 100 watts per square meter. This technique is used in multi-story buildings.

In private houses, the average power value will depend on the area of the building. Thus, experts have compiled the following indicators:

- area up to 150 sq. m. – 120 W/m2;

- area from 150 to 300 sq. m. – 100 W/m2;

- area from 300 to 500 sq. m. – 90 W/m2.

Having considered the methodology for calculating power, you need to calculate the number of pipes. But to do this, you should first familiarize yourself with the methods of installing them.

Where do the calculations begin?

Heated floor calculations should be made with special care. If shortcomings are made during the operation of the floor, they can only be corrected by dismantling the screed. Depending on the type of room, temperature indicators are recommended to be taken with the following values:

- For a living space, which includes bedrooms, a living room and a kitchen, the temperature is 29 degrees.

- Areas near external walls - 35 degrees.

- Bathroom - 33 degrees.

- For parquet flooring, it is recommended not to exceed a temperature of 27 degrees.

For installation of a heating system, it is recommended to use pipes of three diameters: 16 mm, 18 mm and 20 mm. If you plan to install an installation of short pipes, then for such purposes you will not need a powerful circulation pump.

Methods for installing pipelines for a water floor

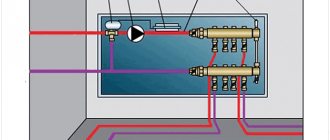

Before installing pipes, you need to plan their location. There are several methods, which are divided into the following forms:

- a snail of two bends;

- snake;

- double snake;

- corner snake.

Snail pipe laying is used in rectangular or square rooms. With this installation, heat is evenly distributed over the entire floor surface.

Snake laying is used for long and small rooms.

Calculation of the amount of pipeline for the heating system will depend on the chosen form of installation.

How many degrees are allowed when temperature changes

System design, in addition to heat and pressure losses, involves temperature changes. The maximum difference is 10 degrees. But it is recommended to focus on 5 °C for uniform operation of the system. If the specified comfortable floor surface temperature is 30 °C, then the direct pipeline should supply about 35 °C.

Pressure and temperature, as well as their losses, are checked during crimping (checking the system before the final filling of the finishing screed). If the design is done correctly, then the specified parameters will be accurate with an error of no more than 3-5%. The higher the t difference, the higher the floor power consumption.

How to calculate the pipe pitch for a water floor

Pitch is an indicator of the distance between pipes when installing a heating system.

The optimal step using a pipe is when the floor is heated evenly over the entire area. But here it should be taken into account that the step towards the edge should be no more than 10 centimeters, and in the center no less than 15 centimeters.

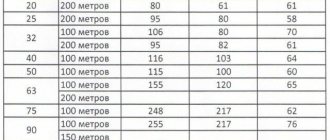

The following table will help you independently calculate the required pipeline length for the selected step.

[jtrt_tables id=»1108"] For effective floor heating, the interval between steps should not be more than 30 centimeters.

Outline length

In order for the heating system to be more efficient in heating the room, the optimal length of the circuit should not be higher than 80 meters. Since only in this case can the design create the necessary circulation and pressure in the heating system. But what to do if the calculations for the room require 130 - 140 meters of pipe? In this case, you will need to make several contours. Thus, if you need to install 160 meters of pipe, then you need to divide it into 80 meters and make two separate circuits.

They do not have to be the same in size, since, according to experts, the difference can be up to 14 meters.

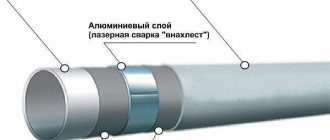

The calculation of a pipe for a warm water floor also depends on their models.

Pipe models for circuits

According to the recommendations of experts, the length of the pipeline laying form depends on the following pipe models .

- Made of metal-plastic and polyethylene with a diameter of 16 millimeters, the circuit can reach 100 meters.

- The maximum limit for a contour of polyethylene pipes of 18 millimeters reaches 120 meters.

- A circuit of 120 - 125 meters is used from plastic pipelines of 20 millimeters.

The calculation of a pipe for a heated floor depends not only on the manufacturing material, but also on the diameter.