Video description

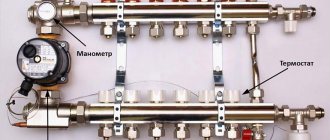

Pump in the heating system.

The coolant is heated using a boiler. The liquid then moves through the pipes, gradually releasing heat as the floor warms up. When it passes the entire circuit, the temperature is already lowered. Thus, during natural movement through the pipes, the heating of various parts will be uneven.

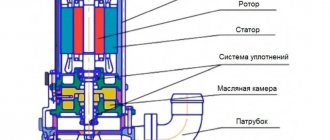

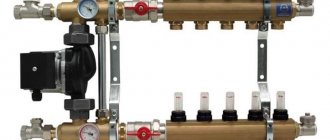

Design of a wet rotor pump Source bouw.ru

The situation changes when using a pump for water heated floors. Then the increase in heating occurs not due to an increase in the boiler temperature, but due to accelerated circulation. At the same time, heating of the entire area will become more uniform.

Heated floor pump Source teplowood.ru

Modular scheme on a wooden base

Provides for the use of ready-made OSB boards with sawn grooves for pipes and metal plates. The thickness of the slabs is at least 22 mm; in the diagram, the installation of thermal insulation is provided in the ceiling. The variety of modules in configuration allows them to be placed in the desired sequence according to the developed scheme. Depending on the pitch of the plastic pipe, it is possible to use strips measuring 130–280 mm. They have convenient latches for fixing pipes. Sizes 150 mm, 200 mm and 300 mm. After assembling the pipes and checking them for leaks, the circuit is covered with gypsum fiber boards.

Warm floor on a wooden base

Photo of laying heated floor pipes

Is it necessary to install a pump?

For some types of heated floors, you can do without installing a water floor pump. However, there are situations when it is necessary. This happens, for example, in the following cases:

- The installation of a heated floor requires ensuring the optimal location of the pipes. It is important that the heating of the floor, air and objects in the house is uniform. If this rule is violated, materials may be damaged. For example, exposure to heat can deform parquet. The connected pump will increase the circulation rate of the coolant and prevent overheating in certain places.

- If the pipes for fluid circulation have a small cross-section, this increases energy losses. A pump for a water heated floor will speed up the movement of water, and this will ensure a more uniform heat transfer. If this is not done, the boiler will overheat, which will lead to increased wear and tear.

- Rooms may have floors made in different ways. For example, one room may have laminate flooring, while another may have parquet. Their heat capacity will differ, which will ensure uneven heating. Increasing the rate of fluid circulation will lead to a more harmonious distribution of heat between rooms.

If the rooms have a large area, then if the water flows slowly, it will give off heat too quickly. If you install a pump, this will increase the speed of its circulation.

How and why to bleed air when the circulation pump is running can be found in the video below.

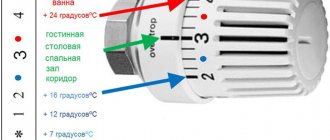

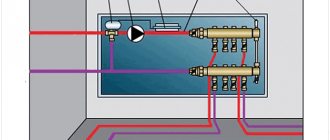

Automatic temperature control of TP

Automatic adjustment of a heated floor can be carried out thermomechanically or electronically using electromechanical actuators that control the operation of shut-off valves.

Thermomechanical control system

It is based on the operation of thermostatic valves or taps with thermal heads that respond to changes in coolant temperature. Various models of such shut-off and control valves are offered today by many manufacturers, for example, Oventrop. However, regardless of the name and type of thermosetting substance used in them (liquid or gas), these are thermomechanical self-regulating mechanisms that are most appropriately installed to control the temperature of one, individual circuit.

The operating principle of thermal valves is simple, which makes them very reliable and fault-tolerant. A copper, brass or bronze core installed in the device body, heated by the passing coolant flow, transfers the temperature to the thermosetting filler. In turn, the thermosetting element, which increases in volume, pushes the core, which, by moving the valve, gradually blocks the circulation of the heated liquid.

The thermostatic valve for heated floors, in addition to being installed on the distribution comb, can be mounted in a separate “unibox” type assembly. Such assemblies also include automatic air vents, which, together with thermostats, are placed in compact boxes (boxes). The use of a “unibox” allows you to adjust the temperature in a separate branch of the TP without being tied to bulky manifold cabinets, which is especially convenient with a small number of circuits.

In addition, thermomechanical floor heating controllers can have remote air sensitive elements. They allow you to configure them to control the flow of coolant not according to its temperature, but according to the air temperature in the rooms. The principle of their operation is the same, only the thermosetting substance is much more sensitive. It is advisable to install an air thermal head for simultaneous control of several circuits in one room, where water underfloor heating is the only source of heating.

Electronic control system

It consists of electronic thermometers, a controller and electric drives (actuators, servos). Electric drive mechanisms can be attached to the mixing heads of conventional control valves (valves) or be part of their design. The change in coolant supply intensity is carried out in accordance with specified threshold values. The measuring medium for the temperature sensors of the automatic floor heating temperature controller can be both the coolant and the air in the premises.

Video description

How and why to bleed air from the circulation pump.

A decrease in coolant temperature may depend on the following:

- Usually, when considering pumps for a warm water floor, it is assumed that the characteristics are taken for a temperate climate, typical of the European part of Russia. If we are talking about a region with colder conditions, then the coolant will cool faster. The power reserve of the device should be greater the further north it is planned to be used. Usually it is enough if it is 25%-30%.

- The longer the pipes for underfloor heating, the greater the difference between the initial and final temperatures. If there are several circuits in the house, each of them must be considered.

- Having good insulation prevents heat leakage. The smaller it is, the weaker the coolant cools during operation. For example, when the floor was made with technological violations, the temperature decrease can become significant.

If a pump is installed, it increases the speed of water flow. As a result, the heat distribution will be more uniform in each floor contour.

You need to consider what kind of power supply is needed for the purchased device. In this regard, the most common are those designed for 220 V. If the motor runs on a three-phase voltage of 380 V, it is more efficient and reliable. However, this pump can operate on a warm floor only where such a network is available.

Dry rotor pumps Source teplowood.ru

What data will be needed for calculation

Before you start making your own calculations, you need to determine for what purposes the heating system is intended - for the entire heating of the room or for individual rooms. Then you need to calculate preliminary data to calculate a warm water floor.

Let's consider the most important indicators that affect the efficiency of all heating equipment as a whole, and make a preliminary calculation of them.

Power

To save the family budget on the functioning of the comfortable lower part of the room, it is necessary to correctly calculate the heat loss power of the heating system

To do this, you should pay attention to the following:

- area of the selected room;

- height of doorways;

- location of windows;

- what are the walls made of?

- temperature selection.

You also need to consider whether there is an attic or balcony.

In order to make this calculation, you also need to pay attention to the design of the building where the warm water floor will be calculated. If this is a multi-story building, then in further calculations for power use an average value of 100 watts per square meter

If the system is installed in a private, one-story house, the power is determined depending on the area of the room, thus:

- 120 W/sq. m. - 150 sq. m. area.

- 100 W/sq. m. - from 150 to 300 sq. m. area.

- 90 W/sq. m. - from 300 to 500 sq. m. area.

The calculation of a heated floor is also affected by the length of the contours.

Circuit

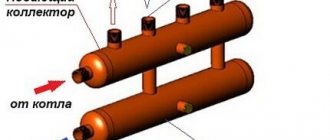

The efficiency of heating a room is affected by the volume of the heating system circuit, which is made in the form of a snake or snail. For better coolant circulation, the calculations include a circuit length of no more than 80 meters. If this is not a sufficient value for the area of the room, you can install two or more circuits, and also in this quantity enter them into the program for calculating heated floors.

It is worth noting here that the size of the contours depends on the characteristics of the pipes.

Pipes

There is a large selection of pipes that have different diameters and compositions. But for underfloor heating circuits, experts recommend choosing the following models:

- Metal-plastic with a diameter of 1.6 centimeters. A circuit of such pipes can reach up to 100 meters.

- Plastic with a diameter of 2 centimeters. From such pipes it is possible to construct a circuit of 120 - 125 meters.

- Polyethylene with a diameter of 1.8 centimeters. Of these pipes, the maximum circuit size reaches 120 meters.

Step

When laying out the contours, the average pitch between the pipes depends on the climatic conditions of the region. Thus, if in winter the average temperature is from – 19 to 22 degrees, the step is 15 centimeters. If the temperature is below these indicators, the optimal step is 10 centimeters.

Thus, given the ratio of the pitch and the square meter of the room, it is possible to calculate the length of the pipes for designing the contours.

These data apply to water heated floors only when thermal insulation is installed.

Thermal insulation

The program for calculating underfloor heating depends entirely on heat loss. If you carry out thermal insulation work correctly, you can not only save your budget by 20% in the future, but also achieve the desired results of the floor temperature regime. Thus, the floor in multi-story buildings is insulated with 5 centimeters of polystyrene foam; in single-story buildings, the thickness of the insulation should be at least 10 centimeters.

Heat loss in a residential building (apartment)

Pump operating principle

If a pump is installed in the system, it helps push water through the pipes. This mechanism is not intended to create excess pressure. The speed of fluid passage depends on how strong the heating should be. Therefore, it is more profitable to install pump models on heated floors in which this parameter is adjustable. For example, three-speed models meet such conditions.

The video below describes in detail the features of the GRUNDFOS ALPHA brand pump.

How to choose a pump for heated floors

When purchasing, it is important that the performance and pressure force match the floor design. How to calculate the pump power for a heated floor will be discussed below. Most often, heated water is used as the working fluid. Calculation of a pump for a heated floor includes determining the performance using the following formula:

Q = 0.86 x (P/(TN-TK))

The following notations are included here:

- P is the heating power of the heated floor, which is measured in kilowatts;

- TN is the initial temperature when the coolant enters the system;

- TK is the temperature of the water after passing through the entire circuit.

If several circuits are used, the values for each must be summed. In most cases, the temperature difference does not exceed 5 degrees.

Markings used for pumps Source teplowood.ru

You also need to make sure that the circulation pump you purchase for underfloor heating creates the required degree of pressure. This characteristic is important when using various types of pipe connections. The fact is that not only the pipe itself, but also each of them creates resistance to the movement of water.

The video will help you choose a pump.

The best manufacturers of such structures: a brief overview

There are quite a lot of manufacturers of such products on the shelves of furniture stores in Russia. But there are several brands that are the most popular. These are the ones we will talk about now.

This brand is on everyone's lips. But this is not what brought him popularity, but rather high quality products at reasonable prices. Here you can purchase storage system designers, or you can buy ready-made, assembled racks. The most popular of the line are the Elvarly and Algot models. We will talk about them.

| Model | Number of sections | Type of allocation | What can be stored | Cost, rub. |

| ELVARLI 1 | 1 | Shelves | Shoes, outerwear, hats | 9500 |

| ELVARLI 2 | 2 | Shelves | Shoes, long, short clothes | 19000 |

| ELVARLI 3 | 3 | Shelves, drawers | Shoes, various outerwear, underwear, bed linen | 41000 |

| ALGOT | 1 | Nets, baskets | Outerwear, small accessories, shoes | 3800 |

| ALGOT | 1 | Shelves, mesh | Outerwear, shoes | 3300 |

What is the quality of Ikea products? You can learn about this from the reviews of those who have already purchased a similar system.

Dressing room from Ikea - simple but tasteful

Modifications of Aristo wardrobe systems

Aristo wardrobe systems are distinguished by their versatility, as well as the quality of the steel from which they are made. They allow you to place not only clothes, bedding, but also various sports or household equipment.

The main feature inherent in their models is the maximum possible use of every centimeter of usable space, due to which, despite their apparent compactness, they have sufficient capacity. One cannot help but be pleased with the decoration of storage systems for Aristo wardrobes with valuable wood species, which give a finished look, fitting into almost any interior.

"Aristo" is mounted directly on the wall. Installation is quite simple

Features of Elfa wardrobe systems

Such storage systems are the most diverse. Depending on the wishes of the home craftsman, they can be installed not only as a wardrobe system. Elfa offers components for garages, laundries, children's rooms or kitchens. The assembly of any of the models is quite within the capabilities of a home craftsman, even alone.

The materials used to make Elfa storage systems are lightweight, but at the same time quite durable. The company itself has been operating on the Russian market for more than 70 years, which indicates its good reputation.

Wardrobe systems from the Leroy Merlin store

As such, the Leroy Merlin brand does not exist. This is the common name for various wardrobe systems purchased in this store. The range of such products in this hardware hypermarket is really very impressive, which allows you to select dressing room equipment to suit any needs. The difference in the cost of one model or another is sometimes also quite large.

However, with all the diversity of the assortment, the most popular are the manufacturers of storage systems for dressing rooms “Loveridge” and “Kansas”.

At Leroy Merlin you can find products of various brands

Advantages of the Loveridge wardrobe system designer

This system allows you to assemble almost any structure. It offers components from the Aristo and Shefilton brands that are suitable for such systems. This opens up great opportunities - after all, it is not always possible to find elements that are suitable in size or fastenings. Installation is incredibly simple. Here's what buyers of similar products say:

Wardrobe system "Kansas": products from a Chinese manufacturer

Here is the case when “Chinese” does not mean “poor quality”. An amazing combination of external lightness and strength. “Kansas” is three sections with a total length of 2.4 m. The depth is only 30 cm, which will allow you to install the system even in a narrow hallway. It is very simple to install. Netizens claim that even a fragile woman can install it. The total weight of the structure is 10 kg.

The tubes look rather weak, but this is not true

Video description

Water heated floor.

Choosing a pump for heated floors. The technical documentation indicates the resistance of each meter of pipe. Before calculating the pump for a heated floor, this parameter will need to be multiplied by the length of the pipe. To take into account the influence of various parts, appropriate numbers are used. For the valve, a value of 1.7 is taken. For each connection point the coefficient is 1.2. When using a powerful boiler, a mixer can be provided. For it the parameter is 1.7. To determine the pressure required for underfloor heating, the following formula is used.

H= (P x L + K)/1000

The formula contains the following notations:

- N represents the desired pressure force;

- P is the hydraulic resistance force of the pipes specified in the technical documentation;

- K is the power reserve factor.

When choosing a suitable model, it is necessary that the calculated parameters are in the middle of the characteristics. For example, if the pump is three-speed, then the indicated capacity and pressure must correspond to the second. Correct calculation of the circulation pump for a heated floor will allow you to choose the most efficient model.

In what position should the pump be installed Source teplowood.ru

When choosing, you need to consider the type of pump. The following varieties are used for domestic purposes:

- An advantageous solution is to use a wet rotor pump. The name reflects the fact that the blades are immersed in coolant. This solution is effective in cases where the area of the serviced floors does not exceed 400 square meters. m. Features of such pumps are quiet operation, low energy consumption and high reliability. During the pumping process, the rotation of the blades sucks in water and sends it further.

- The user can select a pump that uses a dry rotor. It is mounted in a separate container, which must be hermetically sealed. To ensure trouble-free operation, regular cleaning and lubrication is necessary. In such models, the rotor does not have direct contact with the liquid. It does not suffer from the hardness of the water used. Typically, such devices produce noticeable noise when operating.

How the pump works

Before choosing a circulation pump for a heated floor, you need to study this device in more detail. This mechanism is designed to pump coolant through underfloor heating pipes. It consists of the following elements:

- The main part of the structure is the body. It must have significant mechanical strength. For its manufacture, stainless steel, bronze or cast iron are most often used. Recently, the use of plastic housings has become increasingly common.

- The device has connections for connecting pipes. Industrial models use flange connections with a diameter of 40 mm or larger.

- Rotating blades are used to work with coolant. An impeller made of technopolymer is often used. This material is known for the fact that it practically does not wear out.

- The impeller is driven by an electric motor. It is usually mounted on the side of the body. It determines all the main characteristics of the pump.

When installing a circulation pump for a warm water floor, it is recommended to place it in such a position that the motor shaft is horizontal. If this rule is violated, the device may lose up to 40% of its power.

Connecting a floor pump Source lucheeotoplenie.ru

Features of installation and use

When using the floors in question, the coolant is usually low temperature. This makes it possible to install the pump both on the inlet and on the branch after the boiler. If we are talking about a private house where there is more than one floor, it is recommended to install the unit on each of them. If the system uses a mixing unit, you need to install the device after it. This will ensure the correct temperature for the pump to operate. Before choosing a pump for a heated floor, you need to decide where to install it.

Correct installation will ensure high-quality operation of the device Source nicespb.ru

After installing the pump, before starting it, you need to bleed the air from the system. This will avoid the formation of traffic jams. Some designs provide for the use of a special valve for this purpose. If the pump has not been operated for a long time, it is recommended to disassemble it and thoroughly clean it of deposited salts.

Installation of the pump on a heated floor must provide a place where there is easy access to the equipment. In this case, the owner will be able to easily maintain and repair the device. If you are using a motor that makes a lot of noise during operation, it is recommended to install it in a technical room.

It is recommended to bleed the air regularly, every 1-1.5 months. If traffic jams occur more often, it means that errors were made during installation. The unit must be lubricated annually. It is sufficient to descale a wet rotor once every three years.

For floors larger than 50 sq. m pump installation is necessary Source b2b-instrument.ru

Recommendations from experts

To extend the life of the pump, you must remember the following rules:

- The unit must be installed in a place where, if necessary, repair work or warranty service can be carried out without problems.

- Despite the fact that imported pumps are of high quality, before the start of the heating season it is necessary to check their technical condition due to the low quality of water and the peculiarities of operating conditions. Particular care should be taken to inspect the condition of the oil seal, which ensures waterproofing of the device shaft from the rotor.

On the eve of the start-up of the floor heating system, it is necessary to remove any air pockets in it. For this purpose, the water is changed several times and a special valve is installed. The presence of air pockets will become an obstacle to the movement of liquid, and the automation will constantly begin to turn on the circulation.

Nowadays, underfloor heating systems are becoming increasingly popular. They are used both for heating the premises as a whole and for heating its individual segments. Installation of underfloor heating systems is carried out in apartments and individual housing constructions. After all, it’s always nice, and even useful, to splash your bare feet on a warm surface.

By design, underfloor heating systems are either electric or water. It is for the second option that a circulation pump is needed, which is the heart of the entire system.

Possible faults

With use over time, the user may encounter problems. The most common of them are described below.

Tap water is often used as a coolant. During operation, salts will be deposited on the blades. This gradually leads to a decrease in the quality of work and increased wear. Often this problem is encountered with the onset of autumn.

After a long break in operation, deposits appear on the blades. This may result in the pump not starting one day. After switching on, it will begin to hum, but there will be no movement of water. If you turn the impeller manually several times, it will begin to rotate and the pump will be ready for operation.

Internal structure of a floor pump Source prouteplenie.com