Home » Equipment » Warm floor

For an underfloor water heating system, it is recommended to install an automatic control unit. The equipment allows you to control the temperature in the room and regulate the operation of the liquid line.

The simplest device for controlling heating is a three-way valve. Its operation can be done manually, using valves, but achieving a certain mode in the room will be difficult.

Purchase thermostatic equipment. It is used in Moscow and other large cities. It allows you to make underfloor heating autonomous. How does a thermostat work? What is its working pattern?

Types of faucets

With the development of plumbing equipment, various ways have emerged to combine the high-temperature radiator circuit and the low-temperature floor circuit. That is, the market offers a mixer, and not just one. According to the degree of complexity and cost, they can be distributed in the following order:

- Installation of valves for supplying heated floors;

- Installation of a thermostatic mixer;

- Installation of mixing unit.

Today, each of them is actively used in apartments, houses, public institutions and so on. They all have their own advantages and disadvantages.

Valve

In fact, this is the simplest and most affordable way to reduce the temperature in the tubes that distribute the coolant across the floor. You just need to install special valves on the return and supply. Their operating principle is approximately the same as that of heating radiator regulators. That is, you tighten the valve, as a result of which water circulates through the pipes of the circuit more slowly. Due to this, the temperature decreases.

Unfortunately, this solution has limitations. So, it can be used indoors, the area of which is no more than ten square meters. Plus, manual adjustment does not allow you to determine at a given moment what the floor temperature will be after you unscrew or tighten the valve to one level or another. By installing it in one position, the temperature will become constant only after a day.

Thermostatic mixer

By the way, it is divided into three-way and two-way. Two-way valves are modernized, modified manual valves. The temperature can be maintained automatically. Such a valve must be installed in place of one of the two manual valves.

The advantages of this system include automation of adjustment. There is also a drawback, which is that the operation of the mixer is limited by the area of the room and the length of the pipes.

Three-way models function differently. Hot coolant is supplied, into which water from the so-called return is mixed. In fact, such mixers have the disadvantages and advantages of two-way types. But, compared to them, the three-way can change the temperature more evenly throughout the floor indoors.

Mixing unit

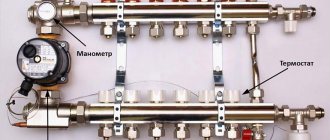

Such a device consists of the following elements:

- Thermostatic mixer;

- Supply manifold, return with the required number of outlets;

- Circulation pump.

The main advantage of this solution is that it includes a circulation pump. With its help, water, that is, the coolant, is transferred over a fairly large distance, quickly and evenly. Plus, other circuits can be connected to such a system.

We can safely say that due to the mixing unit equipped with a pump, it is possible to connect several heated floors equipped in the kitchen, living room, bedroom, and so on, to one system. In this case, the mixing units are divided depending on the mixing group. The basis of the first type of mixture is a three-way mixing valve with a servo drive. With its help, it is easier to control thermostatic devices, connect temperature sensors and controllers. This scheme is used in the vast majority of cases.

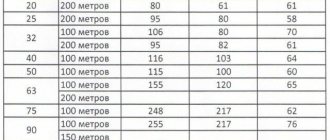

The second type consists of a two-way valve and constantly mixes cold and hot water. The advantage is that it is almost impossible to overheat the floor with such a system. However, experts do not recommend using collectors of this type in rooms whose area exceeds two hundred square meters.

"Smart" programmable thermostats

Devices that can themselves change the temperature level in a room in the absence of people are much more complex, but the savings from their use are enormous. The costs of purchasing and installing them will pay off in the first winter season. We are talking about programmable thermostats. They can serve several circuits simultaneously. It is possible to connect to the “smart home” system.

A programmable thermostat solves many heating problems and ensures a comfortable stay in the room. Allows you to set certain days, hours and weeks to a given temperature. Therefore, even in the absence of the owners, he himself will switch the heating system to economical mode. All information about its operation is displayed on the display.

They can only be installed by a specially trained technician. This equipment is expensive and requires careful handling, but it is completely worth it.

Faucets price

In fact, you can choose the necessary mixer designed for a warm water floor at different prices. Moreover, the cost can vary significantly. So, if the most affordable thermostatic mixer can be found for $30, then the mixing unit may well cost the buyer $1,000. If we take into account average prices, then the situation will look like this:

- About $45 will be asked for a two-way thermostatic valve;

- Approximately $50 will be required for three-way models;

- A mixing unit for a warm water floor will cost about $750.

Yes, a completely prefabricated unit can cost a pretty penny. With all this, they are not very convenient for installation and subsequent maintenance due to their compactness.

If you wish, you can assemble a system that will cost one and a half times less. To do this, the unit is assembled independently; a polypropylene comb is connected. The equipment will be more massive and will require more space to accommodate it. But it is much more convenient to access it. What can we say about the final cost?

Whatever one may say, the installation of all floor heating systems should be trusted to specialists. This is very complex equipment, the installation of which can only be approached with experience, qualifications, and self-confidence. Finding masters of this craft is frankly not difficult.

The installation of water-heated floors in a home requires compliance with a number of essential conditions. In fact, it doesn’t matter whether they are made in a separate room or throughout the house. Since this design does not have such a high temperature (up to 50 degrees) than the batteries we are used to (up to 90 degrees).

It is for combining these two consumers in one circuit that the mixing unit for heated floors is designed. In this article on the “Our Home and Yard” website we will try to understand its purpose, the most important aspects of its operation and structure.

Heated floor mixer

The primary purpose of the underfloor heating mixing unit is to mix hot supply water with colder water from the return circuit, which means that you can always control the temperature of your floor. In addition, compliance with the conditions of SNiP, according to which the temperature of the liquid in the water floor system should not be higher than 55 degrees, will protect the screed from destruction and the flooring from drying out.

The main element of this device is a thermostatic mixer for heated floors, which performs the function of mixing water . Also, as a rule, the system contains a pump; without it, circulation of the coolant is not possible - the water resistance is very high due to the long length of the pipes. But for small circuits the pump is not used.

You can buy a mixing unit for heated floors in specialized plumbing stores or order online. But if you wish, or in order to save money, you can make it yourself; to do this, you first need to study the assembly diagram and purchase the elements separately.

Thermostatic mixer for underfloor heating

Various thermostatic mixers can be used as possible design options that reduce the temperature in the pipeline:

- three-way mixer for heated floors with an electric motor drive;

- the same valve, but with a thermomechanical drive;

- two two-way valves as a mixer for underfloor heating, installed on the supply pipeline and on the bypass.

Each point following the first can significantly reduce costs on mixing equipment, without allowing any loss in quality. It should be understood that there are many more schemes than indicated; we have listed only the most common ones.

It is theoretically possible to completely abandon the mixer only if the boiler is not connected to heating radiators, so it can be set to a low temperature, or the room in which the water heated floor is installed is small in area.

In water floor systems, two main types of collectors are common today. These are mixers with two-way and three-way valves. In any case, a thermostatic mixer for heated floors is meant, that is, a system that smoothly and as necessary regulates the temperature of the coolant .

Sometimes there is no thermostatic valve, then the temperature in the system is controlled manually, but in this case increased energy costs are possible.

The most important problem that the developers of thermostatic mixers sought to solve is the stability of the coolant temperature, and, in fact, the operating principle of any thermostat is the same.

When the thermostat is open, water flows through it, and when it closes, in response to an increase in coolant temperature, water flows through the bypass line, preventing the heating system from further heating the floor surface.

Ideal living room temperature

According to accepted standards, the air temperature at head level should reach 20 ℃, and at the feet it should be about 22-24 ℃. It is worth noting that it is impossible to create such conditions using wall heaters alone. Due to the characteristics of air circulation, its lower layers will be the least heated - no matter what type of heating is used and how warm the room is.

Warm air in the floor area can only be obtained by laying heating elements under the floor covering. In this case, you will definitely need a three-way thermostatic mixing valve for underfloor heating.

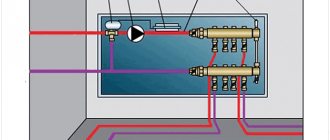

Diagram of a heated floor mixing unit

Externally, the entire underfloor heating system looks like a connection of several pipelines into one. This connection can be made in different order. Essentially, there are three main types of connections: parallel, serial and combined. Sequential mixing is considered the most effective; for parallel mixing, it is necessary to install two-way valves.

In accordance with the selected connection system, the layout of the heating floor mixing unit also changes. The most common includes tees-pipelines, valves on two branches - return and supply, a pump and automatic control systems.

The choice of a mixing system depends on many factors, ranging from the material from which its elements are made, and ending with the features of the heated floor system itself.

And at the end of the article I would like to offer a video on the topic: heated floors and a mixing unit for it.

Tips for choosing

The selection of a thermostat model for a water floor depends on several circumstances: the volume of the building, boiler connection, floor covering, environmental climate, availability of additional or main heating systems.

Purchase criteria:

- Price. The most profitable varieties are mechanical type products. They perform better and are almost impossible to damage due to carelessness. Such thermostats are suitable for those who have children.

- Multifunctionality. Electronic products are excellent at controlling heat in rooms.

- Programmability. This criterion allows us to provide the most comfortable conditions in every room of the house.