Place and role of mixing valves in the heating system "warm floors"

The main task that consumers have to face when deciding to install heated floors in their home is to achieve the required coolant temperature. For radiators, water at a temperature of 750C is quite acceptable, which cannot be said about pipes that are laid in the thickness of a concrete screed.

Important! Excessive heating of the concrete screed leads to a deterioration in the temperature balance inside the heated room. At high temperatures, flooring (in most cases wood-based) quickly loses its aesthetic and technological qualities, becoming unusable.

In accordance with sanitary standards, the normal heating temperature of heated floors should not exceed 260C. Then the middle layers of the air mass inside the room warm up to comfortable values of 20-220C. In order to obtain such temperature parameters, the water entering the loops of the water circuit must be heated to 500C. Slightly less than 50% of the thermal energy of the heated water is spent on heating the layered cake of the heated floor. Taking into account the thickness of the concrete layer, material and type of floor covering, the temperature on the floor surface decreases.

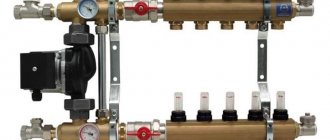

A mixing unit, which is a set of interconnected instruments and devices, helps to achieve a significant reduction in the temperature of the boiler water at the entrance to the heating water circuits. One of the main roles in the operation of the mixer is played by the thermomixing valve, which mixes water for the heated floor. Thanks to this small device, two streams of water are mixed, cold and hot, so that the output is water at the required temperature. Valves installed in mixing units are of two types, three-way and two-way. Each type of crane performs its own tasks and functions determined by the technological process. Which device is best to use for your heated floors? What is behind the choice of the type of mixing and control device?

Thermostatic valve and control valve - differences

The use of thermal valves on a single-pipe heating system is especially important, but only if it is not flow-through. That is, if there are jumpers at the junction of the radiators - bypasses. It happens that there are no bypasses. As a result, the coolant sequentially passes through all radiators, one after another. Installing a thermostatic valve on such a system can only cause harm. Because the thermostatic valve will turn off all radiators located after it. Therefore, if for some reason it is very necessary for a flow-through system, it is better to install a control radiator valve. And don't cover it completely.

The difference between a control valve and a thermostatic valve is the ability to adjust the gap for the passage of coolant - more or less. The thermostatic valve, on the contrary, can only be in two positions. Firstly, it is open to a certain, previously adjusted level. Secondly, it is completely closed. Therefore, there is no need to install a thermal valve on a flow-through heating system without bypasses. Since, when the valve is closed, the circulation of coolant throughout the system will stop. This will create cooling and unbalance the heating system. It will also have a negative impact on the heating boiler. The situation can be aggravated by the absence or poor functioning of the safety valve. That is, a breakthrough may occur in one of the weak points of the system.

What materials are they made from?

Corrosion-resistant metals are used to make the thermostatic valve body:

- Brass.

- Bronze.

- Stainless steel.

Additionally, the surfaces of brass products are nickel-plated, and the bronze body is either also nickel-plated or coated with a layer of chrome.

Advantages and disadvantages

The advantages of installing thermostatic valves in the heating system include the following factors:

- Energy independence of the device.

- Compactness.

- High precision temperature control.

- Easy to operate and highly reliable.

- Aesthetic appearance.

- The optimal combination of price and functionality.

The disadvantages of using thermostatic valves are:

- Difficulty setting up.

- There is a danger of the thermal head malfunctioning under the influence of a draft or a nearby stove.

Methods of use

The three-way valve can be installed either in the mixing unit or without it. In the second case, the device completely takes over the collector function.

Installation of a tee for adjusting the water temperature of a heated floor without additional mixing devices is carried out in rooms whose area does not exceed 25 square meters. The supply of liquid at the desired temperature is carried out through a control device and a thermostat installed in the valve itself.

Installation according to this scheme is suitable for bathrooms, toilets and balconies. The disadvantage of installing a three-way valve as the main device for mixing hot and cold coolant is the inability to dose flows.

When installing a floor heating system for large volumes of living space, a three-way valve is a component of the manifold group. In such cases, the device ensures a complete uninterrupted process of all heating equipment. Due to it, liquid at the required temperature enters all circuits of the floor heating system.

The three-way valve is effectively used in facilities with a large area - more than 200 square meters. In this case, the warm floor can operate both from an autonomous network and from a central heating system.

Types and their structure

In a thermostatic distribution valve installed on a heated floor, the heated water is mixed with cooled water from the return pipe. This process is continuous as long as the heating is on.

There are two-way and three-way mixing valves for underfloor heating. They also differ in the method of mixing and the direction of flow.

Two-way

The two-way thermostatic valve is an improved manual type model. It can be hydraulic, pneumatic or electrically driven.

The design is simple, but capable of effectively regulating the temperature level of the coolant in automatic mode. The device is mounted in the heating system, instead of a manual valve.

Main advantages:

- Automatic reduction of liquid temperature level;

- Simplicity of design and low price;

- Easy installation.

Disadvantages - the possibility of installing it on pipelines with a small size. If you use this faucet when installing heating in a room with a large area, the thermostat will function intermittently. A two-way valve is more often used if heated floors act as additional heating.

The valve device is a brass or bronze body, with one or two seats. A double-seated valve can completely shut off the flow of water.

The device is equipped with a thermostatic head with a scale. The head position can be changed manually or automatically. Manual models are simple and inexpensive. More modern devices work automatically.

The two-way valve operates according to the following principle - the coolant from the return line is again supplied to the floor pipes, but before this, a device is activated that opens the supply of heated water. The two flows are mixed inside the housing to the desired degree, then the temperature sensor is triggered and the shutter automatically closes the hole with the hot coolant.

The valve consists of a plunger and a seat. The plunger has a disc, needle and rod shape. It is located perpendicular to the movement of the fluid.

Three-way valve

The operating principle of a three-way thermostatic valve for floor heating is that cooled water from the return line is added to the hot water coming from the boiler.

The valve is designed for heating systems that are installed in large rooms. They have the same advantages as two-way valves. Particularly worth noting is the ease of adjusting the water temperature for heated floors.

But this thermostatic valve also has a minus - if the thermostat is triggered, the valve opens completely, thereby allowing hot coolant to enter the circuits. And this can cause overheating of the heating system, and even rupture of pipes. In addition, it has a lower flow capacity than a two-way valve.

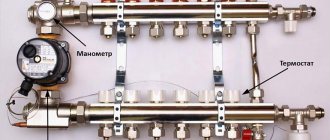

Three-way thermostatic mixing valves are available in brass and bronze. They are equipped with a thermal head or thermostat, and can have an electric drive or a servo drive. The design is a faucet with two inlets and an outlet. Inside the case there is a mixing chamber, on which there is a thermostat with a regulator on which there is a digital panel. A thermal valve is connected in front of the manifold.

Operating principle of three-way thermostatic valve:

- heated water moves through the right and front pipes - if its heating degree meets the required parameters;

- if the temperature of the liquid increases or decreases, the thermostat comes into operation, it sets the rod in motion, as a result, cooled water is mixed with hot water;

- after reaching the set temperature, the front hole opens completely.

It should be said that when the device is turned on, the water flow voltage does not change. This leads to a uniform change in the temperature of the liquid supplied to the line.

Features of Three Way Valve

Mixing fluid flows, which a thermostatic mixing valve allows, makes it possible to direct flows with a stable, standard temperature into the underfloor heating system. This operation is performed automatically. For mixing that takes place inside the device, already cooled liquid from the “return” is added to the hot water.

Description of three way valve

Operation occurs in the following sequence:

Operating principle of three-way valve

- hot water flows to the collector included in the underfloor heating system;

- when passing through the thermo-mixing valve, the degree of heating of the liquid is determined;

- if the water temperature is higher than the set one, then a passage opens into which the cooled liquid enters;

- two flows are mixed inside;

- after reaching the desired value, the cold water passage closes.

Among the disadvantages of three-way valves, there is the possibility of sudden temperature jumps that occur during the start-up of heated water, which negatively affects the condition of the pipeline.

Heat supply and treatment to the floor of a three-way mixer

This faucet, made of brass, has three strokes in its design, which determine the use of different methods of mixing liquid flows, depending on which there are three types of three-way valves.

Overall and installation dimensions of the three-way valve

- Valve with the thermostat function required for heated floors. Such a device not only regulates the intensity of the mixed flows, but also ensures that the system maintains a given temperature. This function is facilitated by the presence of a heat-sensitive element, which, by detecting the degree of heating of both flows entering the tap, changes the cross-section of the holes.

- The three-way thermostatic valve of the second type is distinguished by the fact that it provides regulation of the supply intensity of only the hot flow. The package includes a thermal head with a remote sensor.

- You can also select a mixing valve from the assortment of three-way models that does not automatically maintain the set temperature.

By mixing method

Mixing taps for heated floors, depending on the mixing method, are:

- With a thermostat function - with it it is possible to achieve and maintain the desired degree of heating of the coolant, since the device is able to regulate both flows (heated and cooled). The thermostat in the mixer, reacting to the level of heating of the liquid, opens or closes the hole through which heated or cooled coolant is supplied. In addition, the mechanism is designed in such a way that in the absence of cold water, the automation shuts off the flow of hot water.

- Thermostatic - the device is equipped with a sensitive thermal head that has an external temperature sensor, it is located in each line. The operation of the valve is to determine the water temperature and send a command to the actuator.

Gas or liquid

The effectiveness of a thermostatic valve depends on the properties of the substance in the bellows. Gas-filled thermoelements are more accurate and reliable. They respond faster to temperature changes, but are more difficult to produce and therefore more expensive.

Liquid ones work a little slower, but are easier to manufacture. The advantages of liquid thermoelements also include the high accuracy of transfer of the internal pressure of the bellows to the thermostatic valve stem.

With remote sensor

Thermal valves with a remote sensor are designed for installation in radiators with a bottom connection or located in a niche. The thermostatic head is mounted on the valve using a threaded connection, and the temperature sensor is attached to the wall in any convenient place. The head and sensor are connected to each other by a capillary tube.

Such models maintain temperature more accurately, but are more expensive than others.

Criterias of choice

The technical characteristics of a three-way device have a significant impact on the quality of underfloor heating. Therefore, when selecting a valve, it is worth considering the following indicators:

- The volume of the heated room. Heating large areas requires the installation of a three-way valve with automatic regulation, which independently controls the temperature of the coolant entering the pipeline of the floor heating system. For small rooms there is no need to buy expensive mixing devices with a complex design. A simple valve is suitable for heating balcony rooms, bathrooms and small corridors.

- Throughput indicator. The maximum level of liquid pumped by the mixing valve is determined at the beginning of the design of the floor heating system. The three-way valve must meet the established flow rate, otherwise the device will not withstand the pressure load.

- Cross section diameter. This parameter is necessary to connect the mixing device to the heating system. If necessary, special adapter devices are used that allow precise connection of devices.

- Material of manufacture. The valve must be made of metal that has a low expansion coefficient and does not change its original characteristics when interacting with a hot coolant. Three-way valves made of bronze and brass have these properties.

It is recommended to purchase mixing devices from trusted manufacturers. The product must be accompanied by warranty documentation, instructions with the specified technical characteristics and a quality certificate.

When choosing a three-way valve, consider the flow rate

Before installing a three-way valve in a heated floor system, you should check the device for functionality. To do this, set the control ring to the lowest temperature value, and then pass a hot stream of water through the valve. A properly functioning device should immediately close the hole.

How does automation work?

A thermostatic three-way valve for underfloor heating is connected in front of the manifold. A certain temperature heating mode is set on the sensor. The device starts working when the parameters are changed.

- The device consists of a semiconductor, which has the temperature of the coolant entering the line. Energy is transferred to the thermostat fluid.

- As the heat increases, the liquid expands and puts pressure on the rod, which lowers.

- In this case, the outlet from the hot pipe is closed and the outlet from the return circuit is opened.

- The cooled coolant enters the three-way mixer chamber, where it is combined with hot water from the boiler. The mixing process can take place according to a T-shaped pattern: hot and cold coolant flow enters the thermostatic mixing valve symmetrically from both sides. The liquid exits into the main line at an angle of 900. With an L-shaped design, hot water enters the mixing chamber from the side.

- The coolant temperature decreases. It enters the floor line cooled. The heating mode strives to reach the set norm.

- As the temperature drops, the liquid in the thermostat contracts. The spring-loaded rod straightens, closing the outlet of cold water that flows through the return pipe. Hot coolant again enters the main line.

When using servo drives, a device that operates from the network is connected to the mixing valve for heated floors. The sensor heats up and closes the electrical circuit. The plate is heated, which in turn transfers heat to the thermal fluid. It expands, pressing on the rod, which makes the poppet valves work.

When using a servo drive, the heating system changes operating mode within 3 minutes. If you use a thermal head as an automatic device, it will take up to 15 minutes to heat the liquid in the thermostat.

The operating principle of a two-way valve for underfloor heating is somewhat different. When the temperature in the main increases, the thermostat causes poppet valves or a ball device to operate, which completely blocks the outlet for hot water. The cooled coolant from the return pipe returns to the floor circuit.

When the temperature decreases, the valve opens hot water and closes the return flow. There is no mixing of the liquid. The principle of operation of a two-way thermostatic valve for underfloor heating is identical to manual switching of valves, but the system operates in automatic mode.

A three-way thermostatic valve for underfloor heating is installed in a heating system for a large heating area. The equipment is necessary for a boiler that heats water to a high temperature. A two-way valve is connected to the system as additional heating control for individual rooms.

Equipment for automatic control of the heating mode can be installed in a single-circuit or double-circuit heating system. This is convenient when using various types of heating, radiator and floor. The mixer is connected before the circulation pump. I recommend installing a water filter first. When connecting, use the threaded installation method.

How to choose equipment?

Thermostatic devices are selected depending on the throughput of the coolant. It must correspond to the volume of liquid that is pumped into the heating system. The data is indicated in the technical data sheet for the boiler.

For the hot and cold circuits, metal pipes with a diameter of 26 * 2 mm are used. The nozzles of a three-way mixer should have the same diameter. Otherwise, you will have to install adapters, which is not desirable for a heating system. The seams bear a high load. It is always necessary to ensure their tightness.

The liquid temperature in the floor line is 55-35 0C. The equipment is selected depending on the specific thermal regime that can be set on the thermostat. Radiator heating requires a wider temperature range, up to 80 0C.

To control the temperature in a room with water underfloor heating, thermostatic equipment is used. Automation will facilitate the operation of the heating system, ensure a normal microclimate in individual rooms of the cottage, and save energy.

When using the device with software, it becomes possible to regulate the temperature of the floor line depending on the time of day and days of the week.

General principles of adjustment

Three-way mixing valves, depending on the type of control mechanism, are divided into several types:

- Standard. Adjustment in such devices is carried out due to the expansion of the coolant in the pipeline. The liquid in the system heats up to maximum levels and pressure occurs on the shut-off part in the valve, blocking the access of cold water. As a result, the valve opens and the cooled flow mixes with the hot coolant. The accuracy of the working process for such products is not high.

- With thermal head. The design of the three-way valve includes a thermal head, which is equipped with a special sensitive element that reacts not only to the temperature of the liquid in the system but also to the heating indicators of the air masses.

- Electrical. In electrically driven valves, commands are sent by a controller that activates temperature sensors without additional devices.

- Electronic. The temperature control of such a valve is carried out thanks to a built-in electric motor and a control device equipped with thermometers.

The most common are mixing valves with a thermal head. They are equipped with a sensor and do not require an additional connection to the electrical network. At the same time, the device is distinguished by accuracy and wear resistance. Standard valves are installed when water is supplied to a system with a constant temperature regime.

Installation of a three-way valve requires careful approach. Incorrect connection of the mixing device can cause not only a decrease in the efficiency of the heated floor process, but also lead to emergency failures of all heating equipment. Therefore, if you lack the skills, it is not recommended to install the valve yourself.

How to choose a thermal head?

The floor covering heating system has a mixing unit, the most important element responsible for changing the parameters of the heating circuit. This is due to the fact that the moisture from the heating equipment enters the pipeline too hot, sometimes up to 90 degrees Celsius, and inside the screed there can only be a maximum of 40 degrees Celsius.

In order not to overheat the system, a thermal head is installed on the damper, maintaining acceptable parameters of the coolant. The mixer is responsible for bringing together the temperatures of different flows, as a result, antifreeze or water of the required and permissible temperature enters the water circuit.

Types of thermal heads

Depending on the substance in the bellows, thermal heads can be gas, liquid or paraffin based. Liquid - inertial, working slower, taking a long time to heat up and cool down, but the most accurate.

Gas ones have a large error and are vulnerable to drafts. Inside the head there is a mnemonic diagram on which zones with temperatures are marked.

The thermal head can be controlled mechanically or electronically. Manual, mechanically controlled, have a radial scale with marks of 2...5 degrees. Turning the knob will increase the distance between the elements and increase the pressure on the rod.

Electronic devices are controlled by a display, and an electric drive presses on the rod. Such equipment is more expensive, but is highly accurate.

The thermostat contacts the surface in several ways, so the thermal head can be a surface-mounted one, with an air sensor, or an immersion type.

The thermostat heats up at the place of fixation, and the overhead and air thermostats are connected to the sensor by a sealed capillary-type tube. The bellows expands from the heating of a canister located remotely - such units are used in heated floors.

What does a three-way valve for heating with a thermostat do?

Why regulate heat flow?

The area of the room is taken into account, and then possible heat losses are analyzed. Based on this, the performance of the heating system necessary to create a comfortable microclimate in the rooms is calculated. After that, a heat balance is compiled for all rooms.

- temperature changes outside;

- solar Activity;

- wind force;

- the presence of household appliances that generate heat.

As a result, the calculated temperature balance is disrupted and the room becomes hot. However, it is impossible to remove parts of the radiator from the room or muffle thermal radiation. Thus, there is a need to manage the energy generated by heating devices in order to maintain a comfortable microclimate in the room.

There are two ways to regulate the energy released by the radiator:

In both cases, manipulations with the liquid circulating through the pipes are necessary.

In order to regulate the microclimate in the room, you can switch the heat generator to a different operating mode - as a result of which the temperature of the water supplied to the radiators changes.

You can switch the mode on a wall-mounted boiler if we are talking about a country house. However, the situation is much more complicated in the case of a boiler house in an urban neighborhood.

Quantitative regulation of heat flow using a three-way heating valve with thermostat

A three-way valve for the heating system and a temperature controller installed on the radiator can be used separately, however, in autonomous heating systems of modern apartments and private cottages, a combined method is often used to increase efficiency. Thus, it is advisable to purchase a three-way valve for heating with a thermostat.

It is important to consider that the operating principle of a three-way mixing valve allows you to increase or decrease the radiator temperature only within established limits. These limits are dictated by the technical characteristics of the heating device, namely, the value of its maximum heat transfer, and depend on each specific radiator.

To understand how three-way valves work in a heating system, it is important to understand its structure.

Visually, this device looks like an ordinary metal tee. The material for making the valve is usually brass, sometimes cast iron or steel is used. There are three pipes in the device body.

The operating principle of three-way valves in a heating system, depending on the type of actuator

Three way valve actuator types:

Changing operating modes of heated floors

The thermostat is an effective solution for monitoring the water temperature in the heating circuit. This method is inexpensive and accessible to almost every owner. The boiler heats the water to 90 degrees, and water should flow to the floors at a temperature twice as low.

The desired degree can be achieved thanks to the thermostatic head:

- The supply of hot water is short-term - the water fills the pipeline, the supply ends until it cools to an acceptable temperature;

- Constant water supply with the addition of cool coolant from the return pipe.

Periodic short-term supply

With a short-term water supply, the system works in a small space - a bathroom, ceramic floor in the toilet, shower room and other places. At the supply point there is a valve with two strokes, a remote-type floor sensor and a thermal head.

As soon as the circuit is filled with coolant, the sensor is triggered and the flow is blocked by the valve. After some time, the screed will cool down, the valve will open again and hot water will fill the system. This circuit is economical and can replace the mixer unit.

For heated floors, special thermal heads from the RTL series have been developed, without an external sensor. They are installed on the return line to maintain the set water temperature without depending on the heating of the floors. By installing this model of thermostat, the automation changes the threshold heat values (no more than 40 degrees Celsius).

The installation feature is installation in an exclusively horizontal position. Experts from Moscow do not recommend setting the water level in the floors lower than the temperature in the room.

Periodic short-term injections of water into the circuit allow you to maintain stable movement along the coolant circuit without overheating the system.

Constant coolant supply

A constant supply of water requires the installation of a three-way valve in the system, complemented by a floor sensor and a thermal head. Using a tee, a connection is made from the return to the third stroke of the mixing unit. The direct water supply must always be open, so the valve must be installed professionally and correctly.

Experts recommend installing the thermal head on a three-way valve using a locking type axle box. When the sensor heats up, the valve stem moves and a gap is formed inside. This gap receives cool water from the return line.

This sequence of work allows the coolant to stably enter the circuit, while the temperature remains within acceptable limits. Due to the continuity of the flow, the floor covering quickly heats up to 28 degrees Celsius and remains comfortable for the owner, and the circuit does not overheat.

Pipes and screed will last longer due to the absence of excessively high temperatures. The addition of cold coolant is important for heating large rooms where a comfortable temperature is needed.

Advantages and disadvantages

Advantages of three-way mixing valves:

- Simple design.

- Stable regulation.

- Reliability.

- Tightness.

- Sufficient adjustment accuracy (maximum accuracy – up to 1°C).

- Durability.

- Relatively compact dimensions.

The biggest advantage of using three-way valves is that the pipelines and, accordingly, the screed and floor covering do not overheat, which prevents premature failure of the screed and coating.

Flaws:

- The hydraulic resistance of three-way designs is higher than that of a conventional two-way valve.

- The design of the body and spool allows for the presence of stagnant zones - periodically you will have to dismantle the device and clean it of scale, debris, and organic impurities.

- Insufficient accuracy of room temperature control. The control valve quite accurately regulates only the temperature of the outlet coolant, and the temperature of the heated room - approximately.

To ensure a comfortable level of heating, you will have to select the ratio of the temperature of the outlet flow and the temperature in the room “at random”. Unfortunately, the underfloor heating pipelines are much larger than the radiator, and it is impossible to ensure accurate adjustment. The situation is further complicated by the inertia of the heated floor - a 100-mm cement screed warms up very slowly.

But if you are stoic about slowly heating or cooling a room, then a valve with mechanical adjustment is quite suitable for use in the heating system of a private house or apartment.

Much greater comfort is provided by electrically driven valves controlled by a smart home system with temperature sensors in each room. But such devices are very expensive.

Large areas

Installing heated floors as the main type of heating involves installing full-fledged mixing equipment that is capable of dividing the flows into two - heated floors and central heating. Here, three-way thermostatic valves with full flow into the system are required.

Experts recommend installing one common circuit where the working fluid is pumped by a pump. At the entrance to the heated floor there is a mixing valve. It is controlled by a special temperature regulator. The mixing valve is installed between the bypass and return. A sensor at the top of the valve regulates the set temperature.

If the temperature rises, the mixing valve closes the return flow. Further circulation of the working fluid occurs in the coolants of the heated floor.

Sources

- https://ProUteplenie.com/otoplenie/termostaticheskiy-klapan-dlya-teplogo-pola-vidy-i-kak-vybrat-shemy-montazha

- https://bph-saratov.ru/otoplenie/termostaticheskij-ventil.html

- https://OtoplenieBlog.ru/oborudovanie/teplyj-pol/kak-vybrat-termostaticheskij-klapan-dlya-tyoplogo-pola.html

- https://seti.guru/termogolovka-dlya-teplogo-pola-vodyanogo

What do you think of this article?

Equipment characteristics

The coolant from the boiler passes through the pipe line to the collector. From it the liquid flows into the floor pipeline. Giving up heat, it returns back to the collector, which has a separate return outlet for the cooled coolant. The circulation pump forces water back into the boiler.

When manually controlling the temperature regime, valves are installed on the circuit with cold water and high-temperature coolant. If the room has warmed up well enough, then the hot water valve is closed. If the room is cold, the valve is opened.

To automatically regulate the heating mode, install a three-way mixer with a thermostat and an external temperature sensor. This system forms a thermostatic valve. It is installed at the entrance to the collector. The equipment is made of brass or bronze.

- The three-way valve has 3 outlets for hot, cold water and coolant, which is supplied to the floor line. Markers on the body indicate the direction of flows of different temperatures.

- A mixing chamber is provided to mix liquids of different temperatures.

- On the body there is a thermostat with a temperature regulator.

- The temperature sensor is located on the thermostat.

- The valves close the outlets for cold and hot flow. They can be disc-shaped or needle-shaped. Their operation depends on the thermostat.

- The thermostat is a system that consists of a capsule with liquid and a spring-loaded rod. Valves are attached to it.

- The temperature sensor has a digital panel on which the heating modes are indicated.

We recommend: Is it possible to lay heated floors under linoleum?

The thermostat can be located in the thermal head or in the servo drive. The devices have different circuits, but the same principle of operation. The thermal head is a thermostat, the operation of which is carried out using a liquid: it is sensitive to temperature changes.

Servo drives operate from the electrical network. The liquid is contained in a container. It contains a heating plate. The servo drive is installed on the manifold.

The three-way mixer is designed for heating systems of large areas. In separate rooms or in country houses, a two-way valve is connected to the collector. It is installed on a circuit with a high temperature coolant. Water flows through it in only one direction.

Job

The principle of operation of the valve is to mix water flows with different temperatures. Why do you need to do this?

Without going into technical details, we can answer this way: to extend the life of the heating boiler and make it more economical.

A three-way valve mixes heated water with cooled water after passing through the heating devices and directs it back to the boiler for heating. Everyone can answer the question of which water to heat faster and easier - cold or hot.

Simultaneously with mixing, the valve also separates the flows. There is a natural desire to automate the management process itself. For this purpose, the valve is equipped with a temperature sensor with a thermostat. In this case, an electric drive works best here. The quality of functioning of the entire heating system depends on the drive device.

Installation features

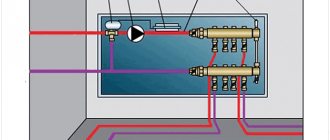

The thermostatic mixer is installed in the heating system in the mixing unit with single or multi-circuit heat distribution.

There may be several such circuits. The schematic diagram will not change. Only new elements will be added.

For example, a mixing unit. The presence of an additional coolant distribution circuit is its main distinguishing feature. Why is it needed? For connecting additional heat consumers. For example, heated floors.

When performing installation work to install the valve, you must remember that it is installed in front of the system pump. The performance of the entire system depends on compliance with this requirement.

When cutting into the valve, you need to make sure that welding waste (slag, drops of molten metal) does not get into it. It is also necessary to provide for the possibility of easy removal of the valve during its operation. This action will be required when periodically checking its performance.

Valve Installation Technology

Typically, a three-way valve is installed using a threaded connection method. The tightness of the thread is achieved by using a sealant, which can be FUM tape, Tangit Unilok thread or ordinary linen thread together with insulating compounds.

During installation, the following rules must be observed:

- the valve must be installed only in full accordance with the direction of movement of the coolant, indicated by arrows on the equipment body or letters (A and B - inlet, AB - outlet);

Correct way to install the valve

- It is recommended to install pressure gauges before and after the equipment to monitor the pressure in the system;

- to protect the valve from the effects of impurities contained in the central lines, a filter is installed;

- there must be straight sections of pipeline before and after the valve, the size of which is established by the device manufacturer and indicated in the technical documentation;

- it is necessary to install any device in front of the valve that throttles excess pressure in the system;

- the equipment must not be under load.

Installation diagram of valve and additional equipment

Where and how to install the valve correctly, watch the video.

You can select and install a three-way valve yourself. However, failure to follow the installation instructions recommended by the equipment manufacturer will void the valve's warranty.

Providing heat in the right place is the main requirement for a heating system. In apartments this issue can be considered resolved.

In private homes, sometimes you want to additionally equip the floor with heating. And not always electric. This is where the problems begin.

The temperature of the floor and the heating radiator cannot be the same. To prevent this from happening, a three-way valve is installed in the heating system. Thanks to it, the distribution of heat flows will be ensured. The floor is warm, the radiators are hot - the house is warm. The presence of such a device in the hot water supply system is simply necessary.