Heated floors are an example of hygiene and comfort in an apartment. Heated floors are economical and allow automatic adjustment of the heating temperature, however, even they require thermoregulation. This is why a mixing unit is installed. In fact, unlike a heating system with a temperature of 60–80°C, as a rule, heated floors are connected to them; it can only be heated to 35–40°C.

To obtain a similar result, the technology of mixing liquid streams having different heating temperatures is used.

Purpose of mixing units

First of all, it should be noted that a mixing unit is used for water heated floors, since the same coolant flows in both the floor heating system and the radiators.

The heating system usually consists of:

- heating boiler in which water is heated;

- one circuit with high-temperature batteries;

- several circuits included in the design of the heated floor.

The boiler included in the system heats the coolant to the temperature required for the operation of the radiators, usually 95 °C, but in some cases 85 and even 75 °C. In accordance with sanitary standards, the temperature on the floor surface cannot be more than 31°C. The restriction is due to many reasons, including comfortable movement around the house.

Taking into account the height of the screed into which the heating system pipelines are embedded, as well as the type and parameters of the floor material, the temperature of the working medium in the pipes should be no more than 55 degrees. It is clear from this that hot water directly from the boiler should not be sent into the heating circuit, since it has too high a temperature.

Therefore, in order to reduce the degree of heating of the working environment at the entrance to the circuit, a mixing unit for a heated floor is installed. It mixes coolant flows with different temperatures. As a result, its temperature decreases and water is supplied to the heating circuit.

Often, property owners are interested in whether a heated floor always requires a mixing unit, and when it can be omitted. Experts say this is quite possible. If the arrangement of heat supply in the house involves the use of low-temperature circuits, and the unit heats the water only to the required temperature for the heating system, then there is no need to install mixing units.

An example is the use of an air heat pump. If the heating boiler supplies water not only to the heated floor structure, but also for taking a shower at a temperature of 65 - 75 ° C, then the heated floor cannot be used without a mixing unit.

The finished system and its features

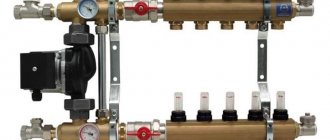

If you don’t want to assemble the unit with your own hands and sweat over the diagrams, you can assemble the heating system ready-made in any construction supermarket.

Of course, they won’t be cheap, but you will save yourself from possible consequences if you assembled the knot with your own hands, making an incorrect calculation or not understanding the purpose of each element.

One of the most famous brands is a mixing unit for heated floors with a Valtec pump (Italy). Its cost is about 15 thousand rubles. Its American equivalent, the Watts Isotherm brand, costs approximately the same. If you don’t want to spend that kind of money, then collect the necessary parts and assemble the assembly yourself.

Remember that after assembling the structure yourself, it should be connected to the circuits using fittings for fastening. Next, balance the node and only then can you put it into operation.

As you can see, assembling a mixing unit is quite complex and it is better to entrust it to professionals if you do not understand something or are not sure that you will be able to do such work.

Features of the operation of mixing units

The node operates like this:

- The hot coolant reaches the floor heating manifold and reaches the safety valve with thermostat.

- When the heating of the working medium exceeds the required level, the valve is activated and the supply of cold water from the return line begins, as a result of which it is mixed with the hot coolant.

- After the temperature reaches the desired value, the valve is activated again and the flow of hot water stops.

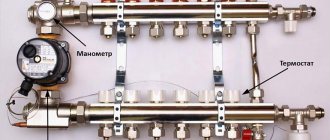

The collector unit is responsible for regulating the degree of heating of the coolant and its circulation in the circuit, and consists of two main elements:

- A safety valve that supplies the heating circuit with hot water as much as required, monitoring the inlet.

- A circulation pump that ensures the coolant moves along the circuit at a certain speed, as a result of which the floor covering will be evenly heated over the entire area.

In addition to them, the mixing unit for heated floors and radiators may include:

- bypass, which prevents system overload;

- air vents;

- shut-off and drain type valves.

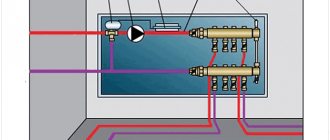

Depending on the tasks being solved, the mixing unit of the collector can be equipped in different ways. It is always installed before the contour of the heating structure, but the installation location itself is not precisely indicated. For example, the unit can be made in a room where there is a heated floor, or in a boiler room.

When there are several rooms in a building with heated floors, then the mixing units are placed in each of them separately or in a nearby manifold cabinet. The main difference in the operation of these units is the use of different safety valves. These devices come in 2-way and 3-way types.

Crane device

The design of a three-way valve consists of a body, a ball locking device, two polymer O-rings, a handle connected to the valve through a spindle, and seals responsible for sealing the entire device.

The body is designed in the form of a tee with three branch pipes threaded for connection to pipes.

The photo shows a diagram of a three-way ball valve:

Mixing unit with two-way valve for heated floors

The 2-way type of device is also called the feeding type. It has a thermostatic head equipped with a liquid sensor that constantly monitors the degree of heating of the working medium, which is supplied to the floor circuit. The head serves to open/close the valve, as a result of which the supply of hot water from the heating boiler is added or cut off.

Mixing of flows is carried out as follows: water from the return flows constantly, and the heated coolant is supplied if necessary, due to the fact that the valve regulates this process. As a result, the floor heating system never overheats and thereby increases its service life.

The two-way device has a low throughput, so the temperature of the working medium is adjusted smoothly. When connecting a mixing unit for a heated floor, specialists prefer using this type of valve. True, there is a restriction on its use - the heated area should not exceed 200 “squares”.

Automatic valves

It was mentioned above that 3-way valves can be operated manually using a stem, which is located on one side of the valve and is equipped with a turning handle or nut. But this method of control is not entirely convenient.

As you know, the power of the heating circuit is adjusted taking into account the return temperature , so the manual method can only determine the proportion of mixing water with different lines. Changing the final temperature may take too long, and the distribution of thermal potential is uneven.

Because of this feature, automatic valves that operate on the basis of servo drives or special hydrodynamic and pneumatic heads have recently become very popular. These elements are capable of instantly changing the current three-way valve configurations, taking into account the outlet temperature.

Automatic valves are easy to use, therefore they are more popular than manual ones.

According to the principle of operation, the electric drive is similar to manual control, but it operates without human intervention, but on the basis of an electronic control unit. The unit itself is a power unit that rotates the rod and changes its position taking into account the signal.

Almost all three-way valves support the installation of a servo drive, but it is advisable to buy special designs that are small in size and designed for electric drives.

After receiving the required values, a signal to action is sent to the servo drive, then it begins to change the location of the rod or rotate the ball inside the tee. Uninterrupted and high-quality operation of the system is ensured by the operation of the electronic control unit. The absence of this node makes the installation useless.

Servo drives have many advantages. Their main advantage is the ability to automate the entire operation of the heating system and deprive yourself of additional hassle. If you connect a node with a Smart Home system, this will also allow you to control the heating directly from your smartphone.

Mixing unit with three-way valve

The three-way version combines two functions: a bypass balancing valve and a bypass supply valve. Inside it, the flows of cold return and hot coolant are mixed.

Three-way devices are often equipped with servos designed to control thermostatic devices and weather controllers. In this case, there is a damper inside the valve located in the 90 ° zone between the return pipeline and the heated coolant supply pipe from the unit. It can be installed in any location - with a slope to one side or in the middle, depending on the required ratio between hot water and return.

It is generally accepted that this type of valve is indispensable for heating systems with a large number of circuits.

Among the disadvantages of these elements, the following should be noted:

- Cases cannot be excluded when, as a result of a signal from the thermostat, the valve opens and admits coolant having a temperature of 95 ° C into the floor circuit. Such sudden temperature changes during operation of the system are unacceptable, since the pipeline may burst due to excess pressure.

- Three-way valves with significant flow capacity, even in the case of a minimal failure in the adjustment of the device, can greatly change the temperature in the circuit.

To change the power of the floor heating system depending on the weather, special fittings are used - a weather-dependent controller. For example, in the event of a sudden cold snap, the room in the house begins to cool down faster and the heating structure cannot cope with its purpose. To increase its efficiency, the heating of the coolant and its consumption should be increased.

You can use manually controlled valves and turn the valve every time the weather changes. But the disadvantage of this method is obvious: it is difficult to set the optimal mode. That's why many homeowners prefer automatic valves. The controller calculates the required temperature and smoothly controls the device.

The entire 90-degree zone is divided into 20 sectors, each of which has 4.5 degrees. The controller checks the temperature conditions every 20 seconds. When the actual temperature of the water entering the system does not correspond to the calculated one, then the valve turns to one side by 4.5 degrees.

In addition, the controller allows you to save energy. In the absence of residents, it lowers the temperature in the rooms to the lowest possible level.

What is it and what is it for?

Valve is a type of shut-off valve for pipelines that has three pipes for connection to pipelines. A three-way valve is a control valve that can be used to:

- Regulate the supply of two media simultaneously.

- Control their consumption.

- Completely shut off the pipeline.

The electric drive is used when using three-way valves in automated heating and ventilation systems, industrial devices for supplying chemical reagents, etc. The use of an electric drive is mandatory when operating valves on large-diameter pipelines.

When heating a private home, thermal valves help save heat consumption - with proper heating adjustment, fuel savings can reach 30%.

Having calculated how much it costs to equip radiators with three-way valves and comparing this with financial savings on fuel, we can conclude that it is more profitable to use modern thermostats with an electric drive.

Purpose and scope

Three-way valves are widely used in everyday life and in all sectors of the national economy.

Previously, every house had a mixer - a three-way valve. Now such devices have been replaced by more convenient mixer taps with electric drives. But the engineering communications of houses are constantly becoming more complex, and today it is impossible to do without control valves when organizing modern engineering systems of buildings. Three-way devices in private homes are used mainly to regulate the heating of radiators, heating in general and underfloor heating systems.

They cannot do without three-way valves with an electric drive and a home air conditioning and ventilation system. In recent years, such regulators have been installed on hot water pipelines.

In industry, three-way control valves with an electric drive are indispensable - they are common in many industries that require transportation and dosed supply of gases and liquids. Three-way control valves with electric drive are used:

- In the chemical industry.

- In mechanical engineering.

- In metallurgy.

- At mining and processing enterprises.

- In agriculture.

- In the food industry.

Electrically actuated valves are also used in numerous hydraulic transport pipelines and working equipment (these are available in almost all industries).

Characteristics

Main characteristics of three-way valves:

- Separating or mixing.

- Diameter of pipes for connection.

- Bandwidth.

Floor mixing unit diagrams

There are many mixing schemes for heated floors. It is possible to arrange the mixing of coolant both upstream of the collector and at all outlets from it.

Each branch must be equipped with such devices as thermostats, flow meters, valves:

- Balancing device for the secondary circuit . Thanks to this valve, the mixing unit of the heated floor is adjusted - the ratio between the volumes of hot and cold coolant from the return is adjusted. To turn the valve, a hex wrench is used, and to prevent displacement, it is secured with a clamping screw. In addition, the device has a flow scale that reflects its throughput, ranging from 0 to 5 cubic meters per hour.

- Balancing shut-off valve for the radiator circuit . This device is intended to connect the mixture group for a heated floor with other elements of the heating system. To turn it, use a hex key.

- Bypass valve . This is a safety device. It protects pumping equipment when operating in a mode where no water is supplied through it. The device is triggered if the pressure in the system drops to a certain value set by the handle.

The mixing unit diagrams for radiators differ, depending on whether a one- or two-pipe heat supply system is being installed. For example, when installing a single-pipe structure, the bypass is always in the open position so that the hot coolant can always partially move towards the batteries. In a two-pipe system, the bypass is closed because it is not needed.

The collector group is not always mounted before the radiator circuit. When the structure has a small area and the drop in temperature of the working environment is insignificant, then the collector with a mixing unit is located on the return of the radiator circuit. In this case, the underfloor heating manifold with a mixing unit works most efficiently.

general information

It is no secret that the problem of uneven heat distribution in a room often causes a lot of trouble for owners. To get rid of this unpleasant phenomenon and create a comfortable temperature regime, you need to introduce a special device into the heating system - a thermal power regulator or a three-way valve.

The mechanism ensures recirculation of the coolant fluid by mixing a certain amount of cooled treatment with the main current. Currently, tees are installed in hot water supply systems, heating circuits and plumbing systems.

Three-way valve – multifunctional, durable

In most cases, three-way valves are installed in heating systems with many components and circuits, which is necessary to stabilize the temperature in all radiators. The use of the device allows you to control the flow of coolant, distributing it to different parts of the room (for example, in the kitchen, garage and living rooms). Among the main advantages of the invention are:

- compact and ergonomic dimensions;

- multifunctionality;

- ease of installation, operation and maintenance;

- high tightness;

- long service life;

- ease of switching between operating modes.

In addition to the advantages, tees also have disadvantages. These include the likelihood of valve jamming if operating rules are not followed and rapid wear of inexpensive products.

This video will tell you how to install a three-way valve correctly:

Installation and operation

To ensure successful installation of a three-way valve, it is important to follow the drawings and step-by-step instructions. also need to pay attention to several nuances of the upcoming installation:

To properly install a three way valve, it is important to follow the drawings and step-by-step instructions

- On the body of the tee there is a special diagram with arrows that show in detail the direction of water flow. Its presence significantly simplifies installation work and allows you to quickly and accurately connect important components.

- When welding metal mechanisms, the temperature flow in the joint area must not be allowed to exceed +100°C. It is important to ensure that scale or dirt does not penetrate the system, otherwise this can lead to irreparable consequences.

- To install the tee, you need to choose a place that will be easy to reach for repairs or maintenance. If the tap has to pass insufficiently high-quality liquid, it is recommended to additionally equip it with filter units.

- The method of fixing the product can be either vertical or horizontal. This does not affect work efficiency in any way. As for the valve, it is installed directly in front of the circulation pump.

In order for the tee to function for a long time, reliably and efficiently, it is necessary to take into account the operating rules and maintain it on time. The service life of the device depends on proper and correct use.

Useful tips

Before starting the heating system, you must make sure that the three-way valve and other components are in full working order, do not need repair or replacement, and also meet operational requirements. It is not recommended to install a tee on a pipeline with a pipe diameter of 40 millimeters or more. When operating in a hot environment, the valve must be opened with extreme caution, otherwise there is a risk of hydraulic valve failure.

The best material for a three-way valve is brass.

Experts recommend placing control devices or a turning handle with a rod so that they are freely accessible. When choosing a suitable faucet model, it is advisable to give preference to products made of brass. They are characterized by a long service life and resistance to all kinds of influences.

As for the control method, the best option would be a product with pneumatic control. Before making a choice and buying a tee, it is better to consult with a specialist, talk about the possible pros and cons of the available models, and also read reviews about them on thematic forums.