When organizing an autonomous sewer system in a private house, as a rule, a non-pressure scheme is used, in which the wastewater moves by gravity. But in some situations such an implementation is not possible. Difficult terrain, hard soil and other reasons may make it difficult to create the required pipe slope. The only solution in such cases is to connect a pressure sewer system (hereinafter referred to as NK). We will tell you about its operating principle and implementation features, which will allow you to use this information as a guide for those who are going to assemble a similar circuit with their own hands.

Pipe laying

During the work, pay attention to the following points:

- Laying depth. You should always try to place pipelines below the ground freezing level. Due to the fact that the main line is laid with a slope, and the temperature of the wastewater is much above zero, part of the line (no more than 1-1.5 m) can be located above the freezing depth;

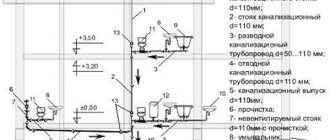

- Slope. Highway slope. Liquid waste contains suspended and solid particles that move together as a single mass. If the flow rate is higher than the optimum, separation of fractions occurs, some of which fall out in the form of precipitation. This leads to clogging of the internal lumen of the line. To prevent this from happening, a pipe with a diameter of 110 mm is laid with a slope of 2:100 (there is 2 cm of rise per meter of length);

- Pipe laying. Work begins from the treatment plant towards the house. At the water level, mark the required slope. Having laid the pipe, level the sand cushion so that the section takes on the required slope (checked with a level). Next, the sections are connected one by one using seals;

- The final stage. After installation, check whether the slopes are observed. If this is okay, make sure the joints are tight. To do this, water is poured into the pipelines. If after testing the system the sand cushion near the joints does not become moistened, the sections are assembled hermetically. In case of leaks, it is recommended to replace the rubber seal liners. At the final stage, the highways are covered with sand (layer thickness - 20 cm), and then with soil. The sewer is ready.

Review of advantages and disadvantages

When choosing, they study not only the characteristics of the pipes, but also the advantages and disadvantages. Metal products are heavy and susceptible to corrosion, which shortens their service life. But they are characterized by high strength.

Polymer products are characterized by long-term operation. They withstand high loads without loss of properties, do not rust, withstand the influence of aggressive environments, and have smooth walls. Among the disadvantages, low resistance to extreme temperatures is noted.

Installing a sewer pump on a toilet.

sewerage installation Sololift2 WC-1

More or less general rules for installing such pumps are discussed here. Therefore, you need to read the instructions that come with the product. So, let's begin:

If a vertical section is provided in the pressure sewer, then it MUST be located at the beginning. The height of the vertical section varies depending on the distance from the general sewer riser and the diameter of the pressure sewer. Horizontal sections of the pressure sewer must have a slope towards the sewer riser. The amount of slope may differ from one manufacturer to another, so it must be clarified in the instruction manual. It is necessary to correctly select the diameter of the pressure sewer, based on the number of connected “sources”, that is, if in addition to the toilet, your pump is also connected to a shower stall and a washbasin, then you need to make a pressure sewer from a pipe of a larger diameter. Tables for selecting pipe diameters are available in the pump instructions

In addition, pay attention to the maximum flow rate of your pumping unit; it must be able to pump out all the wastewater. Otherwise, a breakdown will occur. For turns of the pressure pipeline, it is better to use bends at 45º

This will reduce the likelihood of clogging in the pressure part. It is advisable to connect the sewer pump directly to the toilet. If it becomes necessary to install a toilet through a pipe, then you need to specify its maximum length in the instructions. For example, for Grundfos pumps this distance should not exceed 150 mm. Manufacturers prohibit installing sewage pumps in pits near the toilet. How this is explained was never clearly explained to me. But to maintain the guarantee, I recommend observing this point. The pumping unit must be firmly fixed to the floor surface.

I recommend watching this video:

Rationale for application

In most cases, when organizing a local sewage system for a private home, a gravity-flow scheme is used, since it is more economical and easier to maintain. But in some situations, the installation of NK is not only justified, but also has no alternative. The basis for making a decision in favor of installing a water pumping station may be:

- complex terrain, which does not allow providing a constant slope necessary for organizing a gravity system;

- the presence of rocky or moving soil, which complicates or makes it impossible to lay the pipeline at the calculated depth.

- the pipeline route is long, which eliminates the creation of conditions for gravity movement of water.

- The drainage point is located below the inlet pipe, a clear example is shown in the figure below.

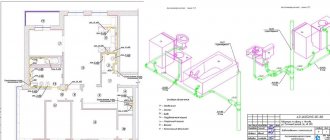

Simplified sewerage diagram in a private house

The figure shows in red the nodes where the installation of a toilet pump or other plumbing equipment is required.

Please note that moving a toilet in an apartment, as a rule, is not possible without appropriate repair and plumbing work. To avoid this, you need a household low-power SPS, such as Sololift in Figure 2.

Pressure sewer design

Any construction work begins with a project, and sewerage, regardless of type, is no exception. Therefore, the first thing to do is to think through all the nuances and draw up a project.

The pressure sewerage device must be designed taking into account the following parameters:

- terrain features;

- pipeline length;

- depth of soil freezing in the region;

- parameters of the pump or station to be used.

First of all, determine the location where the well or container for collecting waste water will be located. Of course, everything depends on the topography of the site, but it is still desirable that the wastewater can flow by gravity into the container.

This is what will help you avoid purchasing and installing additional equipment for internal sewerage. Also, the location of the well will affect the number of pipes required for assembling the pipeline and other structures (rotary wells, etc.).

The depth of freezing affects the volume of excavation work; in order to avoid freezing of the pipeline, it must be below this level or well insulated. Pressure sewerage must be equipped with a sewage pump or pumping station.

The pump power is selected based on the length of the pipeline, the expected amount of waste and other factors. If a pumping unit is used, there is no need to install a waste container.

On a note!!!

To develop a pressure sewer project, it is recommended to contact specialists. In this way, you can insure yourself against errors that can ruin all your work and completely or partially disable the system.

Installation instructions for pump station

Installation of household pumping stations is carried out exclusively by qualified workers, due to the high requirements for the accuracy of work and compliance with the sequence of actions.

Failure to comply may result in damage to the tank or associated pipes. Next, we will consider step-by-step instructions for installing the CNS for people who want to do it themselves.

Step #1. The location for installation of the pumping station is being selected. SNiPs require digging a tank at least 20 m from the walls of a residential building. If geodetic levels allow, then it is advisable to choose a higher site so that a lot of groundwater does not accumulate under the station.

KNS should not be installed on the front side of the house, near children's playgrounds and near picnic areas

Step #2. A hole is dug taking into account the diameter of the container and the location for convenient installation work. If the soil is obtained by an excavator, then work must be stopped 20-30 cm above the design level. Next, the soil must be removed manually with a shovel to maintain the integrity of the soil.

When digging a hole for a sewer tank, you do not need to make it huge. A diameter 1.5-2 meters larger than the size of the container itself will be sufficient.

Step #3. The type of foundation for installing the water pumping station is selected and installed. To do this, after digging a hole, the soil water content is assessed. If the soil is dry, then you can make formwork and fill it with a 30-centimeter layer of concrete.

And if groundwater constantly seeps into the pit, then only a ready-made reinforced concrete slab with a thickness of at least 30 cm is suitable for the foundation.

The concrete base must be strictly horizontal, so when laying the finished concrete slab you need to take care of this in advance.

KNS containers have a skirt or legs for attaching to the foundation. Anchor bolts are used as fasteners, although when pouring concrete onto the ground, metal rods can also be built into the mixture, onto which the container can then be attached.

You should not skimp on the size of the anchor bolts. Their optimal length is 200 mm and diameter is 20 mm. And before laying in liquid concrete, metal rods must be bent with a hook or the letter G (+)

Step #4. The water pumping station tank is installed on the foundation, secured and connected to the drain pipe of the internal sewer system of the house. With a vertical type of station and a large amount of groundwater, it is necessary to load the container with concrete. To do this, concrete is poured around the tank 20 cm above the level of the first stiffener of the station.

It should be borne in mind that after pouring concrete it will be impossible to change the tank, so it is necessary to calculate its volume taking into account the expansion of the house and the increase in the number of its residents

Step #5. The station is backfilled with fine soil, the maximum grain size of which is 32 mm. Each layer of earth should be no more than 50 cm. After filling the next belt, it is filled with water for shrinkage and compacted.

This completes the external installation of the pump station. After being fixed in the ground, pumps, sensors, check valves and other auxiliary equipment are installed inside the station.

For safety reasons, it is recommended to close the hatches of sewer tanks with locks, because while playing, children can hide in them and lose consciousness

It would not be superfluous to install an emergency warning system in the house about the critical level of domestic wastewater in the tank, which will warn about malfunctions in the operation of the station.

Stages of installation of pressure sewerage in a private house

Self-assembly of such a system is done in the following sequence:

- Drafting the project;

- Purchase of pipes and equipment;

- Taking into account the project, earthworks are carried out: a trench is dug for a pipeline and a hole for a well or station;

- Pipeline assembly;

- Equipment installation;

- The parts of the system are connected into one whole;

- Connecting the sewerage system to the central system (if possible);

- Checking the system functionality;

- Backfilling of pipelines and equipment.

If all norms and rules for installing pressure sewerage are observed, the system will operate for a long time and efficiently. All houses and plots are individual and require a different approach, so it is better to turn to professionals when drawing up a project and installation.

Video: Installation of PVC pressure pipes.

https://youtube.com/watch?v=vEdcR6GPWbs

What to look for when choosing elements

Pressure sewer channels must be protected and highly reliable. Such requirements are explained by the characteristics of the network:

- transfer of liquid under pressure;

- water hammer when starting pumps;

- sudden changes in pressure.

Ideally, products for pressure sewerage will withstand pressure values of up to 1600 kPa. Currently, the most popular are pipes made of polymers (most often unplasticized polyvinyl chloride). They are durable, relatively lightweight and affordable.

PVC-U pressure channels are chosen with a smaller cross-section than for the construction of non-pressure analogues. The connection can be achieved by cold welding or special fittings. It is important to consider that pipes for such systems should not have sockets.

The intermediate tank must have a sufficient volume to accommodate three days' worth of wastewater. This is important for situations where the pump breaks down or there is a power outage, when the sewage system does not function for some time. To carry out the necessary calculations, it is better to use current standards.

The pump power is selected based on the depth of the intermediate tank and the distance to the central sewerage system. For example, 0.4 kW is enough to lift wastewater 2 meters and transport it 200 meters.

Pressure dampers in different types of sewer systems ↑

Wells for pressure regulation are installed in different types of sewer systems:

- Livnevoy. The need to change pressure arises due to the large length of local direct branches laid before the entrance to the urban system.

- Local household. The number of extinguishing points and the type of well design are selected depending on the number of problem areas and the characteristics of a particular network.

Functions of differential and extinguishing wells ↑

The main task of installing a pressure suppressor well in a sewer is to restore operating pressure, flow speed and pipe filling level in difficult sections of the pipeline.

Functions of adjustment devices:

Decreased pressure. Installing a large-volume container reduces excessive liquid pressure on the walls that occurs inside the pipe.

- Increased pressure. With a sharp change in the level of pipe laying, it becomes necessary to create greater pressure for gravity movement of the liquid. Such containers are installed when constructing a pressure sewer system.

- Changing the direction of flow and protecting the pipe. To avoid damage to the pipe wall in a bend from the impact of the flow at high speed, containers that accumulate liquid are installed. The drainage is supplied to the next section of the pipeline under lower pressure.

Change of direction schemes

Types of design of tank-regulators ↑

Wells designed to relieve excess pressure are manufactured in several types. The type of design is selected after studying the main parameters that require adjustment. All structures are tubular or shaft type. Internal organization of dampers:

Standard drop tanks: used if you need to reduce the speed at the point of a sharp change in pipe height.

Differential tank

Dampers with a fender system: vertical walls are installed inside the shaft to absorb the impact of falling liquid.

Vertical baffle wall

Wells with a cascade water body: multi-stage fenders are installed in the form of plates inside the barrel. Installed in areas with significant excess flow velocity.

In addition to extinguishing tanks, sewerage systems use high-flow currents with the function of increasing pressure within the system. The well is filled with liquid from the supply pipe to inject the required pressure inside the next section. Such systems are installed when it is necessary to lay a private branch on a rise in terrain before connecting it to the city network.

Locations for installing pressure control points in the local pipeline ↑

In private sewer pipelines, adjustment points are installed along long sections. If the total length of the branch in a straight line exceeds 30 - 40 m, then it is advisable to install at least one sewer pressure suppressor well. On a straight pipe line laid at an angle, the drains develop too high a speed. If there are no bends, splitters or damping points, the sewer pipe wall will rupture due to excessive stress.

Places for installing drops and dampers

In places where the direction of the pipeline sharply changes direction, if it is impossible to increase the angle of rotation, rotary wells are installed to reduce the risk of a breakthrough from a hydraulic shock of the flow at the turning point.

Installing a damper in a corner

In difficult areas, the pressure in the pipe is reduced by installing differential wells. The type of internal arrangement of the mine is chosen depending on the height of the drop and the pressure force at the entrance. The tank is a shaft with an inlet at the top and an outlet at the bottom of the side wall.

For storm pipelines, quenching wells with the installation of filters are used. Along with rainwater, leaves, stones and small debris get inside the pipe. A mesh basket installed at the entrance to the well acts as a mechanical filter.

Types of drop wells

High currents in pressure networks are equipped with electric pumps if it is impossible to naturally raise the pressure inside the system to operating levels.

In places where the local pressure network is connected to the general gravity network, a pressure damper must be installed.

How to dampen the speed of water movement

The damping of the flow force is achieved due to the difference in the wastewater level. The design of a standard damper well allows reducing the pressure by 17-20%. The deeper it is, the more the waste flow will slow down.

In multi-stage wells, water moves along planes located at different levels. In this case, the next plane is lower than the previous one, like steps. The flow rate decreases repeatedly as the water moves through the cascade.

The flow rate is slowed down by the thickness of the water in the reservoir (the pool) into which it hits. Installing an additional partition (water trap) further reduces the flow rate. Instead of a partition, a special grill can be fixed.

The pressure is reduced by a 90º swivel elbow installed on the incoming pipe.

If large debris is found in wastewater, the well is equipped with a trash basket (grid). It will trap floating objects and prevent pipes from clogging. The trash basket also reduces the speed of wastewater.

Surface devices

Surface-type devices intended for pumping out sewage are placed close to the collector that collects and moves waste liquid, or in any inspection well that is most convenient for installation. The last installation option is called dry.

Surface models are also considered to be pumping stations for forced sewerage due to the presence of separate parts assembled into one structure. In this case, the contaminated liquid is sucked through a hose connected to the pump and lowered to the bottom of the storage tank.

When choosing a surface unit, special attention should be paid to such an indicator as the suction depth - the manufacturer indicates it in the instructions supplied with the equipment. Most often this is 8 - 10 meters, but from a greater distance it will not lift wastewater from the storage tank

It is necessary to take into account both the height of the tank and the distance from it to the pump.

A surface low-power device for a forced sewer system is a compact device that is located next to the storage tank. To install more powerful equipment for pumping out wastewater, it is necessary to prepare a special place for it with reliable fixation to the floor.

When installing an outdoor unit, care should be taken to ensure its reliable protection from moisture. Unlike a submersible sewage pump, it is not intended for use in wet environments. Its body has minimal protection from water. If liquid gets inside the surface device, there is a high probability of a short circuit.

This pump is inexpensive, easy to operate, but very noisy. It is better to place it in a basement or other heated room. But, if the pump will be used from time to time to pump out the septic tank, then submersible installations are preferable.

Norms

Sewer discharge is done according to certain rules. They are listed in SNiP 2.04.01-85, or in their more recent edition SP 30.13330.2016. These regulatory documents detail all the conditions for correct assembly of the unit and define the maximum and minimum values of all parameters. The main requirements include:

- The laying depth of external pipes must exceed the soil freezing level. The sewer outlet from the building must comply with this requirement. If it is not possible to lay the line at such a depth, you will need high-quality insulation of the pipes and outlet. The installation of the heat insulator is done on the very floor of the lower floor;

- When calculating the depth, the slope should be taken into account. It is only 2 cm for every meter of horizontal line. However, if you do not take this value into account, you may make a mistake when connecting the line to the manhole;

- the length of the sewer outlet from the outer wall to the inspection well should not be less than 3 m;

- it is prohibited to locate open sections of the system in an unheated basement or basement;

- it is necessary to make a minimum number of bends along the route of the drains;

- the minimum distance between sewer outlets is 40 cm. Experts do not recommend making several nodes; it is more correct to first combine all the lines into a single riser, and then take it outside the walls of the house.

Following the standards and rules will ensure stable operation of the system.