SML pipes - These are high-quality structures made of cast iron. SML pipes are made by centrifugal casting. Such products meet the basic requirements established in the field of modern construction. The product is distinguished by the absence of the usual bells. Thanks to this, the pipes are connected to each other “joint to joint” using clamps. They consist of cuffs that are made of steel and high-quality EPDM rubber.

SML pipes are installed in sewer and drainage systems. With their help, you can set up a reliable system designed to drain sewer and storm water. During the manufacturing process, such structures are subjected to external and internal processing, as well as anti-corrosion treatment. Inside the sml pipes there is a special epoxy layer. Surface protection meets high requirements for anti-corrosion protection. Most often, systems are installed in residential multi-storey buildings, as well as in airports, train stations, hospitals, office buildings and hotels.

SML socketless pipes and fittings are easy to install. Many users have managed to appreciate the following advantages: • The system is installed quickly and simply (due to the absence of bells); • The structures are hermetically sealed (reliable connecting clamps eliminate the formation of leaks);

Basic technical conditions

| L=3000 mm | Diameter | |

| № | kg | mm |

| 1105013 | 12,5 | 50 |

| 1108019 | 18,2 | 80 |

| 1110025 | 24,3 | 100 |

| 1112535 | 34,3 | 125 |

| 1115041 | 40,9 | 150 |

| 1120068 | 67,4 | 200 |

| 1125098 | 97,3 | 250 |

| 1130127 | 126,8 | 300 |

Features of sml pipes

SML are high quality systems made from cast iron. As is known, this material has high strength. In addition, the manufacturer uses flake graphite to produce products. Thanks to their special composition, the pipes are characterized by high strength and durability. Throughout the entire period of operation, the structures retain their technical qualities. sml pipes meet all the requirements. Therefore, the products are excellent for use in residential and public spaces.

SML socketless cast iron pipes have become a worthy replacement for socketed structures, which were actively used in the Soviet Union. Due to their excellent technological characteristics, SML products are in great demand in the domestic market as well as abroad. Socketless sewer systems include all kinds of connecting parts, fittings, and other accessories.

Distinctive characteristics of SML products

As has already become clear, the abbreviation includes the concept of high quality construction made from cast iron. In addition to other advantages of the material, one of the most important is the highest degree of strength, achieved by adding a plate-like graphite element by the manufacturer. It is because of this, since the products contain a special element, that they are the strongest building material with a long service life.

It is known that over time, the quality properties of pipes are not lost, they remain in their original form, in addition, the technical characteristics remain unchanged. SML products are manufactured in accordance with all relevant standards. All of the listed properties ensure the creation of a reliable structure in residential neighborhoods and areas with large crowds of people.

SML cast iron products that do not have expansions have today practically replaced structures with an existing expansion section. The latter became almost legendary, widely used in the 80s. Having many advantageous technical differences, SML pipes began to occupy leading positions on the domestic shelves of well-selling goods, as well as abroad.

We recommend: Types and advantages of ball valve

SML pipes that do not have extensions and are intended for the sewerage system are supplied with a variety of connecting units, fittings and other related items.

Basic technical conditions

Advantages of SML cast iron pipes

SML products that do not have extensions are popular due to their advantageous qualities. These include:

1. Low resistance to the pressure flow of water (the smoothness of the products helps to reduce to zero the possibility of the appearance of various deposits);

2. High level of protection from extraneous sounds and noise (cast iron material fully complies with quality standards);

3. Simple installation process (there is no need to use special equipment to install SML products).

The SML system for sewerage meets the requirements of regulatory documents on sound insulation in residential buildings. The high-speed flow of wastewater inside the product is guaranteed by the fact that the possibility of deposit formation in the internal cavity of the pipe is completely excluded.

The advantageous characteristics of SML products include high strength to mechanical shock, resistance to corrosion, resistance to high temperatures, and, in addition, the acoustics of the pipes do not create discomfort.

If the choice fell on the use of SML products without extensions, then work on creating additional noise insulation and fire resistance is not expected. Since pipes have a long service life, the time period between repair work differs significantly. It is significantly reduced. Based on this, it can be assumed that the consumer of these products will not have to spend a lot of money and time on maintaining the products in proper quality.

The costs allocated to maintaining properties for quality use will be kept to a minimum. So, the positive aspects of the products include high sealing properties of joining areas, seams, and good resistance to mechanical influences. All this ensures high-quality operation of the structure for many years.

In addition to state quality standards, SML cast iron pipes must also comply with international standards. They extend their effect, in addition to pipes, to connecting parts, among other things. In these international documents, you must read all the standards regarding dimensional parameters, materials and mechanical properties. In addition, the document provides for mandatory functions that must be performed by both SML cast iron pipes and connecting parts.

Differences in SML Product Manufacturing

As is already known, this type of product is produced using the famous casting method under the influence of centrifugal forces. They contain an alloy of iron and a carbon element, with carbon contained within 2%. Using this specific casting method, pipes, in the process of performing their assigned functions, reach a new level of quality, firmly withstanding high temperatures. By the way, the cooling of products in such conditions occurs smoothly and slowly.

During the cooling process in the molding element, a special texture of the metal is obtained, in the form of small grains. The dimensional parameters of the inclusions vary depending on their location, namely, closer to the edges of the product, the grain inclusions are largest, and near the internal cavity they are smaller.

By exposing SML cast iron products to high temperatures, the graphite element is produced in a specific form. Due to the presence of such a unique element in the pipe alloy, the mechanical properties of the metal increase significantly.

We recommend: Bends for metal, sewer, exhaust pipes: GOST

Socketless cast iron pipes sml

This process involves a significant decrease in pressure inside the product, in addition, it increases the possible limit values of such properties as tensile strength. The result of the thermal effect on SML pipes is the presence of insignificant hardness within 210 Brinell.

That is why pipes that do not have expansions respond well to various impacts on them. This type of pipe lends itself well to cutting. The cavity inside has excellent protection from chemical loads and mechanical stress. All this is achieved using an absolutely safe, clean and modern coating method with a special layer.

With their smooth walls, pipes provide excellent modeling of the effects of media on liquids moving in it. All connecting parts of SML products are inevitably subject to processing, this applies to both the internal and external surfaces.

sml cast iron pipe

The uniqueness of cast iron material

A material such as cast iron is one of the first on the list of the best materials for creating sewers and water drains. SML is a unique sewerage system, which is made from cast iron during the casting process.

Socketless cast iron sewer pipe sml duker

In the current construction industry, such a system is implemented in accordance with all requirements. Such material and products made from it are best suited for installation in residential buildings and public buildings. Namely, this type of pipe has proven itself well in buildings that have a high level of claims against it, for example, commercial buildings, healthcare institutions, and equipped sports grounds. Such products will be able to be used without creating any problems, including those directly related to the preparation and equipment of water supply and sewerage systems. Unlike similar products, cast iron material is famous for its advantageous features.

Advantages of cast iron pipes sml

SML socketless pipes are in great demand due to their positive characteristics. These include:

- low resistance to water flow (ideal smooth surface eliminates the formation of deposits);

- high sound insulation rates (cast iron belongs to safety class A1, complies with DIN 4102 standard);

- ease of installation (installation of sml pipes does not require the use of special tools).

SML sewerage systems comply with the standards for noise insulation in residential buildings (according to DIN 4109). In addition, the high speed of internal movement of wastewater is ensured due to the fact that sediments do not form inside the structures. The positive characteristics of sml pipes also include increased strength, impact resistance, resistance to corrosion, high temperatures, as well as excellent acoustic comfort (complies with DIN 4109).

In the case of using socketless sml pipes, no additional noise and fire protection work is required. Thanks to the durability of the structures, the service life and overhaul period are significantly increased. Thus, the user will be able to reduce operating costs to a minimum. Absolutely sealed joints, seams, high ability to resist mechanical loads are advantages that ensure the longevity of the system.

The products comply with the European standard DIN EN 877, which applies to pipe fittings and pipes. This standard specifies all requirements for dimensions, materials and mechanical properties. In addition, the standard describes the (functional) requirements for all elements, including connections.

Socketless cast iron sewer pipe at a competitive price in the Inzhplast Trade House

SML cast iron socketless pipes are supplied in 3 meter lengths. The Inzhplast Trade House store offers all the necessary fittings and accessories for the installation of this type of pipe. Products are manufactured in China and meet all Russian building standards. Their cost is higher than standard cast iron socket pipes, but the ease of installation can significantly reduce costs in terms of the number of workers and reduce time costs. The products are in demand for the installation of internal and external sewage systems, and can be used in any climate and weather conditions. At the Inzhplast trading house, every buyer will find a suitable option for installing a sewer system - both in price and in design. We deliver SML socketless pipes throughout Russia. To the TK terminal is free.

Features of sml pipe production

The products are made using the well-known De Lavoe centrifugal casting method. The structures consist of an iron-carbon alloy (carbon content is more than 2%). Thanks to a special casting, the pipes are able to function at high temperatures. At the same time, uniform and slow cooling of the pipes occurs. In the metal form, as a result of cooling, a fine-grained structure of the material is formed. The grain size gradually decreases from the edge of the pipe (outer) to its inner side.

Such heat treatment ensures the formation of graphite of a special shape. Thanks to this, the mechanical properties of cast iron are significantly increased. This ensures a reduction in internal stresses, as well as an increase in tensile strength. The result of processing sml pipes with temperature is a low Brinell hardness (about 210).

Therefore, socketless pipes lend themselves well to processing. They are very easy to cut. The inside of the pipes is well protected from mechanical and chemical influences. Such indicators are achieved through the use of an environmentally friendly and advanced coating method. A smooth surface increases the aerodynamic performance of structures. All sml pipe fittings are subject to surface treatment (both inside and outside).

Manufacturing and couplings

The manufacturing method ensures the sml has an ideal geometric shape. The inner and outer surfaces are coated with a special epoxy compound, which provides some characteristics. The coating is applied by dipping followed by firing, which gives the pipes the smoothest possible surface.

During the production process, reliable protection against corrosion and chemical attack is created. This increases aerodynamics. Pipes are non-flammable materials, so in the event of a fire they retain their properties without generating hazardous emissions. Due to its high characteristics, sml is used for various purposes.

To connect the two elements, an elastomer coupling is used. A stainless steel clamp is wound on top. There are 2 types of clamps:

- Rapid. Equipped with 1 screw.

- CV. There are 2 screws.

The inner surface of the coupling is equipped with a limiting stop. It is installed between the two ends of the pipes, which ensures a good seal. For cutting products, a hacksaw and a grinder with special discs are used. It is forbidden to cut BT with a gas torch or cook them using a welding machine. If there are defects in the pipe, it is dismantled.

Unique properties of cast iron

Cast iron is one of the best materials for sewer and drainage systems. RUS - SML is a unique sewage system made of cast iron. It meets the requirements in modern construction. Cast iron structures are best suited for installation in public and residential buildings.

Cast iron pipes are excellent for installation in buildings with high performance requirements: shopping centers, hospitals, stadiums. The use of cast iron pipes allows us to solve many problems associated with the arrangement of water supply and sewer systems. Compared to existing analogues, cast iron has many advantages.

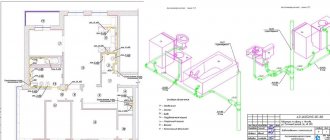

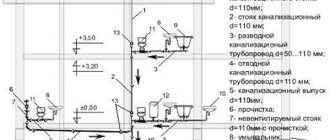

Installation and design work

The socketless cast iron pipe sml can be used for arranging sewer and drainage systems for the construction of buildings of various heights. Installation of systems and design work must be carried out in accordance with the requirements of DIN EN12056, as well as generally accepted rules and regulations. For installation of products, connecting clamps are used. These devices are installed in non-pressure sewer systems. Specially designed clamps can withstand pressures from 3 to 10 bar. The parts of the sewer system are connected using clamps. Installation and dismantling of sml cast iron structures is very simple.

The following advantages for builders and installers can be highlighted:

- the sewerage system is quickly installed (work completion time can be reduced to a minimum);

- during installation it is not necessary to use a special tool (the structures can be sawed with an ordinary grinder, the clamps are tightened with an ordinary simple key);

- cast iron does not crack (cost savings during construction, excellent maintainability of the system);

- high-quality material ensures safety of use and durability of the system.

The offered products have Russian certificates. If necessary, any element of the system can be simply replaced. In this case, the overall integrity of the system will not be compromised. All that needs to be done in this case is to remove the clamps, then release the necessary elements. Due to the high strength and elasticity of the material, the pipe walls are thin and at the same time durable. Thanks to this feature, the weight of the pipe can be significantly reduced. Installation, repair or dismantling of systems is much easier and faster. It is not necessary to use special supports.

Installation and design

SML pipes without extensions can be used to equip sewer channels and drainage systems even in a multi-storey building. In this case, the number of floors is not the main thing; pipes can exist organically in structures of different levels. Installation and design must be carried out in strict compliance with international documents, in addition, in accordance with generally recognized standards and regulations.

To install pipes, connecting parts in the clamp concept are used. These special parts are designed specifically for sewer systems that will not be subject to pressure pressure. Special connectors can withstand pressures up to 310 bar. The connecting sections of sewer pipes are created using connectors in the form of a clamp. Installation and disassembly of the SML cast iron structure is quick and easy.

Installation of sml pipes

Benefits for installers:

1. The sewerage system is quickly installed (the time allocated for this process can be successfully reduced);

2. During installation, the use of specialized equipment and tools is not required (it is quite possible to make the cut with a metal saw, and tighten the connectors with an ordinary wrench);

3. Cast iron products will never break (a cost-effective material, no expense will be required to repair it);

4. High quality cast iron will ensure complete safety in use and long service life.

Cast iron products have quality certificates of the Russian Federation. If necessary, any part of the system can be easily changed. The unity of the design in such a situation will not be violated. The actions that need to be done are just to free them from the clamps, subsequently freeing the necessary parts.

We recommend: Camozzi fittings for pneumatic systems

The strength and elasticity of the cast iron walls of the product ensure their thinness, but this does not detract from their strength properties. These features make it possible to reduce the specific gravity of the product. Installation, repairs and disassembly of the system are much faster and easier. And all this is achieved without the help of special supporting elements.

Distinctive properties

The following distinctive features of cast iron structures can be distinguished:

- the tensile strength of pipes is >200 MPa, of fittings - >150 MPa;

- compressive strength: three or four times the tensile strength;

- the maximum noticeable temperature without changing mechanical properties is 400 degrees;

- absolute tightness during assembly allows the use of sml pipes for non-pressure and pressure systems;

- The material is characterized by high impact resistance, resistance to temperature, and corrosion.

The outer coating of sml cast iron products has an epoxy base, its thickness is 80-100 microns. The structures are covered with cherry-brown varnish. The top layer is necessary to give the pipes an original appearance. In addition, it protects structures from rust formation. As for the fittings for fastening structures, they are also coated with epoxy varnish on top (approximate thickness is 40-80 microns). In addition to durability and reliability, the designs comply with all regulations. Many tests carried out confirm the quality of sml products.

Differences

Let us dwell on the following differences between cast iron products:

1. The level of tensile strength of products is more than 200 MPa, and of connectors is more than 150 MPa;

2. The tensile strength index is equal to four times the previous parameter;

3. Do not lose their mechanical properties and remain unchanged at a maximum temperature of 400 degrees;

4. A high level of tightness during installation ensures their use both for systems subject to pressure pressure and those that are not subject to it;

5. Ability to withstand mechanical loads, high temperatures and the appearance of corrosive formations.

The outer surface of SML cast iron pipes includes an epoxy element that forms the base. Thickness varies from 80 microns to 100 microns. The products are treated with a layer of burgundy varnish. It is this that gives the products an unforgettable appearance.

In addition, the varnish provides SML pipes with a protective film, which is designed to combat the appearance of rust. Regarding the connecting units for fixing cast iron products, their upper surface is similarly treated with an epoxy substance (thickness about 75 microns). Despite all the advantages, the design is inherent in all compliance with all document standards. Many tests have been carried out on this type of pipe, and yet the quality of SML products has been approved.

Quality Standards

The quality standard DIN EN 877 defines the general requirements for fittings and cast iron pipes. The diameters of sml products vary from DN40 to DN600. The above standards contain the necessary requirements for materials. They establish tolerances, certain dimensions of structures, as well as compositions and mechanical properties for fittings and pipes. The DIN EN 877 standard also includes requirements for the various components produced (the requirements apply to various connections). Pipes in most cases exceed the requirements of the mentioned standards, as well as ISO6594, DIN19522.

In the modern building materials market, RUS-SML cast iron structures are presented in a wide range. Thanks to this feature, each user can satisfy their own needs. Due to the fact that sml products are of high quality, they are quite in demand among construction companies. The demand for SML products is increasing every year. Moreover, the scope of their application is significantly expanding not only in residential premises, but also in commercial, retail and even industrial premises.

The properties of the sml product are such that they can be used in various fields of construction and industry. Moreover, to buy an sml pipe on our website; it ensures excellent system performance under various climatic conditions. In many cases, the sml cast iron design turns out to be more efficient compared to traditional sewer and drainage counterparts. This can be explained by the resistance of cast iron to various negative factors and environments.

Advantages of RUS-SML connection products

Many buyers have already been lucky enough to test them and draw appropriate conclusions about a number of such advantages:

1. A structure made from this type of pipe is installed very quickly and is distinguished by its simplicity (all this is due to the fact that there are no extensions);

2. The created channels have high tightness, which, in turn, eliminates various leaks (thanks to reliable fittings).

Technical features

SML products are a material with special properties, as they are made from cast iron designed for casting. They are produced using a technology that involves casting metal in special molds, in which, acting on cast iron, centrifugal forces force it, being in a molten state, to stick to the walls of the mold, thereby solidifying, forming a cast workpiece. Such pipes meet all the principles and quality standards that exist in the construction industry.

Products obtained during the casting process do not, surprisingly, have many of the usual and well-known expansion areas. To connect several of these products and form joining areas, it is necessary to use special devices in the form of clamps.

Such connecting units are a cuff type of connector made from steel material or from ethylene propylene diene rubber, which has a high level of quality. This material is made artificially by treating it with soot. The quality features are represented by a high degree of resistance to high temperatures and ability to compress and compress.

The presented type of pipes is in most cases used in the creation of sewerage and drainage systems. With their help, it is possible to provide a reliable channel, the function of which is to drain wastewater from sewer and city systems, as well as atmospheric precipitation. When producing this type of structure, it is initially necessary to influence it in order to give it new qualities, in particular, to process it externally and internally. In addition, it is necessary to carry out all anti-corrosion preventive actions and work.

The internal cavity of the products has a special epoxy coating. The protective anti-corrosion system on the surface of the pipe is made in accordance with all requirements and principles. These types of structures are considered popular for installation in multi-storey city buildings, airport buildings, railway stations, health resort institutions and hospital buildings, offices and hotels.

sml cast iron pipes