Today, thermal insulation of pipelines is necessary both to reduce heat losses of the corresponding systems and to lower the temperature of communications for their safe use. In addition, without it it is difficult to ensure normal operation of networks in winter, since the likelihood of freezing and failure of pipes is quite high and also dangerous.

According to existing standards, as well as rules for the safe operation of steam and hot water supply pipes, for pipeline elements with a wall temperature of more than 55 degrees and at the same time they are located in accessible places, it is recommended to use additional thermal insulation in such a way as to reduce their heating. In view of this, when calculating the thickness of the protective coating laid in a room, heat flux density standards are taken as a basis. In some cases, the temperature of the outer part of the insulation itself is also taken into account.

How to calculate insulation?

The choice of the required insulation is carried out on the basis of mathematical calculations, from which it is clear which material is better to take, its thickness, composition and other characteristics. If everything is done correctly, then it is quite possible to significantly reduce heat losses, as well as make the operation of systems reliable and absolutely safe.

Thermal insulation of pipes with foam plastic

What to pay attention to during calculations:

- difference in ambient temperatures where communications are used;

- the temperature of the surface that is supposed to be insulated;

- possible loads on the pipes;

- mechanical impacts from external influences, be it pressure, vibration, etc.;

- the value of the thermal conductivity coefficient of the insulation used;

- impact and corresponding magnitude from transport and soil;

- the ability of an insulator to resist various types of deformation.

It should be noted that SNiP 41-03-2003 is considered the main document on the basis of which materials for insulation and their thickness are selected, according to specific operating conditions. The same SNiP states that for networks in which the operating temperature of the pipes is less than 12 degrees, it is necessary to additionally lay a vapor barrier when treating the surface.

Thermal insulation of pipes can be calculated in two ways, and each option can be called reliable and convenient for specific conditions. We are talking about an engineering (formula) and online version.

In the first case, the actual thickness of the optimal insulating layer is determined by a technical and economic calculation, in which the main parameter is temperature resistance. The corresponding value should be within 0.86ºC m²/W in the case of pipes with a diameter of up to 25mm, and at least 1.22ºC m²/W - from 25mm and above. SNiP provides special formulas by which the total temperature resistance of the insulating composition of cylindrical pipes is calculated.

Please note that if you have any doubts about the correctness of the calculation, it is better to seek help and advice from specialists who will carry out the work reliably and efficiently, especially since the prices for their services are quite reasonable. Otherwise, a situation may arise where the scope of certain actions may be more costly in terms of money than doing everything from scratch.

When performing the work yourself, you should also understand that all calculations of the thickness of pipe insulation are made under certain operating conditions, which take into account the materials themselves, temperature changes, and humidity.

The second method is implemented through online calculators, of which there are countless today. Such an assistant is usually free, simple and convenient. Often it also takes into account all the norms and requirements of SNiP, according to which professionals perform calculations. All calculations are carried out quite quickly and accurately. Figuring out how to use the calculator will be easy.

Initially, the required task is selected:

- Preventing liquid freezing in utility pipelines.

- Ensuring a constant operating temperature of protective insulation.

- Insulation of communications of water heating networks of two-pipe underground channel laying.

- Protection of the pipeline from the formation of condensation on the insulator.

Then you need to enter the main parameters by which the calculation is carried out:

- Pipe outer diameter.

- Preferred insulation component.

- The time during which water crystallizes in an inert state.

- Temperature indicator of the surface to be insulated.

- Coolant temperature value.

- Type of coating used (metal or non-metal).

After entering all the data, the calculation result appears, which can be used as a basis for subsequent construction and selection of materials.

Thermal insulation of central heating pipes

Standards for thermal insulation of pipelines

Requirements for thermal insulation of equipment pipelines are formulated in SNiP. Regulatory documents contain detailed information about materials

which can be used for thermal insulation of pipelines, and in addition methods of work.

In addition, the regulatory documents indicate standards for thermal insulation circuits , which are often used to insulate pipelines.

SNiP contains the following recommendations for thermal insulation of pipelines:

- regardless of the temperature of the coolant, any pipeline system must be insulated;

- Both ready-made and prefabricated structures can be used to create a thermal insulation layer;

- Corrosion protection must be provided for metal parts of pipelines.

It is desirable to use a multilayer circuit design when insulating pipelines. It must include the following layers:

- insulation;

- vapor barrier;

- protection made of dense polymer, non-woven fabric or metal.

In some cases , reinforcement can be built , which eliminates the collapse of materials, and in addition prevents pipe deformation.

Let us note that most of the requirements contained in the regulatory documents relate to the insulation of high-power main pipelines. But even in the case of installing household systems, it would be useful to familiarize yourself with them and take them into account when installing water supply and sewerage systems on your own.

The right choice of insulation

The main reason for freezing of pipes is the low circulation rate of working fluids in them. A negative factor is the freezing process, which can lead to irreversible and catastrophic consequences. This is why thermal insulation of networks is extremely necessary.

Particular attention should be paid to this aspect in pipelines that operate periodically, be it water supply from a well or country water heating. In order not to have to restore working systems in the future, it is still better to carry out their timely thermal insulation.

Until recently, insulation work was carried out using a single technology, with fiberglass used as a protective element. Currently, a huge selection of all kinds of heat insulators are offered, designed for a specific type of pipe, having different technical characteristics and composition.

Due to their intended use, it would be wrong to compare materials and say that one is better than the other. For this reason, below we will reveal the insulators that exist today.

According to the component representation option:

- sheet;

- roll;

- pouring

- casing;

- combined.

By area of use:

- for water drainage and sewerage;

- for steam, heating, hot and cold water supply networks;

- for ventilation pipelines and freezing units.

Any thermal insulation is characterized by its resistance to fire and its thermal conductivity.

Next, let's look at popular materials:

- Shell. Its advantage is ease of installation, optimal characteristics and high quality workmanship. It has low thermal conductivity, fire resistance, and a minimal level of moisture absorption. Suitable for protecting heating networks and water supply systems.

Shell pipe insulation

- Mineral wool. It is usually supplied in rolls and is used for processing pipes whose coolant has a very high temperature. This option is only advisable for small processing areas, since mineral wool is quite an expensive material. Its installation is carried out by winding communications and fixing them in a given position with stainless steel wire or twine. Additionally, it is recommended to carry out waterproofing, since cotton wool easily absorbs moisture.

Insulation mineral wool cylinder

- Expanded polystyrene. The design of thermal insulation of this type is more like two halves, or a shell, through which the pipeline is insulated. The option can safely be called high-quality and convenient in terms of installation. Due to minimal moisture absorption and low thermal conductivity, high fire resistance, minimal thickness, polystyrene foam is excellent for protecting heating and water supply networks.

Expanded polystyrene for pipes

- Penoizol. Thermal insulation has similar parameters to polystyrene foam, although with a significant difference in installation. Application is carried out using an appropriate sprayer, since the material is in a liquid state. After complete drying, the entire treated surface of the pipe acquires a dense and durable hermetic structure that reliably maintains the temperature of the coolant. A significant advantage is that there is no need to use additional fasteners to secure the material. The only downside is that it is expensive.

Insulation of pipes with foam insulation

- Penofol with foil base. An innovative product that is becoming more popular every day. It consists of polyethylene foam and aluminum foil. The two-layer design allows both maintaining the temperature of the networks and heating the space, since the foil is able to reflect and accumulate heat. We especially pay attention to the low combustion ability, high environmental data, the ability to withstand high humidity and significant temperature changes.

Pipe insulated with foil penofol

- Foamed polyethylene. Thermal insulation of this type is very common, and it is often found on water mains. A special feature is the ease of installation, for which it is enough to cut the required size of the material and wrap it around the production line, fixing it with tape. Foamed polyethylene is often supplied in the form of a wrap for a pipe of a certain diameter with a technological cut, which is put on the desired section of the system.

Foamed polyethylene

It is important to know that when insulating pipelines, all insulation materials, except penoizol, require the additional use of waterproofing and adhesive tape for fixation.

From all of the above, it is clear that there are quite a lot of options for processing pipes, and the choice is very large. Experts advise paying attention to the conditions in which each material will be used, its characteristics and installation method. Naturally, competent thermal insulation calculations also play an important role, which will allow you to be confident in the work done.

Video No. 1. Thermal insulation of pipes. Installation example

Foamed polyurethane (polyurethane foam, PPU)

Reduces heat loss by more than half compared to glass wool and mineral wool. Its advantages include: low thermal conductivity, excellent waterproofing properties. The service life declared by the manufacturers is 30 years; The operating temperature range is from -40 to +140 °C, the maximum withstandable for a short time is 150 °C.

The main brands of polyurethane foam belong to the flammability group G4 (highly flammable). When the composition is changed by adding fire retardants, they are assigned G3 (normally flammable).

Although polyurethane foam is excellent as an insulating material for heating pipes, keep in mind that SP 61.13330.2012 allows the use of such thermal insulation only in single-family residential buildings, and SP 2.13130.2012 limits their height to two floors.

Might be interesting

Thermal insulation

Self-adhesive thermal insulation: how to choose and apply?

Thermal insulation

What are thermal insulation materials: comparative…

Thermal insulation

How to insulate a roof from the inside and not make mistakes?

Thermal insulation

Roofing and drainage: heating rules

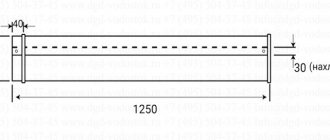

Thermal insulation coating is produced in the form of shells - semicircular segments with tongue and groove locks at the ends. Ready-made steel pipes insulated with polyurethane foam with a protective sheath of polyethylene are also available for sale.

Installation

The shells are secured to the heating pipe using ties, clamps, plastic or metal bandage. Like many polymers, the material does not tolerate prolonged exposure to sunlight, so an open ground pipeline when using PPU shells requires a covering layer, for example, galvanized steel.

For underground ductless placement, thermal insulation products are laid on waterproof and temperature-resistant mastics or adhesives, and the outside is insulated with a waterproof coating. It is also necessary to take care of the anti-corrosion treatment of the surface of metal pipes - even the glued joint of the shells is not tight enough to prevent the condensation of water vapor from the air.

Methods of thermal insulation of pipelines

SNiP specifications and many professionals recommend following the following options for protecting trunk lines:

- Air insulation. Typically, communication systems running in the ground are protected by thermal insulation of a certain thickness. However, the factor that the freezing of the ground goes from the top to the bottom is often not taken into account, while the heat flow from the pipes tends to the top. Since the pipeline is protected on all sides by a component of minimal thickness, the rising heat is also insulated. In this case, it is more rational to install insulation over the upper part of the line, so that a thermal layer is formed.

- Use of insulation and heating element. Great as an alternative to traditional options. In this case, the point is taken into account that the protection of lines is seasonal, and laying them in the ground is not rational for financial reasons, as is the use of a large thickness of insulator. According to SNiP rules and manufacturers' instructions, the cable can be located both inside and outside the pipes.

- Laying a pipe in a pipe. Here, individual pipes are additionally installed in polypropylene pipes. The peculiarity of the method is that it is possible to warm up the systems almost always, including using the principle of suction of warm air masses. In addition, if necessary, an emergency hose can easily be laid in the existing gap.

Do-it-yourself thermal insulation of pipelines

There are a number of factors on which the technology for creating a thermal insulation layer on pipelines may depend. One of the most important is how the collector is laid - outside or in the ground.

Insulation of underground networks

To solve the problem of ensuring thermal protection of buried communications, insulation work is carried out in the following order:

- first, sewer trays are laid at the bottom of the trench;

- after this, pipes are laid on top of them, after which they begin to seal the connections between them;

- Next, casings are put on the pipes, and then the structure is wrapped using vapor-proof fiberglass. To fix materials, clamps made of polymeric materials are used;

- Then the tray is closed with a lid, after which it is filled with soil. A sand-clay mixture is placed in the gap between it and the trench , followed by careful compaction;

- if there are no trays, then the pipes are laid on compacted soil with a sand-gravel mixture.

Requirements for thermal insulation of heating pipes

Technical requirements for thermal insulation of pipelines are established by SP 61.13330. During operation, it is exposed to various influences - mechanical, chemical, thermal, humidity, therefore it must not only be energy efficient, but also reliable, durable, and safe.

Characteristics of materials that are taken into account when choosing:

- Thermal conductivity, density - determine the thickness of the insulation layer, the load on the pipe, its supports.

- Heat resistance - ensures that the original properties remain unchanged upon contact with a hot surface.

- Elasticity and compressive strength are responsible for the stability of shape and structure when caking and laying in the ground.

- Water resistance - eliminates the absorption of water, allows you to maintain thermal insulation properties.

- Biostability and resistance to aggressive environments are important for long-term operation.

- Flammability, content of harmful substances - must meet sanitary and hygienic requirements, fire safety standards.

From a practical point of view, convenient, simple installation is important. It saves time and eliminates additional costs for installation materials.