- Production Features

- Our prices for polyethylene casing pipes

- Scope of application

- Advantages of using HDPE cases

The main purpose of the polyethylene sheath is to protect a certain section of the pipeline from mechanical damage. This product has an annular cross-section and fairly thin walls, so protective polyethylene pipes can be made from pipes using recycled materials.

It is made by extrusion. The material used is HDPE. PE casing pipe is used in the following areas:

- Protection of main networks, the elements of which are steel pipes - polyethylene casing for PPU pipes

- A case made of polyethylene pipes used during the installation of HDPE pipes that are part of the plumbing system.

- Construction of reservoirs.

- Manufacturing of air ducts.

- In the process of laying electrical wiring and power cables.

Depending on the scope of application of protective pipes, the technology of their use also changes.

Features of the production of technical casing pipes

The polymer shells of the protective polyethylene pipe are made from heat-stabilized HDPE. In most cases it is black in color. The parameters of this raw material are strictly regulated by GOST 16338-85. In turn, GOST 18599-2001 determines the characteristics of the product and possible deviations from them. According to standards, the outer surface of the polyethylene shell must be smooth without any roughness. Longitudinal stripes and slight waviness are allowed. The product must not have burrs, cracks or any other physical defects.

You can buy a HDPE pipe casing at a fairly low price. Pay attention to our prices for polyethylene sheathed pipes. HDPE protective pipes using recycled materials have a lower cost, and therefore we can offer prices lower than pressure ones.

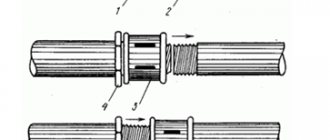

Installation of thermally insulated products

Laying pipelines using insulated pipes consists of the following steps:

- stripping the thermal insulation at a distance of no more than 30 cm from each edge of the product;

- performing a welded connection;

- installation of a heat-shrinkable sleeve on a pipe;

- filling the cavity under the coupling with foam;

- deposition of the coupling in place by heating to produce a sealed joint.

The welded joint must be checked for strength using a portable flaw detector. When sealing joints, during welding work, it is important to cover the ends of the stripped insulation with some non-flammable material (for example, asbestos fabric), since both PE and polyurethane foam are flammable materials.

Often, installation of channels with pre-installed thermal insulation is carried out using horizontal drilling. Heat-shrinkable sleeves or tapes allow you to obtain a protective casing, which in its properties and qualities will not be inferior to the product shell. In addition to pipes, insulated bends with angles of 15-90 degrees, transitions, tee branches, tees (different and equal), elements with an output cable, U- and Z-shaped elements are also produced. All characteristics of auxiliary products for pipelines are specified in the standards.

Thus, a pipe insulated with PPU PE is a highly efficient product that allows you to quickly install a heating network, heating, hot water supply pipeline laid underground.

Price for a protective pipe with a polyethylene sheath

DIAMETER 110 mm

| Technical parameters of PE pipe with a diameter of 110 mm | Price per meter |

| Pipe casing polyethylene technical SDR 41 wall thickness 2.7 mm | 66,41 |

| Pipe casing polyethylene technical SDR 33 wall thickness 3.4 mm | 82,84 |

| Pipe casing polyethylene technical SDR 26 wall thickness 4.2 mm | 101,09 |

| Pipe casing polyethylene technical SDR 21 wall thickness 5.3 mm | 124,96 |

| Pipe casing polyethylene technical SDR 17.6 wall thickness 6.3 mm | 146,72 |

| Pipe casing polyethylene technical SDR 17 wall thickness 6.6 mm | 153,74 |

| Pipe casing polyethylene technical SDR 13 wall thickness 8.1 mm | 186,73 |

| Pipe casing polyethylene technical SDR 11 wall thickness 10.0 mm | 224,64 |

| Pipe casing polyethylene technical SDR 9 wall thickness 12.3 mm | 269,57 |

| Pipe casing polyethylene technical SDR 7.4 wall thickness 15.1 mm | 320,81 |

| Pipe casing polyethylene technical SDR 6 wall thickness 18.3 mm | 374,87 |

DIAMETER 125 MM

| Technical parameters of PE pipe with a diameter of 125 mm | Price per meter |

| Pipe casing polyethylene technical SDR 41 wall thickness 3.1 mm | 87,05 |

| Pipe casing polyethylene technical SDR 33 wall thickness 3.9 mm | 106,7 |

| Pipe casing polyethylene technical SDR 26 wall thickness 4.8 mm | 134,27 |

| Pipe casing polyethylene technical SDR 21 wall thickness 6 mm | 160,76 |

| Pipe casing polyethylene technical SDR 17.6 wall thickness 7.1 mm | 188,84 |

| Pipe casing polyethylene technical SDR 17 wall thickness 7.4 mm | 197,26 |

| Pipe casing polyethylene technical SDR 13.6 wall thickness 9.2 mm | 240,08 |

| Pipe casing polyethylene technical SDR 11 wall thickness 11.4 mm | 292,03 |

| Pipe casing polyethylene technical SDR 9 wall thickness 14 mm | 348,19 |

| Pipe casing polyethylene technical SDR 7.4 wall thickness 17.1 mm | 413,48 |

| Pipe casing polyethylene technical SDR 6 wall thickness 20.8 mm | 484,38 |

DIAMETER 140 MM

| Technical parameters of PE pipe with a diameter of 140 mm | Price per meter |

| Pipe casing polyethylene technical SDR 41 wall thickness 3.5 mm | 108,81 |

| Pipe casing polyethylene technical SDR 33 wall thickness 4.3 mm | 133,38 |

| Pipe casing polyethylene technical SDR 26 wall thickness 5.4 mm | 164,97 |

| Pipe casing polyethylene technical SDR 21 wall thickness 6.7 mm | 202,89 |

| Pipe casing polyethylene technical SDR 17.6 wall thickness 8 mm | 237,98 |

| Pipe casing polyethylene technical SDR 17 wall thickness 8.3 mm | 247,10 |

| Pipe casing polyethylene technical SDR 13.6 wall thickness 10.3 mm | 301,16 |

| Pipe casing polyethylene technical SDR 11 wall thickness 12.7 mm | 364,34 |

| Pipe casing polyethylene technical SDR 9 wall thickness 15.7 mm | 438,05 |

| Pipe casing polyethylene technical SDR 7.4 wall thickness 19.2 mm | 520,18 |

| Pipe casing polyethylene technical SDR 6 wall thickness 23.3 mm | 596,00 |

DIAMETER 160 MM

| Technical parameters of PE pipe with a diameter of 160 mm | Price per meter |

| Pipe casing polyethylene technical SDR 41 wall thickness 4 mm | 141,10 |

| Pipe casing polyethylene technical SDR 33 wall thickness 4.9 mm | 171,99 |

| Pipe casing polyethylene technical SDR 26 wall thickness 6.2 mm | 216,22 |

| Pipe casing polyethylene technical SDR 21 wall thickness 7.7 mm | 264,65 |

| Pipe casing polyethylene technical SDR 17.6 wall thickness 9.1 mm | 309,58 |

| Pipe casing polyethylene technical SDR 17 wall thickness 9.5 mm | 322,92 |

| Pipe casing polyethylene technical SDR 13.6 wall thickness 11.8 mm | 393,82 |

| Pipe casing polyethylene technical SDR 11 wall thickness 14.6 mm | 476,66 |

| Pipe casing polyethylene technical SDR 9 wall thickness 17.9 mm | 570,73 |

| Pipe casing polyethylene technical SDR 7.4 wall thickness 21.9 mm | 676,73 |

| Pipe casing polyethylene technical SDR 6 wall thickness 26.6 mm | 779,22 |

DIAMETER 180 MM

| Technical parameters of PE pipe with a diameter of 180 mm | Price per meter |

| Pipe casing polyethylene technical SDR 41 wall thickness 4.4 mm | 175,50 |

| Pipe casing polyethylene technical SDR 33 wall thickness 5.5 mm | 217,62 |

| Pipe casing polyethylene technical SDR 26 wall thickness 6.9 mm | 270,27 |

| Pipe casing polyethylene technical SDR 21 wall thickness 8.6 mm | 332,05 |

| Pipe casing polyethylene technical SDR 17.6 wall thickness 10.2 mm | 391,01 |

| Pipe casing polyethylene technical SDR 17 wall thickness 10.7 mm | 409,27 |

| Pipe casing polyethylene technical SDR 13 wall thickness 13.3 mm | 498,42 |

| Pipe casing polyethylene technical SDR 11 wall thickness 16.4 mm | 603,02 |

| Pipe casing polyethylene technical SDR 9 wall thickness 20.1 mm | 723,06 |

| Pipe casing polyethylene technical SDR 7.4 wall thickness 24.6 mm | 855,04 |

| Pipe casing polyethylene technical SDR 6 wall thickness 29.9 mm | 982,80 |

DIAMETER 200 MM

| Technical parameters of PE pipe with a diameter of 200 mm | Price per meter |

| Pipe casing polyethylene technical SDR 41 wall thickness 4.9 mm | 216,92 |

| Pipe casing polyethylene technical SDR 33 wall thickness 6.2 mm | 272,38 |

| Pipe casing polyethylene technical SDR 26 wall thickness 7.7 mm | 334,85 |

| Pipe casing polyethylene technical SDR 21 wall thickness 9.6 mm | 412,78 |

| Pipe casing polyethylene technical SDR 17.6 wall thickness 11.4 mm | 485,78 |

| Pipe casing polyethylene technical SDR 17 wall thickness 11.9 mm | 504,04 |

| Pipe casing polyethylene technical SDR 13.6 wall thickness 14.7 mm | 614,25 |

| Pipe casing polyethylene technical SDR 11 wall thickness 18.2 mm | 744,12 |

| Pipe casing polyethylene technical SDR 9 wall thickness 22.4 mm | 891,54 |

| Pipe casing polyethylene technical SDR 7.4 wall thickness 27.4 mm | 1 061,42 |

| Pipe casing polyethylene technical SDR 6 wall thickness 37.4 mm | 1 537,38 |

DIAMETER 225 MM

| Technical parameters of PE pipe with a diameter of 225 mm | Price per meter |

| Pipe casing polyethylene technical SDR 41 wall thickness 5.5 mm | 274,48 |

| Pipe casing polyethylene technical SDR 33 wall thickness 6.9 mm | 339,07 |

| Pipe casing polyethylene technical SDR 26 wall thickness 8.6 mm | 419,80 |

| Pipe casing polyethylene technical SDR 21 wall thickness 10.8 mm | 522,99 |

| Pipe casing polyethylene technical SDR 17.6 wall thickness 12.8 mm | 613,55 |

| Pipe casing polyethylene technical SDR 17 wall thickness 13.4 mm | 640,22 |

| Pipe casing polyethylene technical SDR 13.6 wall thickness 16.6 mm | 779,22 |

| Pipe casing polyethylene technical SDR 11 wall thickness 20.5 mm | 940,68 |

| Pipe casing polyethylene technical SDR 9 wall thickness 25.2 mm | 1130,22 |

| Pipe casing polyethylene technical SDR 7.4 wall thickness 30.8 mm | 1339,42 |

| Pipe casing polyethylene technical SDR 6 wall thickness 37.4 mm | 1537,38 |

DIAMETER 250 MM

| Technical parameters of PE pipe with a diameter of 250 mm | Price per meter |

| Pipe casing polyethylene technical SDR 41 wall thickness 6.2 mm | 337,66 |

| Pipe casing polyethylene technical SDR 33 wall thickness 7.7 mm | 414,18 |

| Pipe casing polyethylene technical SDR 26 wall thickness 9.6 mm | 511,75 |

| Pipe casing polyethylene technical SDR 21 wall thickness 11.9 mm | 626,18 |

| Pipe casing polyethylene technical SDR 17.6 wall thickness 14.2 mm | 706,21 |

| Pipe casing polyethylene technical SDR 17 wall thickness 14.8 mm | 772,2 |

| Pipe casing polyethylene technical SDR 13.6 wall thickness 18.4 mm | 940,68 |

| Pipe casing polyethylene technical SDR 11 wall thickness 22.7 mm | 1137,24 |

| Pipe casing polyethylene technical SDR 9 wall thickness 27.9 mm | 1361,88 |

DIAMETER 280 MM

| Technical parameters of PE pipe with a diameter of 280 mm | Price per meter |

| Pipe casing polyethylene technical SDR 41 wall thickness 6.9 mm | 418,39 |

| Pipe casing polyethylene technical SDR 33 wall thickness 8.6 mm | 518,07 |

| Pipe casing polyethylene technical SDR 26 wall thickness 10.7 mm | 638,11 |

| Pipe casing polyethylene technical SDR 21 wall thickness 13.4 mm | 793,26 |

| Pipe casing polyethylene technical SDR 17.6 wall thickness 15.9 mm | 926,64 |

| Pipe casing polyethylene technical SDR 17 wall thickness 16.6 mm | 968,76 |

| Pipe casing polyethylene technical SDR 13.6 wall thickness 20.6 mm | 1179,36 |

| Pipe casing polyethylene technical SDR 11 wall thickness 25.4 mm | 1635,66 |

| Pipe casing polyethylene technical SDR 9 wall thickness 31.3 mm | 1712,88 |

DIAMETER 315 MM

| Technical parameters of PE pipe with a diameter of 315 mm | Price per meter |

| Pipe casing polyethylene technical SDR 41 wall thickness 7.7 mm | 525,79 |

| Pipe casing polyethylene technical SDR 33 wall thickness 9.7 mm | 656,37 |

| Pipe casing polyethylene technical SDR 26 wall thickness 12.1 mm | 814,32 |

| Pipe casing polyethylene technical SDR 21 wall thickness 15 mm | 996,84 |

| Pipe casing polyethylene technical SDR 17.6 wall thickness 17.9 mm | 1172,34 |

| Pipe casing polyethylene technical SDR 17 wall thickness 18.7 mm | 1221,48 |

| Pipe casing polyethylene technical SDR 13.6 wall thickness 23.2 mm | 1495,26 |

| Pipe casing polyethylene technical SDR 11 wall thickness 28.6 mm | 1804,14 |

| Pipe casing polyethylene technical SDR 9 wall thickness 35.2 mm | 2162,16 |

DIAMETER 400 MM

| Technical parameters of PE pipe with a diameter of 400 mm | Price per meter |

| Pipe casing polyethylene technical SDR 41 wall thickness 9.8 mm | 849,42 |

| Pipe casing polyethylene technical SDR 33 wall thickness 12.3 mm | 1060,02 |

| Pipe casing polyethylene technical SDR 26 wall thickness 15.3 mm | 1305,72 |

| Pipe casing polyethylene technical SDR 21 wall thickness 19.1 mm | 1607,58 |

| Pipe casing polyethylene technical SDR 17.6 wall thickness 22.7 mm | 1888,38 |

| Pipe casing polyethylene technical SDR 17 wall thickness 23.7 mm | 1965,60 |

| Pipe casing polyethylene technical SDR 13.6 wall thickness 29.4 mm | 2400,84 |

| Pipe casing polyethylene technical SDR 11 wall thickness 36.3 mm | 2906,28 |

| Pipe casing polyethylene technical SDR 9 wall thickness 44.7 mm | 3488,94 |

Be sure to check current prices with your wholesale sales manager by calling 8 917 908 2660.

Cable communication wells

Article: 15304

Cable well KS-1

Price Ⅰ: up to 50,000 rub. 5,600.00 rub.

Price Ⅱ: from 50,000 rub. up to 150,000 rub. 5,112.80 rub.

Price Ⅲ: from RUB 150,000 upon request

Units of measurement: pcs.

Article: 15305

Cable well KS-2.2

Price Ⅰ: up to 50,000 rub. 7,400.00 rub.

Price Ⅱ: from 50,000 rub. up to 150,000 rub. 6,756.20 rub.

Price Ⅲ: from RUB 150,000 upon request

Units of measurement: pcs.

Article: 15311

Cable well KN-780/1000

Price Ⅰ: up to 50,000 rub. 15,550.00 rub.

Price Ⅱ: from 50,000 rub. up to 150,000 rub. 14,197.15 rub.

Price Ⅲ: from RUB 150,000 upon request

Units of measurement: pcs.

Article: 15301

Cable communication well base d800 h500

Price Ⅰ: up to 50,000 rub. 5,955.00 rub.

Price Ⅱ: from 50,000 rub. up to 150,000 rub. 5,610.00 rub.

Price Ⅲ: from 150,000 rub. 5,265.00 rub.

Units of measurement: pcs.

Article: 15303

Cable communication well cover d800 h500

Price Ⅰ: up to 50,000 rub. 3,968.00 rub.

Price Ⅱ: from 50,000 rub. up to 150,000 rub. 3,856.00 rub.

Price Ⅲ: from 150,000 rub. 3,744.00 rub.

Units of measurement: pcs.

View all products: Cable communication wells »

Scope of application of HDPE COVER PIPES

Among other options for using protective HDPE pipes, one can highlight their ability to serve as a shell for steel pipes.

Polyethylene casing for PPU pipes

The production process is as follows:

- The surface of the steel and protective pipe is installed parallel to each other. This is done using special centering supports.

- The space between the pipes is filled with a special mixture.

- The mixture should harden. This happens within 30 minutes under natural conditions.

The process of producing shaped products that are used as connecting elements in pipeline systems is carried out in approximately the same way. HDPE protective pipes are characterized by high water resistance and strength, which allows you to count on a long service life of the pipes, since they receive excellent protection from any damage and moisture penetration under the heat-insulating layer.

Polyethylene shells are also used as a protective layer when creating utility lines.

Case made of polyethylene pipes with PE shells for laying power systems

The polyethylene case is an indispensable product when laying electrical and communication networks. In addition to protection from physical damage, electrical cables become immune to the negative effects of moisture. This is especially true in very wet soil conditions.

HDPE protective pipe for laying power cables

If HDPE products are used as a protective material for cables, then the use of the horizontal drilling method will be most relevant.

HDPE casing pipe for water supply

Recently, there has been a trend in which steel water pipes are being replaced with polyethylene ones. This is due to the greater durability of the latter and their resistance to the appearance of traces of corrosion. It is also worth noting that they cost significantly less than steel ones. But the strength of HDPE is significantly lower than steel. Therefore, for polyethylene pipes it is advisable to use additional reinforcement in the form of shells.

Such measures are relevant when laying:

- Railways and highways.

- Tunnels.

- Diversion channels.

- Collectors.

- Sewer networks.

- Gutters.

Polyurethane foam as a material

The PPU PE pipe has a polyurethane foam layer as a heat-insulating material. It is characterized by a low thermal conductivity coefficient (at the level of 19-28 mW/m*K). In general, for pipes (St, PE), polyurethane foam is an infusible thermoactive plastic with a cellular structure.

About 97% of its volume is occupied by pores and cavities filled with gas with very low thermal conductivity (the proportion of closed pores is from 90 to 95 percent). The remaining 3% of the volume of polyurethane foam is a solid material that forms a frame of walls, ribs, and gives it mechanical strength.

Polyurethane foam is a two-component system. It consists of:

- polyol component containing catalysts, polyols, stabilizers, blowing agent;

- isocyanate component containing PMDI (polymer diphenylmethane diisocyanate).

This material is one of the most effective heat insulators used in modern construction of oil, heating, gas pipelines, floors, floors, walls, enclosing structures, etc.

Note! Polyurethane foam is characterized by a significant density range: 40-200 kg/m3. This allows the use of polyurethane foam as thermal insulation for floors.

Polyurethane foam is a dense material that significantly reduces heat loss

Casting rigid polyurethane foam is a foam material. It is obtained in the form of blocks in accordance with the dimensions of injection molds. The shrinkage tolerance value is 4 cm.

Protective polyethylene pipe

The properties of these products allow them to be used as a protective shell for the water supply network in order to prevent exposure to the external environment and deformation. Often used when laying communications using the trenchless method.

The shell is installed in the following order:

- The required amount of soil is removed from the site to ensure the required depth.

- The necessary equipment is placed in the pit to create a hole of the required diameter.

- A protective shell spreads. Its dimensions should be approximately 100-200 mm larger than the main communication in diameter. As for the length, the shell must be laid so that it extends beyond the outer plane of the structure by 2 meters or more.

- Plumbing is being installed. In this case, you should try to avoid connections throughout the entire area of the case. In cases where the pipeline is laid in the wall of a building, the shell must be laid with a margin of 50 mm beyond the boundaries of the building envelope.

Accessories for cable wells

Article: 15521

110 mm sealed inlet adapter

Price Ⅰ: up to 50,000 rub. 736.00 rub.

Price Ⅱ: from 50,000 rub. up to 150,000 rub. 638.00 rub.

Price Ⅲ: from 150,000 rub. 540.00 rub.

Units of measurement: pcs.

Article: 15519

63 mm sealed inlet adapter

Price Ⅰ: up to 50,000 rub. 271.40 rub.

Price Ⅱ: from 50,000 rub. up to 150,000 rub. 243.70 rub.

Price Ⅲ: from 150,000 rub. 216.00 rub.

Units of measurement: pcs.

Article: 15511

Cover for well KN-780

Price Ⅰ: up to 50,000 rub. 3,950.00 rub.

Price Ⅱ: from 50,000 rub. up to 150,000 rub. 3,606.35 rub.

Price Ⅲ: from 150,000 rub. 3,318.00 rub.

Units of measurement: pcs.

Article: 15507

Fasteners (clamp) for KS-3 wells

Price Ⅰ: up to 50,000 rub. 169.00 rub.

Price Ⅱ: from 50,000 rub. up to 150,000 rub. 162.50 rub.

Price Ⅲ: from 150,000 rub. 156.00 rub.

Units of measurement: pcs.

Article: 15505

Rack L 600 (guide) for KS-5 (including installation)

Price Ⅰ: up to 50,000 rub. 935.00 rub.

Price Ⅱ: from 50,000 rub. up to 150,000 rub. 917.50 rub.

Price Ⅲ: from 150,000 rub. 900.00 rub.

Units of measurement: pcs.

View all products: Accessories for cable manholes »

Advantages of HDPE cases

All the advantages of these products are based on their properties:

- Light weight. They are easy to transport and install.

- Long service life.

- Does not require grounding or cathodic protection.

- Restoration work does not require large financial costs.

- Do not cause problems during operation.

- High level of protection against aggressive environments.

- Low thermal conductivity. This property allows you to reduce heat loss in heating networks and water supply systems. The amount of condensate that forms on communications is reduced.

- Low cost compared to steel.

Low weight allows you to install protective polyethylene pipes in hard-to-reach places. Their range of applications is quite wide. This is due to the operational properties of the product.

HDPE protective pipe is supplied in lengths of 4,6,12 meters. Delivery of technical polyethylene HDPE casing pipes is carried out to all cities and regions of Russia. Incl. Abakan, Adler, Angarsk, Apatity, Arkhangelsk, Astrakhan, Achinsk. Balakovo, Barnaul, Belgorod, Biysk, Bratsk, Bryansk, Bugulma. Velikiye Luki, Veliky Novgorod, Vladimir, Volgograd, Volgodonsk, Volzhsky, Vologda, Voronezh. Dzerzhinsk, Dimitrovgrad, Dmitrov. Ekaterinburg, Zheleznodorozhny, Zelenograd. Ivanovo, Izhevsk, Irkutsk, Yoshkar-Ola. Kazan, Kaliningrad, Kaluga, Kamensk-Uralsky, Kamyshin, Kemerovo, Kirov, Klin, Kolomna, Kostroma, Krasnogorsk, Krasnodar, Krasnoyarsk, Kurgan, Kursk. Lipetsk, Magnitogorsk, Miass, Moscow, Murmansk, Murom, Mytishchi. Naberezhnye Chelny, Nizhnevartovsk, Nizhnekamsk, Nizhny Novgorod, Nizhny Tagil, Novokuznetsk, Novomoskovsk, Novorossiysk, Novosibirsk, Novocherkassk, Noginsk. Obninsk, Omsk, Orel, Orenburg, Orsk. Penza, Pervouralsk, Perm, Petrozavodsk, Podolsk, Pskov, Pushkino, Pyatigorsk. Rostov-on-Don, Rybinsk, Ryazan. Samara, St. Petersburg, Saransk, Saratov, Severodvinsk, Serov, Serpukhov, Smolensk, Solnechnogorsk, Sochi, Stavropol, Simferopol, Stary Oskol, Sterlitamak, Stupino, Surgut, Syzran, Syktyvkar. Taganrog, Tambov, Tver, Tolyatti, Tomilino, Tomsk, Tula, Tyumen, Ulan-Ude, Ulyanovsk, Ufa, Ukhta, Khanty-Mansiysk, Cheboksary, Chelyabinsk, Cherepovets, Chita, Engels, Yuzhno-Sakhalinsk, Yaroslavl, delivery to other cities.