Water heated floor is a heating system that is well known to everyone. Everything in it is based on pipes through which the coolant flows and these pipes are filled with concrete screed. That is, pipes are essentially the key element of the system. Therefore, their choice must be taken seriously. In this article we will talk about choosing cross-linked polyethylene pipes for heated floors.

Let's first analyze the variety of pipes that can be used for this system and when choosing, we will need a method of sequential elimination. First, we will remove those types of pipes that are unsuitable in our case, but are successfully used in other areas. Thus, we exclude from the list a polypropylene pipe and a metal pipe made of copper or stainless steel. The use of such pipes when installing heated floors is considered economically unjustified.

Now we will discuss in more detail the following options: 1. Pex-AL-Pex pipe made of metal-plastic, 2. Pert pipe made of uncrosslinked polyethylene, 3. Pipe made of cross-linked polyethylene.

Metal-plastic pipe Pex-AL-Pex

This pipe consists of 5 layers: the first, fifth layers are cross-linked polyethylene, the second, fourth are an adhesive layer, and the third are aluminum foil.

Moreover, an ethylene polymer with cross-linked molecules has several different cross-linking methods: A, B, C. The advantage of the adhesive layer is that it rigidly binds the aluminum layer to the layers of polyethylene. The aluminum foil in the pipe is a 100% oxygen barrier. Oxygen molecules do not pass through aluminum foil into the coolant at all. There is another factor in using aluminum foil in a pipe - it significantly minimizes the linear elongation of a metal-polymer pipe.

The metal-plastic pipe entered the domestic market quite a long time ago, somewhere in the 90s of the last century. And as you noticed, the pipe partly consists of cross-linked polyethylene. It can be convincingly said about it that it has been tested by harsh operating conditions and harsh Russian specialists.

There is a serious concern among installers. That when laying and using a metal-plastic pipe, the pipe may peel off or crack.

When these products appeared on the Russian markets, these facts were real. Now such products have been produced and used for quite a long time, so manufacturers have already fully mastered the entire technique for producing such pipes and the possibility of delamination has been reduced to a minimum.

Characteristics of pipes for water heated floors

The construction of a water heated floor is a complex and time-consuming process, especially when using a concrete screed and the need to reinforce the structure. Therefore, great demands are placed on the pipes that are planned to be laid in the “pie”.

Important! The use of standard PVC water pipes is prohibited.

Since they cannot withstand high loads that are formed due to high temperatures and pressure created in the pipeline.

The main requirement for a pipeline in a warm water floor, both in a private house and in an apartment, is durability and tightness. It is necessary that during a sharp temperature change the system does not depressurize.

After all, if there is a screed, it is difficult to find and eliminate the defect. In addition, it must withstand the effects of aggressive chemical compounds found in the coolant and mechanical loads. The elasticity of the contour is of no small importance - it should bend easily.

We should not forget about the level of thermal conductivity when choosing a coil for water-type underfloor heating; the higher this coefficient, the more efficiently the device works. And also, regarding the degree of expansion when heated, up to 0.25 mm/mK is considered acceptable.

Pipes are produced in coils with a certain footage. When purchasing, remember that the loops must be solid, without joints.

For your information! The pipeline for heated water floors must be marked to permit their use in heated floors.

Pert half-crosslinked polyethylene pipe

The pipe is also produced with the addition of certain chemical additives in the base material, but the molecular special. the output structure is somewhat different. There are no spatial molecular bonds and the interlocking and intertwining of the molecular branches of the material occurs. Due to this, the material obtains slightly different properties compared to cross-linked polyethylene pipes. Starting from a temperature of 70 degrees, rapid aging of the pipeline begins. The pipe appeared relatively recently on the all-Russian market; it began to be actively produced as a way to reduce costs during the crisis.

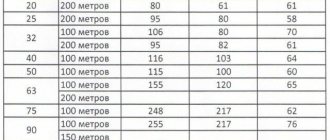

Selection of the optimal diameter

When choosing the diameter of the circuit, you should proceed from the length of the loop and the thermal conductivity of the material. Common sizes used in the construction of heated floors are 16, 20 and 25 mm.

When determining the diameter of the product, the following points must be taken into account:

- the smaller the diameter of the pipes, the higher the hydraulic resistance increases, and the level of heat transfer decreases;

- The larger the cross-section, the thicker the screed must be made, which increases the load on the floors and reduces the height of the ceiling.

Important! If the length does not correspond to the diameter of the circuit, this may lead to the hydraulic resistance exceeding the technical capabilities of the circulation pump.

With a pipeline length of 70 meters, it is recommended to take a pipe diameter of 16 mm. For a loop size of 90 meters, the appropriate cross-section is 20 mm, and for 120 meters, 26 mm.

When choosing the diameter of the product, it is necessary to take into account the level of heat transfer of the pipe material. When laying a copper or metal-plastic coil, it is better to use a contour with a cross-section of 14 or 16 mm. When using polymer pipes - 20 or 25 mm.

Pipe made of cross-linked polyethylene Pex-A, Pex-B, Pex-C

This pipe often has 3 layers, that is, it consists of a layer of cross-linked polyethylene, an adhesive layer and an oxygen-protective layer. (in a metal-plastic pipe it is performed by aluminum foil). In a cross-linked polyethylene pipe, the oxygen-protective layer acts as a specific polymer coating. There are manufacturers who are trying to make their products five-layer.

Methods for cross-linking PEX pipes

PEX-A , chemical: peroxide cross-linking, peroxides are added to the initial volume of the substance and at the exit phase from the instructor, with careful temperature control, we obtain a pipe with 70-75% cross-linking. There is a three-dimensional interweaving of structural lattices within the material used. This method is the most expensive.

PEX-B , chemical: silane crosslinking, organic silanides are added to the starting composition, additives are more affordable and an uncrosslinked pipe comes out of the instructor. It receives the final crosslinking coefficient after the hydration procedure. It is important to control time indicators, temperature dynamics, and at the final stage we obtain a cross-linked polyethylene pipe with a given cross-linking coefficient.

PEX-C, radiation cross-linking, the process of exposing a substance to streams of electrons or γ-rays.

It is necessary to control how the electrode is positioned relative to the pipe, since we need to end up with a uniformly stitched pipe both in length and thickness. The stitching method is a non-duplicating method of solving a given problem. Summarizing the information received, it is worth noting that the main thing is the reliability and reputation of the manufacturer, the use of high-quality materials, increased quality control at all stages of production and the presence of a representative office in Russia.

Rehau pipe installation tool analogue

At the end I’ll also add about an analogue of the tool that can be used to install Rehau pipes. The original one, like all specialized tools, costs exorbitant amounts of money. If you need to make several connections, then of course you can find it for rent. But if you plan to mount more than one object, then I suggest for consideration this analogue of the Rehau tool - the Chinese manufacturer TIM.

This is the best Chinese replica today. Tested at more than one pipe installation site, both Rehau and its analogues (STOUT). The pipe does not break, the expander is durable (it expands up to 32 diameters without problems). Some of the attachments are already sold as a set. Additional ones can be purchased - both original ones and the same manufacturer are suitable.

The main advantage of cross-linked polyethylene pipes

And one more important quality of a pipe made of cross-linked material is that it has memory at the molecular level, which increases its ability to recover. In other words, if during installation the pipe was subjected to mechanical stress or a break occurred during bending, then regardless of which option for stitching the pipeline A, B or C, you can use an industrial hair dryer heated to 110 degrees and heat the pipe. As a result, it takes its original position while maintaining its functionality, physical and chemical characteristics.

Pert pipes and Pex-AL-Pex metal-plastic pipes are not renewable. Also, a pipe made of cross-linked polyethylene Pex-A, Pex-B, Pex-C has the most impressive coefficient of linear elongation in relation to other pipes - an elastic modulus of 670 mPa.

So, in the end, we can choose for installing a heated floor a pipe made of metal-plastic Pex-AL-Pex and a pipe made of cross-linked polyethylene Pex-A, Pex-B, Pex-C. Let's compare them with each other:

- working pressure: Pex-AL-Pex - 10, Pex - 8;

- temperature: Pex-AL-Pex - 95, Pex - 70-90;

- coefficient of thermal expansion: Pex-AL-Pex - 0.26x10-4, Pex - 1.9x10-4;

- recovery ability: Pex;

- ease of installation: only Pex-AL-Pex;

- oxygen barrier: Pex-AL-Pex - 0, Pex - 0.1;

- thermal conductivity through the pipe wall: Pex-AL-Pex - 0.45, Pex - 0.38;

- coolant resistant to freezing: Pex is more resistant;

- price: Pex is often cheaper.

Having considered all the important indicators and characteristics of various types of pipes, you will be able to make the right choice.

Pipes made of cross-linked polyethylene are considered to be high-tech, strong and durable; this is a completely modern choice. The product is completely safe, easy to install and more or less affordable for the average consumer. Warm floors provide comfort in the room, create a temperature balance, and provide an opportunity to save energy. The qualitative characteristics of cross-linked polyethylene pipes are resistance to corrosion and fractures, high temperatures, low thermal conductivity, excellent sound insulation, and ease of installation. PEX pipes are particularly soft and elastic.

But even with such high characteristics of the product, you should not forget about your consumer rights. To date, the regulatory framework has not been fully thought out and is not capable of maximally regulating the quality of the material, which is why not very pleasant surprises arise in buyer-seller relations.

Difusão de oxigênio em tubos de polímero. Diffusion of oxygen in polymer pipes…

In distant Soviet times, there was no question of which pipe to choose for your home - there was only one pipe, steel, and there was only one evaluation criterion - price.Over the past decades, the situation for consumers has become significantly more complicated: steel pipelines began to be replaced by polymer and composite ones, the number of types of pipes used has reached a dozen, and the number of evaluation criteria has increased significantly.

In fact, for the average consumer, choosing a piping system has become like guessing with coffee grounds. He is asked to make a choice based on a variety of specific and non-specific indicators.

In these conditions, an ordinary person, confused in numerous indicators, is forced to trust the advice of relatives, friends, acquaintances and strangers installers and plumbers. This method of choice most often leads to higher costs for the pipeline system, and what is more dangerous, to its rapid failure.

We will try to make the selection process more understandable. To do this, we will use the well-known cumulative assessment method. Its essence is simple: each indicator is given a numerical score in the range from 0 to 1, then all scores are summed up, and a rating of total scores is built for each pipeline system. In this way, we will be able to move away from difficult-to-perceive qualitative assessments to simple numerical rating values.

1. Operating temperature and pressure

One of the favorite motives for praising a pipeline system is the exaggeration of the temperature and strength characteristics of pipes. Some promoters of the achievements of Chinese industry go to the point of absurdity - they convince buyers that their pipes can withstand as much as 130-135 degrees, although it is enough to look in a reference book on polymers and make sure that almost all heat-resistant pipe polymers simply melt at these temperatures (the usual softening temperature range is 122-122-135 degrees). 130 degrees).

If in the last century comparing pipeline systems in terms of operating temperature and operating pressure was quite an urgent task - there were few heat-resistant polymers, then in the 21st century such a comparison is meaningless. Almost all pipe heat-resistant polymers make it possible to produce pipelines for operating temperatures of 95 ° C, and these indicators have become unconditional requirements of existing standards: GOST R 52134-2003 , “Thermoplastic pressure pipes and connecting parts for them for water supply and heating systems” and GOST R 53630-2015 , “Multilayer pressure pipes for water supply and heating systems.” In addition, the main trend in the development of heating systems is to reduce the temperature of the coolant, and very soon a temperature of 95 ° C will become completely anachronistic.

In other words, in modern conditions, operating temperature and pressure are not a criterion for assessing the type of pipeline system, but a kind of “entry ticket” to the class of water supply and heating pipes.

.

.

2. Specifications

There are relatively few key significant indicators of the pipeline system. Let's compare different pipes according to these indicators using simple numerical estimates from o to 1, Table 1.

Table 1

Corrosion resistance. All polymer and composite piping systems are corrosion resistant. But in Russia, about 50% of all pipelines used are still steel, and we need a correct comparison of this indicator. Typical values: 0 – no corrosion, 1 – yes.

Life time. An obviously significant indicator that does not require comment. The most typical service life: up to 15 - 0 points, up to 25 years - 0.5 points, up to 50 years and above - 1 point.

Temperature expansion. One of the most important indicators of pipes is that the higher the thermal expansion of the pipe, the higher the cost of the pipeline system, because To compensate for thermal expansion, the use of additional elements - temperature compensators - is required. Typical ranges of the coefficient of thermal expansion: above 0.5 – O points; 0.3…0.5 – O.5 points; below 0.3 – 1 point.

Oxygen impermeable. Another important indicator that many people frivolously do not pay attention to. In radiator heating systems, the use of oxygen-permeable pipes leads to rapid failure of the pipeline system due to the occurrence of cavitation processes that destroy the metal components of the system: valves, pumps, etc. In low-temperature systems (underfloor heating, panel heating and air conditioning), oxygen diffusion provokes the growth of aerobic bacteria, and the system quickly becomes silted with bacterial waste products. Oxygen-permeable pipes - 0 points, oxygen-tight pipes - 1 point .

Flexibility. Flexible pipes can increase reliability and reduce the cost of the pipeline system, because... require fewer connections, fittings, and, accordingly, less labor costs. In addition, only flexible pipes are used in energy-efficient heating systems (warm floors, panel heating and air conditioning, geothermal heat systems). Rigid pipes – 0 points, flexible pipes – 1 point.

Connection method (welding/mechanical connection). Affects both the cost of the system and its reliability. The European Association of Polymer Pipe and Fitting Manufacturers (TEPPFA https://www.teppfa.org) recognized that over more than 50 years of operation of polymer pipelines, pipe connection using diffusion welding has proven to be the most durable and reliable pipe connection. In addition, a welded connection is significantly cheaper than a mechanical one. Mechanical connection (brass, PPSU fittings) – 0 points, Welding connection – 1 point .

Based on the obtained technical indices, we will construct a rating of pipeline systems, Fig. 1.

Picture 1

3. Cost of the piping system

Sellers of polypropylene pipes like to dissemble when comparing the prices of their pipes with other pipeline systems. For example, compare a polypropylene pipe with a diameter of 20 mm. with a metal-plastic pipe of the same diameter. This is a completely incorrect comparison, since these pipelines have different wall thicknesses and different internal flow areas. It is possible to correctly compare pipes only by internal diameter, because... it is he who determines the throughput of the pipe, and, accordingly, the admissibility of its use in a particular section of the pipeline system. It is best to use the correspondence table when comparing, Tab.2.

Table 2. Correspondence to the outer diameters of pipes with the same flow area

Now let's estimate the cost of pipeline systems, taking into account the price of pipes and fittings, and the cost of installation for the most used pipes with an internal diameter of 12 mm., Tab.3.

Table 3

Pipe cost. Typical values: more than 50 rubles/meter - 0 points, 30...50 rubles/meter - 0.5 points, less than 30 rubles/meter - 1 point.

Cost of fittings. Values (for a feed-through coupling): more than 30 rubles/piece – 0 points, less than 30 rubles/piece. — 1 point.

Consumption of fittings per 1 meter of pipe. Values: up to 2 pieces/meter – 0 points, up to 1.5 pieces/meter – 0.5 points, up to 1.2 pieces/meter – 1 point.

Installation cost. Key indicator of system cost. Unfortunately, the true values are not available to the average consumer. For assessment, we will take SNIP values: up to 200 rubles/meter - 0 points, up to 150 rubles/meter - 0.5 points, up to 100 rubles/meter. – 1 point.

Based on the resulting price index, we will construct a rating of pipeline systems. The higher the rating, the lower the cost of the pipeline system . Fig.2.

Figure 2

4. Versatility of the pipeline system

Ultimately, in addition to convenience, the versatility of the piping system reduces installation costs. The fewer types of pipes used, the lower the overhead and transportation costs, the less waste, and the higher the productivity of installers. Let's evaluate the versatility of pipes by their areas of application, value 1 corresponds to applicability, 0 – not, Tab.4

Table 4

* Energy efficient systems - panel heating and air conditioning (ceiling cooling), systems for using geothermal heat, heat pumps, snow melting and road heating systems, heating the soil of greenhouses.

Based on the obtained index, we will construct a rating of the universality of pipeline systems, Fig. 3.

Figure 3

4. Price/quality rating of pipelines

Using the obtained indices, you can build a rating with almost any price/quality ratio.

To construct a rating of the optimal price/quality ratio, we obtain summary indices consisting of 45% technical index, 45% price index, and 10% versatility index, Table 5, Fig. 4.

Table 5

Figure 4

5. Instead of conclusions

The ratings obtained using numerical assessments, despite their simplicity, reflect the current situation and market trends.

The authors are absolutely sure that the use of steel pipes in water supply and heating networks is unacceptable, but they are forced to admit that the high share of consumption of steel pipes (about 50% of the Russian market) is partly due not only to the resistance of the metallurgical lobby, but also to their relatively good price/quality ratio. In fact, steel pipes are a kind of boundary between single-layer polymer pipes, which were designed to replace them, and multilayer composite pipes, which came to replace polymer pipes.

Figure 5.

The main and defining disadvantage of steel pipes is corrosion. Their short lifespan leads to an avalanche-like increase in the accident rate of pipeline networks. Therefore, the continued use of steel pipes threatens the Russian housing and communal services sector with mass accidents, Fig. 5.

Single-layer polymer pipes, due to the ease of their manufacture, the low cost of equipment, and the ease of their connection by diffusion welding, have occupied a rather significant niche in our country. They coped with the main disadvantage of steel pipes, but their own shortcomings: oxygen permeability and high temperature expansion did not allow them to become a worthy replacement.

By the way, polypropylene pipes reinforced with glass fiber in their essence and technical characteristics should be classified as single-layer pipes, or quasi-single-layer pipes - thanks to the glass fiber, thermal expansion is reduced in them, but their oxygen permeability blocks their way into heating systems.

The fact that only multilayer composite pipelines can have a set of properties that combine the best properties of steel and polymer pipes has long been known. An example is more than 30 years of experience in the operation of metal-plastic pipes in Europe and the USA, where metal-plastic pipes dominate in the heating system segments, and more recently in the gas supply and fire extinguishing segments, and the total share of consumption of which has long exceeded 50% mark.

In Russia, multilayer metal-plastic pipes appeared much later, at the end of the 90s of the last century, and still show high rates of growth in consumption.

The cloudless promotion and reputation of PEX - Al - PEX metal-plastic pipes have been spoiled by regular injections of Chinese crafts made from recycled polymers and aluminum into the market. Only a national tendency to believe in miracles can explain the fact that our consumers purchased Chinese HENCO pipes for their homes at a price of 10-15 rubles. per meter at a time when real Belgian HENCO cost 60-80 rubles. and then they complained that after a year and a half, the miracle of Chinese industry began to crack, leak, and flood newly refurbished dwellings.

It seems that consumers have now become more careful when choosing pipes, and Chinese surrogates have begun to be recognized. First of all, the fakes are given away by the unrealistically low price. The minimum real price of metal-plastic pipes is easy to calculate - the geometric characteristics of pipes are set by national standards, and the cost of raw materials, polymers and aluminum, is regulated by world exchanges, and prices in different countries differ slightly. Using simple calculations, you can calculate raw material costs, add well-known production costs, add a minimum profit of 20-25%, transportation costs, we get a theoretical minimum price, Fig. 6.

Rice. 6. Theoretically, the minimum price for a 16x2 metal-plastic pipe

Not only that, a high-quality Chinese pipe cannot cost 10-15 rubles. , but due to high transportation costs it cannot cost less than Russian-made pipes.

.

.

The new generation of welded metal-plastic pipes PERT - Al - PERT certainly have the highest potential for development. They have absorbed the best properties of traditional metal-plastic pipes PEX - Al - PEX, and received the main advantage of polypropylene pipes - welding using inexpensive polymer fittings. They can equally be called welded metal-plastic pipes and flexible reinforced polypropylene pipes. Most likely, in order to distance PE - RT / Al / PE - RT pipes from their outdated counterparts, manufacturers and consumers will come up with a new name for them.

| PRINTABLE OPTION |

Pipe quality guarantee

For each type of cross-linked polyethylene pipes, components, consumables and various accessories for installation, the contractor or developer offers an official quality guarantee for the material provided, as well as information about it. Considering that the law obliges the manufacturer to ensure uninterrupted operation of the product during the warranty period, manufacturers use pitfalls to refuse a warranty at the request of the buyer.

Companies offering products from global manufacturers, for example, Germany, the Czech Republic, Norway, Italy, indicate their warranty period from 10 to 22 years, service life up to 60 years. Literally all domestic companies specializing in the sale of pipes, elements and equipment for creating heated floors promise the buyer a long-term guarantee for a period of 50 years.

Looking at this figure, it is hard to believe that after such a long period of time the buyer will be able to protect his consumer rights or the system will work without incident. However, manufacturers copy this deadline like a carbon copy. It would be much more correct to indicate that the operating period is up to 50 years, and the warranty period is 7-10 years. But even here, some manufacturers and sellers are trying to play tricks. The consumer is obliged to carefully study the terms of the warranty. If you do not comply with the manufacturer's stated requirements, this will be an excellent reason to deny you a warranty. Keep this in mind

How to calculate the length of a pipe for a heated floor?

Watch the installation video on how to make calculations and which pipe materials to choose and why.

The size of the contour for a water floor should be determined when designing the structure. Its length depends on the laying step. The standard pitch ranges from 100 to 300 mm.

The simplest method to calculate the length of the pipeline is to take the average figure, per 1 m2 - 5 meters of contour, with a step of 200 mm.

A more accurate way is to use the formula

L = S / N * 1.1, where:

L—contour length;

S is the area of the room;

N—laying step;

1.1 - stock of product for rotation.

The calculation for each floor loop must be done separately, and then add up all the indicators. In addition, you should not forget to add the distance from the floor to the collector.

For your information! If the result obtained exceeds the permissible loop size - 120 meters, then the room must be divided into several loops.

You can simplify the calculation process by using an online calculator to determine the length of the pipeline.

The most effective step in installing underfloor heating! How not to make a mistake

Application of pipes depending on diameter

It's actually not that complicated. As a rule (but not always) in residential premises, be it apartments, houses, country cottages, a 16mm diameter heated floor pipe is usually used. At the same time, the size of the room does not play a major role here. This could be a one-room apartment with an area of 40 square meters. m, as well as a mansion, the area of which is about 300 sq. m.

In what cases can a pipe with a diameter of 20 mm be used? Take, for example, a large gym with an area of 700 square meters. m. This is a non-residential premises and it requires thick, dense thermal insulation, as well as a dense screed with a thickness of 100 mm or more, depending on the coating. In accordance with these characteristics, a heated floor pipe with a diameter of 20 mm is selected.

But note that the pipe diameter is not chosen just like that. After all, there are exceptions, and 20 mm pipes can be used both in public buildings, for example, in a shopping center or even in a hospital, and in residential premises

In order to determine what diameter of pipe and where to use it, special calculations are carried out and only then proceed with the installation of heated floors.

Which pipes are better?

Usually the choice comes down to metal-plastic and PEX pipes. More and more people prefer the second option. However, the final decision, of course, is up to the buyer. To help, we offer a video that describes in detail about the materials for making pipes:

If you are not confident in your abilities, it is better to entrust the design of a water heated floor system, selection of materials and installation to specialists. Additional costs for their work will be repaid due to long and trouble-free operation of the system. This is the case when excessive savings can affect the comfort in the home.

Reviews

“I recently installed heated floors in my home. It took me a long time to choose the material, but I finally settled on polypropylene pipes. The installation was simple, I did it myself. But no one warned that there could be pitfalls. A year later I discovered a fountain in the corridor. It turns out that polypropylene tends to expand at high temperatures, and joints are a potential danger for leakage. Now I don’t recommend anyone to use polypropylene.”

“We thought about heated floors for a long time. We chose pipes, listened to reviews from experienced specialists, read forums and decided on metal-plastic. They laid them independently in 30 cm increments in a spiral. Everything took no more than 3 hours. My wife drew the placement of the pipe, and I implemented everything in reality. There was no need to connect the pipes; everything turned out to be a continuous carpet. They only invited people to fill the screed. We did it in a day. They allowed it to dry for 2 weeks (as recommended by the craftsmen), and tests were carried out. We have been keeping warm in the winter for 3 years now and have no problems with the loan. I recommend it to everyone.”

Basic installation details

When installing pipes, special fastening elements are used - profiles; fastening to the floor is done with dowels and screws. The loop should be loose, there is no need to tighten it.

Products are sold in coils. Pipes must not be pulled out of the coil before installation. This can damage the structure of the material. They need to be unwound as needed.

Before installation, some additional work needs to be done:

- Before laying the floor, it is necessary to prepare the base. It is desirable if the deviation error does not exceed 3 cm to eliminate heat loss;

- laying insulation mats;

- after which it is necessary to perform a hydro- and vapor barrier layer;

- then the reinforced mesh is laid;

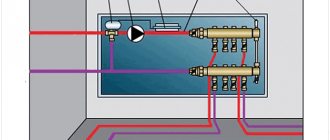

- collector installation.

Installation sequence

How to connect the structure to the heating system can be seen in the video:

Watch this video on YouTube

Laying pipes for a warm water floor

The installation method mainly depends on the size of the room. The most popular options are:

- “snake” – wiring is laid in parallel;

- “snail” - installation of wiring in a spiral, gradually tapering towards the center.

For small areas, we can recommend the installation option in the form of a snake. It is also suitable for installation near cold areas - windows and doors.

Laying in the shape of a snail will allow you to evenly heat fairly large areas. Pipes that supply and return coolant are located nearby.

For any installation method, it is necessary to maintain a design step, which can be within 0.1÷0.35 m. The step near windows or doors should be 0.15 m.

The pipe along the entire circuit must be solid, this will prevent leaks during operation.

The principle of laying several circuits in one area

Connection options

When connecting the floor into a solid structure, you will need the following tools and elements:

- Fittings for connecting copper, corrugated or metal-plastic products.

- Welding for joining polyethylene or polypropylene.

For fixation you should use:

- Anchor staples or dowel staples and a special stapler.

- Clamps.

Mounting options

Step-by-step installation and connection process

Let's consider step-by-step installation in the apartment and connection to the collector:

| Illustration | Description of work |

| It is first necessary to lay the foil backing. | |

| We mark the installation. | |

| Plastic fastening clips are installed on the dowel screws in increments of 50÷70 cm. On bends, the spacing should be reduced. | |

| Laying pipes in the form of a snail. | |

| The finished room took 75 m. | |

| Installation of the system in the second room is carried out in a similar way. | |

| Installation and connection of the collector. |

This installation can be viewed in the master class:

Watch this video on YouTube