Many private houses are heated using water heated floor systems. This factor is explained by the efficiency of this type of heating. The coolant circulating through the pipeline laid under the floor has a much lower temperature than in radiators. This means that much less energy resources are spent on heating it.

Water heated floor system from Pert pipes

Warm floors do not spoil the interior of the premises at all, since they are hidden from the eyes of others by the finishing coating. And the air, heated over the entire surface of the floor, is always directed upward, creating a favorable microclimate and increasing the level of comfort.

Ideally, the use of such heating systems should be envisaged at the stage of building a house. Otherwise, you will need to carry out calculations and large-scale work that requires certain skills and craftsmanship. In addition to choosing high-quality heating and pumping equipment, it is necessary to pay close attention to the selection of consumables, the main of which is the pipe.

PERT pipes for water heated floor systems

It is a mistake to believe that any pipe can be laid in a concrete screed. Increased demands are placed on this element of the system, since the service life of the heated water floor and the quality of operation of the entire system will depend on it.

And although this consumable material is presented in a huge assortment on the construction market, not each of them meets all quality and safety requirements.

Which pipe is suitable for laying the water circuit and will not only extend its service life, but also save money? What do the designations PEX and PE-RT mean? What are the advantages of PERT polyethylene, which recently appeared on the Russian market?

Requirements for pipes

In most cases, the contours of a water-heated floor are filled with a heavy concrete screed, closed with a finishing finish. Even after removing tiles or removing part of the laminate, it will be impossible to visually inspect the system for leaks or any other malfunctions.

Therefore, any pipe that is part of a water-heated floor system must meet strict requirements stipulated by the special conditions of its operation.

Dimensions of polyethylene pipe coils

- The pipe for water systems must be made of materials that are not subject to corrosion. It must have a special structure of the internal cavity, which does not become overgrown when the coolant is in it for a long time. The material, like PE-RT polyethylene, must be resistant to high temperatures and chemicals.

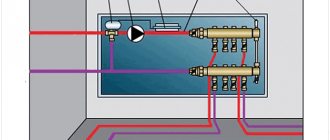

- Each water circuit must consist of a single section, excluding the use of welded technologies. For this reason, the pipe cannot be made of steel, galvanized or stainless metal. When arranging systems, they can be used, but only on the segment leading from the heating boiler to the manifold cabinet.

Connecting a water heated floor - The material must have a large bending radius so that kinks do not form on it during laying. And given that the pipeline is laid out according to a certain pattern, the pipe must maintain its given shape.

- Pipe for water heated floor systems is always supplied in a coil. Therefore, when purchasing, you should take into account that its length must correspond to the length of the pipeline and have some margin.

The main element of water heated floor systems has a standard diameter, which can correspond to the following values:

- 16 mm;

- 20 mm;

- 25 mm. Characteristics of pipes for heated floors

It should be noted that when using consumables of a smaller diameter, heat transfer decreases, which leads to a reduction in the distance between the loops of the circuit and, accordingly, to an increase in material consumption. In addition, the small diameter of the pipe leads to overloads of the pumping equipment. It is also inadvisable to use pipes of too large a diameter, since in this case the thickness of the concrete screed will increase and, as a result, the load on the floor.

DIY water heated floor

[ads-mob-1][ads-pc-1]

Marking

Marking of HDPE pipes

The most common products are those characterized by black or blue color. They are used to deliver gas and liquid. A stripe may be applied to the outer wall: dark blue if the internal medium is liquid, and yellow on products intended for gaseous substances. There are polyethylene pipes on sale:

- in bays;

- in segments.

The choice of option should be made taking into account the purpose of the pipes and their properties. For example, only small-diameter products can be purchased in coils. Other types of pipes are sold in sections. In addition, the pipes must be marked: a diameter of 40 mm or less is used for installing a cold water supply pipeline, and a diameter of 160 mm is used for outdoor work. This size of communications is often chosen when it is planned to build a sewerage system.

Density of polyethylene

There is no need to look for pipe characteristics from the manufacturer, since everything that is needed is often applied to the surface of such products. After the main designation (PE) you can see the numerical value:

- 32: one of the first options for the material, today it is practically not used due to the emergence of an alternative - a more advantageous offer;

- 60: characterized by fragility, which is due to the unequal distance between the molecules, as a result, finished pipes break under the influence of loads, the scope of application is limited to free-flow systems, sewer systems;

- 80: polyethylene of this density is durable, and therefore is a more universal option, so that pipes are not exposed to low temperatures, they should not be used without insulation; if the wall thickness is significant, communications of this type can be used for industrial purposes;

- 100: products are used in the installation of pipelines transporting different media (gas, liquids), are durable, and are universal in the full sense of this definition.

The material obtains the necessary properties due to the peculiarities of production. So, polyethylene is passed through an extruder, from where products with certain parameters appear, which are additionally calibrated on another machine. This allows you to obtain communications of the required diameter and length.

What materials are pipes for heated floors made from?

So what material should be preferred when installing water-based floor heating systems? And here you should not rely on sellers’ assurances that all their goods meet the necessary requirements. Such carelessness can lead to problems that arise already at the installation stage of the systems.

Several materials are used in the production of pipes for heated floors.

- Polypropylene. This option is the most budget-friendly. And this is perhaps his only positive quality. It will not be possible to mount a circuit from a single piece of pipe, since they are sold in small quantities. This material is not highly ductile, so laying the contour is possible only if a large step is observed between the loops. And most importantly, polypropylene has a very low heat transfer coefficient, so the system will be ineffective. Polypropylene pipes

- Metal. Metal pipes can be made of copper and corrugated steel. These materials are of high quality and durability. But their significant disadvantage is their high cost, which is unaffordable for most of the population. Characteristics of corrugated pipes

- Polyethylene (PEX and PE-RT). This also includes metal-plastic. In the production of all varieties, different types of polyethylene are used, and each pipe has a special structure and is processed using different technologies. These materials are distinguished by ease of installation, resistance to mechanical and temperature influences, as well as affordable cost. Pipe for underfloor heating made of cross-linked polyethylene

The final touch

Of course, it is impossible to cover all issues regarding the operation and maintenance of cross-linked polyethylene in one brief publication. However, the topic will continue, and therefore we recommend that you often look at the “Plumbing” section of the site.

Via: Pexuniverse

BRIEFING

Zetsila - publication of materials that are interesting and useful for society. News of technologies, research, experiments on a global scale. Social multi-thematic information - media .

RANDOM CONTENT

Suppressor diode - electronic protection by suppressing voltage surges

21.09.202010.07.2021

Eddy current brakes: How does the eddy current braking mechanism work?

07.07.201908.03.2020

Electrofusion welding – pipe connection technology

26.05.201811.04.2021

Air compressor: make it from a refrigerator with your own hands

28.10.201723.02.2021

Connecting a smartphone to a TV - methods

03.03.202023.02.2021

Contacts + RSS feed

Business inquiries: Contact RSS site feed: News feed

Politics + Navigator

Terms: Site Policy Site Map: Navigation

PEX pipes

First of all, you need to understand what the term “cross-linked polyethylene” or PEX means. Many household items are made from polyethylene. However, in its original form, this material is sensitive to high temperatures.

PEX Pipe

And it’s all because of the structure of the material, the molecules of which are not connected to each other in any way. This drawback is eliminated by using a special treatment of polyethylene, which allows the molecules to be “cross-linked”, due to which the polyethylene becomes stable and does not melt under the influence of high temperatures.

Pipes for heated floors

As a result of such processing, the PEX pipe acquires another positive quality, which is the ability to return to its original shape. That is, if during the operation of water heated floor systems the pipe experiences overload or is subject to mechanical stress that changes its position, after reducing the intensity of the load it will take on its originally specified shape.

Cross-linking of polyethylene is carried out using different technologies, designated as follows:

- PEX-a;

- PEX-b;

- PEX-c;

- PEX-d. Polyethylene cross-linking

It should be noted that when arranging water circuits, PEX-a pipe is most often used. The next two varieties are used much less frequently due to their lower quality. And PEX-d pipes have not found use at all in recent years.

Which is better - polyethylene or metal-plastic?

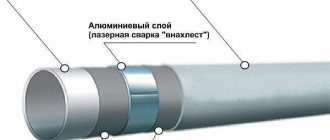

Cross-linked polyethylene can also be considered metal-plastic if one of its layers is aluminum foil, which performs two functions. The main one is reinforcement, that is, an increase in strength. Also, this layer prevents polyethylene from coming into contact with oxygen, which does not have the best effect on it.

When choosing a material, you should be guided by practical considerations that do not oppose polyethylene and metal-plastic, but call for the use of one or another material in accordance with its purpose.

In order to understand the purpose, it is worth paying attention to the features of both options.

Metal-plastic:

- susceptible to delamination, temperature changes are undesirable for it;

- not elastic, water frozen inside can tear it;

- prone to creases.

Based on this, it is not advisable to use metal-plastic pipes, for example, when installing a heated floor or a garden irrigation system that is not dismantled for the winter. Often used for radiator heating.

Polyethylene:

- less tensile strength;

- afraid of direct sunlight;

- elastic, can expand and return to its original shape;

- withstands temperatures up to 95 degrees Celsius.

It is not advisable to use the products in closed systems. This can lead, for example, to the layer of plaster laid on top beginning to crack. At the same time, such material is recommended for the installation of heated floors, use in hot water supply and heating systems.

Thus, this or that material is able to demonstrate its best qualities under appropriate conditions. It would be correct to use both options if it is technologically and practically justified. Find out how to make a brick oven for your dacha yourself using the link.

PE-RT polyethylene pipes

The designation on the pipe “PE-RT” means that it is made of polyethylene with increased heat resistance. This concept does not mean that cross-linking technology was used in relation to it, since the unique PE-RT material already has all the necessary qualities. A distinctive feature of the PERT pipe is the possibility of connection in the circuit using welding or fittings. Regardless of the type of work performed, PERT does not lose its strength and ductility.

Pipe for heated floor KAN-Therm PE-RT

According to experts, PE-RT material will soon completely displace PEX from the market, as it has many more advantages.

- The ease of production of PERT is ensured by the absence of the need to resort to a cross-linking process.

Properties of polyethylene PE-RT - The ability to recycle PERT without affecting the unique qualities of the material.

- PE-RT polyethylene can last more than 50 years.

- Resistance to negative temperatures.

- Possibility of repairing a PERT pipeline directly in a concrete screed.

- A PERT polyethylene pipe has an absolutely smooth inner surface, which prevents the formation of noise even with a strong flow of coolant.

PERT polyethylene is also used in the production of metal-plastic pipes, the distinctive feature of which is the presence of an internal aluminum layer. If a PE-RT polyethylene pipe is produced without an internal metal layer, it is protected from oxygen penetration by other means, for example, by an airtight layer of OXYDEX.

Cross-linked polyethylene Lavita PERT

A water heated floor mounted from a PERT pipe has higher performance characteristics. This material, unlike PEX, has increased elasticity and the ability to withstand heat up to 124.7°C. Considering the lower cost of production of PE-RT polyethylene, the installation of heated floor systems from PE-RT pipes is somewhat cheaper, while meeting all the requirements for this heating method. [ads-pc-2][ads-mob-2]

Comparing pex and pert

So, what do you need to know about long-term operation (as stated by the manufacturer, this is at least fifty years, with characteristics that correspond to a warm water floor). If we look at the aging graphs of pert and pex below (pex on the left, pert on the right), we can see that the process is almost the same up to about seventy degrees Celsius.

Consequently, at operating temperatures greater than or equal to seventy degrees pert, the pipe is significantly inferior to the pex type. Consultants in the store will say that pert pipes are products of increased heat resistance and can withstand temperatures of more than one hundred and ten degrees. This is true, but the amount of time worked decreases very sharply.

The next quality that can be considered is the flexibility or rigidity of the pipe . This parameter does not depend on its type, but only on the specific manufacturer. By the way, the same developer has a pipe, for example, of the pert type, which can be either rigid or flexible. This rule also applies to the pex variety. Rigidity properties mean the ability to accept the smallest bending radius of a pipe without deformation.

By the way, this quality is important if you decide to install pipes yourself because of the convenience of working with a more pliable material. But if you are a customer, then this property should not bother you at all. In this case, the entire complexity of working with the product falls on the shoulders of the installers. There is one more nuance. Some installers make installation mistakes by installing the pipe on the reinforcement mesh. They bend it very strongly and try to do it evenly, and not in the form of a loop or drop, and if a rigid material is also used, then the pipe is deformed, showing a cross-section at the bend in any other shape, except for the shape of a circle. This reduces the hydraulic performance of the pipe loop and affects the circuit settings.

Today there is no difference in the repair of pert and pex pipes. The advantage over metal-plastic pipes is that their manufacturers have polymer and brass fittings (pipeline connecting parts) and these are products with a long service life.

Directly about the markets

It is no secret that there are many cheap counterfeits of trustworthy brands on the markets. They do not withstand temperature and pressure tests, tensile strength tests and do not meet the characteristics of the declared raw materials. As a rule, these are fakes from Southeast Asia, made with savings on raw materials and technology, without any control. Therefore, the client receives who knows what, and then cannot compensate for his losses. The current situation is very alarming due to the presence of a huge number of “specialists” who work in the construction markets, buying pipes and doing installations for private customers with their own hands. When working with polymer pipes, they know very well what they are dealing with (especially for metal-plastic pipes), they know about delaminations and leaks.