Water heated floor is a modern heating system. The comfort in the apartment depends on the efficiency of its work.

Our article provides information about the installation of heated floors and existing temperature standards for residential premises. Also, you will learn the operating temperature of water underfloor heating, and how to adjust the temperature level of the coolant.

Warm floor in a frame house

The structure of a water heated floor

A warm water floor is a multi-layer “pie”, which includes:

- base;

- Warm and waterproof material;

- heating element (pipeline) - coolant circulates through it;

- concrete screed;

- flooring.

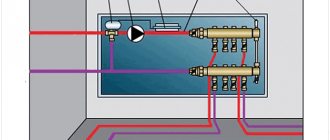

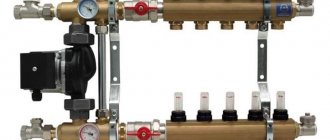

In addition, a collector group is required, which is responsible for distributing the coolant along the circuits and for regulating the temperature.

Minimum and maximum thickness of screed for heated floors

Minimum thickness

Heated floor screed thickness

SNiP indicates 20 mm, however, this applies to metal-cement screed. If you do not use reinforcement, then professionals recommend a screed height of at least 40 mm (provided that the diameter of the water pipe does not exceed one inch (25 mm)). This is due to the fact that a small thickness will not be able to provide the necessary strength of the floor covering. Of course, a thin screed also has its own conditions, including:

— The presence of an existing subfloor;

— And the so-called rough screed (allowing further work to be carried out on a flat surface).

A thin layer is unacceptable in technical rooms, such as a garage, and rooms with more intense loads, for example, kitchens, baths, hallways.

“There is one point to consider. When heated, linear expansion occurs, which means that the dimensions of the concrete screed and the finishing floor covering will change slightly. Taking this into account, along the perimeter of the walls, just above the height of the floor, a damper tape is glued, which plays the role of a “compensator” for the physical dynamics of heated materials and takes on the resulting pressure.”

Sometimes developers offer to equalize differences in floor level due to thickness. The consequences are inhomogeneous heating. This happened to my colleague. Level differences in one of the rooms reached 13 cm (!). He did not give consent, and the builders “solved” the problem by adding crushed stone, sand, expanded clay, and also a jackhammer.

Is there a temperature standard or not?

Regulatory documents have been developed, according to which standard temperature values are established for various rooms.

| Living rooms | 20° – 22 ° | 18° – 24 ° |

| Kitchen, bathroom | 19 ° – 21 ° | 18° – 26 ° |

| Bath | 24 ° – 26 ° | 18° – 26 ° |

| Corridor | 18 ° – 20 ° | 16° – 22 ° |

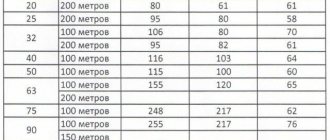

According to SNIP, the maximum and minimum heating degrees are in the range +26 - 36 °C. The temperature level must be determined based on the type of room.

Special requirements when installing heated floors

The floor structure must have a distribution layer that provides a uniform temperature indicator over the entire surface of the floor, this is in order to avoid the concentration of high temperature in individual areas.

It is necessary to be able to control and adjust the surface temperature with a high degree of accuracy.

The entire floor area must be heated. However, this does not apply to comfort heating systems that are in addition to the main heating.

In this case, the temperature should be significantly lower than the permitted 27°C for the floor surface.

The installed floor - including the intermediate layer - must have good thermal conductivity.

In floor construction, waterproofing should be located as close to the wood floor as possible. It is especially important that the waterproofing be close to the wooden floor if there is a heavy and dense beam floor. Under no circumstances should the waterproofing layer be placed on the opposite side of the beams.

How to install a heated floor temperature sensor To create comfort and coziness, both in private houses and apartments, electric floor heating is used. In order for the heated floor system to operate automatically and also be economical, it is necessary to install and connect additional reliable electronic equipment that maintains the temperature in a given mode. This equipment is a temperature controller and a temperature sensor. Before installing them, it is recommended to understand the principle of operation, as well as master the basic connection and installation techniques.

Coolant temperature for heated floors

A comfortable temperature for people is when the floor is heated to +22 - 25 degrees, and in the head area the readings are about +20. In hydrofloors, the distribution and transfer of heat energy depends on the diameter and material of the pipeline, laying pitch, finishing material, and how correctly the flow meters are configured.

When choosing the coolant temperature, you need to take into account

- type and thickness of screed;

- terms of Use;

- is there an additional heating system;

- type of finishing;

- desired heating level.

In the “water heated floor” system, the standard temperature of the supplied coolant is +45 - 50 degrees, the limit is +60.

Such values allow you to heat the entire area at the required level, and not allow the optimal values to be exceeded. That is, there is no overheating and damage to the finishing material.

The permissible difference between the level of water heating at the inlet and outlet fluctuates in the range of 5 - 15. Less than 5 is impossible, since the coolant consumption by the circuits will increase, which will reduce the pressure. A difference of more than 15° is also not recommended. This can result in different levels of floor heating in different areas.

The most optimal differences are within 10 - 12 °C.

Inertia.

The accuracy of maintaining room temperature is directly proportional to the rate of change in floor temperature, which, in turn, is inversely proportional to inertia.

In my underfloor heating system, I deliberately made the screed with pipes extra thick in order to increase inertia in case of a power failure.

It turns out that heating radiators smooth out inertia during heating, accelerating the heating of the room.

Increasing the temperature of the coolant also eliminates inertia, but is undesirable, again, due to inertia.

But I chose inertia, radiators and low coolant temperature.

Maximum temperature of water heated floor

The permissible temperature level for consumers is determined by SNiP 41-01-2003. According to it, the maximum temperature of water-heated floors in rooms where people stay for a long time should not be higher than + 26 degrees. In rooms with high humidity, this value should reach + 31. In kindergartens and schools, the maximum according to standards is + 24.

If the maximum water temperature in a heated floor is +55°C, then this will ensure that the surface is heated to +28°C, which is considered a comfortable heating level.

The specifics of the floor finishing material also affects the level of heating. As a standard, the entire finishing can withstand + 27 °C, but when varnishing the limit is + 21, as it will be destroyed. In addition, if there is a carpet in the room, then you should add 5 degrees.

It is not recommended to exceed these standards; this can lead to:

- unpleasant tactile sensations;

- excessive consumption of thermal resources.

Comfortable temperature in the rooms of a private house.

I would never have thought that a person’s comfortable temperature lies in such a narrow range.

Until I started using thermostats.

Although we lived without thermostats before and did not grieve.

| It turned out that at 21.5 degrees you want to add heating, and at 23 you want to turn it down. It is believed that at night, during sleep, the temperature should be low. During the day, when most likely no one is at home, there is also no need to heat it to 22 degrees. Of course, such desires arise when there is a way to put them into practice. Actually, this is what weekly room thermostats are for. |

In new programmable weekly room thermostats, the night temperature is factory set to 16 degrees.

This is probably how it is done in China. I can’t imagine anyone in Russia sitting at +16 degrees if there is a thermostat with a “+” button.

It's another matter when there is a child in the house. And when the house has laminate floors on screed and no carpets.

In the interior hallway I have linoleum, and there are no heated floors, and no carpets. And nothing. There is no desire to install a carpet. The screed placed on a layer of polystyrene does not cool down much.

But there are other rooms around this room and no one sits on the floor in it.

In residential premises, using laminate flooring on concrete would not be very pleasant.

Floors with laminate on screed must be heated.

Optimal coolant temperature depending on coating

A water heating system is often installed in a concrete screed, and it has a high degree of heating. If the screed is thick, the floor surface will warm up worse. In addition, different flooring materials have different degrees of thermal conductivity.

The optimal temperature for a heated floor when laying laminate or parquet heated by water heating is considered to be +28 degrees. Excess may deform the material.

If the hydrofloor is located under the tiles, then the permissible value is + 33. When laying carpet, the maximum heating of the coolant is +27 degrees. When using linoleum, overheating is not recommended, and the temperature should not exceed more than + 26°C.

In any case, it is necessary to choose a material that is intended for heating systems, otherwise toxic substances may be released.

Characteristics of polymer pipes

To transport coolant in water heating systems of apartments and private houses, the following types of plastic pipelines are used:

- PP-R and PP-RCT are polypropylene random copolymer reinforced with a layer of aluminum, basalt or fiberglass. The PP-RCT plastic modification is characterized by increased thermal resistance.

- PE-X - cross-linked polyethylene grades A, B and C. Products must have an oxygen-protective barrier - a thin layer of impermeable polymer. For example, Rehau pipes use a complex compound called ethylene vinyl glycol (EVOH).

- PE-RT - polyethylene thermostabilized products with an oxygen barrier.

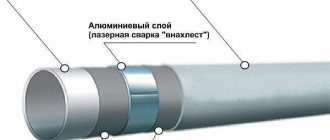

- PE-X / Al / PEX and PE-X / Al / PE – five-layer metal-plastic pipelines.

Reference. According to GOST 32415-2013, products made from polybutylene PB, polyvinyl chloride PVC-C, polypropylene block copolymer and homopolymer (PP-B, PP-N) are also suitable for installation of heating networks. These materials are not widely used in private housing construction due to poor technical parameters.

Products made from polyvinyl chloride PVC-C (photo on the left) and polybutylene PB (on the right)

Briefly about the methods of joining pipe polymers during the assembly of home heating:

- PP-R wiring is joined with polypropylene fittings using soldering (thermal polyfusion welding);

- cross-linked and heat-stabilized polyethylene (PE-RT) is mounted using the axial method in 3 stages - flaring the end, tensioning the fitting, installing the sliding sleeve;

- Metal-plastic is connected in 2 ways - compression or pressing.

Now we will give a brief description of each type of pipeline, go through the list of requirements and check how suitable the products are for water heating of floors in living rooms.

Polypropylene - material for radiator heating

Despite the price attractiveness and commitment of many craftsmen to using PP-R, we immediately note that it is impossible to make a warm floor from polypropylene pipes. There is no need to check the statement in practice - just carefully study the technical characteristics of the material and read reviews of homeowners who wanted to save money in this way.

How polypropylene pipelines are arranged (see diagram):

- the inner layer of PP-R, which forms the flow section of the highway;

- aluminum reinforcing foil, which inhibits thermal expansion and prevents the penetration of oxygen;

- 2 adhesive layers holding aluminum to polymer;

- the outer protective layer of PP-R is white or gray (green for some manufacturers).

Important addition. Now polypropylene manufacturers, instead of perforated foil, place a layer of basalt or glass fiber inside the pipe.

Let's figure out how PP-R pipes comply with the requirements for underfloor heating branches:

- Thermal conductivity 0.24 W/(m•°С) is the worst among polymer products. If we take into account the wall thickness of 3.4 mm with Ø20 mm (PP-R reinforced pipelines are not produced with a diameter of 16 mm), we obtain a heat transfer resistance of R = 0.0034 / 0.24 = 0.014 m²•°C/W. The resistance value is too high for active heat transfer.

- There are no questions about the smoothness of the internal walls of polypropylene - a roughness of 0.01 mm does not create increased hydraulic resistance.

- When heated to 50 degrees, a 100-meter PP-R pipe with an aluminum layer will increase in length by 150 mm, with fiberglass - 31 cm. The elasticity of polypropylene is very low, which is why the product inside the monolith will be under high load. The material can crack, first of all, at the joints.

Diagram of elongation of metal and polymer pipes as a result of heating by 50 degrees - Resistance to pressure and temperature is beyond doubt. When the coolant is heated to 70 °C, the PP-R line can easily withstand a working pressure of up to 13 Bar. If you raise the temperature to 95 ° C, the pressure threshold will drop to 9 Bar.

- The polymer is resistant to any chemical influences and practically does not allow oxygen to enter the coolant. The main problem is the large number of joints that fall under the screed, because bending the polypropylene section is unrealistic.

Note. The technical parameters of PP-R products are adopted according to the documentation of the Valtec brand, published on the company’s official website. We also took the prices and characteristics of other pipe polymers from this manufacturer for a fair comparison.

Let's clarify some points. The value of the thermal resistance of the walls R = 0.014 m²•°С/W will not tell the average user anything without comparison with the indicators of other plastics. These calculations are given below in the descriptions of polyethylene and metal-plastic pipes.

The problem with polypropylene heating systems is the inability to visually check the quality of welded joints. Sometimes joints leak a year after high pressure testing (pressure testing). Imagine the consequences of a leak inside a concrete monolith - searching for a defect, destroying the screed and repairing it.

If you solder a heating circuit made of PP-R, a good dozen joints will fall under the solution layer

A separate issue is the lengthy fuss with installation; there will be a lot of joints in the concrete. Examples of heating circuits assembled by home craftsmen from PP-R are shown in the photo above. Even the low price of a pipe Ø20 is 51...83 rubles. (0.8...1.25 USD) per linear meter - is not a basis for using such pipes in heated floors.

Parameters of cross-linked and heat-resistant polyethylene

Pipelines made of PE-X plastic are produced in two varieties - 3 and 5-layer. The difference lies in the location of the anti-diffusion barrier - in the first case, the impermeable EVOH polymer serves as the outer shell of the pipe, in the second, it is embedded inside the wall and glued to polyethylene on both sides. External color – brown, silver, red.

Users often have a question about which polyethylene pipes are better to use for floor heating - PE-X or PE-RT, and how they differ. We answer:

- the molecular lattice of PE-X plastic is cross-linked in 3 ways, hence the three types of polyethylene - A, B and C;

- from the point of view of installation and operation of heating, pipes made of PE-X / A do not differ from PE-X types B and C;

- material of increased heat resistance PE-RT is made from ordinary polyethylene using cheaper technology - a complex polymer molecule is modified with the help of branches;

- PE-RT loses to PE-X in terms of durability, strength and thermal stability;

- PEX is significantly more expensive than PE-RT, by about 20-40%;

- PERT pipe walls do not have an anti-diffusion barrier, so the coolant is saturated with oxygen at a rate of at least 0.1 g/m³•day. (on open air);

- PE-RT material is thermoplastic, the pipeline can be repeatedly melted and welded without loss of properties.

Reference. The cost of a Valtec 16 x 2 mm cross-linked polyethylene pipe is 51 rubles. per meter (about 0.8 USD). A product of the same diameter made of heat-stable plastic PE-RT costs 33 rubles/1 m. p. (0.5 c.u.).

The PE-RT plastic system does not contain an oxygen barrier.

Let's move on to our list of requirements:

- The pipe for warm water floors “PEKS” and “PERT” has the same thermal conductivity - 0.38 W/(m•°C). Let's calculate the thermal resistance of walls 2 mm thick: R = 0.002 / 0.38 ≈ 0.005 m²•°C/W - almost 3 times lower than that of PPR. That is, polyethylene contours transfer heat to the screed much better.

- The equivalent surface roughness of 0.007 mm is an excellent indicator of the smoothness of the pipes.

- Having heated up to 50 °C, a 100-meter free section of the PEX pipeline will lengthen by as much as 100 cm. But thanks to elasticity and some installation techniques, the expansion inside the concrete slab is easily compensated by the material.

- The maximum operating temperature of the PE-X material is 90 °C, PE-RT - 80 degrees, short-term permissible - 95 and 90 °C, respectively. The operating pressure of the coolant is 6…10 Bar, depending on the degree of heating. The parameters meet the requirements for water heating circuits.

The weak point of polyethylene systems is oxygen permeability. Equipped with a barrier, “PEKS” allows less than 0.1 g/m³ per day to pass through, “PERT” - much more. But since the pipes are sealed with cement-sand mortar, the access of air is significantly limited, and the penetration of oxygen is reduced to a minimum.

Polyethylenes have a dual property - molecular memory, which causes the pipeline to bend to its original coil shape. This feature makes it difficult to attach the heating loops to the floor insulation - if the pipe is not rotated around its own axis, the ends will begin to ride up. How to deal with the described phenomenon, watch the video of our expert.

The positive effect of molecular memory is the ability to recover after a break. It is enough to straighten the damaged area and heat it with a hairdryer - the plastic will take its previous shape without losing elasticity and strength.

Analyzing the properties of metal-plastic

In fact, this five-layer pipe is an analogue of the PEX material, where a rigid aluminum frame with a thickness of 0.25...0.4 mm (depending on the diameter of the product) acts as an anti-oxygen EVOH polymer. Inside there is a self-supporting tube made of cross-linked polyethylene, and outside there is a shell made of the same plastic. The layers of the structure are held together with special glue.

Reference. The marking of metal-polymer pipes corresponds to the structure - PEX-AL-PEX. An interesting point: the Rehau brand offers a universal line of RAUTITAN Stabi pipelines with an outer shell made of ordinary (not cross-linked) polyethylene.

Let's analyze metal-plastic according to the initially specified criteria:

- The thermal conductivity of the five-layer structure is 0.45 W/(m•°C), the wall thickness of pipes with a diameter of 16 and 20 mm is 2 mm. This means that the resistance to heat transfer R is equal to 0.002 / 0.45 = 0.004 m²•°C/W.

- The elongation from heating a 100-meter section to 50 °C is only 13 cm.

- Operating temperature at a pressure of 10 bar is up to 95 degrees, short-term emergency temperature is 130 °C. The oxygen permeability of the walls is close to zero.

- The price of Valtec pipe Ø16 x 2 is 60 rubles. (0.9 c.u.), Ø20 x 2 – 97 rub. (1.45 USD) per linear meter.

Please note: the thermal conductivity, operating temperature and relative elongation of metal-plastic structures are the best among all polymer pipes. The smoothness of the material is not mentioned, since the roughness value is identical to polyethylene - 0.007 mm.

An important difference between metal-plastic is the lack of molecular memory. When bent, the rigid aluminum frame takes the required shape, overcoming the elastic force of the polyethylene layers. This property is a great help during installation; the main thing is to maintain a minimum bending radius of 6 and 8 cm for pipes Ø16 and 20 mm, respectively.

How to regulate the temperature of a water heated floor?

In order for a warm floor to work effectively and to its full potential, it needs to be adjusted correctly. There are several ways to adjust the temperature of a water-type heating system.

Weather-compensated automation

The essence of the PZA is that the system settings change depending on the weather outside. But for this you will need a thermal controller, it will be responsible for these functions.

In addition, the design of the mixing group for such automation is more complex. Therefore, it is easier and cheaper to install room regulators.

Thermostats

Thermostats are devices for adjusting heating systems. There are several types of temperature controllers for warm water floors; they differ in both characteristics and price:

- mechanical - regulation is possible only manually, the degree of energy saving is low;

- electronic - equipped with digital displays and several control buttons, the settings are more precise;

- programmable - have a setting button or touch panel, are equipped with many functions, which simplifies the adjustment process.

In terms of price, the cheapest models are mechanical, and the most expensive are software, but they allow you to save heat resources and, accordingly, money.

Changing the supply temperature

The heating level of hot water systems can be adjusted by controlling the supply temperature of the coolant. The essence is to change the indicators on the heat generator (boiler).

This method is suitable if a separate boiler is installed that will supply hot liquid to the TP. This method is simple, but not very effective.

Using a thermal head

Using a thermal head, you can also set and control the degree of heating of the coolant. This can be achieved in two ways:

- By installing a three-way valve with a thermal head in the supply unit of the manifold, where the return flow is mixed. In operation, the device takes into account the heating degree of the coolant, not the air, while the volume of liquid consumption is low.

- By controlling the supply of hot water to the pipes - this is done by installing a thermal head on the valve, it allows you to limit the reverse flow. The return and supply valves are connected by a bypass, through which the liquid is regulated.

In both options, the operation of the thermal head depends on the degree of heating of the return.

Setting the pump speed

Another way to lower the system temperature is to lower the temperature of the coolant in the pipeline. That is, the greater the amount of water passing through the circuits, the smaller the temperature difference on the floor surface.

Therefore, the pump power should be set taking into account the difference in flows at the inlet and outlet. It should be within 3 - 5 degrees, depending on the pipe laying pattern.

To properly configure the pump, you need to set the expected motor speed. After an hour of pumping, you need to measure the difference at the inlet and outlet. If it is large, then the pump speed should be increased. The smaller the difference, the more uniform the heating of the room will be.

Floor switching frequency

Adjustment of the water floor according to the cleanliness of inclusion is carried out using a servo drive.

Servo drive is an electromechanical type device (electric drive and pressure rod) that allows opening or closing the return flow line. Under the influence of the rod, the valve located in the manifold takes an open or closed position, this depends on the state of the thermostat. The device is installed on the return line.

Kinds

According to SNiPs and manufacturers' instructions, underfloor heating pipes must be laid without welds or fittings in concrete. Any such connection is a potential point of water rupture and leakage. The screed will then become unusable. And repairing it is not only difficult, but highly problematic.

As a result, only pipes are suitable for heated floors:

- copper;

- made of corrugated stainless steel;

- made of cross-linked polyethylene (PEX);

- metal-plastic (PEX-AL-PEX).

Metal

Of the metal pipes used in heated floors, only two options are allowed - copper and stainless steel corrugations. Steel analogues (even in the form of stainless steel) cannot be used. They are too susceptible to corrosion and are connected by welding, which is unacceptable for the heating systems in question.

Steel pipes last 10-15 years

By all indicators, copper is the best choice for installing water transformer transformers. Its only and significant drawback is the high cost per meter. Stainless steel corrugation is 2–3 times cheaper than a copper product, but is not as durable and, due to its design, is not smooth inside.

Copper pipes have better thermal conductivity

Polymer

Of the plastic pipes for floor systems, only cross-linked polyethylene (PEX) and metal-plastic (PEX-AL-PEX) are suitable. Conventional polyethylene (PE) products, as well as their polyvinyl chloride (PVC) and polypropylene (PP) analogues, cannot be taken. They either bend poorly, are not designed for high temperatures, or expand greatly when heated.

Cross-linked polyethylene is characterized by plasticity, resistance to pressure changes, as well as high tensile and compressive strength. Pipes made from it can easily withstand heating up to +90–95 0C. When heated, they expand quite strongly, but in a screed this is not so bad. Warm floors made from such pipe products last for 40–50 years.

Polymer pipes last approximately 40-50 years

Metal-plastic

The metal-plastic analogue consists of two layers of PEX, between which there is an aluminum layer. This type of pipe is less susceptible to expansion, while having all the advantages of cross-linked polyethylene. This option is most often used when installing warm water floors.

Metal-plastic and cross-linked polyethylene pipes are sold in coils with a length of up to 200 m. They bend easily when laid on insulation and are easy to install. With their help, heated floors can be assembled independently in rooms of 15–20 m2 in a day. Then it will take a lot of time for the screed to harden, but the pipeline itself and the mixing-collector unit are assembled in this case in the shortest possible time.

Metal-plastic pipes are very easy to install

To what temperature is it permissible to heat a warm water floor?

As mentioned above, the standard hydrofloor heating level is +27 °C, the permissible limit is +33. If it is higher, you will feel discomfort during contact with the floor, and the room will be too hot. In addition, it is not very healthy, especially for varicose veins.

The temperature of the coolant moving through the pipeline should be in the range of +45 - 55 degrees. It is not recommended to turn on a higher degree of heating of the liquid; this can cause deformation of the pipes and their rapid failure.

How to choose pipes?

In terms of performance characteristics, the best underfloor heating pipe is copper. However, it is expensive and difficult to install. Most often, metal-plastic is used for such heating systems. Its price per meter is 5–6 times less than that of copper. Metal-plastic products are inferior to copper ones in terms of thermal expansion and durability, but are easier to install and assemble.

Contours up to 80 m long are made of pipes with a diameter of 16 mm. If the pipeline is 80–100 m long, then it is better to choose the 20 mm option. The larger section is practically not used here.

Construction of a water floor with a polystyrene base

You cannot take pipes made of steel, PVC, PP or regular PE for water TP. They are not intended for the heating systems in question and will not last long in their composition, sooner or later causing water leakage.

To install a heated floor yourself, it is worth purchasing flexible and relatively inexpensive metal-plastic. Its installation is not difficult to handle. This, of course, does not mean installing and adjusting plastic windows in the house. But the water floor system should not cause any particular difficulties during assembly even for an inexperienced craftsman. It is enough to be able to cut pipes and connect them with fittings to the manifold. Properly calculating and assembling a mixing-collector unit will be more difficult.

Laying a water floor

What temperature should I set on the boiler for optimal heating of the coolant?

A boiler is a device where water is heated. Boilers can be gas, electric or powered by combustion of solid fuel.

The temperature regime depends on the time of year (weather conditions) and the quality of insulation of the house. Therefore, it is recommended to select the indicators that need to be set on the boiler individually, but based on the established values:

- 40 degrees is not an economically justified mode. If a gas boiler is used, then in this mode the heating of the coolant may not reach the specified level. Because of this, the heating and pump will not be turned off, and this will increase fuel consumption. In addition, due to power outages, water heated to this level will quickly cool down and the room will be cold.

- 50 degrees - when setting this indicator, resource consumption is low. But at the same time, the pump runs longer, which increases electricity consumption. However, during power outages, the coolant heated to this level keeps heat in the floor longer.

- 60 is the most economical mode, but this is possible heating for the TP. Heating is carried out better, and the boiler will consume less resources in total.

- 70 and above - this mode is installed only with combined heating (radiators and heated floors). Since for underfloor heating water heating is allowed at +55 degrees, installation of a mixing unit is required.

It is not recommended to set a value higher than 70 on the boiler sensor, since this is quite enough for heating a home when using radiators and heated floors.

Automatic temperature control of TP

Automatic adjustment of a heated floor can be carried out thermomechanically or electronically using electromechanical actuators that control the operation of shut-off valves.

Thermomechanical control system

It is based on the operation of thermostatic valves or taps with thermal heads that respond to changes in coolant temperature. Various models of such shut-off and control valves are offered today by many manufacturers, for example, Oventrop. However, regardless of the name and type of thermosetting substance used in them (liquid or gas), these are thermomechanical self-regulating mechanisms that are most appropriately installed to control the temperature of one, individual circuit.

The operating principle of thermal valves is simple, which makes them very reliable and fault-tolerant. A copper, brass or bronze core installed in the device body, heated by the passing coolant flow, transfers the temperature to the thermosetting filler. In turn, the thermosetting element, which increases in volume, pushes the core, which, by moving the valve, gradually blocks the circulation of the heated liquid.

The thermostatic valve for heated floors, in addition to being installed on the distribution comb, can be mounted in a separate “unibox” type assembly. Such assemblies also include automatic air vents, which, together with thermostats, are placed in compact boxes (boxes). The use of a “unibox” allows you to adjust the temperature in a separate branch of the TP without being tied to bulky manifold cabinets, which is especially convenient with a small number of circuits.

In addition, thermomechanical floor heating controllers can have remote air sensitive elements. They allow you to configure them to control the flow of coolant not according to its temperature, but according to the air temperature in the rooms. The principle of their operation is the same, only the thermosetting substance is much more sensitive. It is advisable to install an air thermal head for simultaneous control of several circuits in one room, where water underfloor heating is the only source of heating.

Electronic control system

It consists of electronic thermometers, a controller and electric drives (actuators, servos). Electric drive mechanisms can be attached to the mixing heads of conventional control valves (valves) or be part of their design. The change in coolant supply intensity is carried out in accordance with specified threshold values. The measuring medium for the temperature sensors of the automatic floor heating temperature controller can be both the coolant and the air in the premises.

Important! Such control equipment is quite expensive, but at the same time it is capable of providing optimal operating conditions for underfloor heating and maximum energy savings. In addition, electronic regulators allow programming of the TP with binding of its operating modes to different time periods, which guarantees the user maximum thermal comfort.

Recommendations

In order not to encounter problems when operating water-heated floors that are caused by incorrect temperature conditions, you should adhere to a number of rules:

- use high-quality thermal insulation, at least 5 cm;

- pour the screed 3 - 5 cm above the pipe;

- make pipe laying spacing no more than 15 cm.

A warm water floor can create a comfortable atmosphere in the house, the main thing is to set the temperature correctly. If you doubt your abilities, you can invite a specialist.

Temperature of heated floors in the House PART-1

Heating system of a private house.

It's good if the house has good wooden floors.

But making a wooden floor now is both expensive and troublesome, and there are other technologies.

That's why they make a screed under the laminate.

Therefore, it makes sense to make a heated floor, because it is not as expensive as it might seem.

Here is the cost of the mixing unit with the manifold: “Estimate of plumbing equipment for the central control unit for water heated floors TIM.”

It makes sense to make a water heated floor.

An electric heated floor will not be much cheaper, the required power of the electrical network will not always be provided and electricity is expensive.

Minimum

The temperature of the floor covering directly affects the comfort of people using a particular room. This also affects their health. That is why experts do not recommend that floor temperatures fall below the following values:

- In living rooms - below 18 degrees Celsius.

- In the kitchen - below 18 degrees Celsius.

- In the toilet - below 18 degrees Celsius.

- In a shared bathroom or bathroom - below 18 degrees Celsius.

- In the corridor - below 16 degrees Celsius.

- In the lobby or stairwell - below 14 degrees Celsius.

- In the pantry - below 12 degrees Celsius.

Thus, it is necessary to ensure a temperature regime in all of the above rooms that exceeds the indicators indicated in the list.

Important

At what temperature does the floor freeze? If water flows through the pipes, then it is necessary to maintain the temperature of the coolant above zero, otherwise the pipes will simply freeze. The best option is to use antifreeze as a coolant, then you can be calm at temperatures down to -65 degrees Celsius.