When installing the washing machine, it is connected to the cold water supply system using a special hose, adapter fittings and shut-off valves. At the same time, the faucet for the washing machine should not only shut off the water supply, being highly reliable, but also be located in an easily accessible place after installation and be convenient to use.

When choosing a faucet to connect a washing machine to the water supply, they consider various options for its design, materials of manufacture, manufacturers, cost, choosing the optimal combination of all parameters. It is quite easy to connect a washing machine with all the components, the main ones of which are a tap and flexible hoses, simple plumbing tools and any type of sealing materials, by yourself, following the basic rules and instructions outlined below.

Ball valves - varieties

Why do you need a faucet for a washing machine?

The need to install a tap when connecting the washing machine and disconnecting it from the water line during idle periods is justified in the operating instructions from the manufacturer; two main reasons are given:

- The flexible supply hose is not designed to maintain constant pressure in the system; if it increases or undergoes sudden surges, the shell may break through.

- The non-return (shut-off) valve in the water supply system is designed in the form of a spring and a rubber disk; it is designed for temporary operation when the chamber with the drum is filled with water. The constant pressure of the water column leads to stretching of the spring and, accordingly, to a loose fit of the shut-off diaphragm valve. Also, with constant squeezing, the rubber gasket itself may burst - these factors lead to malfunction of household appliances and leaks.

Important: The absence of a tap in the water supply system is dangerous because breakthroughs occur with a constant increase in pressure at night, thereby increasing the amount of damage. If for the lower floors this factor is not of decisive importance, then for the residents above, a penny saving can lead to damage, the amount of which can be used to compensate for more than one thousand taps.

In a water supply system, the faucet must operate in an on-off mode that does not require adjustment of the water flow, therefore, simple, inexpensive and reliable designs are used with long time intervals for maintenance, repairs and replacement of worn-out components. The shape of the housing during installation is selected from the point of view of the most convenient connection option and access to the handle, which, in turn, is designed as a long asymmetrical lever or a butterfly-shaped handle.

Bugatti brand design

Plumbing connection

Steel pipe

What you will need:

- Saddle coupling.

- A drill with a radius equal to half the hole in the coupling.

- Tap.

- Tow.

- Spanners.

What to do:

- Turn off the water supply and drain the remaining residue using the faucet located nearby.

- Select a part of the pipe for inserting the coupling that is freely accessible close to the machine.

- Clean and polish the pipe using a knife or sandpaper

- Try on the coupling by turning it and positioning the tap correctly.

- Install the bolts, tightening with a wrench, and the gasket.

- Place a cloth or container under the pipe to allow water to drain into it.

- Drill a hole in the pipe through the sleeve located inside the coupling.

- Wrap the tap with a piece of tow, wrapping it lengthwise in the direction of twist. Apply sealant.

- Screw the coupling onto the tap.

- Connect the hose from the washing machine to the tap and tighten it by hand.

Pipe tapping

Metal-plastic pipe

What you will need:

- Tee with single internal thread.

- Pipe cutter

- Pipe calibrator.

- Tap.

- Spanners.

- Fum tape.

What to do:

- Turn off the water and drain off the remainder.

- Select a part of the pipe for inserting the coupling that is easy to reach.

- Cut the pipe and spread its ends, bending them carefully.

- Calibrate the two ends of the pipe and remove the chamfers by inserting the device and turning it a small number of times.

- Remove the nuts and rings from the tee.

- Place the nut, and then the ferrule, on both ends of the pipe.

- Screw the pipe into the tee hole all the way and tighten the nuts by hand.

- Hold one nut with a wrench, tighten the second, and then also tighten the first nut.

- Wrap the faucet with fum tape, placing several turns along the entire length in the direction of winding

- Screw it all into the fitting.

Connect the washing machine hose to the tap, twisting it by hand.

Polypropylene pipe

What you will need:

- MPV tee with a thread of the required radius.

- Faucet for washing machine.

- Pipe cutting device.

- Soldering iron.

- Fum tape.

Actions:

- Turn off the water and drain the water.

- Select a part of the pipe that is freely accessible for a soldering iron, close to the washer.

- Cut a piece 3 cm smaller than the tee.

- Wipe the pipes free of water and dry them to prevent defects from appearing during sealing.

- Place a suitable size nozzle on the soldering iron and heat it to the desired temperature.

- Place the soldering iron on the pipe and one end of the tee and wait about 6 seconds.

- Quickly remove the device, connecting the hot elements, and wait approximately 10 seconds.

- Repeat the same steps for the second end of the pipe.

- Wrap the faucet with fum tape, placing the turns on the thread where it will be screwed.

- Combine it with a tee.

Next, connect the washing machine hose to the tap, tightening it.

Useful articles, news and reviews on our Yandex Zen channel

Design

The ball valve has a simple design, a high degree of water resistance, small size and easy to use, the main structural elements of the standard product are:

- Frame. The typical collapsible design is made of nickel-plated or chrome-plated brass; the inlet and outlet pipes have external threads for connection to the pipeline and plumbing fixtures, electrical equipment.

- Ball. Made of ground and polished brass, coated with chrome, inside its body there is a rectangular recess on top into which the stem is inserted.

- Stock. It is a brass rod with sealing rubber rings installed on the body; a tap is attached to one of its ends. There is a hole at the top for screwing in a fixing screw, or the pulley has a thread for attaching the handle to the nut. The opposite side of the stem has a rectangular cross-section and is designed for insertion into the ball valve body.

- Seat and seal rings. Seat rings located on both sides of the ball at the inlet and outlet of the passage channel provide a tight seal, preventing water from entering the outlet pipe when closed. A rubber ring placed on one of the parts of the body prevents it from leaking when connected to another part.

- Pen. The rotary handle is made in the shape of a butterfly or an elongated lever, attached to the rod with a screw or a self-locking nickel-plated steel union nut. It is made of aluminum, nickel-plated steel, coated with polymers in a liquid plasticizer (plastisol).

Characteristics and materials of a typical valve

Conclusion

Connecting a washing machine to the water supply can be done in different ways, but in any case you need to use a special tap. With its help, it is possible to easily shut off the water after stopping the wash, which is definitely recommended by manufacturers, otherwise additional pressure is created on the valve of the device.

The valve can be installed independently in any suitable location. The video in this article will give you the opportunity to find additional information on the above topic.

Did you like the article? Subscribe to our Yandex.Zen channel

Types of taps for washing machines

Cranes with various parameters are sold on the construction market; they can be divided into the following groups according to:

Material of manufacture . Plumbing fittings are often made of metals: brass, stainless steel, silumin; brass products are considered the most expensive and high-quality. The cheapest shut-off valves are made from silumin - an aluminum alloy; the products have low strength and light weight; unlike expensive metals, they have low ductility and crack under load.

You can find budget polymer shut-off valves on the market; plastic taps can be conveniently mounted into a polypropylene pipeline by soldering - this allows you to save on adapters from plastic to metal and in cost compared to using metal products.

The principle of operation of the locking mechanism . There are two main types of shut-off valves: screw and ball, in the first there is a gradual multi-turn shut-off of the flow due to the rotation of the screw shut-off valve, which is irrational for fittings whose sole purpose is to supply and shut off water flow. In a design with a ball, it is enough to turn the handle at a right angle to supply and turn off water - this is much faster and more practical, therefore, with rare exceptions, a two-way ball locking valve is installed in the water supply system for washing (dishwashing) appliances.

Polymer valves

Execution of the case . Depending on the location of the pipeline and ease of access, the following types of taps are installed in the water supply system:

- A straight or pass-through faucet for a washing machine has inlet and outlet pipes located on the same line and is mounted in a pipeline that has a separate outlet for connecting equipment.

- Tee tap . In this type of design, water flows inside the housing in a straight line, and there is a branch in the side wall for connection to the machine. The tee for connecting the washing machine to the water supply is used in water supply systems with previously connected plumbing equipment. Typically, a three-way valve is installed under sinks in the kitchen or bathroom, connecting the flexible line from the sink and washing machine to the inlet and outlet pipes, respectively, and the faucet body to the water pipe.

- Corner . Often the washing machine is connected to a water socket built into the wall, and it is much more convenient and rational for the inlet fitting of the flexible water supply to approach it at an angle of 90 degrees. To do this, screw a corner faucet for a washing machine of the appropriate diameter into it and connect a hose to it that runs down the wall.

Types of valve bodies: straight, tees, angled

Non-standard options

Installation of built-in equipment

A built-in washing machine is a great space saver in an apartment or house. You can build a cabinet for the washing machine, place it in a closet, on a shelf, mount it in a wall and other places. Only such creative ideas should be carefully thought out to avoid trouble.

In a private house

The classic installation option is the bathroom. All the necessary communications are present here, and it will be convenient to use the machine here. The only risk is increased humidity in the room, which in the future may affect the performance of the equipment.

In a private house there are many unusual ideas for installing a washing machine: in a closet, under the stairs, in a closet, in any buildings located in the courtyard of the house, etc. Only here can a problem arise with communications, water and electricity.

In the kitchen or hallway

If there is not enough space in the most common places, then the equipment can be installed in the kitchen or in the hallway. But it’s unlikely that anyone in the corridor will have the required communications. You will have to bring everything to the installation site, and this will significantly complicate and increase the cost of the process. But it will fit quite comfortably in the kitchen. Most often it is mounted next to the sink or in a built-in kitchen unit. It is worth considering that the temperature and humidity of the kitchen will not always correspond to the operating rules of the device.

Drain installation

At first it may seem that organizing the drainage of such household appliances is as simple and understandable as possible. However, in reality, everything depends on certain connection nuances.

This can be done in two main ways.

- Temporary. With such a connection, the drain hose is lowered into the toilet or bathtub (in case of a combination).

- Stationary. At the same time, a tie-in is made into the sewer. However, here owners quite often face a number of problems.

The machine is connected to the sewerage system in accordance with the following important requirements:

- the length of the drain hose should not be too long, as this may cause a significant load on the drain pump, which may cause it to break;

- as the drain is connected to the siphon, it will be possible to prevent the penetration of characteristic odors into the equipment directly from the sewer, which is a significant advantage.

Now let’s look in detail at how it is possible to ensure the drainage of such household equipment using different methods. You can drain the water from the device into a bathtub or washbasin. This option is quite simple, but not very practical.

Some manufacturers add to the equipment kit such an element as a special hose-hook. It is fixed on the wall of the bathtub or sink. The main advantage of this solution is that to ensure it, there will be no need to connect equipment to the sewerage system.

It should be taken into account that this solution has many more disadvantages. Firstly, the contaminated liquid will stain the bathtub or sink. This problem will be especially acute if the plumbing fixtures are made of acrylic. Secondly, even a very minor blockage in the sink during the draining process can become a provoking factor for flooding of neighbors.

In addition, in many cases, due to strong vibrations during the draining process, the hook falls to the floor, which can also cause leaks. The connection can be made using a siphon. In order for the drainage from the equipment to be stationary, the specified part will be needed.

The siphon is equipped with an outlet for machines. It should be located under the knee part of the siphon. Otherwise, contaminated liquid may be sucked into the equipment itself. Because of this, a bad smell can “settle” in it.

You can also make a connection to a sewer pipe, which should be 4-5 mm thick. Usually a special sealing element and an S-shaped hose are used here. The last part is inserted directly into the pipe so that it does not come into contact with the drains. The top of the hose should be placed at a height of 55 cm from the floor.

Criterias of choice

When selecting a shut-off valve for connecting household appliances to the water main, we are guided by the following principles:

1. Ball valves are best suited for quickly stopping and turning on the water supply, in which a shut-off mechanism in the form of a ball with a through hole instantly shuts off the water flow when the handle is turned 90 degrees.

2. For an aesthetic appearance and to prevent unplanned rotation of the handle, products with a compact butterfly-shaped rotary lever should be used. In places where access is difficult and it is impossible to correct the situation, it is more rational to use a model with an asymmetrical long lever, which is lighter and easier to turn.

3. The best material for making shut-off valves is brass, which is not subject to corrosion and has a service life of tens of years; household valves of this type have a chrome coating, which gives it a beautiful aesthetic appearance. Brass taps are installed in a steel metal or polymer (polypropylene PP) pipeline, and an adapter from plastic to metal is soldered into the latter.

4. The choice of faucet body design depends on the connection option - if it is installed in a gap or pipeline to which sinks, a mixer or its outlet, or a shower hose are connected, a triple design is used. When a water socket comes out of the wall, the best option is a corner housing; the straight pass-through version is not used too often and is connected to pipelines or water sockets located below the floor.

Note: In the retail chain there is a design type of a walk-through faucet, specially designed for simultaneous connection to a faucet and a washing machine; during installation, the faucet and extension pipes are screwed between the water sockets and the mixing unit.

A faucet with an inlet hose connected to a water socket

5. When purchasing, sometimes you should pay attention to the position of the handle in which the faucet is open or closed; for example, it is more convenient for a valve with a long lever located close to the wall covering to close closely parallel to the wall, and open perpendicular to it plane, protruding outwards - this will prevent involuntary rotation and unwanted opening of the channel for the flow of water.

6. When choosing a suitable model in a hardware store or on the market, you should pay attention to the manufacturer (for branded fittings, the company logo is printed on the body). The sanitary fittings of the following Russian and European brands are of high quality and have proven themselves in the domestic market: Bosch, Bugatti, Elsen, Grohe, Itap, Valtec.

Recommendations from installation experts

It often happens that equipment installed independently or by a master begins to vibrate during the spin cycle. This indicates that the installation was performed incorrectly. Therefore, even before purchasing, you need to decide on a place for the machine and read the recommendations of installation specialists.

Professional advice on installing a washing machine, as well as step-by-step instructions will help you complete the installation and connection according to all the rules.

Tip #1 - prepare the conditions for installation

When choosing the overall dimensions, type of construction and technical characteristics of the model, they are guided not by their own wishes, but by the capabilities of the room in which it will stand.

In a spacious bathroom, as a rule, there are no problems with installing a washing machine. In order to save money, it is placed as close as possible to the outlet, water supply and sewerage distribution

Necessary conditions for the operation of the washing machine include close proximity to an outlet and water. This will help avoid lengthening of electrical cables and hoses.

They also pay attention to ease of use, as well as the aesthetic component. Problems with placement most often arise in small apartments

Tip #2 - choose the optimal room

Most users, when choosing a location, choose the bathroom as the most suitable from a logical point of view. After all, this is where the water pipes and sewer drains are located. In addition, the washing process will be hidden from view.

The washing machine can also be placed in a small bathroom, having previously decided on the size and location. In this case, to save space, the machine was installed under the sink

When choosing a location for the machine, pay attention to the following points:

- the ability of the floor to withstand vibrations;

- possibility of laying communications over remote distances;

- during measurements it is necessary to take into account unevenness on the walls;

- the space for installing the machine must be at least 1 cm larger than its nominal dimensions.

If space is limited and the dimensions of the machine are large, you should think about placing the unit in the kitchen or hallway.

Tip #3 - The Importance of Proper Connection

The issue of correctly connecting the washing machine to communications should be treated extremely carefully. Next we will consider this process in more detail.

Connecting water to the machine

Machine washing, like any other, is impossible without water. The water supply must meet two basic requirements: sufficient pressure in the pipes and clean water.

If they are not met, a pump is installed to increase the pressure, and the water is filtered. A tap is built into the pipe supplying water to the machine to shut it off. Thus, the likelihood of leakage becomes minimal.

Electricity supply issue

A washing machine is a powerful unit. Residents of old apartments in which the wiring has not been changed are recommended to install a separate cable, since the wires and sockets installed many years ago are not suitable for connecting modern equipment. The cable cross-section must correspond to the expected load.

The socket for connecting the washing machine is installed with grounding. If we are talking about a room with high humidity, for example, a bathroom, then it is advisable to choose models with a protective cover

We discussed in detail the installation and connection of a grounded outlet in this material.

Tip #4 - take into account external factors

The ambient temperature and type of flooring should also be taken into account when installing the washing machine.

High quality flooring and flooring

There are high demands on the quality of the floor. It must be strictly horizontal, hard and even.

The floor covering will have to withstand the vibrations created by the rotating drum. If there are doubts about the quality, it is necessary to strengthen it at the installation site of the machine.

Ambient temperature

In a heated apartment or house, equipment is kept warm. During prolonged heating outages, which are often observed in country houses and technical rooms, the equipment cannot be left in place.

The water remaining inside the machine after washing will definitely freeze. This will result in a rupture of the hose or even the pump and will require repair/replacement

How to install a faucet

There are several ways to connect a washing machine to a cold water supply line, depending on which different types of plumbing fixtures are purchased; the following components and tools are used during the operation:

- Adjustable wrench, screwdriver.

- A polymer inlet hose included with the machine or a product purchased in a retail chain with a 10% reserve in length for long distances from the water outlet to electrical equipment.

- Ball valve with angle, straight-through or tee body design.

- Sealing materials: flax fiber, plumbing thread, Fum tape.

Between the water socket and the mixer

One of the simplest ways to connect a washing machine is to install a screw (a swivel head looks more aesthetically pleasing) tee tap in the gap between the wall and the water socket on a set of pipes purchased in advance from a retail chain. One of them has a three-way tap built into it and through it cold water is supplied to the mixer to the washing machine, and the other has a similar length and is designed to supply hot water to the mixing unit. The connection method is quite simple and consists of the following operations:

- Shut off the cold and hot water, use an adjustable wrench to remove the mixer from the adapter eccentric couplings with external threads.

- The pipes are screwed into the water sockets: with a tap into the cold water supply line and a smooth-walled extension pipe into the hot supply through an American threaded connection, which does not require the use of sealing tape or flax fiber.

- The union nuts of the mixer are screwed onto the top of the adapters with external threads using an adjustable wrench without the use of additional seals.

Connecting the inlet hose to the faucet via an extension

The main disadvantage of this connection method is the unaesthetic appearance of the structure due to the distance of the mixing unit from the wall, and the remote location can cause some inconvenience when using the bathroom.

In the mixer

Sometimes a tee assembly, one of the outlets of which is connected to the inlet hose, is mounted in the mixer itself; the main options for its installation are: between the gooseneck and the mixer body or between the body and the shower head hose. The main difficulty in this case is to select a tee pipe with a tap with a suitable thread; due to the abundance of goods, this is not too difficult if you correctly measure the fitting dimensions before purchasing.

Options for placing a tap integrated into the mixer

The main disadvantage of this design is the worst aesthetic appearance of all options due to the presence of parts in the mixing unit that violate symmetry and harmony.

To the pipeline from the sink

One of the popular and common options is to connect a tee to the pipe to which the flexible sink line is connected. The work does not present any difficulties even for a housewife when purchasing a tee ball valve of standard diameter. To install it:

- Turn off the water and unscrew the flexible cold water supply hose from the water pipe.

- Screw a tee with a tap onto the pipe using an American-type threaded connection.

- The nut of the flexible connection to the mixer is screwed onto the direct outlet, and the inlet hose is connected to the side pipe.

Thanks to the American design with O-rings, all connections do not require the use of sealing materials.

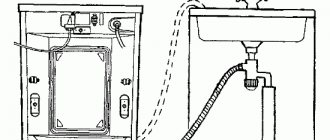

Inlet hose under the sink

Into a water socket on a wall or pipe

Sometimes, to connect the inlet hose, a special outlet with a water socket is made in polypropylene PP water pipes, which is placed under the bathtub or walled up in the wall, placing the water supply in grooves.

In this situation, the water socket has an internal thread, a pass-through or corner fitting with a tap is screwed into it using an adjustable wrench, using flax fiber or sealing Fum tape, and the connection on the wall is closed with a decorative cover (disc).

Tapping into the pipeline

In the bathroom, the inlet hose is rarely connected to the water supply pipeline to the handwash faucet, since the sink is usually located on the opposite side and an extended hose will create some inconvenience. Connecting to a faucet in the bathroom is an unaesthetic and inconvenient option, since the hose from the washing machine interferes with water procedures.

If water sockets are not made in advance in the pipes and are not placed on the walls, you can cut a polypropylene pipe under the bathtub and solder (embed) a polymer tee with a tap into the gap, but for this you will have to call a plumber and pay a considerable amount. If the pipe is metal, inserting into it without welding or using special expensive couplings and adapters is not an easy task.

In this situation, one of the best options for cutting into a pipeline made of any materials is to use an overhead clamp with a central threaded outlet. The operation is carried out in the following sequence:

- Screw a clamp with rubber gaskets to the pipe in the right place, tightly connecting its halves with four union nuts.

- A hole is drilled in the middle of the pipe through the side pipe of the tee, and it must have an external thread.

- Screw a straight-through or American angle valve to the outlet pipe and connect the inlet hose to it.

Insertion into the water supply using clamps

The abundance of plumbing fittings on the market from domestic, Chinese, and European manufacturers makes the task of choosing a faucet to connect a washing machine quite simple; you don’t even need to measure its parameters with a unified design of the units. Even a housewife can handle connecting the tap and inlet hose to the washing machine; in the most difficult case, using overhead clamps will require minimal construction experience and skills.

List of tools and materials

To connect the unit to the water supply, it is not enough to find a valve of a suitable configuration. Tools are also needed. Their list should include:

- Adjustable wrench. It is required for installation work, tightening nuts and connecting pipes.

- Calibrator. A necessary tool for working with plastic pipes. It makes it possible to adjust the screen when installing it on a pipe cut-in.

- Lerka. It can be replaced with any similar tool that allows you to cut threads.

- Screwdriver, file, drill. All this is necessary for work on arranging holes and other manipulations.

- Scissors for plastic. Instead, you can take a grinder, which is suitable for working with elements made of plastic and metal.

The washing machine must include a double hose. It will also have to be used during work. The length of the product should be slightly longer than necessary. This will make it possible to get a small margin during the rearrangement. When a hose has to be purchased specifically for these purposes, it is recommended to give preference to models with wire reinforcement. They will best withstand the pressure inside the pipes.

A filter must be installed on the threaded part of the tap. It is designed for water purification. It is fixed to the outlet of the water pipe. This element is small in size and improves the quality of the liquid used. This reduces the risk of lime deposits forming. When water rich in minerals is used, several filters can be used simultaneously.

When planning to install plumbing parts, you cannot do without sealing rings and FUM tape. In addition, you will need winding and spare bolts. This set will allow you to secure the faucet tightly and, therefore, reliably. It is necessary to select a suitable connection option, taking into account the characteristics of the room and the area where plumbing fixtures are installed.