Polypropylene pipes are used to equip water supply systems in residential, industrial and administrative buildings. The material used for the production of plastic water conduits belongs to the group of polyolefins and, like all substances in this category, is an environmentally friendly product. The products are distinguished by impact strength, chemical resistance and mechanical strength in different temperature conditions.

Polypropylene pipes for cold and hot water supply have become popular and widely used due to their advantages.

Polypropylene pipes for cold and hot water supply: scope of application

Today, polypropylene pipes are very common in various areas:

- in industry;

- during gasification;

- when pumping oil;

- in the agro-industrial complex;

- in the sewerage system;

- for underfloor heating systems;

- for water pipes.

The opinion that any polypropylene pipe is suitable for water supply is erroneous. Manufacturers produce several types of products, each of them has its own role. Polypropylene products are designated by the letters “PP”.

Products may vary in parameters

When constructing new water pipelines, you can immediately give preference to this product rather than choosing between polypropylene and metal. The products are also widely used when it is necessary to replace an outdated water supply system. The most common application is for intra-house and intra-apartment networks.

Fitting

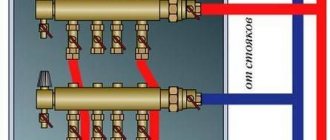

A full range of fittings, shut-off and control valves and auxiliary installation elements are produced for polypropylene pipes. Standard set includes:

- elbow 90o;

- tee;

- stub;

- through coupling;

- ball valve;

- coarse filter;

- adapter fittings for a threaded connection for metal (with internal or external thread, American).

Using the entire available set of elements, systems of almost any configuration are assembled from polypropylene, taking into account the combination of materials. Manufacturers produce a set of fittings and adapters for each batch of pipes.

Advantages and disadvantages of polypropylene pipes

It should be noted that products of this type have many advantages. That is why she gained popularity so quickly. Main advantages:

- corrosion resistance;

- resistance to acids and biologically active substances;

- the lack of reaction allows you to obtain pure water without impurities or iron content, which has retained its color and taste;

- the water pressure is stable, since the hydraulic resistance inside the product is small;

- installation is very simple, in addition, you can easily create a system of any complexity;

- the material is not afraid of high and low temperatures;

- low cost;

- a reduced level of thermal conductivity avoids heat loss.

Speaking about the material, one cannot fail to note its shortcomings. These include:

- the need to carefully select products for a specific pipeline, otherwise the material will become unusable very quickly, and ruptures are possible;

- the presence on the market of a large number of cheap low-quality products;

- the need to have a special device for processing joints and be able to work with it.

There are practically no disadvantages to this type of product. Serious problems are not related to the pipes themselves, but to defects in their production.

Polypropylene does not react with water and does not change its taste or color

Chlorinated PVC

For the installation of the heating circuit, only structures made from a chlorinated variety of material are used. They are more resistant to high temperatures. The corrugated version of the CPVC construction is used only when arranging branches located underground or in walls. This is due to the fact that flexible products must be well protected from physical influences and high humidity levels. In addition, such a measure will compensate for linear expansion.

The process of chlorination of polyvinyl chloride involves the interaction between chlorine and the homopolymer. They react with each other under the influence of ultraviolet rays. The international marking of this type of material is designated as CPVC.

The key advantages of chlorinated polyvinyl chloride are:

- long service life, which is about fifty years;

- chemical inertness;

- easy installation;

- UV resistance (due to the presence of titanium dioxide);

- ability to work at media temperatures up to ninety-five degrees;

- high fire safety indicator.

The chlorination process makes it possible to obtain a substance consisting of 1/3 hydrocarbons and 2/3 table salt. It is worth noting that when using different production technologies, the proportions may differ.

CPVC can have chlorine content ranging from 57 to 74 percent. In most cases, designs are used with a content of the mentioned substance from sixty-three to seventy percent.

Remember that the more chlorine a material contains, the higher the temperature it can withstand. The molecules of the mentioned additive are characterized by strong bonds with PVC. Moreover, they are not subject to destruction under the influence of high temperatures. Therefore, the release of chlorine in the form of gas is completely excluded.

Constructions made of polyvinyl chloride have:

- low oxygen permeability;

- linear expansion index equal to 0.062;

- thermal conductivity 0.14;

- density indicator equal to 1.57 g/m3;

- diameters from sixteen to four hundred millimeters.

The designs under consideration compare favorably with other polymer analogues.

Moreover, their installation is quite simple. To perform it, you do not need to have special skills or expensive equipment. The procedure for installing polyvinyl chloride channels is carried out using three methods:

- flanged;

- with clamping fittings;

- adhesive.

Gluing the elements is done using a special glue. Essentially it consists of polyvinyl chloride diluted with a solvent. To make a connection, you need to apply it to the surface of both parts.

Moreover, this must be done evenly. The process of solvent weathering occurs within thirty seconds. In this case, the two elements will be securely fastened to each other.

Types of polypropylene pipes

When laying a pipeline, it is important to understand that for hot water it is necessary to select one type of product, and for cold water - another. Selecting products of the same type is a common mistake, which often causes a system breakdown.

This is how the marking is applied

Products are distinguished:

- according to the material of manufacture;

- by type of reinforcement.

In order to choose the right material, let’s get acquainted with the nuances of its production.

According to the material of manufacture

When purchasing pipes for your own needs, you will definitely pay attention to the markings. These signs and letters speak volumes. First of all, about the material of manufacture. There are several types of products:

- Random copolymer, labeled as PP-R. Made from polypropylene copolymer and designed for hot water supply.

- Homopolypropylene, marked as PP-H. They can withstand high operating pressure and are therefore widely used in industry. Suitable for cold water supply.

- Block copolymer, PP-B marking. Used for underfloor heating systems and cold water pipes.

Important! If the pipeline is external, it is better to pay attention to the presence of an ultraviolet-resistant shell, which will allow the pipes to last an order of magnitude longer.

When examining the product in cross-section, the aluminum layer is visible

The table below shows the safety factor for different types of products:

| Material | Water temperature, °C | ||

| 10−40 | 40−60 | Over 60 | |

| PP-H | 1,6 | 1,4 | 1,25 |

| PP-R and PP-B | 1,25 | ||

As you can see, PP-H pipes are highly dependent on the water heating temperature.

Range of polypropylene products

Related article:

Plastic pipes for water supply. In the publication we will consider the sizes and prices, types, advantages and disadvantages of plastic pipes, selection criteria, as well as the nuances of self-installation and recommendations from specialists.

By type of reinforcement

Reinforcement is an indicator that affects the coefficient of thermal expansion, reducing it. This is done in one of several ways:

- using fiberglass (marked with the letters FB);

- aluminum foil when placing it closer to the inner edge of the pipe (marking AL);

- aluminum foil when placing the layer closer to the outer edge (AL marking);

- using a composite (marked GF).

If the aluminum layer is located closer to the top edge, you will need to clean the edges before work. Elements reinforced with fiberglass or composite are considered to be of the highest quality.

The cut shows the presence of reinforcement in the form of metal strips or multi-colored layers of fiberglass and composite

What accounts for the popularity of black plastic pipe products?

Plastic pipes are the most popular type of pipe products today. They are easy to install and do not cause problems with transportation. Most often they are sold in the form of rolled coils, which makes their transportation hassle-free.

Black plastic pipes can be used in pipelines for various purposes. Due to their resistance to corrosion and clogging, pipes are popular when organizing cold water systems, and their low susceptibility to ultraviolet radiation makes them simply irreplaceable for drainage sewer systems. At the same time, black products made from polypropylene are also used for hot water pipelines and heating systems.

Main technical characteristics of polypropylene water pipes

Let's talk about the main characteristics of pipes, according to which the buyer makes a choice in the store:

- diameter of polypropylene pipes. Products with a diameter of 15 to 1200 mm are produced, which are designed to provide water to both private and apartment buildings;

- PN marking will allow you to select a product for both cold and hot water, as well as for a certain water pressure (the table is shown below);

- internal diameter or wall thickness. The thicker the wall, the more water pressure it can withstand;

- length. This parameter has no qualitative significance, however, let us clarify that all factory products have a length of 6 meters.

Pipes and components for them

Which material is better to choose?

The review of materials made it clear that each has its own strengths and weaknesses. So when choosing, it makes sense to adhere to the combination of “characteristics - ease of installation and maintenance - price”.

Metal pipes are more reliable in terms of heat resistance, while polymer pipes are more expensive.

But conditionally, from all of the above, three favorites can be distinguished in different categories:

- Optimal - reinforced propylene or cross-linked polyethylene. Good performance and affordable price tag from 41 rubles/m.

- The most economical option is polypropylene. The cost of pipes starts from 14 rubles per linear meter.

- The most durable is copper. They can last up to 100 years, but the cost starts from 180 rubles.

Everything you need to know about hot water is presented in this section of the site.

Technical requirements for polypropylene pipes for water supply according to GOST

Expert's point of view

Kirill Mikhailov

Head of the Water Supply and Sanitation Group, GRAST LLC

Ask a Question

“In our country, GOST R 52134-2003 applies to polypropylene pipes for water supply, which determines the quality standard.”

This quality standard is the only one to characterize the quality of both pipes and fittings and connecting elements. The general requirements for polypropylene water pipes are:

- they must have a round cross-section;

- must be pressure;

- used in residential and non-residential buildings, as well as in industries;

- serve for both technical and drinking water.

Plumbing system

Repair of PP pipes

For various reasons, polypropylene water pipes leak. To prevent accidents, you need to know the main causes of the leak, and most importantly, be able to eliminate them in a timely manner.

The causes of leaks are the same in pressure and non-pressure lines:

- The weak areas of the pipeline are the joints, so the majority of accidents occur due to their depressurization.

- Malfunctions in non-pressure pipelines are associated with improper operation, manufacturing defects and poor installation of water supply elements.

- A common cause of leaks is poor-quality welding of joints.

- Exceeding the permissible pressure.

- Often the influence of external forces violates the tightness and integrity of the polypropylene pipeline.

Repair of polypropylene pipes requires partial or complete replacement of a section of the main line.

To prevent depressurization of connections, during the installation of the water supply it is necessary to check whether the seals are in place; to do this, measure the depth in several places. If the ring is positioned properly, then the depth will be the same everywhere.

Carrying out repair work

Repairs begin with identifying the location of the leak; most often they appear in butt joints. Then the water is shut off in the section of the pipeline where repair work will be carried out.

Polypropylene water pipes for cold water in non-pressure mains are joined using a socket method and the joints are sealed with a rubber seal.

Accidents are more common in pressure mains, so the service life of the pipeline depends on the correct installation.

If the seals are worn, disassemble the joint and replace the rings. Joints in pressure pipelines are connected using soldering. To do this, use a special heating device (soldering iron), and only dry and clean pipes and fittings are used for welding to prevent depressurization in the future.

Marking of polypropylene pipes for water supply

Marking of polymer pipes for water supply allows the buyer to quickly determine whether this product is suitable for him or not:

- PN-10 are intended for cold water and the construction of “warm floors” (up to a temperature of +45°C);

- PN-16 is suitable for installing “warm floors” or hot water, the brand is unpopular among craftsmen;

- PN-20 are designed for hot water supply with a maximum temperature of up to +80°C;

- PN-25 are the most durable, they can withstand water temperatures of +95°C.

Important! Hot water products must withstand high temperatures.

The table below includes the main characteristics of pipes. The marking is present directly on the product.

Table of main characteristics of pipes

| Marking | Allowable pressure, MPa | Outer diameter, mm | Wall thickness, mm | Permissible water temperature, °C |

| PN-10 | 1 | 20-110 | 1,9-10 | 45 |

| PN-16 | 1,6 | 16-110 | 2,3-15,1 | 60 |

| PN-20 | 2 | 16-110 | 1,6-18,4 | 80 |

| PN-25 | 2,5 | 21,2-77,9 | 4-13,3 | 95 |

Table of standard sizes of polypropylene pipes

We suggest that you familiarize yourself with the table of standard sizes of PP products. Presented as an option with a reinforced product, and with a non-reinforced one.

Standard Size Chart

| Polypropylene pipe | Diameter, mm | Quantity per package, m | Polypropylene pipe reinforced with aluminum foil | Diameter, mm | Quantity per package, m |

| 20 | 100 | 20 | 100 | ||

| 25 | 80 | 25 | 80 | ||

| 32 | 40 | 32 | 40 | ||

| 40 | 32 | 40 | 32 | ||

| 50 | 20 | 50 | 20 | ||

| 63 | 16 | 63 | 16 | ||

| 75 | 12 | 75 | 12 | ||

| 90 | 8 | 90 | 8 | ||

| 110 | 4 | 110 | 4 |

How to choose the diameter of polypropylene pipes for water supply

In everyday life, water pipes from 20 to 32 mm are considered the most used. The diameter depends on the length of the water pipe as follows:

- more than 30 meters - Ø32 mm;

- from 10 to 30 meters - Ø25 mm;

- up to 10 meters - Ø20 mm.

The diameter of PP pipes is also selected based on the following conditions:

- pressure magnitude;

- length of the water supply system;

- number of connections and turns;

- number of users.

If the design is complex, you will need to increase the diameter of the pipe. The same law also works with a significant increase in consumers.

Water supply in a standard apartment

Which polypropylene pipes are better for water supply?

The plumbing system is divided into two types:

- cold water supply;

- hot water supply.

Very often in private houses only cold water is supplied, which is also supplied to the boiler, and then hot water is distributed through a separate branch to sinks and bathtubs. The use of metal pipes is unjustified, since their service life is not so long. In addition, water reacts with the material, rust forms, and water quality decreases.

Sectional view of a metal pipe after many years of service

Polypropylene pipes for hot water

Plastic pipes for hot water must withstand high pressure and not deform when heated.

Important! Polypropylene softens at a temperature of +140°C.

The manufacturer always indicates that the maximum permissible water temperature inside the system can reach +95°C.

Only in the conditions of the Far North the use of plastic pipes is not always justified

For hot water supply, it is better to use a reinforced pipe, because it is protected from expansion and has a longer service life. The highest quality reinforcement occurs using fiberglass or composite. The most suitable product for hot water is marked PN-20 or PN-25.

Polypropylene pipes for cold water

High-quality polypropylene products can effectively serve up to 50 years as an element for cold water supply. She has proven herself excellent.

Creating a water supply system in a new house

For these purposes, you can use products with any marking; it is important that they are of high quality. You just need to choose the right diameter.

Installation

Welding of polypropylene is carried out using special equipment - a soldering iron. This is a plate with a built-in heating element on a stand on which nozzles of different diameters are attached. A sleeve with a hole is used for heating, and a mandrel with a protruding pipe is used to heat the fitting.

To prevent the molten plastic from sticking to the nozzles, they are coated with Teflon and require careful handling, avoiding mechanical damage and contamination.

Polypropylene must be locally heated to 260ºС, and then the parts must be connected. Due to diffusion, the material is mixed, and after hardening, a monolithic, inextricable connection remains. The cleanliness of the elements at the joint and the correct heating mode determine the quality of the weld.

For fastening along the route, latch clips are used to hold the pipe, but without rigid fixation, which makes it possible to compensate for thermal deformation. By default, fastenings are needed on the side of the long section from the fitting at a distance of 5-10 cm.

Connections of polypropylene pipes are considered non-separable, so hidden laying of pipes is allowed, including sewing into walls and pouring into a screed or layer of plaster. However, it is more practical, even with hidden installation, to use special boxes recessed into the wall.

Features of the use of polypropylene pipes in the heating system

When creating heating systems, products with the following external diameters are standardly used:

- for the “warm floor” system - Ø16−18 mm;

- for water supply pipes - Ø20 mm;

- for risers - Ø25 mm.

The master should pay special attention to the linear expansion of the product, because only hot water will be pumped through it. The higher its temperature, the shorter the service life of propylene pipes for water supply and heating. You should choose products with a low coefficient of thermal expansion.

Warm floor system using Ø16 mm pipe

Installation and distribution of polypropylene pipes: what are the nuances?

To work with PP pipes, you need to have two important tools: a pipe cutter and a special soldering iron. Using the example of pipeline installation, we will show the nuances of the work.

Pipe cutter - a tool for neat cutting of products

| Illustration | Description of actions |

| Cutting is done on the floor or table. To ensure the correct size, take into account the height of the clips and bends, as well as other elements. | |

| You can mark the system map directly on the wall with a pencil or pen, and also pre-attach the clips holding the plastic pipes. | |

| After the part is heated up, you have only 4 seconds to solder it to the pipe. You should only use a soldering iron with gloves. | |

| Quickly connect the two parts and secure them. You can pre-treat the soldered edges with a solvent. |

The main problem is not to create hard-to-reach places for yourself to work on weight. Full video available at the link:

What determines the service life of polypropylene pipes for water supply?

There are several main reasons for reduced product life:

- constant exposure to sunlight;

- high operating temperature of polypropylene pipes;

- increased pressure in the system;

- low quality material.

Product after water hammer

To avoid problems, give preference to well-known manufacturers.

Black pipes for sewerage

The black color of pipes is used not only for marking plumbing products, but also pipes for sewer systems.

For laying sewers, black pipes are used along with orange (for external pipes) and gray (for indoor sewer systems). Black pipes are found, although less frequently, but they have a special purpose. Black pipes are used to make drainage lines. Because their UV-protective properties cope with the task of draining water in areas exposed to sunlight.

Major manufacturers of polypropylene products for water supply

On the Russian PP pipe market you can most often find domestic manufacturers, as well as products from China, Turkey and the EU. European manufacturers have the highest prices, while Russian manufacturers are considered the most budget-friendly.

Jakko-products from Turkey of good quality

Good quality and the best price can be offered by such well-known brands as:

- Blue Ocean (China);

- FIRAT (Turkey);

- Kalde (Turkey);

- Jakko (Turkey);

- PROAQUA (Russia);

- PBK (Russia);

- Aquatherm (Germany).

The same companies also produce connecting elements.

Range of polypropylene products

Related article:

Copper pipes and fittings for residential water supply. Although they are much more expensive than others, they have a whole set of advantages in comparison with their polypropylene and metal-plastic counterparts, which we will discuss in the article.