Areas of application

Unlike round pipes, profile pipes have different sections: square, rectangular, diamond, star.

They find their application:

- In ventilation systems as air ducts.

- In the manufacture of furniture as the basis for frames and installation of built-in elements.

- To create protective insulating channels when installing cables of various types.

- In non-pressure drainage systems: drainage, storm, domestic sewerage.

- In the manufacture of greenhouses, greenhouses, irrigation structures.

The polymer profile is used to strengthen plastic structures. The rectangular profile perfectly serves as a stiffener in large polypropylene containers.

Product purpose

The products in question are used in a variety of fields.

Square pipes have become widespread in such areas as:

- furniture manufacture;

- construction of various structures inside buildings;

- Agriculture;

- creation of cable channels;

- production of plastic windows;

- creation of pipelines and ventilation ducts.

Each direction has its own types of products considered. This must be taken into account when purchasing it.

Technical characteristics and properties

What all polymer bends have in common is their high wear resistance and complete absence of corrosion.

A profile pipe made of plastic has greater strength compared to a round pipe made of the same material.

Their chemical and physical properties differ depending on the type of polymer.

Thus, PVC and its derivative uPVC are resistant to external precipitation, tolerate high temperatures of up to 100 degrees, and begin to burn only at 640 degrees. Polyvinyl pipe products are used in the production of cable ducts and ventilation outlets.

Among the characteristics of polypropylene pipes, high thermal expansion should be highlighted, as well as a simple and reliable method of installation - diffusion welding. The temperature range of their normal operation is from -30 to + 95°.

Plastic profiles differ in such technical parameters as the dimensions of the sides of a square or rectangular outlet, the thickness of their walls and specific gravity.

Life time

According to manufacturers, all plastic bends can last at least 50 years. At the same time, the characteristics of the products remain unchanged, including during underground installation in aggressive chemical environments.

Polymer pipes from a warehouse in the Moscow region.

Why is our polymer pipe plant located in the Moscow region?

A plant for the production of polymer pipes in the Moscow region is very convenient. Especially for potential consumers of the product. The infrastructure of Moscow and the Moscow region is such that there is constant reconstruction, construction, renovation and a lot of repairs. Such a large volume of work requires high-quality and reliable building materials that are also quite easy to use and apply. Polymer pipes are precisely such materials.

What are the benefits for both the manufacturer and the consumer? For the manufacturer, the benefit is that Moscow is practically a stone’s throw away, but the cost of renting premises for production is much lower than in the capital.

For our clients, there is an obvious benefit in the cost of delivering material for construction or repair: our polymer pipe plant is located not far from Moscow. And, of course, the low price of polymer pipes, which, thanks to the relatively low payment for production premises, becomes more affordable than in other places. And since pipes made of lightweight polymers and delivery are much cheaper than pipes made of metal, the direct benefit of using polymer pipes made at a plant in the Moscow region is visible.

Production of polymer pipes near Moscow.

The production of polymer pipes is aimed at making very useful things from fairly simple raw materials and completely unnecessary waste. The raw materials for such pipes are most often both primary polymers and various waste polymers, and secondary polymer raw materials. This also includes polyethylene waste, of which there is a lot nowadays - used polyethylene film, waste of the same polyethylene or polymers, a mixture of polymers such as PE100, PE80 and many others.

The essence of the production of such polymer pipes is conventional extrusion (in simple terms, the extrusion method). The granular polymer is heated to a high temperature - about 170 degrees or more. The viscous and thick mass obtained in this way is pressed by a screw to the extrusion caliber, where it is converted into rolled tubular products, and then cools and a ready-to-use polymer pipe is obtained. Already at the last stage, this rolled product is cut into certain sections that are needed for pipe standards.

Manufacturers of polymer pipes in Russia are represented by many enterprises producing products from various materials. Our company is distinguished by the fact that its production is located near Moscow. For the production of technical pipes, recycled materials are used, namely HDPE (low-density polyethylene). All this makes delivery cheaper and prices lower. Sales of polymer pipes are carried out from a warehouse in the Moscow region. In addition, delivery is carried out to any corner of Russia. Call us and we will definitely select the pipe you need, which will fully comply with international quality standards.

Design Features

Modern plastic pipes are mostly made multilayer. The main layer is made of heat-resistant and durable material, and is covered with a protective layer on top. Between them they place either a layer of aluminum or fiberglass.

This increases the wear resistance of the product and its ability to withstand increased loads.

For example, PPR-FB-PPR bends are made of two layers of polypropylene, between which fiberglass is placed. This kind of bend is called “fiberglass”.

Advantages of polymer sewer pipes.

Among the materials that are used to make sewer pipes, there are currently four favorites. This:

- Polymers are currently in first place. Polymer sewer pipes are superior to products made from less advanced materials in most respects;

- Metal, it is slowly losing its position, although previously it was used constantly;

- Asbestos, reinforced concrete, they are used quite often, but mainly for pressure drain systems;

- Ceramics, these pipes are rarely used, mainly for external and non-pressure drains.

Why are polymer sewer pipes gradually coming to the forefront, although they appeared not so long ago? This is because their installation is quite simple, their service life is very long, their weight is small and the cost is reasonable, and the cost of transportation is low. These factors have greatly influenced the fact that all other materials and pipes made from them are slowly losing their positions in favor of polymer pipes.

Polymer pipes of large diameter and medium cross-section are used for both internal and external sewage systems, and this is very convenient. Because when the material is the same in both places, the work and maintenance of sewer systems is much simpler. Pipes made of PE are especially good for internal sewage systems - this is polyethylene. They are also suitable for spillways, which means that they are also ideal for external sewerage. So it turns out that they are applicable everywhere, which means that installation, installation, and subsequent maintenance become as convenient and profitable as possible.

How are they produced?

Plastic bends are made on automated production lines. They include loading equipment, a system of devices for melting the polymer mass, forming a workpiece of a certain configuration from it, its further cooling and calibration.

Manufacturing technology

The production of polymer pipe products is based on the extrusion method.

Molten raw materials from polymer materials and additives are forced through the slot of the extruder molding device. The workpiece then goes through a calibration and cooling process. Next, the products are labeled, cut into measured pieces and stacked.

To create multilayer profiles, coextrusion technologies are used, when a new layer of a different polymer composition is applied to each created layer of the product.

A new modification - a fiberglass bend - is produced by pultrusion. The fiberglass blank is passed through a container of polyester resin and then pressed while hot through a molding head.

Composition of a plastic ventilation system

The ventilation system includes supply and exhaust ventilation units, a network of air ducts and air distribution devices. For domestic use, exhaust ventilation is usually installed to remove exhaust air and natural gas combustion products in gas stoves.

It is equipped with:

- duct fan;

- check valve;

- a set of filters for cleaning air flows;

- external ventilation grille;

- air distribution devices;

- fan speed controllers;

- temperature regulators;

- air ducts with section dimensions 55x110; 60x120; 30x204; 60x204.

In addition to the main equipment, a set of additional fittings is required for connecting plastic rectangular pipes for exhaust, designing turns or transition points.

It consists of:

- Rectangular bends 90º. Used to connect branches or in places where pipes bend at right angles to the main line.

- Bends 45º. With the use of such bends, it becomes possible to install air ducts with a shorter length.

- Rectangular transitions with different parameters of inlet and outlet openings. They are used to connect lower power lines with large main pipelines.

- Rectangular inserts. Necessary for connecting new lines to the main trunk.

- Fastenings. To fix air ducts to supporting structures, plastic clamps are used, the dimensions of which can be adjusted to the parameters of the pipes.

- Tees and crosses. Used to connect additional branches at right angles.

- Connectors. They connect sections of air ducts of the same standard size, reducing the consumption of building materials.

- Conversions of rectangular pipes into pipelines with a round cross-section. Allows you to connect branches of various geometries into a closed chain.

- Ventilation hatches. Designed for designing outlet openings. Can be mounted both vertically and horizontally. For a more even distribution of air flow throughout the room, blinds are equipped.

- Node of passage through the roof covering. A fastening element of various heights and widths for connecting side outlets.

- A rectangular damper designed to regulate the force of the air stream. Can completely disable a number of areas.

- Damper Used to automate ventilation systems.

- Stubs. Rectangular plastic plugs are used to protect structures from the penetration of dust and moisture and ensure their aesthetic appearance.

Attention. Additional reinforcement is selected taking into account the parameters of the main part of the structure.

Often the profile of the ventilation pipe entering the room is covered with an anemostat. It is a short piece of pipe, at one end of which a flat round plug is installed, at the other end there is a mounting flange and is intended to stop the flow of air. The flow is adjusted manually using a plug, which, when rotated, reduces or increases the size of the passage opening of plastic rectangular exhaust pipes.

5. Video

Regulations

The creation of plastic profiles is regulated by various state standards and rules in accordance with their purpose. Products used for water supply, heating, ventilation and gas supply are subject to certification.

There are no specific state standards for the production of profiled polymer pipes. Recommendations for their manufacture are contained in the manufacturers' documentation.

Standards and GOSTs

They are guided by GOST standards for the installation of certain pipelines. For example, GOST 32548-2013 “Ventilation of buildings”.

Various technical conditions approved by higher control authorities are also used.

- TU 2248-001-09801575-2010 (for non-pressure communications).

- TU 2247-001-88915836-2010 (for sheet and profile products made of thermoplastics).

- TU 6-19-215-86 (for PVC-U insulation boxes).

Strengths and weaknesses of square plastic pipes

The strengths of this product include the following characteristics:

- They tolerate climatic influences well.

- Undemanding in maintenance.

- They are not afraid of corrosion.

- Long-term operation.

- Environmentally friendly.

- Water transportation is not accompanied by characteristic noise.

- Excellent hermetic performance.

- Cheaper transportation and storage: this is facilitated by a more convenient form for storage.

List of disadvantages:

- Weak fire resistance.

- Recommendations for limiting contact with heated air.

- Not an easy installation, requiring specific skills and equipment.

- Some products are not suitable for hot water.

Types of assortment sizes and sections

There are profile plastic bends based on the material they are made of.

Profiles are:

- Polyvinyl chloride (PVC, uPVC, CPVC).

- Polypropylene (PP).

- Polyethylene.

- Fiberglass, consisting of two layers of polypropylene and a middle layer of fiberglass (PPR-FB-PPR).

At the same time, each material has varieties by brand. Thus, among polyethylene products PE80 and PE100 are quoted.

Polypropylene types have their own classification.

For example, PPH, the simplest of the entire range of polypropylene, is used for laying ventilation systems. PPB, made from a copolymer, is used for installing pressure water pipes and making load-bearing stiffeners in plastic structures.

The third type - PPR - contains a random copolymer, which gives polypropylene higher heat resistance. This type is used when laying heated floors. High-strength polymer PPs are used for heating networks.

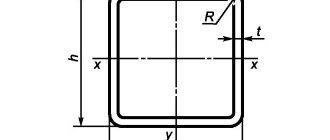

Standard sizes and markings

To select profile bends, we are guided by the dimensions of the sides and walls of the profile. Different standard sizes are popular for different areas of application.

Thus, for ventilation air ducts in residential premises, profile bends of 60×120 and 60×204 mm are most often installed.

For cable channels, depending on the size of the wires and their volume, the width of the channels can vary from 2 cm to 10 cm, and their height can be 2-8 cm.

The wall thickness for a profile 60x40 mm is 3.7-4 mm, for a bend 100x80 mm - 5-5.5 mm.

The standard lengths of such bends are 1, 3, 4 and 5 meters.

All plastic products must be marked every meter of pipe.

It contains:

- Manufacturer's company name.

- Type of raw material from which the product is made (PVC, uPVC, PP, PE, etc.).

- Product class based on the pressure value for which the pipe is designed (indicated by the letters PN and its values 10,16,20,25).

- Dimensions of the profile sides and wall thickness in millimeters. For example, 60x120, 2.0.

- Date of manufacture.

- Details of the regulatory document according to the requirements of which the product was manufactured (TU, GOST).

Types of air ducts made of polyvinyl chloride

Plastic air ducts for ventilation are classified:

- according to the profile shape - round and rectangular section;

- according to the ability to change shape - rigid and flexible pipes.

1.1. Products with round profile

Round PVC pipe is mainly used for installation of main pipelines of ventilation systems. Available in a diameter range of 100 - 200 mm. It does not have a very convenient shape for installation work, but it has a higher throughput. You can buy such a pipe at a price per linear meter of 25 - 40 dollars.

1.2. Rolled pipes with rectangular profile

For the manufacture of ventilation systems in residential buildings, rectangular PVC pipes are most often used. It’s easier to hide them by placing them in the space between the stretch ceiling covering and the ceiling, behind wall cabinets. When laid in visible places, they are significantly more attractive than similar systems of other forms.

Standard sizes and prices of plastic pipes with a rectangular cross-section

| Profile dimensions, mm | Price, USD/m.p. |

| 100x100 | 20 |

| 125x100 | 22,5 |

| 125x125 | 25 |

| 160x100 | 26 |

| 160x125 | 28,5 |

| 160x160 | 32 |

| 200x100 | 30 |

| 200x125 | 32,5 |

| 200x160 | 36 |

| 200x200 | 40 |

| 250x100 | 35 |

| 250x125 | 37,5 |

| 250x160 | 41 |

| 250x200 | 45 |

| 250x250 | 50 |

| 315x100 | 41,5 |

| 315x125 | 44 |

| 315x160 | 47,5 |

| 315x200 | 51,5 |

| 315x250 | 56,5 |

| 315x315 | 63 |

| 350x200 | 55 |

| 350x300 | 65 |

| 350x350 | 70 |

| 400x200 | 60 |

| 400x300 | 70 |

| 400x400 | 80 |

| 500x300 | 80 |

| 500x400 | 90 |

| 500x500 | 100 |

| 600x300 | 90 |

| 600x400 | 100 |

| 600x500 | 110 |

| 600x600 | 120 |

| 800x300 | 148,5 |

| 800x400 | 150 |

| 800x500 | 175,5 |

| 800x600 | 189 |

| 800x800 | 216 |

| 1000x300 | 175,5 |

| 1000x400 | 189 |

| 1000x500 | 202,5 |

| 1000x600 | 216 |

| 1000x800 | 243 |

| 1000x1000 | 270 |

1.3. Flat ducts

Essentially, these are the same rectangular plastic pipes, but more compact, cast with a large difference between the dimensions of the width and height of the profile. Used for installation in places where there is a lack of free space.

1.4. Corrugated pipes

Corrugated PVC pipe is more appropriate in the kitchen for constructing a hood. It has a high degree of flexibility, thanks to which air ducts of complex configurations can be formed. For their production, the extrusion method is used. All types of equipment involved in this technical process are fully automated, so the cost of such products is relatively low.

You can buy a corrugated rectangular PVC pipe with a cross-section of 45x25 at a price of 1.5 - 2 dollars per 1 linear meter.

Attention. For industrial buildings, it is better to use Vents reinforced flexible air ducts, the basis of which is a metal spiral covered with polyvinyl chloride on top.

Advantages and disadvantages

Let's look at the pros and cons of plastic profile pipes.

Experts include the following advantages:

- Light specific gravity.

- Strength. With the same weight, a plastic profile can be stronger than a metal pipe.

- No corrosion.

- High throughput, resistance to blockages and contamination.

- Inert to chemicals, adverse weather conditions, temperature changes in certain ranges.

- Simplicity and ease of installation.

- Durability (up to 50 years).

- Moderate prices.

- More aesthetic appearance compared to metal products.

The disadvantages include:

- Fragility of the material.

- Possibility of leaks at connections.

- Significant thermal expansion.

Use of polymer cable laying pipes.

Today, the use of polymer cable wells is a new step, even a leap, in the development of linear communications and communications. They are much more convenient than those that were used before, which were asbestos-cement pipes and reinforced concrete wells. What were their predecessors so guilty of? They really did not like frosts, their level of frost resistance was very low, which affected the operation of the systems. And since in our weather conditions there are quite a lot of frost cycles, their service life could rarely exceed 5 or 7 years, which is very short and unprofitable.

But the use of polymer wells has shown that they are practically eternal, since they are completely not susceptible to freezing and very reliably protect linear systems from frost. They do not come into contact with salts or water at all, and they can withstand the same loads as reinforced concrete products. And since the connection occurs by cold welding, absolute tightness is obtained.

Plastic cable wells imply exclusively single outputs and inputs, which makes the system quite convenient and reliable. After all, previously reinforced concrete manholes were made in such a way that there was only one hole, and wires had to be inserted into it in bundles. And this greatly complicated access in case of repair or inspection. This does not happen with polymer wells; the principle works here - each cable has its own well!

Previously using reinforced concrete wells was similar to folding a construction set, and only on site. And then it was necessary to connect everything together with mastic and grout, which greatly harmed the cables. Polymer wells are monoblock, they are installed on site very easily, and then there is an ideal connection of cable systems. And what is also very important, the cost of a polymer well for protecting cable systems is cheaper than the assembly and installation of a reinforced concrete well.

That's why this was such a huge leap into new technologies for linear connections and communications!

Tips for choosing

Products are selected based on their purpose. For ventilation ducts, the main thing is to select the appropriate cross-sectional dimensions and frost-resistant outlets for the part that will go outside. Most often, PVC pipe products are used in these systems.

It is necessary to take into account the methods of installation of connections. Polypropylene is joined by welding. As a reliable connection, it is used in pressure networks. But it requires a welding tool and certain skills.

To connect other materials, various fittings will be required: tees, adapters, elbows, couplings.

The high elasticity of HDPE elbows allows them to be used as water pipes in underground installation, where they can successfully withstand variable soil loads.

Approximate price and best manufacturers

The cost depends on the section size and wall thickness, length and weight of the purchased profiles.

Thus, a rectangular bend made of polypropylene 60×40 mm with a wall thickness of 4 mm costs 178 rubles per meter. A profile made of the same material measuring 100×80 mm, with a 5 mm wall will cost 280 rubles.

The list of leading foreign manufacturers is headed by recognized industry leaders: German companies Aquatherm, Banninger, Blauberg Group, Wefatherm. Ventilation products belonging to the Blauberg Group are widely known.

Among the Russian companies we should name the group of companies “Poliplastik”, NPO “Stroypolymer”, PlastProduct, SMP-PLAST, “POLEX PLAST”.

Which pipeline to choose for heating

Heating is a specific system in which all components are subjected to extreme or similar loads. The pipeline must withstand temperatures up to 80 degrees, high pressure, not become clogged, and have a long service life.

Most modern plastic pipe products meet these requirements to one degree or another. But most often, when laying heating communications, polyethylene or polypropylene bends are chosen in various combinations and designs. Third generation polypropylene, PP-3 or PP-R, has proven itself to be a suitable material for the manufacture of elbows resistant to elevated temperatures.

Among polyethylene products, pipes made on the basis of cross-linked polyethylene (PEX) and the latest modification of PE materials - PE-RT (polyethylene with increased heat resistance) are excellent for heating. They have one drawback - the high price.

Connection (welding) of polymer pipes.

Welding polymer pipes is a fairly easy process, which is qualitatively different for the better from joining metal pipes. There are three main ways in which polyethylene pipes are connected:

- The so-called “cold welding”. With this method, the end of the pipe is coated, and then it is inserted into a special coupling on another pipe. In this way, the pipes can be connected in a line. Such a connection can withstand a pressure of no more than 16 bar.

- There is a method called pressure welding. It heats the pipe (its end) to 175 degrees, then it is inserted into a fitting heated to the same temperature. Under the influence of high temperatures, the pipe is pressed into this fitting, and it is able to withstand quite high pressure, about 25 bar. To do this, you need to use a welding soldering iron, but the connection is quite strong and reliable.

- And this connection method allows you to install pipes that will be able to withstand pressure of about 40 bar. The end of the polymer pipe is placed on the fitting nipple; fixation occurs by using a crimp nut or sleeve capable of deformation. It is also called a press sleeve. The connection of polymer pipes is very strong, and therefore can subsequently withstand high pressure.

These are the three ways in which polymer pipes are connected.

Installation Tips

Connections between plastic square and rectangular channels are made using fittings: tees, elbows and couplings. The technology is very simple: the elements are inserted into each other and lubricated with silicone.

Adapters are available for transitions from profile to round cross-section or vice versa.

In the manufacture of volumetric and flat structures, profiles are connected to each other and to sheet parts by welding. For these purposes, use a construction hair dryer, an extruder or a special welding machine.

Fastening of polypropylene structures to walls is carried out taking into account their significant thermal expansion. To do this, alternate movable and fixed fastenings.

Pipe laying

Joining of square plastic products can be done by welding. Most often this method is used in the furniture industry. Installation of profiles of the same or different sections is carried out using fittings. When selecting a connecting component, the operating conditions must be taken into account.

Note that fittings can be used to join round and square pipes. To solve this problem, use a rubber coupling, fixed with clamps. A plug is a fitting that closes the product on one side.

Tees allow you to connect three structures at the same time. They are secured on each side with clamps.

Remember that the fewer joints there are in the system, the higher its reliability. If you decide to use polypropylene square pipes, consider the thermal expansion rate. When heated to sixty degrees, this product increases in length to nine millimeters.

If a component does not have enough room to expand, it may become damaged. Therefore, be sure to take this indicator into account when laying systems made of polypropylene structures.

In order for the pipeline to operate reliably and safely, special elements are added to it - temperature compensators. It is recommended to avoid installing piping systems in too tight spaces.

There are polypropylene products that include an aluminum layer. This element reduces the value of thermal expansion. But such products have a higher cost.

Features of operation

Plastic pipelines must be inspected annually. Inspect the joints and, if necessary, tighten the fasteners in the fittings or replace them.

Possible problems

The main problems may be mechanical damage to the structure and violation of the integrity of the pipeline at the joints. The cause of leaks or separation of system elements lies in improper installation, the use of defective products, and mechanical stress.

As temporary measures, fastening clamps, sealing the leak with a rubber gasket, epoxy glue, or cold welding are used.

Repair of damaged areas consists of replacing failed fittings and individual pipeline segments.

Packaging, transportation and storage

Plastic profiles are packed in bags. For storage, they are placed on a flat surface in stacks no more than 2 meters high.

To protect from sunlight, the products are covered with a protective film or equipped with a canopy.

Bends can be transported by any type of transport in compliance with the rules established by the carrier. The bends should be placed in transport in such a way that they do not receive mechanical damage during transportation. For this purpose, packages in bundles and various supports are used.

Features of installation of polymer pipes.

The ease of installation of polymer pipes makes them very convenient to use. Cutting such pipes can be done with small scissors, and this can be done right on the spot. If the polymer pipe is of sufficiently large diameter, for example for sewerage, then an ordinary hacksaw is perfect.

Bending such pipes is also quite easy. What’s even simpler is that you can completely avoid bending; there are many adapters with which you can install at absolutely any angle.

If the polymer pipe is small in diameter, welding of the pipe may occur during installation using a welding soldering iron. You need to check these pipes with an air supply (for example, just blow into it). This needs to be corrected immediately, otherwise there will be problems later.

You should always remove burrs after cutting a pipe at its end ends. To do this, you can use a regular stationery knife. When connecting for the first time, you need to do it “dry”. The pipe should enter freely into the adapter only two-thirds of the distance, then the entry should go with little effort.

If you follow all these installation features, then polymer pipes will last a very long time and reliably.