Solid bent pipe is a type of seamless pipe.

Solid bent pipe is more expensive than other types of pipes.

The rather high price of these pipes is due to the complex manufacturing process. To produce seamless pipes, expensive equipment is required. But the higher cost is compensated by the high quality of the finished products.

The absence of seams ensures resistance to mechanical and chemical influences, allowing the use of such pipes in more difficult conditions.

Features of the production of seamless and bent pipes

A solid-bent pipe is manufactured using a special technology, the method of drawing hot metal from a mass. Thus, a pipe blank is formed, which is calibrated.

Seamless pipes are also produced on special rolling mills. For example, the method of obtaining a hole by piercing and drilling a hole in cylindrical workpieces is used.

The main goal of the production of solid pipes and other types of seamless pipes is to obtain monolithic products with a uniform structure. A product of this structure is reliable, highly resistant to corrosion and high pressure.

Additional protection for solid pipes

To provide additional protection against corrosion, solid pipes are often coated with zinc. Galvanized pipes are usually connected using couplings or fittings.

Classification and characteristics

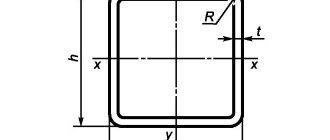

Based on the wall diameter, seamless pipes are divided into extra-thick-walled, thick-walled, thin-walled and extra-thin-walled. In numbers, this is expressed by the ratio of wall thickness and pipe diameter.

Pipes are also divided into ordinary, light and reinforced. Reinforced seamless pipes offer the highest levels of corrosion resistance and strength, and lightweight pipes are well suited for creating curved shapes necessary for the installation of various structures. Ordinary pipes are the most widely used.

Solid pipes can have a length from 1.5 to 10 m.

The main material for the production of seamless pipes is steel. Pipes are also made from alloys and non-ferrous metals.

Features of application

The high strength of seamless bent pipes determines their wide range of applications.

Strong and reliable seamless pipes are used for the construction of pipelines transporting aggressive liquid media. They are also used to transport liquids that are supplied under high pressure or have high temperatures. Seamless pipes with reliable coupling connections are used for the installation of pipelines transporting oil and gas.

Also, solid-bent pipe is used in the energy and nuclear industries, aviation, tractor building, shipbuilding, and carriage building. Solid-bent seamless pipes are widely used in monolithic construction.

Wear resistance and high strength allow the use of seamless pipes in industrial and construction areas with high loads.

View our range of seamless pipes.

Seamless pipes belong to rolled metal products, the specifics of their manufacture imply the complete absence of any joints along the entire length.

The technological process requires the use of specially designed rolling machines, for this reason the production of seamless pipes is simply called “rolling” without using scientific terminology. Seamless metal products continue to be popular in the market, despite the high demand for pipes made from polymer materials. Steel pipes are still indispensable in certain situations.

Advantages and disadvantages

Pipes that do not have a single connection have their advantages and disadvantages,

Pros:

- reliability,

- long service life,

- resistance to high temperatures,

- aesthetically attractive appearance,

- durability,

- high strength,

- tightness,

- Possibility of use in open form,

- resistance to high pressure.

The key disadvantage of seamless pipes is their high cost. However, if you take into account their capabilities and compare them with the price, they pay for themselves several times over.

Types of seamless pipes

Seamless pipes are mainly classified by length:

- Measured; Unmeasured; Multiples of any measured length.

In accordance with the approved GOST, seamless pipes can be divided into the following sizes:

- The cross-section of hot-rolled pipes ranges from 25 to 700 mm, metal thickness - from 2.5 to 75 mm; Non-dimensional parts - from 4 to 12 m; Cold-drawn pipes - 8-450 mm with a layer thickness of 20 mm; Seamless cold-drawn pipes are manufactured in lengths from 4. 5 to 9 m.

Solid drawn pipes are also divided into 4 main categories, which can be divided into 4 subgroups.

Such products are highly reliable and durable, since they are created from cast metal blanks. During the production process, a hole with certain cross-sectional parameters is made in a monolithic hot billet. It should also be taken into account that the thickness of the metal layer in seamless steel pipes is 6-13 mm.

Seamless pipes can also be divided according to the grade of steel from which they are made. Today, about a dozen grades of steel are used to produce seamless rolled metal.

Varieties of seamless products

Depending on the manufacturing method, there are several types of seamless products. It can be a hot-rolled pipe, solid-drawn or cold-rolled.

Seamless seamless pipes are a type of thick-walled pipe.

Seamless owes its name to the production method and the fact that it has practically no joints or seams. Seamless pipe has high strength and is used in cases where high pressure or high temperatures have to be dealt with. Steel has optimal qualities.

Seamless pipe production

Seamless pipes can be produced in several ways:

- Forging; Rolling; Drawing; Pressing.

This process is performed only at specially equipped industrial facilities using materials of various grades, as well as some alloys. The type of material used in the production process is determined by the final purpose of the pipe. Preliminary heat treatment is considered a mandatory condition in the process of manufacturing seamless solid-rolled pipes.

At large metallurgical plants, specialized workshops are equipped where blanks for cold-rolled seamless pipes are rolled. The difference in manufacturing technologies lies in the temperature at which heat treatment is performed.

Cold rolling technology involves processing metal blanks after they have cooled.

Hot-rolled pipes are processed only in a hot state. Modern production shops are equipped with high-quality equipment that allows us to produce seamless products of any diameter with an individual approach to determining the specifics of rolling. In accordance with the technology, during the production of hot-rolled pipes, a temperature is maintained at which the recrystallization process will not be activated.

Each technological process at the enterprise is carried out in strict accordance with current GOSTs, so manufacturers are forced to maintain the quality of their products at a fairly high level. Each plant must have a certificate confirming that pipes comply with established state quality standards.

Cold-worked

Another technology for producing seamless pipes is the cold deformation method. This technology is more optimal because it produces stronger and harder products. Each seamless cold-formed pipe must be manufactured in accordance with government requirements. Basic standards - GOST 8734-75, GOST 8733-74 and others. The production technology looks like this:

- Preparation. Immediately before production, the workpiece is cleaned using chemical active substances. The part can have any cross-section - rectangular, square, round, oval.

- Heat. The workpiece part enters the production workshop, where it is heated to low temperatures (400-500 degrees) for pickling and increasing flexibility. The peculiarity is that at such temperatures the edges of the part do not melt, which is why the technology is called the cold deformation method.

- Formation of the sleeve. Now, using a drill, a large hole is drilled in the workpiece. If necessary, processing is carried out using several drills to increase the smoothness of the inner surface.

- Rolling, compression. Now the blank sleeve is passed through a roller machine, where a rounded cross-section is formed. If necessary, the roller machine can perform compression to reduce the diameter of the part.

Cold-drawn seamless pipe has increased strength and reliability. Therefore, such parts can be made with both thin and thick wall thickness. The main application is the creation of pipelines in houses, shops, engineering facilities, installation of sewers. According to GOST, “cold” parts must have dimensions from 5 X 0.3 mm to 250 X 24 mm. In fact, thin-walled products of short length have become widespread. They are a good alternative to hot formed products, which are usually produced in the form of long, thick-walled products.

Hot and cold forming

How are metal pipes made using the hot rolling technique? The technological process involves certain financial costs, for this reason the cost of these pipes ultimately turns out to be very impressive. The first stages involve performing preparatory work.

A workpiece is an element with a cavity of standard length and cross-section. A special grade of steel is used as a material for manufacturing. The hot deformation process has the following features: Before rolling, the workpiece is heated to a temperature that does not reach the start of the metal crystallization process with a permissible excess of 50-60 degrees. The workpiece becomes more plastic, but still retains its shape and does not melt; At the next stage, the formation of a sleeve is made using a special drilling machine capable of drilling a hole of the required diameter and depth in the workpiece.

A piercing press allows you to obtain a finished hollow cylinder from a pre-heated metal billet. However, this product only resembles a pipe in visual characteristics; During the rolling process, the sleeve is placed on a special machine equipped with several rollers. The sleeve installed between the rollers is gradually stretched in several directions; The required shape of the product is achieved after rolling, the dimensions of the pipe are adjusted during hot deformation. The diameter of the manufactured pipe is controlled using a limiting element; When immersed in water, the hot steel pipe is cooled, then final calibration is performed through several rollers. Some procedures from the above sequence can be performed several times to obtain the product of the required shape. At the final stage of the pipe processing process are cut into products of the required length. Cold forming technology involves two main distinctive features: The cooling procedure is performed after the workpiece leaves the piercing machine. Preliminary calibration of the pipe should be performed only in a cold state. When finishing rolling is performed, the sleeve is fired, heated to a temperature at which the process of recrestallization of the metal begins.

Installation features

The method of installing a seamless pipe depends on the thickness of its walls. The most reliable method of connecting elements is welding.

Important! For better adhesion of pipe fragments, it is recommended to trim their ends.

Pipes with thin walls are connected using gas welding, and thick-walled products are connected using electrical equipment that is more powerful than a gas apparatus.

Metal pipe benders are used to bend hot rolled pipes.

Seamless pipes are rarely used by ordinary people for household purposes. They are quite expensive and for many people it is easier to purchase easy-to-install and lightweight metal-plastic for the water supply system, the capabilities of which will be quite sufficient for the conditions of private housing.

Did you like the article? Subscribe to our Yandex.Zen channel

Scope of application of seamless pipes

Structures made from hot-rolled pipes are installed when it is necessary to reduce the risk of leakage of the equipped working environment. The possibilities for using such pipes are considered limitless. They are used in the following industries: Automotive industry; Tractor building; Aviation modeling; Oil industry; Chemical industry; Water pipelines; Gas pipelines; Coal industry; Defense industry; Shipbuilding; Heavy industry. The quality and fairly high strength of such products makes them so popular. Thick-walled networks are used for technologically complex production processes in which the internal pressure rises very high.

These pipes are also used as components of complex support structures that can withstand heavy weights. All mechanical characteristics and ability to withstand loads are tested in accordance with current government quality standards. Each product must pass several basic tests for endurance to mechanical stress. Only after this is their subsequent sale possible. The rolled metal industry is constantly expanding, for this reason manufacturing plants are constantly expanding their range.

Application area

Pipes that do not have seams have found their application in areas where the possibility of leakage cannot, in principle, be allowed.

For example:

- carriage building,

- chemical industry,

- shipbuilding,

- defense industry,

- mechanical engineering,

- monolithic construction,

- oil industry.

Also, solid pipes are actively used by utilities for the installation of water and gas pipeline systems in the drilling and coal industries.

Advantages

Naturally, the main distinguishing feature and advantage of solid pipes is the absence of any seams. This feature reduces the likelihood of damage and increases resistance to mechanical stress. Hot-rolled pipes made from thick metal sheets are highly resistant to corrosion. However, such products are not particularly flexible in the process of repairing or installing any structures.

This is of great importance, since the installation will not bring the desired result. Hot-rolled pipes are considered literally ideal materials for the construction of various communications. When using different types of connections, all kinds of structures and design structures can be created. This requires strict adherence to existing connection technologies and installation rules. Hot-rolled seamless products, due to their high strength characteristics, are excellent for equipping various types of systems with high internal pressure.