- What is corrugated pipe?

- Features of corrugated pipes

- Technical characteristics of corrugated pipes

- Types of corrugated pipes

- Corrugated pipe sizes

- Where are corrugated pipes used?

- Advantages and disadvantages of corrugated pipes

Features of the room or topography when laying pipelines for various purposes, established installation standards force one to resort to the use of corrugated pipes. Corrugated pipe is a practical and convenient technical invention that makes it possible to simplify the arrangement of engineering systems and make them more reliable and protected. These products are used everywhere - from the implementation of large-scale industrial projects to the laying of household communications.

Design features and technical characteristics

The size of the ridges and the distance between them may vary from manufacturer to manufacturer; the degree of rigidity is adjusted by thickening the rings.

The technical characteristics of corrugated pipes depend on the characteristics of the material and design. For example, for stainless steel corrugations, manufacturers set the following parameters:

- operating temperature range - 1-100 degrees;

- operating pressure range - 10-65 bar (destructive pressure - 210 bar);

- bending radius parameters - 30-150 mm (depending on the diameter of the rolled metal);

- pipe wall thickness dimensions - 0.25-0.3 mm;

- the surface of the corrugated product involved in heat exchange is 40% higher than that of its copper counterpart.

Stainless steel pipes

Corrugated stainless steel pipe has fairly high strength, reliability and a long service life. The advantages of this material include:

- Long service life. Stainless steel products can last for a long time. Throughout their entire service life, cracks do not form on them, and the internal diameter does not change. As a result, the permeability of the corrugated pipe remains unchanged.

- Flexibility. During operation, the pipes do not lose their flexibility. This applies even to sudden changes in temperature after the winter period.

- High reliability. Steel pipes have high strength and are reliable in operation. Thanks to this, you can forget about problems during their use.

- Elimination of deposit formation. During operation, no deposits form on the pipe walls. This ensures uninterrupted operation of the system for a long time.

- Easy to transport and install corrugated pipes. Low weight and dimensions make the products easy to transport and install.

Stainless steel products do not emit harmful substances, are not afraid of ultraviolet rays, rodents and mold. But despite this, such material has some disadvantages:

- Low resistance to mechanical damage and aggressive environmental influences. This significantly reduces the life of the system.

- Possibility of damage due to the use of chemically active cleaning agents.

- Damage occurs as a result of frequent bending of the material in one place.

Despite all the advantages and disadvantages, stainless corrugation is widely used in various fields. It is often used to construct ventilation in residential buildings.

Kinds

The range of corrugated pipes is presented in modern markets with different product models that have differences in design:

- single-layer - very flexible and lightweight, used for connecting gas appliances and protecting cables for various purposes;

- two-layer - have a smooth inner wall and a corrugated outer layer, have increased strength characteristics (rib and ring stiffness), and resistance to mechanical stress.

- corrugated hoses. They are used as flexible connections to portable and mobile communication devices in cases where their connection with rigid pipes is technically difficult or completely impossible.

- reinforced - made of low-density polyethylene by coextrusion with reinforcement with synthetic, mineral or steel fibers. They have a three-layer wall structure, where the base is a smooth elastic HDPE pipe, the outer layer is a corrugated waterproof shell, and a reinforcing insert acts as a layer. This production technology makes it possible to produce large-diameter pipes with high ring rigidity without thickening the corrugations. The metal insert is completely protected by polyethylene and is not subject to corrosion.

Corrugated pipes also differ in the material used for their manufacture:

- low-density polyethylene (LDPE) and high-pressure polyethylene (LDPE). This is the most common type of plastic, having universal physical and chemical properties. Produced in compliance with standards, this plastic is an environmentally friendly material. It is frost-resistant, weakly spreads fire, and does not conduct electric current, so flexible pipelines made of polyethylene corrugated pipes do not need grounding. Polyethylene absorbs shock loads and can provide reliable protection for cable lines from mechanical damage and vibration loads. The inertness of polyethylene with respect to chemicals makes it possible to protect electrical wiring from many types of solvents, acids, oils and other aggressive compounds;

- polyvinyl chloride PVC is a safe material that does not emit toxic substances and does not cause allergic reactions. It is absolutely neither flammable nor susceptible to moisture, is resistant to corrosion and temperature changes, as well as low electrical conductivity. PVC corrugated pipes can withstand heavy loads, so they can be laid under a thick layer of concrete or in the ground;

- stainless steel. The unique properties of stainless steel combined with ease of installation make it possible to use such products for radiator heating systems, “warm floor” devices, and cold and hot water supply pipelines;

- aluminum. Aluminum corrugated pipes make lightweight and durable ventilation ducts, kitchen hoods and chimneys. This material is non-flammable, resistant to corrosion, heat-resistant - can withstand heating up to +270ºС without losing its shape.

Basic information

Corrugated pipes can be single-layer or multi-layer. An example of a single-layer is the same hose that is used to water the beds. Can be made of PVC, PP, HDPE. The choice of material determines the characteristics of the pipe. Thus, for sewer networks today, low-density polyethylene is most often chosen as a material that is more durable, elastic and resistant to static and dynamic loads. Double-layer pipes with a corrugated profile are made from it.

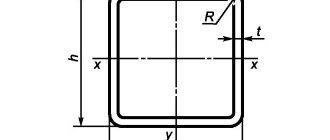

What is a corrugated profile and what is it for?

This type of pipe is distinguished by a special wall structure: it consists of two layers. The inner layer is absolutely smooth, no different from a classic tube. The external one has a relief represented by identical grooves located at equal distances from each other.

Why is this being done? The fact is that sewer networks run underground. The problem is not only in the depth of its location, but also in the loads that the pipe experiences following the direct impact on the soil lying on top of it. This includes passing cars, newly laid asphalt, and storm and melt water.

The characteristic due to which the pipe does not deform is called ring stiffness. The stronger the pipe wall, the higher the ring stiffness. In the case of plastics, the thickness would have to be increased many times over, increasing not only strength, but also weight and material costs. This would lead to a loss of economics and ergonomics of the process: HDPE pipes would become many times more expensive both to purchase and to install.

The corrugated second layer was the solution. It allows you to increase the ring stiffness without a significant increase in weight and change in material consumption. Modern engineers have developed several types of profiles with different heights and groove types, including hollow and reinforced profiles, spiral wound and reinforced pipes with complex profiles to ensure stability even at very large diameters.

Advantages and disadvantages of corrugated pipes

All corrugated pipes, regardless of the material from which they are made, have the following advantages:

- light weight, facilitating the process of storing, transporting and laying such products;

- high flexibility. The ability of the corrugation to bend in any direction allows you to avoid obstacles in difficult areas when laying and reduce the number of fittings and fasteners;

- corrosion resistance. All types of corrugated pipes do not corrode in conditions of high humidity;

- ease of installation, which can be carried out without the use of additional devices, equipment or complex machinery;

- low cost of all types of products;

- maintainability. To connect corrugated products, fittings with a union nut are used, which is tightened manually or with a wrench, and in the same way is easily loosened to dismantle damaged sections of pipes or devices;

- long service life. Properly installed corrugated pipe wiring will last at least 50 years;

- high ring rigidity and mechanical strength, which allow the use of corrugated products for any purpose;

- high throughput. The smooth inner surface of the walls creates minimal friction for the flow of the transported medium and prevents the formation of congestion.

Each type of corrugated pipes has its own disadvantages for use, depending on the technical characteristics of the material of manufacture. Common disadvantages are:

- more complex care than smooth-walled products. The ribbed structure of the walls on the outside makes it difficult to carry out wet cleaning; settled dust in the recesses will have to be washed out with a brush;

- a specific appearance that does not always fit into an elegant interior. In this case, the flexible pipeline is covered with a metal or plastic casing.

Features of corrugated pipes

The main feature that determines the widespread use of corrugated pipes is their structure. Designs with a folded system have a one- or two-layer structure: the inner surface is perfectly smooth, the outer surface is ribbed. Evenly alternating sections with small and large diameters perform specific functions. Thin parts of a smaller circle allow the pipe to bend in any direction, thereby facilitating the laying and installation of communications. Areas with a large diameter give the corrugated pipe the required ring stiffness in the cross section, making the structure impact-resistant and reliable.

The same design features allow the pipe to stretch in length: when assembled, narrow sections are hidden under wide sections: this simplifies the transportation of products.

Where is it used?

Corrugated pipes are designed for long-term operation and are used in the installation of utility lines for various purposes:

Sewerage

For the installation of external sewerage, two-layer corrugated polyethylene pipes are used, capable of supporting the weight of a layer of earth up to 15 m.

For work of this type, pipes with a diameter of 200 mm and 800 mm are produced. They are not afraid of frost, so they are not laid too deep, reducing the cost of working on trench excavations. In internal sewer systems, corrugation is mainly used in siphons, where it makes it possible to adjust the size of the water seal depending on the number of plumbing fixtures, as well as the length of sections vertically and horizontally. The most optimal diameter sizes for internal sewer networks are from 40 to 110 mm.

Electrical installation

Special electrical corrugated PVC pipes with a diameter of 16 to 63 mm are used as protective boxes when laying television cables, wiring electrical and telephone networks. They have dielectric properties, so when they are used in electrical work, there is no need to install a grounding loop.

For the convenience of pulling cables and wires inside electrical pipes, a special device is provided - a probe.

Gas supply

A flexible stainless steel pipe in a protective polyethylene sheath is a good option for connecting gas stoves, water heaters, wall-mounted boilers to a central gas supply system.

Water supply

The corrugation has the ability to compensate for linear expansion when heated, so the hot water supply lines will not bend.

Products made of stainless steel and polyethylene do not corrode, resist the formation of limescale on internal surfaces, do not emit toxic substances, and therefore can be used for drinking water supply installations without any fear.

Ventilation

The diameter of the corrugation for ventilation is selected depending on the total length of the ventilation duct and the power of the equipment.

Lightweight corrugated hoses do not require a supporting device during installation, have good throughput, do not accumulate static electricity, and measuring devices can be placed inside them.

Water disposal

Polymer corrugations with perforations are used to equip drainage systems and pipelines for non-pressure storm sewers. Plastic products do not react with many chemical compounds, do not corrode, are frost-resistant and are suitable for underground installation.

Corrugated pipe sizes

Corrugated pipes, depending on the design and purpose, can have different dimensional parameters. Here are the main, widely used sizes of corrugated pipes.

Standard indicators of products for working with electrical cables:

- 16 mm,

- 20 mm,

- 22 mm,

- 40 mm,

- 50 mm.

There are also pipes that have large diameters. They are usually used to organize a sewer or water supply system:

- 110 mm,

- 160 mm,

- 200 mm,

- 225 mm,

- 250 mm,

- 285 mm,

- 315 mm,

- 340 mm,

- 400 mm,

- 500 mm,

- 630 mm.

The ring stiffness of products varies from SN2 to SN16.

Attention!

Standard sizes of corrugated pipes in accordance with the scope of their use are regulated by GOSTs. Here are the standard sizes, but if necessary, you can buy products even with a diameter of 2400 mm.

Manufacturers and what to look for when purchasing

The most successful enterprises for the production of corrugated pipes are the Korean companies Lavita, Kofulso, Hydrosta, Meibes, the Czech - Wawin and domestic - Gofra - M, Neptune, Politek-3000, FD-plast, Tehstroy, Ruvinil, ProKAN, etc. Products of these companies has certificates with which the manufacturer necessarily confirms the quality of each batch of goods.

When purchasing corrugated pipes, you should check the availability of documents, as well as the integrity of the packaging, in order to exclude the substitution of branded products with goods from an unknown manufacturer.

In addition, it is necessary to visually assess the quality of the surface of the pipe, which may have been damaged during transportation or improper storage of the product.

Aluminum products

Aluminum corrugated pipes are widely used in ventilation systems in residential buildings and industrial buildings. Their popularity is due to the presence of many advantages, among which are:

- High flexibility. Thanks to this property, you can easily bend the pipeline in any direction, without the use of couplings and bends. This significantly reduces the cost of installing the system.

- Good strength. Corrugated aluminum products have high strength, which allows them to be mounted without the use of an additional support frame. Often, a collapsible clamp and self-tapping screws are used for fastening.

- Compactness. Aluminum pipes fold, which greatly simplifies their transportation.

- Resistance to corrosive processes. Erosion does not occur on aluminum products, which allows them to maintain their integrity and presentable appearance.

- Easy to install. Due to its light weight, installing the corrugation is quite simple. All work can be easily done with your own hands.

As for the disadvantages of aluminum corrugated pipes, these include:

- High thermal conductivity.

- Instability to various mechanical damages.

Installation Tips

Corrugation is widely used in the installation of communications both indoors and outdoors. It can be laid open or closed.

How to fasten

With an open installation method, the corrugation is attached to the base with plastic ties in increments of 30 - 40 cm; with a closed gasket, cement mortar can be used to fix the product; concrete can also be used on the floor.

How to connect

To connect flexible corrugated pipes of small and medium diameters, compression fittings with a union nut, which have a large engagement area, are used. It is recommended to connect larger diameter pipes using couplings or fittings in the form of flanges. To connect sections of different diameters, special adapters are used.

A number of models of sewer and drainage corrugated pipes with high annular rigidity have one bell-shaped end. When connecting sections of a pipeline, the straight end of one pipe is inserted into the socket of the other until it stops. The tightness of this type of connection is ensured by sealing the socket with elastic rings or hardening substances.

Corrugated pipes are produced in a wide range of standard sizes, from different materials, each of which gives it special properties. Among such a variety of corrugated products, you can always choose the option you need in terms of size and characteristics. Subscribe to our channel and share useful ideas on social networks.

(

2 ratings, average: 5.00 out of 5)

Corrugated pipe for sewerage

Corrugated pipes for sewerage differ significantly from products for cables. They are products made of PVC and PP with ring stiffeners in black or light gray. The diameter of the pipes varies from 110 to 300 mm, there can be products larger and smaller. They are used for laying intra-house, sanitary, all-alloy, non-pressure and storm sewer systems.

Unlike corrugated pipes for electrical networks, pipes with a diameter of 300 mm or more for storm sewers are more rigid and lack the main physical property of pipes for electrical systems - flexibility. They are laid linearly above ground and underground; special adapters are used for turns.

Large corrugated pipes can be laid in trenches without special preparation. Their key advantage is considered to be light weight, facilitating transportation and delivery to the construction site.

There are also flexible products that can be used in internal engineering systems to connect a bathtub, sink, shower cabin or tray. Flexibility makes it easier to install and connect plumbing to drains in tight spaces.

Features of material selection

In order for the system to operate efficiently and for a long time, it is necessary to choose the right pipes. This is especially true for those used for laying water pipes. When purchasing material, you should pay attention to the following aspects:

- Fitting. They must be fully equipped.

- Appearance of the product. There should be no cracks or other damage on the pipe that would lead to improper operation of the system.

- After installation, the system must be tested under pressure, which will identify hidden damage that was not previously detected as a result of an external inspection.

Advantages of laying corrugations

Corrugated pipes are laid in an open or hidden way. Due to the presence of many advantages, such products are used in various fields. This is especially true for those places where there are difficulties in laying other materials. It is also worth noting that laying corrugated pipes does not require special equipment or a large number of connecting elements.

To join pipes, union nuts, angles, couplings and other connecting elements are used. Ball valves are mounted in designated locations.