Pipes that are presented on the construction market today are made from the following polymers: polyethylene, polypropylene, polyvinyl chloride, polybutylene. The most popular material for modern sewage systems is PVC pipes. These pipes are resistant to almost all aggressive substances contained in the surrounding soil, industrial and domestic wastewater. Thanks to the extremely light weight of plastic pipes, the work of installers is greatly facilitated. And in order to install a sewer network from PVC pipes, there is no need to use expensive and bulky equipment for electric and gas welding. It is also important that due to the ideal smoothness of their surface, plastic pipes are much less susceptible to clogging, as well as rapid wear and tear from wastewater that contains small solid inclusions (sand, etc.). All of the above are among the indisputable advantages of PVC pipes when used for arranging sewer systems.

However, if used improperly, even the best material will not be able to display its unique performance qualities. Thus, problems can be caused by poor-quality pipe preparation and unscrupulous installation of the sewerage system. In urban high-rise buildings, the situation is partly saved by the significant volume of wastewater drained simultaneously from several apartments. In cottages, the situation is different - here any piece of paper, once caught in one of the joints of the sewer system on an insufficiently straight edge of the pipe, can eventually become a full-fledged dam.

Avoid hangnails

A blockage is one of the main enemies of the sewer system. It can arise not only due to the use of sewerage for other purposes (as an alternative garbage disposal). The sewer system can become clogged even if used correctly. The likelihood of a blockage is directly proportional to the degree of roughness of the inner surface of the pipes. In addition, sharp turns, ledges, and changes in the sewer network also have a negative impact. In such problem areas, dirt will accumulate much more often than on relatively flat sections. These factors must be taken into account when preparing sewer network elements for installation, as well as when choosing fittings and connecting parts.

PVC pipe cutting saws

One of the advantages of PVC pipes is their ease of processing. To cut pipes to size, various methods can be used. When there is enough space and a large number of pipes need to be cut, then you can use a special cutting machine that makes cuts with virtually no burrs. A saw designed for PVC materials also allows you to achieve a high-quality cut. The wide saw blade is easy to hold in a perpendicular position. Sometimes it is permissible to use an ordinary hacksaw for metal. The fine teeth of a hacksaw minimize the formation of burrs on the pipe, but the narrow blade makes it difficult to make perpendicular cuts.

All of the above methods are good if there is quite a lot of space. What to do if the room is quite cramped or the pipe that needs to be sawed off is located close to other communications? Then you can use a piece of thin steel cable equipped with plastic handles at both ends. One of the ends is passed under the pipe, the cable is placed perpendicular to the pipe, and alternately pulled by the handles with light, smooth movements. When the cable rubs against the pipe, the polyvinyl chloride melts. When using any tool to cut pipes, pay special attention to the perpendicularity of the cut.

Burrs for PVC pipes

As a result of cutting a PVC pipe, burrs often form (both inside and outside the pipe). From the inside, burrs must be removed very carefully so that the waste can move freely to its final destination. Those burrs that are located on the outside of the pipes can interfere with the fitting of the elements and their adhesive connection. Consequently, these roughnesses must also be removed. To remove external burrs, run a knife blade along the edges of the flange. The inner surface of the pipes is processed in the same way as peeling an apple. In order not to miss any of the slightest burrs, experienced craftsmen regularly run their fingers along the edges. After all, even tiny hangnails can catch hair, which subsequently quickly collects waste.

Types of materials from which plastic pipes are produced

Three types of material can be used to make sewer pipes:

- PE (polyethylene). This is the cheapest polymer that is frost-resistant and does not rot. But at temperatures above 40 degrees it tends to soften, so it is only suitable for cold drains. In view of this, PE pipes can only be used for collecting and draining rainwater, connecting storm drains, sewer systems where boiling water is not poured, etc.

- PP (polypropylene). This material is more expensive than the one described above, but is designed for continuous operation with a liquid temperature of 70-75º C. If you need to drain water at a higher temperature, the sewerage system can easily withstand a short-term increase in temperature up to 90-95º C. The estimated service life of the material is 50 years, but It is important to protect communications from hypothermia, since at -5º the walls become fragile.

- PVC (polyvinyl chloride). Pipes made of polyvinyl chloride or its unplasticized version (UPVC) have an average heat resistance of 60º C, but are better able to withstand alkalis, acids, oils and other aggressive substances. PVC is also not affected by alcohol and aliphatic compounds. Most often, it is reasonable to organize such a sewer system at enterprises for draining technical fluids, in a garage or workshop. But it can also be used in ordinary residential buildings.

PVC or PP pipes for internal sewerage

To drain wastewater inside buildings for socio-cultural, administrative or public purposes, as well as private houses and apartments, sewer pipes made of PVC (uPVC) or PP and intended for internal use are used. These pipes are painted grey.

Pipe 110 mm for internal sewerage.

Since there are differences between these materials, which we wrote about above, pay attention to this point. When choosing, you should only remember the temperature difference and different chemical resistance.

If the temperature of the wastewater is in the range of 2-80 degrees and sometimes rises to 95º C, then PP sewer pipes will be more ideal for such conditions. They are available in lengths from 15 to 300 cm and come in diameters of 32, 40, 50 and 110 mm.

Pipe 32 mm.

Pipe 50 mm.

This allows you to create different throughputs and lay them in standard holes left after the cast iron sewer.

In pipes with a diameter of 32-50 mm, the wall thickness is 1.8 mm, and in “weaving” the plastic cross-section reaches 2.7 mm, providing increased strength. Additional size ranges are possible, but they depend on the specific manufacturer.

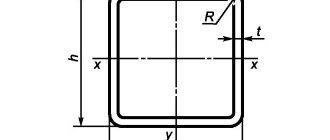

Table 1. The most popular pipe sizes for internal sewerage

| Diameter, mm | Length, mm | Wall thickness options, mm |

| 32 | 150 | 1,8 |

| 250 | ||

| 500 | ||

| 750 | ||

| 1000 | ||

| 1500 | ||

| 2000 | ||

| 40 | 150 | 1,8 |

| 250 | ||

| 500 | ||

| 750 | ||

| 1000 | ||

| 1500 | ||

| 2000 | ||

| 50 | 150 | 1,5; 1,8 |

| 250 | ||

| 500 | ||

| 750 | ||

| 1000 | ||

| 1500 | ||

| 2000 | ||

| 3000 | ||

| 110 | 150 | 2,2; 2,7 |

| 250 | ||

| 500 | ||

| 750 | ||

| 1000 | ||

| 1500 | ||

| 2000 | ||

| 3000 |

Polypropylene pipes with reduced noise level, for internal sewerage

In multi-storey buildings, when the neighbors above have a volley of water discharged, noise can be clearly heard along the riser. The murmur in the bathroom can also be heard when liquid flows into the kitchen sink. To reduce the volume of sound, they previously used wrapping sewer pipes with foamed polyethylene or installing communications in a box (with decorative plastic lining or tiling). To increase protection, the box was filled from the inside with mineral wool.

But recently polypropylene pipes have appeared, which have improved sound insulation. In diameter and configuration, they are similar to gray products and are completely interchangeable. They differ only in white color.

Sewage pipe with reduced noise level.

With the same outer and throughput diameters, their noise level is 7-11 dB lower. This indicator was achieved by adding modified mineral additives to the composition. They increase the viscosity of the material and dampen sounds passing through the walls.

Such polypropylene pipes are suitable for free-pressure sewerage of houses, apartments, commercial and administrative buildings with a wastewater temperature of 2-80º C and periodic increase to 90-95º C. The mass of pipes with an increased level of noise insulation is identical to ordinary gray PP pipes, therefore, in case of replacement, install additional fasteners you won't have to.

Cast iron pipes for sewerage

Produced in two versions, bell-shaped

and

clamps

with internal coating.

There are also pressure pipes

, but they are intended for water supply and the cost of pipes with the addition of graphite is higher than those made from simple cast iron.

Assembly from this material is labor-intensive; the structure is quite heavy, but can withstand the high temperature loads of the transported medium. Installed in areas with increased fire hazard or placed in the ground.

Cast iron sewer pipes

- Clamps, enameled with a special epoxy resin composition, work without replacement for up to 100 years.

- Bell-shaped ones, due to the rough surface, grow from the inside and the service life is limited depending on the intensity of use.

The standard diameters of cast iron pipes and corresponding fittings, most in demand in wide construction, are 50, 100, 130, 150 and 200 mm nominal diameter. The length of the products starts from 500 mm to 2100 mm, four-meter whips have a cross-section from 200 to 400 mm and are now rarely used.

Polyvinyl chloride

Sewage pipelines equipped with parts made of polyvinyl chloride are extremely popular. The manufacturing process of such pipes involves preparing a special mixture of the main component (PVC) with polymers and stabilizers. From the finished heated mass, sewer pipes of the required diameter and shape are formed.

The advantages of such products are as follows

- Cost of the finished product;

- Low weight;

- Ease of installation work, eliminating the use of a welding machine to connect parts together. It is enough to purchase special couplings in the kit;

- Low coefficient of thermal expansion. In the event of a short-term or constant increase in temperature in the drain, the pipe will not sag;

- No problems with exposure to ultraviolet rays, allowing the parts to be used when laying an external drainage system;

- Ability to resist corrosive processes;

- No silting due to the smooth surface inside the product.

Despite all the advantages, such pipes also have disadvantages:

- Small operating temperature range. In the case of constant influence of sub-zero temperatures, polyvinyl chloride loses its elasticity and sealing properties. The situation is identical under the constant influence of high temperature;

- Low fire resistance threshold;

- Change in the internal cross-section parameter due to the influence of waste water temperature. This feature will affect the throughput of the entire system;

- Aggressive chemistry found in drains destroys parts over time.

To install a PVC sewer system, you will need to additionally purchase connection elements. Most often in installation work you will need knees, with the help of which the pipeline can be turned at an angle. A branching tee, a cross connecting four pipes, as well as a reduction designed to connect parts with different internal cross-sections.

Concrete pipes for external sewerage

These are large reinforced concrete products. They are characterized by increased mechanical strength and do not rust. Often have high throughput. But due to the large mass, transportation is expensive and installation is difficult.

Concrete sewer pipes.

In most cases, it is more appropriate to use corrugated two-layer systems made of PE or PP. But if a very high load on the site is expected, and the organization has equipment for transportation and installation, then you can choose concrete pipes.

Conclusions and useful video on the topic

Below we offer a video that gives recommendations on choosing pipes for internal and external sewerage.

It is impossible to say unequivocally which type of pipe is the best. When considering product options, it is important to know for what purpose they are intended and under what conditions they will be used .

Only taking into account all the individual characteristics of the site, the owner can make a choice which option is best for him for arranging a sewer system.

Are you selecting pipes for sewer installation and still have questions after reading the article? Or did you notice errors or inaccuracies in the material reviewed? Please write to us about this in the comments below the article.

Or maybe you have already chosen the material and installed the sewer pipeline on the site? Tell us what type of pipes you preferred and how comfortable it was for you to work with them.

Corrugated pipes for external sewerage

When describing the types of sewer pipes, we will separately mention special corrugated versions for outdoor use.

By design, corrugated pipes are divided into:

- single-layer;

- two-layer.

Single-layer pipes are corrugated both outside and inside.

Single-layer corrugated pipe.

The two-layer version has an internal smooth channel through which drains flow, and an outer skin with an air gap. The pipe ribs protect the communication from mechanical stress and contribute to increased strength.

Double layer pipe.

Corrugated pipes are classified according to load resistance:

- For light loads. They are light in weight, very flexible and easy to lay in difficult areas. Suitable for external drainage systems.

- For medium loads. The pipes have average resistance to mechanical loads and can be laid underground.

- For extra heavy loads. Corrugated pipes with thick walls that can be laid under highways and in industrial areas.

To organize a sewage system in a domestic environment, light and medium category pipes are most often used. They are resistant to standard loads for such places from pedestrians, equipment and ground movements, and also retain these characteristics throughout their entire service life.

The connection of corrugated pipes is carried out with a special fitting. The diameter of the pipes ranges from 100 to 1200 mm, depending on the need for sewer throughput.

Types of treatment structures

Autonomous sewerage requires the presence of a treatment facility. They come in three types:

- In the form of a cesspool. Easy to do with your own hands. To do this, prepare a pit, which is laid with rings of concrete, tires, or brick. As the pit fills, it must be pumped out manually, with a pump, or using machinery.

- In the form of a septic tank. The device is intended for collecting and processing waste using mechanical or biological methods. The recycled wastewater can then be used on the farm.

- In the form of an autonomous cleaning station. The station can treat wastewater up to almost one hundred percent using a biological method. The device regularly receives oxygen, which promotes the growth of beneficial microorganisms. Due to them, organic waste quickly disintegrates.

When constructing a pit, it is important to remember that wastewater can seep into the soil and pollute it; the design is suitable for summer cottages and temporary use. In houses with permanent residence, a type of structure in the form of a septic tank or an autonomous station is suitable. The installation of a septic tank requires the presence of a filtration well on the site. It can be equipped with low levels of groundwater flow.

Asbestos cement pipes

Asbestos-cement pipes are durable, which is why sewer pipelines are made from them. Cement and asbestos fiber are not destroyed by rot, acids or corrosion.

Advantages:

cheapness, durability, resistance to acids, alkalis, aggressive media, strength, ease of installation, resistance to blockages. Disadvantages:

fragility, instability to mechanical influences, harm to people and the environment. Given their low cost and durability, asbestos cement pipes are not the best option. They are more difficult to transport and install than polyplastic - the weight is higher than that of polymers.

Also, asbestos cement crumbles along the edges, which is why the seal is compromised with incorrect or poor-quality connections. Camo dangerous, especially for internal connections: environmental damage of asbestos concrete. Asbestos releases carcinogens, it is dangerous to work with it, and to live near it.

Gray cast iron

Traditional material had no alternatives in the construction of domestic sewerage just four to five decades ago. The risers, beds (horizontal sewer branches), combs (intra-apartment wiring), outlets to the well and the entire external network, with the exception of collectors, were made of cast iron.

Now cast iron sewerage has been practically replaced by the ubiquitous plastic; When overhauling buildings, it is massively changed to PVC and polypropylene.

What's wrong with cast iron?

Peculiarities

- Both the pipes and the fittings are very heavy. The fragility of the metal has to be compensated by the significant thickness of the walls. In order not to be unfounded, I will give the mass of a linear meter of pipes of the most common sizes:

| Nominal diameter, mm | Weight per meter, kg |

| 100 | 20,8 |

| 125 | 26,8 |

| 150 | 33,7 |

| 200 | 48,8 |

Sometimes plumbers say words that are not accepted in polite society. Transportation of cast iron pipes to the upper floors is on the list of leaders in the number of unflattering epithets.

- Over time, cast iron becomes brittle. The reasons are corrosion and limited resistance to aggressive wastewater. After 30 - 40 years of operation, risers and beds gradually begin to crumble. The sockets undergoing significant loads are given first;

The picture allows you to assess the condition of the cast iron sewer after several decades of service.

- The price of pipes is far from budget. Let's say, a two-meter pipe with a diameter of 100 mm costs about 1,500 rubles. For comparison, a PVC product of the same size will cost 4-5 times less;

- Finally, the main thing: both installation and dismantling of cast iron sewers is a long and difficult process. About it - in a separate subsection.

Connections

The socket of a cast iron sewer is usually sealed by caulking, followed by sealing with cement mortar. The sealing material used is a heel - a material reminiscent of roughly twisted hemp rope impregnated with bitumen. Minting is done like this:

Chasing a cast iron bell.

There are a few more things to know about joining cast iron pipes.

- Homemade coinage can be made by flattening a thin steel tube at one end and bending it into a Z shape;

- Instead of chasing, you can use a wide screwdriver;

- If possible, it is better to replace the heel with a more durable graphite oil seal;

- The solution for sealing the socket is prepared in the proportion of 1 part cement to 1 part sand. Pure cement can also be used;

- In order to disassemble a socket joint, you must first destroy its seal. For this purpose I usually use a strong, wide screwdriver and a hammer;

- Sometimes builders use molten sulfur to seal sockets. To disassemble such a bell, you will have to heat it with a hairdryer or blowtorch. A respirator is required for this work: the fumes are so caustic that they are quite capable of causing respiratory paralysis.

Fitting

Fittings also influence the choice of pipes for sewerage, although to a lesser extent. Fittings are connecting parts of a pipeline that allow you to branch, close pipes or direct them to the other side.

The most common fittings are for plastic pipes. They are made from the same polymers: PVC, PP, PE - they have different diameters and sizes and are easy to install. An assortment of metal fittings.

They are just as easy to install, but the parts and their dimensions are smaller. Same thing with capamic fittings. For other types of pipes, fittings are not sold at all; they are connected differently. In terms of fittings, polymer pipes are better for sewerage.

Materials for the construction of sewerage systems are largely similar in characteristics: insensitivity to aggressive environments, relative smoothness inside, strength.

But plastic pipes are also always light and also elastic. Installation and joining are made easier. At the same time, pipes made of different plastics are easily connected to each other.

Therefore, internal and external sewerage can be made from different, most suitable polymers. It is obvious that plastic pipelines are the future for both internal and external sewerage systems.

Polyethylene

The use of polyethylene pipes when arranging an internal drainage system can be observed extremely rarely. But, if installers or the homeowner decide to use this particular material, then you should look for either cross-linked or low-density polyethylene. The second option is able to withstand temperatures within +400C, so it is used only for cold drainage systems.

Among the advantages of the material it is worth noting

- High threshold of strength characteristics, as well as flexibility;

- Resistance to corrosive processes;

- No silting;

- Low weight;

- Ability to withstand pressure drops in the system;

- Long service life;

- Easy installation;

- Price.

All of the above advantages are also inherent in other materials. But here are some of the disadvantages:

- Lack of resistance to ultraviolet radiation. This feature will not allow the use of parts when installing an external wastewater disposal system;

- The material allows oxygen to pass through, damaging metal parts of the system. Naturally. Manufacturers coat the pipes with a special mixture. However, it does not provide 100% protection. And during the installation work you should be extremely careful so as not to cause damage;

- Rapid surface wear (abrasion).

You may also like: Sewer pipe diameters - table and dimensions

Sewerage assembly

Three basic rules that should not be violated during installation:

- Slope

- Diameter sequence

- Reliable fixation

A meter of pipeline in a horizontal plane must have a slope of 2 mm

in the direction of flow, with a difference of more than

5 mm

, also negatively affects the operation of the line.

If for a long span, for example, underground on a private plot, you make a sharp slope of the sewer pipe, then the solid fractions will quickly settle on the walls. A uniform level decrease of 2 mm per meter

allows the flow to freely deliver the contents to the well. It is also worth paying attention to the fact that the slope of the pipe also depends on its diameter; if you are not sure of your decision, it is better to consult a specialist.

In apartment wiring, it is permissible to lay small sections exactly along the horizon, but a negative slope cannot be left under any circumstances.

Sewer pipe slope

But you also should not reduce the cross-section of the pipeline in the direction of the drain, that is, 50 mm cannot be connected to 40 mm, and then go to 100, you must always maintain the sequence in the set, increasing the passage by at least one size. Another rule for systems with intensive filling is not to make right angles from one shaped part; it is better to turn two branches at 45° each and, before inserting any branches into the manifold, insert a fitting with an inspection hatch.

The entire structure must be attached to a stable surface with special metal or plastic clamps, especially silent transit systems.

In the trench, the sewage system is laid on a sand cushion or sifted from excavated soil, so as not to damage the walls with stones or anything similar. There are not so many requirements for performing work with the waste pipeline, and by adhering to simple rules, as a result, you can independently assemble a workable circuit.

Diameter selection

The range of pipes used for the installation of domestic sewer systems is quite narrow and falls within the size range from 40 mm to 220 mm. In accordance with current building codes, as well as manufacturers’ recommendations, the following diameters are used:

- 50 mm – sinks, sinks (single and paired);

- 75 mm – shower trays, urinals, bathtubs;

- 110 mm – toilets, central sewer risers, drain valve outlet;

- 110-150 mm – installation of a complex sewerage system, carried out in the basement;

- 160 mm – branch from the central riser to the external septic tank.

Polymer pipes have a particularly wide range of standard sizes, which is due to the manufacturability of their production PHOTO: ua.all.biz

ductile iron

Peculiarities

What is ductile iron?

Ductile graphite nodular cast iron is gray cast iron modified with magnesium.

As is known, cast iron differs from steel in its high carbon content (mainly in the form of graphite plates). During the modification process, these plates turn into miniature balls, which dramatically changes the physical properties of the material: it acquires the ductility and toughness characteristic of steel, while maintaining high resistance to corrosion.

Lamellar and spherical graphite in the structure of cast iron.

As a result, ductile iron pipes:

- Not afraid of blows;

- Do not crack under deforming loads;

- They have a service life of 80 years or more.

The only manufacturer of ductile iron pipes in Russia is Lipetsk. Its pipes are provided with an external coating of zinc and bitumen mastic; Inside, protection is provided by a cement-sand coating. The products are used for external sewer networks, as well as for water, heat supply and the needs of the oil industry.

Structure of a sewer pipe made of ductile iron.

Connections

All products are socket pipes with rubber ring seals. Installation does not require caulking or any additional materials at all: just insert the pipe into the socket and you can move on to the next connection.

Don’t rush to rejoice: the instructions for assembling the connection are simple, but its implementation is not so much. The fact is that with a sewer diameter of over 250 - 300 mm, the force required for joining can reach tens or even hundreds of kilograms. Obviously, it is impossible to assemble such a bell with your own hands.

In practice, when assembling pipelines, the following are used:

- Clamps and levers that allow you to increase mechanical force many times over;

- Loading equipment. Simply put, the excavator bucket forces the pipe into the socket through a wooden spacer.

Installation of socket pipes made of ductile iron.

Asbestos cement

Peculiarities

Asbestos-cement pipes are used exclusively for the installation of external sewerage. The asbestos fiber in them acts as reinforcement, making the material less brittle. However, asbestos cement still does not withstand shocks and displacements of soil layers.

Asbestos-cement socketless pipe.

Advantages of the material:

- Resistance to domestic and moderately aggressive industrial wastewater;

- Long service life (at least 50 years);

- Cheapness. Despite the material consumption (a pipe measuring 100 mm x 3.95 m weighs 26.5 kg), the material is even cheaper than PVC: the wholesale price of this same four-meter pipe is only 280 rubles;

- Possibility of laying pipelines with minor bends (up to 3 angular degrees per connection).

The main disadvantage is fragility. In my memory, pipe fractures occurred even under the sidewalk and lawns, not to mention the traffic zone of cars with their significant loads.

Connections

Modern asbestos-cement pipes are produced both with sockets and smooth, for connection with a coupling.

Asbestos-cement couplings.

Bells and couplings are equipped with rubber sealing rings. Installation is no different from assembling a ductile iron pipeline.

Coupling connection with rubber seals.

Several decades earlier, other methods of sealing socket joints of gravity sewers were practiced:

- A heel sealing the socket with cement or mastic;

Coupling connection with sealing with cable and mastic.

- Cement-sand mortar with the addition of liquid glass. Sodium or potassium liquid glass made the solution waterproof and accelerated its setting to 15 - 20 minutes.

Ceramics

Ceramic sewer pipes are made from raw and fireclay clay by extrusion, drying and subsequent firing at temperatures up to 1250 degrees. Nominal diameter - from 150 to 1400 mm (diameters over 600 mm are offered by manufacturers at the request of the consumer and are not available for free sale).

Before firing, the pipes are dried.

Peculiarities

The material has all the properties characteristic of ceramics:

- Low resistance to shock loads;

- High ring rigidity;

- Resistance to high temperatures and their differences over a significant range;

- The ability to transport aggressive wastewater, including concentrated solutions of alkalis and acids, without harm.

Prices... the word “horse” cannot be called literary, but it exhaustively characterizes the situation. Here is a fragment of the price list for Steinzeug Keramo products.

| Nominal diameter, mm | Cost per linear meter, rubles |

| 150 | 2250 |

| 200 | 3375 |

| 300 | 5775 |

| 400 | 10125 |

| 500 | 15375 |

| 600 | 21225 |

Steinzeug Keramo products.

The characteristics of the material and the pricing policy of manufacturers limit the use of ceramics to specific areas - transportation of high-temperature and aggressive wastewater. Pipes are widely used in metallurgy and the chemical industry.

Connections

Some time ago, when installing ceramic pipes, seals made of helix (“resin strand”) were used, sealed with asphalt mastic or (in case of special requirements for temperature conditions) with greasy crumpled clay - soap.

Description of sealing ceramic sockets from an old textbook.

Currently, ceramics are installed mainly using coupling and socket joints with an elastic seal; the technology is already familiar to us - the pipe is pressed into the socket using a lever with clamps or loading equipment.

There are two types of butt joints. F joints involve the use of rubber seals inside the sockets. Joints C are sealed with a sealant on the sleeve; it can be rubber or polyurethane.

Reinforced concrete

Peculiarities

The large mass of reinforced concrete pipes limits their use to connections of wells (including storm sewers) and the construction of collectors. Service life is estimated at 30 - 50 years; The main problem is reinforcement corrosion. Loading equipment is used for installation.

Connections

Rubber seals are used to seal socket joints; To protect them, the sockets are sealed with cement-sand mortar.

The photo shows the O-rings clearly.

The procedure for installing large-diameter reinforced concrete sewers is described in detail in one of the manuals for SNiP 3.07.03-85:

- The pipes are connected using a truck or crawler crane located as close as possible to the edge of the trench;

Installation diagrams for reinforced concrete sewerage.

- Before installation, an O-ring is installed in the groove of the socket. The bell must first be cleared of debris and free from chips and other visible defects;

- The socket and sealing ring are pre-lubricated with graphite-glycerin grease or soap solution;

- After assembly, the socket is sealed with cement-sand mortar. To prevent the lock from collapsing when installing the next pipe, the sockets are sealed with a delay (3-4 pipes from the installation site).

For home, for family

There are so many types of pipes... it's easy to get confused. Which ones are better for home sewerage?

I would advise not to reinvent the wheel and take advantage of the experience of thousands of house and apartment owners:

- Orange PVC pipe is used for external installation (discharge to a well or septic tank, connection of wells, etc.);

External sewerage is laid with an orange PVC pipe.

- Gray - also made of PVC - is used for internal networks. Everything else only entails increased costs without any tangible benefits.