Outer diameter categories

Metal pipes are produced with an outer diameter from 10 mm to 1420 mm.

Based on the value of this parameter, they are conventionally divided into three categories: 1. With an outer diameter from 10 mm to 108 mm, pipes are classified as products with a small diameter. They are used for laying water supply systems in apartment buildings and private buildings;

2. With an indicator from 114 mm to 530 mm - to pipes with an average diameter. They are used in crude oil collection systems and in the construction of urban water pipelines;

3. With an external size from 530 mm to 1420 mm - for pipes with a large diameter. They are used when laying main oil and gas pipelines.

What are the GOST standards for steel pipes?

The list of technical indicators of any type of steel pipe directly depends on which manufacturing method was used. All this is determined using GOST standards, knowledge of which will at least make it possible to take into account recommendations for the operation of a certain type of pipe.

Currently, the following regulatory documents for the production of steel pipes are most often used:

GOST 30732-2006. It was adopted in 2006: its provisions apply to pipes and fittings made of steel coated with a heat-insulating layer.

Steel products that use polyurethane foam thermal insulation and a polyethylene shell, or a protective steel coating, are used in cases where it is necessary to lay underground heating networks. The coolant temperature should not exceed 140 degrees (an increase to 150 degrees is allowed only for a short time). In this case, the pressure in the system should not exceed 1.6 MPa. GOST 2591-2006 (88).

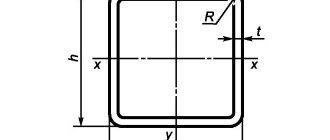

GOST, designed for hot-rolled steel, was adopted in 2006, although some sources allow the use of the old GOST - 2591-81. The document contains information relating to square rolled steel, for the production of which the “hot” method was used. This GOST applies to all products with side dimensions from 6 to 200 mm.

Larger square pipes are produced if the manufacturer and the customer draw up a separate agreement. GOST 9567-75. It specifies precision steel pipes for which high manufacturing precision is required. There are cold-formed and hot-rolled precision pipes of galvanized or chrome-plated type.

The engineering industry especially needs the products of this increased GOST standard. GOST 52079-2003. This document specifies standards for longitudinally welded and spiral-welded steel pipes with a diameter of 114 - 1420 mm. Main gas pipelines and pipelines through which oil and petroleum products are transported are constructed from such dimensional products.

GOST 52079-2003 indicates that only products that are not corrosive can be transmitted through these pipes. Using steel pipes with large diameters, it is possible to transport substances with pressures of up to 9.8 MPa. The minimum temperature for the environment is -60 degrees.

It is important to know that officially GOST 52079-2003 is no longer valid: from January 1, 2015, the new GOST 31447-2012.GOST 12336-66 is in force. Its provisions apply to closed products of profile type, with a cross-section in the form of a square or rectangle

Starting from January 1, 1981, the powers of GOST 12336-66 were transferred to TU 14-2-361-79, but the relevance of its provisions has not been lost to this day. GOST 10705-91 (80).

Contains a list of technical conditions under which straight-seam electric-welded steel pipes with a diameter from 10 to 630 mm are produced. To produce pipes according to this GOST, carbon or low-alloy steel is used. These products are used in many areas, but the priority is pipelines for pumping water.

The provisions of the standard do not apply to steel pipes from which electric heaters are made. GOST 10706 76 (91). Applies to straight-seam electric-welded steel pipes that have a general purpose. As follows from this document, the diameter of these products ranges from 426 to 1620 mm. GOST 10707 80.

Here are the standards according to which electric-welded cold-deformed pipes are produced, having varying degrees of accuracy: normal, increased and precision. The diameter of products whose production is oriented towards this document can be from 5 to 110 mm: in this case, unalloyed carbon steel is used. Sometimes electric-welded straight-seam products have references to GOST 10707 80 in the accompanying documentation: this is explained by the fact that in 1991 it was decided to extend the validity of this document.

Division into classes

Conventionally, pipe products are divided into the following classes:

- Class 1 pipes can be used for gaseous and liquid media in irrigation systems. In addition, it is possible to manufacture fencing structures or supports from such products.

- Class 2 pipes can be used in pipelines operating at low and high pressure, transporting oil and petroleum products, gas or water.

- Class 3 pipes are suitable for work at high temperatures.

- Class 4 includes thick-walled drill pipes that can resist strong torsion.

- Class 5 pipes are used in the construction of carriages, cars, overhead cranes, drilling rigs and some furniture structures.

- Class 6 pipes are used in the engineering industry as blanks from which bearings, cylinders, pumps and receivers are produced.

Main types of pipeline parts

| bends | stubs |

| transitions | fitting |

| tees | adapter rings |

There are industrial (technological) and main pipeline transport depending on the territorial location and purpose. Gas and oil pipelines that transport products from production sites to places of processing and consumption, namely to factories or seaports for subsequent unloading into tankers and further transportation, belong to main pipeline transport. From the refineries, finished petroleum products are sent through main product pipelines to areas of consumption. Across Russia, the total length of main pipelines is about 200 thousand km, including various water barriers, which they cross more than 5 thousand times on their way.

More than a third of the pipelines of industrial enterprises are process pipelines. Process pipelines transport liquid, steam, gas, which are considered raw materials, semi-finished products, finished products, production waste or products required for the correct flow of the technological process. In addition, these pipelines transport products that are flammable and harmful to health at different temperatures and pressures.

Process pipelines are classified according to the following criteria:

Location:

inter-shop, intra-shop.

Laying method:

above ground, above ground, underground.

Internal pressure:

non-pressure (gravity), vacuum, low pressure, medium pressure, high pressure.

Temperature of the transported substance:

cryogenic, cold, normal, warm, hot, overheated.

Aggressiveness of the transported substance:

non-aggressive, slightly aggressive (slightly aggressive), moderately aggressive, aggressive.

Transported substance:

steam pipelines, water pipelines, oil pipelines, gas pipelines, oxygen pipelines, fuel oil pipelines, acetylene pipelines, oil pipelines, gasoline pipelines, acid pipelines, alkali pipelines, ammonia pipelines, etc.

Material execution:

steel, steel with internal or external coating, non-ferrous metals, cast iron, non-metallic materials.

Connection method:

one-piece, detachable.

The scope of application of pipeline connecting parts is varied: heavy chemical industry, petrochemical, gas; production of various specialized drugs; electric power industry (CHP and nuclear power plants); exploration, production, processing and storage of oil and gas, as well as other minerals; metallurgical and steel production; shipbuilding, automotive and food industries; civil engineering and utilities (central heat and water supply, water collection and hydropower structures, distribution, irrigation systems, transport and pumping stations, wastewater treatment plants, water recycling and water treatment, regulatory systems.)

Our plant produces pipeline parts from various steels: carbon, low-alloy, alloy steels, with increased corrosion and cold resistance, from non-metallic materials, as well as with various protective coatings.

| www.mrt1.ru | |

| ORDER PRODUCTS BY PHONE 8 (495) 638-07-16 | |

general information

General information

A pipe is a cylindrical product, hollow inside, and longer than its cross-section. Made from:

| metals and alloys | organic materials (plastics, resins) |

| concrete and ceramics | glass, wood and their compositions |

| Under certain conditions, pipes are insulated on site or at the factory. | |

They are used for transporting various media, insulating or grouping other wires. Metal pipe is widely used in construction as a structural profile. Main characteristics of pipes:

Dimensional: - internal diameter - the main dimensional characteristic of water and gas pipes and connecting parts to them. — nominal diameter (Dy, Du) — the nominal value of the internal diameter in millimeters or its rounded value. - nominal diameter (Dn, Дн) - outer diameter - wall thickness, designated s (presumably from the Russian “wall”), t (from English: thick - thick)

Mass: - the weight of one linear meter of pipe is often measured in kilograms - density

Strength: - operating pressure (Pwork) - the highest pressure of the transported medium at the operating temperature, at which long-term operation of the fittings and connecting parts is ensured - nominal pressure (Pn) - conditional pressure (Py). The strength of pipes and their connecting parts must correspond to the nominal pressure Py of the transported medium. Conditional pressure is understood as the highest excess pressure, measured in pascals (Pa) at a temperature of 293 K (20˚C), at which long-term operation of pipelines and their elements (pipeline parts, connecting parts, pipeline fittings) is ensured. The numerical value of the conditional pressure is indicated in GOSTs or other regulatory documents for each type of product. — test pressure, pressure tests, trial pressure (Rip, Rpr), as well as the strength of pipes, connecting parts and fittings are checked with trial (test) pressure Rpr, which is greater than the operating pressure. — excess pressure (gauge) — operating temperature, maximum, minimum. Typically, the operating temperature of the transported medium differs from the temperature of 20˚C within significant limits; temperature fluctuations must be taken into account when designing, because have a destructive effect on the pipe material

Technical and economic: - linear meter of pipe - 1 meter of pipe - cost in rubles (or other currency) per 1 kg, 1 ton of pipe. In economic calculations, when selling, the cost is expressed in rubles (or other currency) per 1 ton.

Material: It is incorrect to say which material is best; each material is good when used in certain operating conditions. Metal and alloys: - copper and alloys containing copper. For plumbing and heating, only phosphorus-deoxidized copper grade M1F and its European analogue Cu-DHP (CW024A) and M1P are used - Steel (see Brand of steels) link - bronze - brass - cast iron from cast iron of various grades; Polymeric: - polyvinyl chloride (abbr. PVC) and others based on chlorine compounds - polyvinyl difluoride (abbr. PVDF) and others based on fluorine compounds - polyethylene (abbr. PE), distinguish PE-80, PE-100, etc. P. - cross-linked Polyethylene (abbr. PEX), PEXa, PEXb, PEXc are distinguished depending on the method of cross-linking - fiberglass - polypropylene; - polybutene Combined: - aluminum metal-polymer pipes consist of an internal working layer of heat-resistant polyethylene PERT or PEX, an intermediate load-bearing layer of aluminum and an external protective layer of polyethylene, using adhesives - copper metal-polymer pipes consist of an internal working layer of copper 0.3 mm thick and an external protective layer polymer material 2-3 mm thick without the use of adhesives - steel with an internal cement and external protective waterproofing coating against corrosion, also an enamel coating is used to protect against corrosion Based on concrete, other materials: - ceramic - asbestos-cement - used as cases for laying various pipelines - concrete - reinforced concrete - are used for drainage of waste, melt, storm water;

Pipe usage:

Pipeline (transportation of substances): - pipes are used to transport various substances: oil, gas, including toxic, aggressive ones, in various states of aggregation: solid phase (bulk), liquid phase (various types of liquids), gas phase (steam, gas). Pipes are also used for transporting documents – pneumatic mail.

Technological needs: - Pipes are also used to transmit pressure as an impulse for technological needs. Construction of buildings and structures:

Round and profiled pipes are often used as structural elements, independent elements: - composite rigid metal structures: beams, crossbars, supports, booms, spans - metal frames of buildings, for example, for subsequent cladding with sandwich panels - foundation elements: bored piles, hollow piles, pile , columnar foundation, supports for fences, bridges - decorative elements

Mining, well drilling: - casing columns that secure the soil so that it does not collapse - wells (well ring), adits, spring captages, galleries

Manufacturing methods (technology): Manufactured pipes must meet the requirements set out in state standards: GOSTs, SNiPs, TU. In cases where the characteristics of pipes not intended for mass use differ from the standard ones, the requirements for such pipes are established by technical specifications (TU). See the regulatory documents link for which MRT Group supplies pipes and other products.

Welded Metal pipes are usually made welded. In this case, either the sheet is folded so that the seam runs along the pipe (“straight-seam pipe”), or the tape is wound in a spiral (“spiral-seam pipe”). Modern technologies make it possible to significantly increase the strength of the seam of a steel pipe - its strength is only 10-15% less than the strength of the rest of its part.

Rolled seamless pipes are produced by rolling an ingot on special equipment that creates a hole in the center. Seamless pipes are used where increased strength and reliability are needed (for example, for gas cylinders, in the oil industry, etc.). Copper pipes for water supply and gas are seamless due to technology.

Drilling You can also make pipes by drilling a hole in a cylindrical blank. With this method, a significant part of the metal turns into shavings, so it is not used for pipes as such, but only for parts of various machines and mechanisms (including weapon barrels).

Folding with compression One of the modern methods of manufacturing a pipe is the formation of a tubular section with a longitudinal fold seam and subsequent compression by rollers into a rectangular profile to impart rigidity to the structure. Such pipes are lighter and are suitable for the construction of light metal structures.

Casting Pipes can also be produced by casting. The material is poured into either a mold with a central core or a rapidly rotating hollow mold.

Extrusion Plastic pipes are most often produced by extrusion (extrusion).

Assortment and sizes The material from which the pipes are made and the size are regulated by regulatory documents and standards.

Submit an application online Submit an application by fax or e-mail

Assortment of seamless steel pipes, according to GOST 8732-78 91

The production of hot-deformed seamless steel pipes in accordance with GOST 8732-78 (91) is characterized by the presence of lengthy and complex processes. This factor explains the rather high price of these products. The use of hot-deformed and cold-rolled seamless pipes is suitable for extreme conditions, where in the event of the slightest leak the consequences can be very serious.

The raw material for the production of hot-deformed pipes without seams are metal blanks: the piercing process and heating to high temperatures leads to the formation of hollow cylinders - sleeves. At first, their irregular shape becomes smooth due to the passage of the rollers. Segments 4-12.5 m long are cut from the sleeve (the length can be measured or unmeasured).

For hot-rolled steel, according to GOST, a slight discrepancy in wall thickness is allowed. The same applies to deviations in diameter: the main thing is that these differences do not exceed special regulatory instructions. The list of permissible diameter deviations in accordance with GOST 8732-78 (91) is available in special documents.

Pipeline accessories

Pipeline accessories

designed to control oil flows transported through pipelines. According to the principle of operation, valves are divided into three classes: shut-off, control and safety.

Shut-off valves

(gate valves) are used to completely block the cross-section of the pipeline,

regulating

(pressure regulators) - to change the pressure or flow rate of the pumped liquid,

safety

(check and safety valves) - to protect pipelines and equipment when the permissible pressure is exceeded, as well as to prevent reverse flows of liquid.

Valves

are called shut-off devices in which the flow area is blocked by translational movement of the valve in a direction perpendicular to the direction of oil movement. Structurally (Fig. 12.10), the valve is a one-piece cast or welded body, equipped with two pipes for connection to the pipeline (using flanges or welding) and a spindle connected to the shut-off element and controlled using a flywheel or a special drive. The point where the spindle exits the housing is sealed using an oil seal.

According to the design of the sealing gate, valves are divided into wedge and parallel.

On main oil pipelines, valves are equipped with an electric drive (Fig. 12.11).

Pressure regulators

are devices used to automatically maintain pressure at the required level. In accordance with where the pressure is maintained - before or after the regulator - there are regulators of the "before" and "after" types.

| Rice. 12.11. Steel flanged valve with actuator: 1 — electrical switch box; 2 — manual drive flywheel; 3 - gearbox; 4 - electric motor; 5 - spindle; 6 - cover; 7 - body | |

| Rice. 12.10. Gate valve 30s64nzh |

Safety valves

are called devices that prevent pressure in the pipeline from increasing above a set value. On oil pipelines, low- and full-lift closed-type safety valves are used, which operate on the principle of discharging part of the liquid from the point where high pressure occurs into a special collection manifold (Fig. 12.12).

Check valve

called a device for preventing the reverse movement of a medium in a pipeline. When pumping oil, rotary check valves are used - with a valve rotating about a horizontal axis (Fig. 12.13).

The valves of main oil pipelines are designed for a working pressure of 6.4 MPa.

Standard marking of steel pipes

All necessary data is applied to the pipes according to a certain standard.

Location of symbols

Manual marking of a steel pipe is printed at a certain distance from the end of the product: no less than 2 cm and no further than 50 cm. With mechanized marking, this value increases and is 0.1 m and 1.5 m.

Symbol size

The letter and numerical designations of the pipe must have a certain size, which is also regulated by a certain regulatory document. Signs must have a height of no less than 0.5 cm and no more than 3 cm, and a width from 0.3 cm to 1.2 cm. The size of the signs is determined in accordance with the parameters of the pipe.

Production technology

The technological process by which electric-welded pipes are manufactured consists of a number of operations. It is quite complex, labor-intensive and time-consuming. In order for an electric-welded pipe to acquire its finished appearance, it is rolled from a strip (strip), which was previously produced by cold or hot deformation.

To produce high-quality and reliable pipes of different diameters, radio frequency welding is mainly used, which allows, among other things, to carry out the process of joining metal at a fairly high speed. With this welding method, high voltage currents are passed through a pre-rolled workpiece, which contributes to the rapid heating of its edges. In order for a reliable weld to form at the site of the heated and molten edges of the workpiece, they are pressed against each other under great pressure. In order to obtain a blank for an electric-welded pipe of the required diameter from a steel strip (strip), special crimping machines are used.

This technology, which uses specialized enterprises to produce straight-seam and spiral-welded electric-welded steel pipes, allows not only to obtain high-quality and reliable products, but also to provide them with an attractive appearance (the weld seam on such products is almost invisible).

Technological process for the production of welded pipes

Other types of GOST standards for steel pipes

The regulatory documents also apply to other types of products and operations related to steel pipes.

List of GOSTs that regulate methods and procedures for installation using steel pipes, as well as various fastening and connecting elements for them:

Welding. GOST 16037-80 - contains a list of requirements for welding steel pipes. There is also an installation for the main structural elements, typical sizes of welded joints with other elements (this does not apply to electric welds, which are on the steel pipes themselves).

GOST 6996-66 - it regulates the strength characteristics of all metal connections. Fittings. This term generally refers to all piping parts of a connection. GOST 8966-75 describes how metal straight couplings are produced, with the help of which steel pipelines are created.

They can be galvanized and have cylindrical threads at the ends: with their help it is possible to install pipelines for transporting non-aggressive media with temperatures up to 175 degrees, at a pressure of no more than 1.6 MPa. GOST 8967-75 refers to the production of galvanized or simple nipples with cylindrical threads: they most often connect water pipes or gas systems. Nipple diameters range from 8 to 100 mm, and galvanized models are designated “C”.

GOST 8968-75 determines the technical characteristics of a locknut with or without an anti-corrosion coating: they are screwed on top of the main nuts. To prevent self-unscrewing. Mass production is focused on locknuts with a diameter of 8-50 mm: larger sizes are produced only upon individual order.

According to GOST 8969-75, the production of fittings is regulated: this fitting is characterized by a thread at the end, which can have different lengths. With their help, fixed connections of pipelines are organized, and their strength is almost the same as that of welded ones. Clamps. They are used to secure pipelines to horizontal sections.

The clamps look like metal U-shaped brackets with bolts for screwing. Steel pipelines can sometimes be secured with plastic clamps, but in this case the strength of the connection is reduced. In addition to clamps, pipelines can also be equipped with brackets, brackets, overlays, and hangers.

Moreover, the task of the fastening elements is not only to securely fix the pipes: they absorb vibration well and slightly prevent thermal expansion. GOST 24137-80 concerns metal clamps for steel pipes with a diameter of 15-240 mm

When creating a fastening, it is important to consider that the distance between the clamps on a horizontal base should be no less than 0.75 mm, on a vertical base - 1-1.5 mm

https://youtube.com/watch?v=z4AjL8HmOcwrel%3D0%26controls%3D0%26showinfo%3D0

- ru-stroyka.com

- www.ktzholding.com

- trubaspec.com

Precision steel pipes according to GOST 9567-75

This group of products is controlled by a separate GOST, since their production requires compliance with increased precision and special measures.

These types of metal pipes are classified depending on the wall thickness and production method:

With especially thin walls. The diameter here has a relationship with the wall thickness above 40, with a thickness of less than 0.5 mm. With thin walls.

For the first indicator, the level is set at 40 and below, with a wall thickness of less than 1.5 mm. With thick walls. The first ratio is from 6 to 12.5. Particularly thick walls. The ratio is less than 6.

All precision pipes are seamless and have high isotropic rigidity. This makes it possible to organize various systems of increased accuracy and complexity even from thin-walled steel products in accordance with GOST 9567-75. The surface of such a pipe can be galvanized or phosphorated, coated with oil.

Non-metallic pipes

Among the group of non-metallic pipes, polymer pipes have undoubtedly become the most popular choice in recent years. This is due to the fact that they have a number of advantages over metal pipes, although they also have certain disadvantages. Let's take a closer look at their characteristics, which will allow you to make a more informed choice between different types of pipes.

2.1. Polyethylene pipes

Polyethylene pipes are widely used in the creation of pressure and non-pressure pipelines both in the housing and communal services sector and in industry.

A few words about the types of polyethylene. According to the production method, there are three types of polyethylene pipes:

- high pressure;

- low pressure;

- made of cross-linked polyethylene (often red, since in most cases these pipes are used for laying heating and hot water supply systems).

When high or low pressure is mentioned in the name of pipes, they mean the method of their production. Both of these types of polyethylene pipes are used for cold water only. Sometimes high or low pressure is mistakenly perceived as the area of use for these pipes, when in fact the opposite is true.

Pipes produced at high pressure are less durable. They can only be used for non-pressure systems. They can also be used for pressure water supply systems, but the strength of such pipes increases due to the thickness of the walls. With normal wall thickness, they are used for constructing domestic sewers, drainage systems, storm sewers, etc. Under these conditions, their qualities are optimal.

The material for the production of which is special engineering polymers (HDPE), manufactured at low pressure: the product is obtained in a special pressure chamber at a temperature of +150 °C and a pressure of 20 atm. HDPE pipes have limitations in application, namely:

- limited temperature range at which their operation is possible. The lower operating limit is 0 °C. At lower temperatures, low-density polyethylene becomes glassy. Products lose some strength characteristics, in particular, ring rigidity, at temperatures above +40 °C;

- low rate of thermal expansion.

HDPE polyethylene pipes for water supply (Fig. 4) are manufactured in lengths from 5 to 12 m, with a multiplicity of 0.25 m and in coils with pipe diameters up to 110 mm inclusive. The following grades of polyethylene pipes are currently used for laying water supply systems: PE80, PE100. The abbreviated designation in the Russian version is PE, in the international version it is PE or PE-X for cross-linked polyethylene.

Polyethylene pipes are used to transport various liquid and gaseous substances.

During operation, a mandatory requirement is compliance with the operating pressure, which is inversely proportional to temperature indicators: the higher the temperature, the lower the pressure. If this requirement is ignored, the service life of the pipeline is significantly reduced.

Rice. 4. Polyethylene pipes in sections (a) and in coils (b)

Compared to metal pipes, under conditions that meet technical requirements, HDPE pipes have significant advantages:

- light weight (m3 weighs only 0.9 t);

- ability to withstand high pressure (from 3 to 5 MPa);

- the material is chemically neutral and resistant to aggressive environments - acids, alkalis, salts (with the exception of nitric). Due to this, it is used in production processes for transporting process solutions and wastewater;

- no reactions with the liquid transported through the pipe, which is very important, since water quality indicators remain unchanged;

- no corrosion;

- lack of conductivity (do not conduct current);

- the smoothness of the inner surface of the pipes ensures low hydraulic resistance and the absence of deposits;

- frost resistance (up to – 70 °C);

- favorable price-quality ratio;

- easy installation and dismantling;

- high sound insulation (polyethylene does not conduct sounds well);

- long service life (up to 50 years).

In addition to the advantages, you need to know the disadvantages of polyethylene pipes. There are not very many of them, but they are quite serious:

- polyethylene burns and releases harmful substances when burned;

- poor resistance to ultraviolet radiation. When exposed to the sun, the material becomes brittle and brittle. Note that pipes made of cross-linked polyethylene, which are the first to be used, are not susceptible to this;

- high temperature expansion - 10 times more than steel. To neutralize this drawback, it is necessary to install compensators;

- when the liquid in the pipeline freezes, the polyethylene may rupture, therefore, when using polyethylene pipes, they are laid below the freezing depth or insulated using additional heating methods.

In pressure pipelines (at high pressures) low pressure polyethylene pipes (LDPE) are used. They are stronger, but more fragile and less flexible. However, they can withstand significant pressure changes without any harm.

Polyethylene cross-linked (PE-X) pipes are a pipe option with high strength and flexibility. They can withstand high pressure (up to 20 atm) and temperatures up to +95 °C, they can be used for hot water supply and heating systems. Metal-plastic pipes are made from this type of polymer. However, this type of material is not weldable. When installing a pipeline made of cross-linked polyethylene, fittings with gaskets or gluing the connected elements are used.

The diameters of polyethylene pipes are manufactured in a wide range - from 20 to 1200 mm. Products of small diameters (up to 40 mm) are used mainly for water supply and heating systems in private houses and individual apartments. Large diameter pipes are used on risers of water supply, heating and sewerage systems, as well as on external networks.

Polyethylene of different densities is used to make pipes. Density is indicated by the numbers that appear after the abbreviation:

- PE32 - appeared first, has the lowest density. Currently, it is practically not used for pipe production;

- PE63 - has a fairly large distance between the chains of molecules, as a result of which it does not tolerate pressure changes. Scope of application - internal wiring in non-pressure systems (irrigation systems from containers, etc.), can be used in private homes for wiring the water supply system. This type of polymer can be used to make pipes for sewer systems;

- PE80 - has high strength, can be used for pipes in cold water supply systems inside the house and external networks with mandatory insulation. With a large wall thickness, such pipes can be used for networks of industrial enterprises;

- PE100 - pipes made of cross-linked polyethylene with a density of 100 are used in hot water and heating distribution. Currently, pipes made from this material are the strongest and at the same time the heaviest. Pipes made from this polyethylene can be used in any area for transporting liquids and gases under high pressure.

Polyethylene pipes are produced by extrusion - in a softened state, the material is squeezed out through a nozzle, then sent for calibration, where it is given the required cross-section and size. Polyethylene pipes can be reinforced. In the production of reinforced polyethylene pipes, nylon, polystyrene or polyvinyl chloride (PVC) fibers are sealed inside the wall. The equipment for this process is much more complex, which is why the price of reinforced PE pipes is much higher.

Below is a selection from GOST 18599–2001 “Polyethylene pressure pipes. Technical conditions”, which includes a number of terms and definitions that are necessary for the correct assimilation of further educational material in the manual:

- nominal size DN/OD, mm : numerical designation of the size of pipeline elements, except for threaded connections, which is a rounded number approximately equal to the production size, referring to the outer diameter;

- nominal outer diameter dn, mm : specified outer diameter related to the nominal size DN/OD;

- nominal wall thickness en, mm : pipe wall thickness established in GOST ISO 4065–2005 “Thermoplastic pipes. Table of universal wall thicknesses" and corresponding to the minimum permissible wall thickness at any point emin;

- pipe series S : dimensionless number to designate pipes conforming to GOST ISO 4065. The relationship between pipe series and standard dimensional ratio is given by the following formula (see GOST ISO 4065)

- standard dimensional ratio, SDR : ratio of the nominal outer diameter of the pipe dn to the nominal wall thickness en;

- nominal pressure , PN : a numerical designation relating to the mechanical properties of piping elements, used for reference.

For plastic pipelines transporting water, the nominal pressure corresponds to the constant maximum operating pressure, expressed in 105 Pa (bar), created by water at +20 °C, taking into account a minimum safety factor;

- maximum operating pressure, MOP, 105 Pa (bar): the maximum fluid pressure in the pipeline that is allowed during continuous operation. MOP takes into account the physical and mechanical characteristics of pipeline elements. MOP is calculated using the formula

- lower confidence limit of predicted hydrostatic strength, σLPL, MPa: a value with a stress dimension that determines the properties of the material, representing a 97.5% lower confidence limit of predicted long-term hydrostatic strength at +20 °C for 50 years at internal water pressure;

- minimum long-term strength MRS, MPa : the value of the lower confidence limit of the predicted hydrostatic strength, rounded to the nearest lower value of the R10 series or R20 series according to GOST 8032–84 (ST SEV 3961–83) “Preferred numbers and series of preferred numbers” depending on the value of σLPL (see GOST 11262–80 (ST SEV 1199–78) “Plastics. Tensile test method”);

- design stress σS , MPa: the permissible stress for a given application, obtained by dividing by a factor and rounded to the nearest lower value of the R20 series, i.e.

- safety factor C : factor C for water pipes is 1.25.

Within products of the same density, the lower the SDR, the stronger, but also the heavier the pipe. For example, the PE100 SDR11 pipe is more durable than the PE100 SDR17 pipe. Brief characteristics and scope of application of polyethylene pipes are given in table. 2.

Table 2. Characteristics of polyethylene pipes

| Name of PE pipes | Characteristics | Application area |

| PE63 SDR11 | Low density, does not tolerate temperature changes well | Internal cold water supply |

| PE63 SDR17.6 | Pressure not higher than 10 atm | Internal water supply systems with low pressure for supplying cold water |

| PE80 SDR13.6 | Density is higher, but does not tolerate temperature changes well | Water pipelines for supplying cold water, irrigation systems |

| PE80 SDR17 | Density is higher, but does not tolerate temperature changes well | Water supply both indoors and outdoors, pressure irrigation systems |

| PE100 SDR26 | High density, ability to withstand temperature changes | Any pipelines for transporting liquids (water, milk, juices, etc.) |

| PE100 SDR21 | Increased wall thickness | Any pipelines, including gas ones |

| PE100 SDR17 | Increased wall thickness, but also greater mass | Most often used for industrial purposes |

| PE100 SDR11 | Low density polyethylene, high strength, increased chemical resistance | Can be used when installing sewer collectors, laid in any type of soil |

In practice, the SDR indicator is rarely taken into account, since it is more “theoretical” than practical. Much more important may be the nominal pressure for which the pipe walls are designed. These data are presented in table. 3. Pressure is at the intersection of columns and rows, indicated in atmospheres. For example, for a PE80 SDR13.6 pipe, the operating pressure is PN10 (10 atm). This means that when transporting media with a temperature of no more than +20 °C and a pressure of no more than 10 atm, the service life of this pipe is 50 years.

Table 3. Pressure ratings of PE pipes of different densities with different standard dimensional ratios (SDR)

| Name of polyethylene | Pipe series | |||||

| SDR41 S20 | SDR33 S16 | SDR26 S12.5 | SDR21 S10 | SDR17 S8 | SDR13.6 S6.3 | |

| Nominal pressure 105 Pa (bar) | ||||||

| PE80 | PN3.2 | PN4 | PN5 | PN6.3 | PN8 | PN10 |

| PE100 | PN4 | PN25 | PN20 | PN16 | PN10 | PN12.5 |

The symbol for pipes consists of the word “pipe”, the abbreviated name of the material (PE32, PE63, PE80, PE100), the standard dimensional ratio (SDR), a dash, the nominal outer diameter, the nominal thickness of the pipe wall, the purpose of the pipe: household and drinking purposes are designated by the word “drinking”, in other cases - “technical” and the designations of this standard.

Examples of symbols.

Pipe PE32 SDR21–32×2 drinking GOST 18599–2001: pipe made of polyethylene PE32, SDR21 with a nominal outer diameter of 32 mm and a nominal wall thickness of 2.0 mm for drinking water systems.

Pipe PE80 SDR17.6–160×9.1 technical GOST 18599–2001: pipe made of polyethylene PE80, SDR17.6, with a nominal outer diameter of 160 mm and a nominal wall thickness of 9.1 mm, not used for domestic and drinking purposes.

Shaped parts for polyethylene pipes can be cast or electric welded. They are designed for connecting pipes of different diameters, changing direction (Fig. 5), creating nodes and junctions of pipelines up to the largest diameters.

Rice. 5. Fittings for polyethylene pipes

Seamless pipes

A distinctive feature of seamless pipes is the integrity of their structure. They are divided into cold and hot deformed. Cold-formed ones are produced on the basis of GOSTs 8734-75 and 8733-74.

They can have an outer diameter and wall thickness of 5-250 mm and 0.3-24 mm, respectively. Such products are distinguished by precise geometric dimensions and high surface cleanliness. They are most often used in the refrigeration industry, automobile and aircraft manufacturing, as well as in pipeline laying.

Hot-deformed pipes are produced on the basis of GOSTs 8732-78 and 8731-74. Their outer diameter and wall thickness can vary between 28-530 mm and 2.5-75 mm, respectively.

Such products have higher rigidity compared to cold-formed ones and bend poorly. Externally, hot-deformed pipes have a rough surface. Most often they are used in mechanical engineering, oil production and chemical industries, as well as for the construction of pipelines with high design pressure.

Seamless pipes are characterized by the absence of any joints

Electric-welded steel pipes with straight seams, assortment, according to GOST 10705-91

The list of technical conditions according to which longitudinally welded electric-welded pipes are made from steel contains GOST 10705-91.

Among the most important provisions of this document are the following:

- The size of the permissible curvature is indicated within 1.5 mm/linear meter for products that have undergone heat treatment, and 2 mm/linear meter for those that have not. If the customer wants it, in the first case the parameter can be reduced to 1 mm, in the second - to 1.5 mm. If the pipe is subjected to heat treatment, then, with appropriate recommendations from the customer, a special protective atmosphere can be created for this procedure. The edges of the straight-seam electric-welded tube, according to GOST 10707-91, are cut off at an angle of 90 degrees, followed by cleaning of all irregularities and defects that have arisen.

Gas and oil pipes made of steel used in industry are subject to a separate GOST.

As already mentioned, GOST 52079-2003 concerns electric-welded steel products with a straight seam and a large diameter. In addition, a special category includes a variety of welded and seamless steel pipes used by the motorcycle and bicycle industry. Any section of these products should not have a curvature of more than 1.5 mm. Thanks to the regulatory document 12132-66, permission is given for the manufacture of products that have an exceptionally high or increased degree of accuracy.

International standard GOST R ISO 3183-1-2007

Pipes with a diameter of up to 48.3 mm inclusive are transported in bags, and the marking is applied with a stamp on a bandage or an attached metal label. The total length is indicated in meters and centimeters.

Requirements for pipes for pipelines according to GOST R ISO 3183-1-2007

Next, with a diameter of up to 406.4 mm, each pipe is marked with paint using a stencil on the outer surface. The length is indicated anywhere at the discretion of the manufacturer.

With a diameter of 406.4 mm inclusive and more, by default they are marked from the inside, unless the customer has specified another option. Apply using a stencil at a distance of 152.4 mm or more from the end of the pipe.

Marking of thick steel pipes at the end of the product

The stamp is not used to mark pipes closer than 25.4 mm from the weld:

- Steel strength groups above L175 without subsequent hardening;

- With a wall thickness of less than 4 mm.

Marking contains

- Manufacturer's trademark or name;

- Designation of the GOST R ISO 3183-1 standard (applied if the product fully complies);

- If it meets several standards, then all may be indicated;

- Designation of mass per linear meter;

- Steel class and strength group;

- Pipe forming method (S, W, F);

- Performed heat treatment;

- Test pressure (if tested above the standard pressure, this number is indicated in Pascals, after the word TESTED);

- There may be additional requirements.

Water supply systems made from steel pipes are used quite often, so you need to know about their properties and classification. Steel water supply pipes - sizes, diameters, materials, quality classes.

Steel strength group

L320 and higher, with niobium content the letter C is indicated, vanadium - V, titanium - T.

Mechanical properties of materials for the manufacture of pipes - steel strength groups

The formation method or production process is indicated by:

S – seamless pipe; W – welded, except those made with a continuous seam; F – pipe made with a continuous weld.

Heat treatment is indicated by the following signs:

- Tempered and/or normalized pipe – N;

- Subcritical stress relief – HS;

- Subcritically cured – HA;

- Quenched and Tempered – Q.

The supplement includes

A paint spot with a diameter of 50 mm can be applied, which corresponds to the steel strength group, this applies to pipes over 114.3 mm in diameter, strength group L320 and higher.

Used color combinations for pipeline markings

Pipe measurement systems

There is one peculiarity in indicating the parameters of water and gas pipes most in demand for domestic needs. When constructing water pipelines using them, individual elements are most often connected using the threaded method.

To do this, threads are applied to the outer surface of the pipes. Considering that this parameter is important when assembling the system, it is indicated by the manufacturer. In this case, the thread diameter is always less than the outer diameter of the pipe.

Today, when describing pipe parameters, two measurement systems are used: imperial and metric. In the first, all parameters are indicated in inches. It is used only in relation to water and gas pipes and fittings for them.

In the metric system, all parameters are indicated in millimeters, centimeters or meters. Sometimes when joining pipes of different types it is necessary to recalculate their sizes from one system to another. For this purpose, special tables are used, given in GOST 6357-81.

Even more information about the types of pipes for water supply and sewerage

You can get more information about the types of pipes for water supply and sewerage from an expert.

Our specialists are familiar with all accepted classifications of pipelines and are ready to recommend suitable products for laying communications. There are pipes and connections for water supply, heating and other utility networks to choose from. You can also order installation of water supply and sewerage systems from polypropylene pipes and HDPE products from us. Order a consultation

Physicochemical characteristics

The change in state when heating or cooling dielectrics characterizes their physical and chemical properties, as well as chemically active substances under the influence of moisture, mechanical loads, etc. Undesirable and sometimes emergency consequences in the operation of electrical installations can be caused by extreme heating of the electrical insulating material. An example of this is fire, short circuit, or electric shock to people. This places high demands on dielectrics in terms of their heat resistance.

Heat resistance is the ability of a dielectric to withstand a given operating temperature for a long time without noticeably changing its electrical insulating qualities. According to it, seven classes of electrical insulating materials are distinguished, used at temperatures of 90, 105, 120, 130, 155, 180, more than 18-0 ° C. A number of materials (asbestos, ceramic materials, mica, etc.) due to their structure have high heat resistance. Fibrous materials - from silk, cotton, cellulose, etc. In order to increase heat resistance, they are impregnated with special substances.

When heated, some dielectrics can melt, such as mica, paraffin, and also soften - resins, bitumen, or even catch fire (a flash of vapors of electrical insulating liquids occurs at certain temperatures): cable oil, transformer oil, synthetic electrical insulating liquids.

Cooling of dielectrics leads to loss of elasticity, as well as to the appearance of cracks, etc. Each material is therefore characterized by cold resistance. Cold resistance is the ability of a dielectric to retain its basic properties when cooled. For example, the cold resistance of a solid dielectric is taken to be the temperature (below 0°C) at which its mechanical destruction begins.

Many electrical installations operate outdoors, and their electrical insulating materials are subsequently exposed to moisture. And depending on the environment and in closed electrical installations the specifics of the technological process, electrical equipment is also exposed to moisture. First of all, its electrical insulating properties are impaired by the penetration of water into the dielectric, since water is undoubtedly a conductor of electric current. The ability of a dielectric to absorb moisture from the environment is characterized by moisture absorption. Moisture absorption is also determined experimentally: a dielectric sample is kept in distilled water for 24 hours at a temperature of usually 20°C; and there are also other ways to determine moisture absorption.

Solid dielectrics are also characterized by the wettability of their surface with water, since the presence of water reduces the specific surface electrical resistance of the dielectric. The wettability is judged by the contact angle. The larger the contact angle, the lower the wettability of the dielectric and the better its electrical insulating properties. Electrical insulating materials intended for operation in a chemically active (aggressive) environment must resist the action of alkalis and acids. Such properties are determined in much the same way as moisture absorption.

In addition to their intended purpose, most electrical insulating materials are also used to protect metal conductors from corrosion. With the rapid development of nuclear energy and space technology, increasingly high demands are being placed on the radiation resistance of dielectrics.

Viscosity is also characterized by liquid dielectrics; it is determined by the time of flow of liquid from a vessel that has a strictly defined hole and shape.

When manufacturing devices, electrical machines and other electrical equipment, repairing or installing electrical installations, it is often necessary to process electrical insulating materials by mechanical methods, such as drilling, cutting, grinding, etc.

This makes it important to know the mechanical properties of dielectrics, such as hardness, tensile strength, etc., and it is also equally important to know the properties of dielectrics to dissolve in solvents and varnishes, and to stick together. Extreme properties are especially common in connection with the introduction of new, progressive methods of performing the assembly of electrical devices, machines and electrical work.

Classification by material of manufacture

Classification by materials of manufacture includes pipes from:

• Metal: steel, copper, cast iron, various alloys, aluminum, etc. (see aluminum alloy pipe); • Polymers: PVC, PE, , PB, etc.; • Metal-polymer; • Asbestos-cement; • Ceramic.

The choice of a pipe from a certain material is determined by its technical characteristics:

- strength,

- the ability to withstand a certain range of operating temperatures without changing its mechanical properties,

- durability,

- corrosion resistance and others.

Offering consumers a wide range of their own products, pipe manufacturers are guided by industry standards, and also offer their own recommendations regarding the preferred scope of application of each type of pipe and recommend compliance with certain operating conditions.

Pipe diameters

To describe the cross-sectional dimensions of pipes, in addition to wall thickness, several different diameters are used:

The internal diameter is always indicated in millimeters; The nominal diameter is a dimensionless value. It is similar to the internal diameter, but may not be the same in size. In fact, the nominal diameter is the value of the average internal diameter of the pipes, rounded up or down.

Its value is important when making calculations for the entire liquid, steam or gas supply system. The convenience of this parameter becomes obvious in practical application

In this case, to assemble a guaranteed efficient system, pipes and fittings with the same nominal bore are selected; The outer diameter is the main overall dimension of the pipes.

Water and gas pipes are the most common material for assembling household plumbing systems.

Gaseous dielectrics

The advantages of gases over other types of electrical insulating materials are: high electrical resistivity, small dielectric loss tangent; low dielectric constant, close to unity. The most valuable property of gases is their ability to restore electrical strength after a discharge. In addition to air, di- and triatomic gases—nitrogen, hydrogen, and carbon dioxide—are widely used as electrical insulation. The electrical strengths of these gases under normal conditions differ little from each other and can be assumed with sufficient accuracy to be equal to the strength of air. Table 3.5.1 shows the ratio of the electrical strength of some gases, including high-strength gases, Epr g to the electrical strength of air, which is taken as unity. The same table gives the boiling points of gases at normal pressure.

Table 3.5.1

| Gas | Density kg/m3 | boiling point °C | ^tf r'^-np in |

| Nitrogen | 1,25 | -196 | 1,0 |

| Sulfur hexafluoride (SF6 gas) | 6,70 | -64 | 2,3 |

| Dichlorofluoromethane (Freon-12) Hexafluoroethane | 6,33* 9,01 | -30 -78 | 2,4 2,0 |

| Trifluoromethylpentafluorsulfur | — | -20,4 | 3,05 |

The requirements for gases used in electrical insulating structures are best met by SF6 gas and freon. Hexafluoroethane cannot be used at elevated pressures due to its low critical parameters.