Each product has its own letter and number designations.

This is necessary to separate them from each other, both by visual characteristics and by technical level parameters. PVC pipes were no exception to the rule. Manufacturer, terms and features of operation are not a complete list of what can be found out only by looking at information such as the marking of polypropylene pipes.

About numeric and alphabetic characters

A lot of letters and numbers are applied to this material. Manufacturers usually open official websites, where, among other things, there is information on the labeling and the information that it represents. But it is best to translate these explanations into a language that everyone can understand.

There are several characteristics that are indicated by the designation of polypropylene pipes.

- Pressure. Unit of measurement – kg\cm2. Denoted as PN. Shows how long the pipe operates normally while maintaining certain characteristics.

The thicker the wall, the higher this indicator is likely to be. For example, they produce brands PN20, PN25. Such options are needed for supplying hot water and heating systems.

Sometimes red or blue stripes are also applied. This will make it clear what kind of water future pipelines are intended for.

- The marking of polypropylene heating pipes includes data related to materials and structure. Large tables are compiled to describe this parameter. But it is enough to be aware of the basic symbols to carry out the correct installation of heating in an ordinary building.

- Al – aluminum.

- PEX is a designation for cross-linked polyethylene.

- PP-RP. This is polypropylene that supports high pressure.

- PP – Common varieties of polypropylene material.

- HI – fire-resistant products.

- TI - thermally insulated version.

- M – designation of multi-layering.

- S – icon for single-layer structures.

Marking of polypropylene pipes for water supply may also indicate data that relates to:

- The presence or absence of certificates.

- Issued batch numbers, serial designation and time, and so on. Such designations may consist of 15 characters or more.

- Manufacturers.

- Wall thickness and section.

Thanks to this information, each buyer himself will choose a water supply material that satisfies all his needs.

Frequently asked questions about pipeline markings

Below are answers to the most common questions regarding the marking of pipelines of industrial and civil facilities.

What color should the pipelines in the central heating substation, heating substation, and boiler room be painted?

According to GOST 14202, the marking of pipelines does not depend on the object, but depends on the substance in the pipeline.

Pipelines with the transported substance WATER are painted green, STEAM - red, AIR - blue, GAS - yellow, ACIDS - orange, ALKALINE - purple, LIQUIDS - brown, OTHERS - gray.

Read more about identification painting of pipelines.

How to mark pipelines in the central heating substation, heating substation, boiler room?

The most common substances in the pipelines of central heating stations/heating stations/boiler rooms are water, steam, gas.

The pipeline with water should be painted green, with steam - red, with gas - yellow. Identification coloring may be applied in sections.

It is also necessary to indicate the name and direction of movement of the substance using labels or self-adhesive markers. Their color must be the same as the color of the identification paint. The locations of the shields are regulated by regulatory documentation.

Download an illustrated guide to pipeline markings.

What color should I paint hot/cold water/coolant pipelines?

All pipelines transporting substances, the main component of which is water, are painted green in accordance with GOST 14202.

How, according to regulatory documentation, can you distinguish the supply pipeline from the return pipeline in a central heating substation, heating substation, or boiler room by color?

If pipelines are marked in accordance with GOST 14202, then the supply and return pipelines are painted green (if the coolant is water).

To identify the supply and return pipelines, appropriate symbols should be used with the direction of movement and the inscription, for example “COOLANT SUPPLY”

Is it correct to mark coolant supply/return pipelines with yellow and brown rings on a green background?

This method contradicts GOST 14202, the main document regulating the marking of pipelines.

According to the rules, the following type of shields with the names “SUPPLY COOLANT” and “RETURN COOLANT” must be applied to the supply and return pipelines.

Rings on the supply and return pipelines are applied only in yellow color even if the coolant temperature is above 120°C

You can familiarize yourself with other regulatory documents on marking pipelines at heat supply facilities here.

The requirement to mark the supply pipeline of the heating network with a yellow ring on a green background, and the return pipeline with a brown ring on a green background, is borrowed from the currently inactive “Standard instructions for the operation, repair and control of stationary network water pipelines RD 34.39.501, TI 34-70-042- 85” and was valid only for network water pipelines on the balance sheet of power plants.

The current regulatory documentation for marking pipelines with coolant refers exclusively to the requirements of GOST 14202.

How to properly mark gas pipelines?

Pipelines transporting any gases are painted yellow in accordance with GOST 14202.

The name of the gas and the direction of movement should be indicated using labels or self-adhesive markers.

It is also necessary, depending on the parameters of the gas, to apply red or yellow warning rings (Table 3, GOST 14202), and if the gas has a dangerous property (flammability, toxicity, oxidizer), then it is necessary to apply the appropriate danger sign.

How to mark steam pipelines?

Pipelines with steam must be painted red and a red label with the name and direction of its movement of the following type must be applied.

If the pressure in the steam pipeline is more than 1 kgf/cm² and the temperature is St. 120C, then a yellow warning ring must be applied over the paint. As the steam parameters increase, the number of applied rings increases (see Table 3 of GOST 14202)

How to mark fire extinguishing pipelines?

The coloring and digital designation of fire extinguishing pipelines are as follows:

– water-filled pipelines – green color or number “1”;

– air pipelines – blue color or number “3”;

– empty pipelines and “dry pipes” – blue color or digital code “3c”;

– pipelines with foaming agent or foaming agent solution, – brown color or number “9”.

The color of the markings indicating the direction of movement of the fire extinguishing agent is red.

View a brief overview of regulatory documentation on marking fire extinguishing pipelines.

Is GOST 14202-69 “Pipelines of industrial enterprises” valid? Identification markings, warning signs and markings”?

GOST 14202-69 has the status of a valid document.

What materials must be used when marking pipelines in accordance with GOST 14202-69?

GOST 14202-69 does not give unambiguous recommendations for materials for marking pipelines, but only indicates that in the case of marking using paints and varnishes, they must comply with current standards.

There are also no documents prohibiting marking using self-adhesive tapes and PVC-based markers.

Moreover, the use of self-adhesive materials is more expedient (generally accepted all over the world) - it is more convenient, faster, neater, and allows you to more accurately comply with the important GOST requirements for color, size, font and shape.

Source: https://www.targis.ru/blog/chasto-zadavaemye-voprosy-po-markirovke-truboprovodov/

What about areas of application?

There are other designations as well. Some of them are able to show where and how to install a pipeline from a particular material.

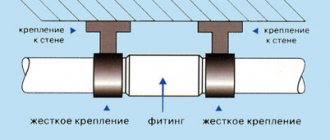

Typically this designation takes the form of a schematic drawing. Marking of reinforced polypropylene pipes is no exception.

The following is a complete list of areas of application.

- For systems providing fire protection.

- In shipbuilding

- For sports facilities.

- To irrigate farmland.

- For use in industrial infrastructure.

- For heating, warm floors and walls.

- In water supply systems.

- With heating pipelines.

- For drinking water pipelines.

Polymers have become especially widespread and have become an integral part of our lives. Labeling of plastic pipes for water supply also cannot be done without them.

Painting of boiler house pipelines according to GOST

- 1 Painting industrial and domestic pipelines: how and why it is done

- 2 Pipeline painting: differences, purpose, standards

- 3 Frequently asked questions about pipeline markings

- 4 GOST 14202-69 pipelines of industrial enterprises.

identification markings, warning signs and markings

As you know, modern engineering, industrial, urban and other communications transport various substances that can harm human health and the environment.

In view of this, even in the era of the USSR, pipeline painting was used to notify service personnel about the contents of the pipeline with which they would have to work. Color marking is still regulated by a special document GOST 14202 69.

Painting pipelines in many cases is a necessary measure - the purpose of the pipeline is determined by the color of the pipes

Purpose of varieties and their features

Pipe products can be reinforced (marked PPR-FB-PPR) or unreinforced.

Thermal elongation is characteristic of any type of PVC materials. This is the property of a pipe to change its size when it is exposed to high temperature.

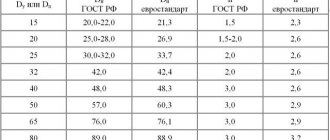

But in this case, products with reinforcement differ from analogues that do not have it. This is also indicated by the table of markings of polypropylene pipes for heating.

The highest rates of thermal expansion are for pipelines that are not equipped with reinforcement.

For example, with a temperature difference of up to 100 degrees, it can be up to 150 millimeters per 10 meters of pipeline. This factor must be taken into account by those involved in installation.

Pipes with fiberglass inside have proven to be the most stable in practice. In some products, aluminum foil serves as a compensator for this characteristic.

This is an important element for those who install heating systems. By marking it is easy to find out what types of materials were used for manufacturing.

- There are polypropylene products reinforced with an outer layer, which is, as it were, covered with an aluminum shell. This wrapper has ends, but they are never “soldered together.” In some cases, you can see internal reinforcement that strengthens the entire structure.

- There are also models that consist of equal parts polypropylene and reinforcement.

- Finally, hybrid versions are produced, which have three components. The outer layers are made of polypropylene. Then there is foil, which becomes a compensator, polyethylene.

Marking will always help determine which material will be best for organizing a water supply or heating system.

Almost all reinforced models have the same strength. The main thing is to take a closer look at how that same thermal expansion is compensated.

Polypropylene pipes for hot water are no exception, the marking of which will always provide the necessary information.

Choosing a simple polypropylene pipe is the most affordable option. Any home craftsman will be able to master the procedure for soldering such products without putting in much effort.

Types of polypropylene pipes

For cold water supply systems and hot water preparation with a temperature not exceeding +70 ºС, two types of products can be used: thick-walled and reinforced. The latter are also installed in pipelines used for heating.

For reinforcement the following are most often used:

- solid or perforated aluminum foil;

- fiberglass;

- composite materials that give products improved strength characteristics.

Regular

It is advisable to install conventional types of polypropylene in drinking and domestic water supply systems. This is dictated by their relative cheapness. Reinforced products are more expensive due to more complex production technology. In addition, they are easier to solder and there is no need to clean the ends before polyfusion welding. The walls of conventional mains are thick and can withstand pressures of up to 20 bar, which is more than enough for domestic water supply systems.

When designing systems with conventional polypropylene, it must be remembered that with increasing temperature it can warp, and the strength of the product will noticeably decrease. At a temperature of about +70 ºС, conventional products can withstand half the pressure stated in the labeling. Due to low resistance to high temperatures, conventional pipes are not used in heating systems.

With aluminum reinforcement

Aluminum-reinforced polypropylene heating pipes are a compromise solution between conventional products and fiberglass pipes. A solid or perforated layer of foil sharply reduces thermal expansion and gives the pipe the necessary strength.

With fiberglass reinforcement

High-quality polypropylene heating pipes, reinforced with fiberglass, can be installed in both hot water supply and heating systems in which the liquid temperature reaches +90 ºС. Fiberglass significantly increases strength, increases resistance to thermal effects, and helps products retain their properties for a long time.

Unlike products reinforced with aluminum, pipes with fiberglass are connected in the same way as conventional ones, that is, without preliminary trimming. This allows you to significantly reduce installation time.

Correct selection of raw materials. We simplify installation

A non-reinforced polypropylene-based tube is the simplest and most convenient option to use. They have a homogeneous structure, which allows them to be installed together with any type of connection.

Structures with fiberglass reinforcement are also quite convenient. The material melts well and does not require additional processing.

You can give some advice to those who are just planning to purchase products.

- Aluminum requires mandatory stripping if it is located on the outer layer at the joint. Otherwise, it will not be possible to create a tight, high-quality connection. It will not be possible to bring the polypropylene layer from the outside to “gluing” due to the compensatory foil. But this does not mean that such pipe products cannot be used at all. This inconvenience can be easily eliminated with special tools.

- Tubes equipped with internal reinforcement also require stripping. Just get rid of the aluminum foil. And make a cut at a right angle so that the work is successful. The exception is not polypropylene pipes reinforced with fiberglass, the markings of which will give clues.

Scary objects

Here GOST leaves only three primary colors:

- red – explosive and flammable, flammable,

- green – neutrality,

- yellow - toxicity, toxicity, extreme vacuum, suffocation, radioactivity, the ability to cause chemical burns, or simply dangerously high pressure.

For pipes containing substances with several hazards, it is possible to apply multiple rings, in other words it is possible to have a red and a yellow ring at the same time.

Note! Pipelines with deep vacuum, in addition to the painting of pipes and rings, must necessarily have the inscription “Vacuum”.

In addition, the short chemical name of the substance is written on the rings themselves and shows the direction of its movement. In normal and emergency situations, this is very important and affects many factors on which people’s lives may depend.

For very scary objects, in addition to everything else, warning signs of different contents are used, the color, shape and content of which are also strictly regulated and established. The sign must have a triangular shape, a yellow background and dark-colored graphics.

In most cases, such signs or symbols indicate the following substances:

- Strong poisons

- Explosive compounds,

- Radioactive substances,

- Other very dangerous compounds and their mixtures, especially harmful when splashed.

If the instruction does not contain specifics, then there is an exclamation symbol on a yellow background.

In addition, marking shields are used, which do not change color when the substance leaks. In most cases, they contain an indication of the type of substance and one of the sharp ends indicates the direction of movement of the medium; from time to time, double-edged shields are used.

Additional tips, some features

Pipes with the thinnest walls are designated PN10. They are only suitable for systems with heated floors or for supplying cold water.

At the same time, they can withstand a nominal operating pressure of at least 1.0 MPa. 20-100 millimeters is equal to the outer diameter.

Pipelines marked PN25 are distinguished by the presence of a layer located on the outside.

The use of glue is no longer necessary when joining layers due to the fact that there was perforation on the surface of the foil. The connection helps improve stability and strength properties. Can be used for hot water supply and heating.

Supplying PN25 with aluminum foil ensures that the products have a low coefficient of thermal expansion. But there are also difficulties associated with installation. Ideal for heating and, accordingly, for hot water supply.

Advantages of polypropylene

Long service life is the main positive feature for such products. But this result is achieved only by those who fully follow the recommendations from the manufacturers.

The operating time does not change if the temperature in the system increases, but only for a short period. Markings and sizes also affect this.

Video: designation of polypropylene pipe products

Marking of plastic pipe Sojet Elfin I + Elan 25A

Some installation tips

There are a number of other advantages:

- Minimal maintenance. They do not need to be painted; their appearance lasts for a long time.

- Light weight, resulting in minimal problems during transportation. And installation requires the involvement of a minimum number of workers.

- Reduced installation time compared to metal products.

- Good sound absorption, thanks to which the coolant passes through the system silently.

- Resistance to even the most severe temperature changes. Low thermal conductivity, virtually eliminating condensation.

- No corrosion on the surface in the internal part. This makes it possible to leave such characteristics as the internal diameter unchanged.

Video: designation of PP pipe products

Webinar “Plastic and metal-plastic pipes PE-X and PE-RT”

Regulations

In addition to GOST standards, the pipe may contain various DIN and ISO standards - standards of other countries, in particular those where the brand comes from. This does not mean at all that a pipe with European standards was produced in Europe - many products are made in China, under European brands. In general, if a pipe is supplied to Russia, then it must comply with a number of GOST standards (links at the end).

Often, pipes are sold on store shelves that do not comply with GOST standards at all - here we can only advise you to pay attention to these points and not trust the quality of such a product. Sometimes on the pipes there are inscriptions in English “for heating only, not for drinking water” - apparently the plastic releases harmful substances that are contraindicated for drinking water. Therefore, it is recommended to translate unclear inscriptions.

And finally, let’s decipher the inscription on the pipe from the first photo: PP-ALUX PP-R100/AL/PP-R100 32×5.4 PN25 SDR6/S2.5 CLASS5/9 BAR GOST R 53630-2015

. This is a pipe reinforced with aluminum foil, three layers: polypropylene random copolymer on the outside and inside, foil in the middle. The outer diameter of the pipe is 32 mm. with a wall thickness of 5.4 mm. The pipe can be used for 50 years in cold water with a pressure of 25 bar. The ratio of diameter to wall thickness is 6, size series is 2.5. The pipe can be used for a long time at all 5 classes with a pressure of up to 9 bar (classes 1,2,3 and 4 have higher pressure, you need to look at the documentation). The product meets all parameters from GOST R 53630-2015.

Sources:

GOST 32415-2013 Pressure pipes made of thermoplastics and connecting parts for them for water supply and heating systems. General technical conditions

GOST R 53630-2015 Multilayer pressure pipes for water supply and heating systems. General technical conditions

GOST ISO 4065-2005 Thermoplastic pipes. Table of universal wall thicknesses (with amendment)

Pipe painting area - calculation methods, formulas and online calculator

In everyday life, construction calculations are usually not given first place. This also applies to the process of painting pipes. Few people calculate in advance how much paint they will have to buy for this job.

And this is wrong, because preliminary calculations will help save a lot of money.

In this regard, the question arises: how to calculate the amount of paint and varnish materials required for painting various pipes?

Where to begin

Paint consumption depends not only on the size of the pipe, but also on the material used to make it and on the shape.

Most often you can find pipes in the shape of a cylinder. But there are other types:

- In the shape of a rectangle. Outwardly, they look like ordinary timber. Otherwise called profile.

- Cone-shaped. The name speaks for itself. Very rarely used. Their scope of application is pressure injection systems.

- Corrugated.

- For sewerage equipment. They are large cement rings.

The dimensions of pipes of each type correspond to the requirements stated for them in special documents.

How it's done

Several geometric formulas will help you calculate paint consumption. They will differ depending on the type of pipe.

Cylindrical

The area of a cylindrical product is calculated using the following formula: S = 2 * π * R * L. The quantities indicated in it are:

- π – number “pi”;

- R – outer radius of the pipe in millimeters;

- L – length in meters.

For example, if the length of the pipe is 10 m and its diameter is 60 mm, the surface area will be 1.88 m2. Calculations for commonly used pipe diameters can be found in the corresponding tables or use our calculator.

Knowing the surface area to be painted and the properties of a particular paint, you can easily determine its consumption.

Cylindrical sewer

The area of such products is calculated using the above formula. The only difference is the larger sizes. The calculation is based on a height of 90 cm. These are the rings that are most often used for sewer installations. The outer diameter can vary from 70 to 200 cm. Here are some examples:

- With a diameter of 70 cm, the area will be 1.99 m2.

- If the diameter is one meter, the area will be 2.83 m2.

- For the largest products (diameter - two meters), the surface area for painting will be 5.65 m2.

Profile

To determine the area of a profile pipe required for painting, you need to know its dimensions:

- H – height of one side;

- W – height of the other side;

- L – length.

For calculations, the following formula is used: S = 2 * H * L + 2 * W * L. If the length of the product is the same 10 meters, and its sides are 5 and 10 cm, the total area will be three square meters.

Cone shaped

For the most part, such structures are a truncated cone. The area of its lateral surface can be calculated using the following formula: S = π * (

R11+ R2

) *

L. It consists of the following quantities:

- R1 – radius of the smaller circle;

- R2 – radius of the larger circle;

- L – generatrix of a truncated cone: the length of the wall from the narrow to the wide part of the pipe.

With the structure measuring ten meters, three and six centimeters in diameter, the painting area will be almost one and a half square meters.

Corrugated

Calculating the area to paint a corrugated pipe is the most difficult thing to do. Experts recommend entering all values obtained during the work into a table.

So, first you need to decide on the following dimensions:

- rounding radius – A;

- projections of straight sections onto length and diameter (B and D);

- pitch of corrugated part – C;

- bevel angle of the flat part – E;

- height of the corrugated section – F;

- the line along which the product can stretch is G.

Essentially, a corrugated pipe is the same cylinder that can be extended along the G line.

The calculations look something like this.

- Let us assume that the value of A is 3 mm. The rounded part is calculated using the formula 2 x π x A. In this case, it will be 18.84 mm.

- The value of D must be doubled. Let it be equal to 20 mm.

- If we take into account the above data, we can determine that the stretched corrugation will be equal to 38.84 mm.

- If you remove the bevel angle, you can calculate the value of E. It is equal to twice the diameter, or 12 mm.

- As in previous cases, the length of the product is 10 m. Knowing this, you can calculate the number of folds. To do this, the length must be divided by step. It turns out 866 pieces.

- Knowing all these dimensions, you can calculate the stretched length of the product. To do this, 866 must be multiplied by 38.84 mm. It turns out that the length of the stretched corrugation will be 33.64 m.

- If the diameter of the stretched corrugation is, for example, 52 mm, the area for painting will be equal to 54.92 m2.

What and how to paint?

After the area of the surface to be painted and the material consumption have been calculated, you can select the coloring composition. The following types of paints are used for painting pipes:

- Acrylic based enamel. It contains organic solvents. A durable shiny coating is formed on the surface.

- Alkyd enamel. Features a wide range of colors. Allows you to create a durable coating that does not crack or wear off.

- Water-dispersed compositions. Dries faster than other dyes. In addition, they do not have an unpleasant odor. Before using such substances, a primer must be applied to the surface of the pipes.

- Oil paint. It is used extremely rarely for such purposes.

The first layer is to apply a primer. It will protect the surface from rust and increase the strength of the connection with the paint. After the primer has dried, apply two coats of paint.

Calculating paint consumption manually is not so easy - for this you will have to remember several geometric formulas. Before starting calculations, it is necessary to take measurements of the structure. To make the process easier, you can use ready-made tables or a pipe surface area calculator.

Source: https://kraska.guru/kraski/rabota/ploshhad-okraski-trub.html