Until recently, an asbestos chimney pipe was considered the best option for arranging heating boilers in a house, bathhouse and other buildings that require heating. The main argument in favor of this decision was that the material is non-flammable, resistant to moisture, and most importantly - inexpensive. These factors contributed to the fact that asbestos chimneys were installed in almost every private household. The heads of small utility companies and agricultural organizations did not ignore this simple solution to current problems.

Is a chimney made from an asbestos-cement pipe really such a universal means of removing combustion products? To understand this, it is necessary to dwell on the technology of manufacturing asbestos cement, its advantages and disadvantages, and the possibility of assembling chimneys from asbestos pipes with your own hands.

Is it possible to use asbestos pipe for a chimney?

This question is increasingly and rightly bedeviling private developers. First, let's look at the manufacturing technology of these products.

They are made from cement, sand, water and asbestos fibers. Plasticizers and dyes are added to the mixture. The ingredients are thoroughly mixed, the resulting suspension is filtered and given the desired shape. Hardening occurs over several days in warm rooms. The finished product is characterized by average strength, water resistance and low weight. The low price is determined by the availability of the mixture components.

Sewerage laying

If water is supplied through pipes, then over time the wall becomes stronger due to the compaction of the cement component. According to research by scientists in a number of countries, the use of such products for drinking water is safe for humans. If asbestos particles enter the body, it is quickly eliminated from the body without any harm.

Well, the main disadvantage of asbestos-cement materials is their fragility. They can easily be damaged during transportation, careless unloading or impact from a heavy object. To prevent this from happening, care must be taken to maintain their integrity during transportation and installation.

Disadvantages of asbestos pipes

Despite its popularity in private construction, a chimney made from this material has many disadvantages.

Defects appear almost immediately or after some time, depending on factors such as the fuel used, climatic conditions and frequency of use of the boiler.

The quality of the pipeline installation also matters. Let's consider the characteristic disadvantages of asbestos-cement chimneys and the reasons for their occurrence.

Burnout and bursting

Initially, the products were developed for mass production for use in land reclamation, construction of sewers and low-pressure gas pipelines. The designers did not provide for their operation at high temperatures. Emphasis was placed on tightness and ease of installation of highways.

The basis of the material is cement, and it is a porous material. It absorbs creosote, which is a flammable material. With strong heating, the process of its combustion begins, as a result of which the structure of the walls changes, they become thinner and burn out.

What temperature can asbestos cement pipes withstand: their limit is + 300 ºС.

With further heating, the pressure of the air enclosed in the walls of the purlins increases. Products crack, burst and even explode.

Maintenance difficulties

The high strength of asbestos cement is a myth that many people want to believe. Working with links requires increased caution and accuracy. The lack of steel reinforcement makes them extremely brittle and brittle, regardless of diameter and type. And that's not all...

Chimney maintenance is associated with the following difficulties:

- the need for regular cleaning, since pipes literally attract soot;

- the inability to make inspection windows to reach hard-to-reach areas;

- sensitivity of products to shocks and loads;

- Frequent replacement of insulation, which is destroyed by chemically aggressive condensate.

Humidification of the pipeline is fraught with unpleasant consequences, both for communications and for the building as a whole.

Condensate

The main purpose of the products was the laying of open and underground water pipelines of various lengths. Asbestos-cement pipes are resistant to water, but quickly collapse when in contact with chemically active liquids. They are the ones that form on the surface of the chimney during the interaction of soot and condensate.

The aggressive solution flows onto the roof and is absorbed into its surface. As a result, stains, unpleasant odors and cracks appear. Watching the video below will help you understand the extent of the damage caused by condensation. This issue can be resolved with the help of properly carried out insulation.

Maintenance difficulties

The only way out is to constantly clean the chimney (see How to clean a chimney). But unlike brick and metal pipes, chimneys made from asbestos-cement pipes are difficult to clean due to the difficulty of installing inspection windows.

The main problem is condensation

Skeptics may argue that this explosion condition only applies to older furnaces and boilers. Modern boilers have increased efficiency, as a result of which their outlet temperature is much lower, 100 degrees, and an asbestos pipe for the chimney is quite suitable. There is a reason for this statement. But let’s repeat, let’s not look at the issue superficially.

Indeed, all modern boilers have good efficiency, and this is wonderful. This means that this necessary heat does not go down the chimney, but is mostly used to heat your home.

As you know, for normal combustion of fuel a supply of oxygen is necessary. Oxygen is supplied along with outside air. Oxygen is supplied along with outside air. Air is supplied by draft. But what affects the quality of traction?

Of course, the quality of the chimney. Many people believe that the chimney is designed to remove combustion products. But it is important to know that, by removing combustion products, the chimney provides a flow of fresh air into the firebox, which ensures normal combustion inside the stove, boiler, or fireplace. This is how traction is formed. The greater the temperature difference in the pipe with the outside air temperature, the better the draft.

The greater the temperature difference in the pipe with the outside air temperature, the better the draft.

Many people have encountered this problem. The old boiler worked fine with a regular brick chimney. It's time to change the boiler. They installed an ultra-modern, economical, high-efficiency unit - and the problems began.

Brick pipe

Not only does the boiler not work as stated in the documentation, but on top of everything else, unpleasant-looking stains began to appear on the walls where the chimney pipe runs, and the beautiful brick pipe installed on the roof began to crumble.

Condensation stains

What is the reason? There is only one answer - condensation. Anyone who thinks that an asbestos chimney pipe in this case would be at its best is deeply mistaken.

How can this be, because asbestos-cement pipes are not afraid of water, they are designed for this. Everything is correct for water. But the condensate in the pipe is not exactly water. Or rather, not water at all. Condensation in a chimney is a very aggressive solution of a mixture of combustion oxides and moisture, which destroys the chimney material.

Why were they popular in the past?

During Soviet times, there was an acute shortage of all types of building materials. Asbestos pipes were a real boon for private developers. The purlins met all safety standards, had no worthy alternative, and were distinguished by their strength, tightness and affordable price. The links were used in furnace making, arrangement of water supply systems, sewerage systems and construction of wells.

Over time, GOST requirements were replaced by TU. Changes were made to the production technology, which negatively affected the quality characteristics of the products.

Modern products are no longer designed to remove combustion products with temperatures above + 300 ºС.

They can only be used for a gas boiler, installed in the middle and end of the chimneys of saunas and baths. But, it is better to abandon this idea and use pipes made according to specifications for arranging low-pressure communications and protective structures for laying cables.

Scope of application

Asbestos-cement pipes are used in various fields of construction. For example, they are used in the construction of sewage drains, both pressure and non-pressure. They often serve to supply water, both drinking and technical. Such pipes can also be used in the construction of a hot water supply system.

We recommend that you read: Which fittings are best suited for drip irrigation

In addition, asbestos-cement pipes are used in agriculture. There they are necessary when installing a reclamation system and drainage structures. In private houses, they are used to build wells, using them as casing pipes. In apartment buildings, there is another area of application for asbestos-cement pipes, in addition to water supply and sewage collection. These are garbage chute pipes. They are designed for both solid and liquid waste.

Due to the fire resistance of both asbestos itself and the structures that include it, such pipes are used for the construction of chimneys. However, there are several limitations in this application. In general, asbestos cement is used wherever there is a need for waterproofing, heat resistance, wear resistance and durability.

Which type is suitable for which chimneys?

Recommendations from experts on the use of asbestos-cement pipes in heating systems are brief. Purlins manufactured according to modern technical conditions should not be installed indoors or directly on brick kilns. At any moment, pipes can crack and dangerous carbon monoxide can fill the room.

As for the use of different types of products, they can be installed in the following places:

- Non-pressure. They have thin walls and low resistance to loads and impacts. It is better to install them inside auxiliary rooms and attics. That is, in places where people are not constantly present and there is no likelihood of mechanical damage to the highway.

- Pressure. The products are more durable and pressure resistant. It is advisable to install purlins on the roof where there is wind load. Pressure pipes can be used for fireplaces and stoves, provided that they are heated with wood.

In all cases, it is necessary to pay attention to the device for smoke removal from asbestos pipes, since they tend to become clogged with soot in a short time.

Advantages of using asbestos

Let's start right away with the positive qualities of asbestos pipes, which during the development of agriculture could easily be purchased (or stolen, whichever is preferable to anyone) at many enterprises and collective farms for pennies.

- Their comparative cheapness. This was due to the fact that asbestos was mined in large quantities in our country and products from it are easy to manufacture.

- They are light in weight, so they are quite easy to install.

- They have no seams and are not susceptible to moisture.

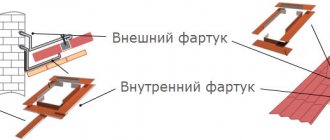

We line the chimney step by step with our own hands

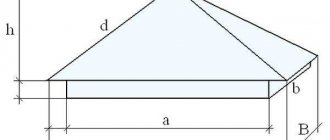

In order for the work to be done efficiently and the chimney to function properly, it is necessary to use products without chips or cracks. Their diameter should be larger than that of the furnace outlet.

How to attach

The chimney is installed from the bottom up. First of all, the section is attached to the boiler or furnace pipe. Since there are no shaped products, cast iron adapters of suitable size are used. The tightness of the connection is achieved using an asbestos cord soaked in refractory clay.

The first section is rigidly fixed. For this, clamps are used that are screwed to the wall.

How to build up

How to connect asbestos pipes during the construction of a chimney? It is enough to purchase special couplings, which are usually sold as a set.

It is necessary to take couplings made of asbestos without rubber gaskets. The joints are filled with a cord made of fire-resistant material. You can extend the pipe going out onto the roof in a similar way. To do this, it is cut with a grinder under the roof, after which a coupling and a new purlin of greater length are installed.

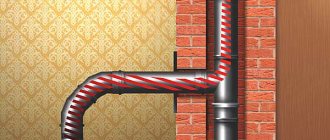

How and with what to insulate

Chimney insulation is carried out to increase draft and prevent the formation of condensation. This event is the final stage of construction. The quickest and easiest way is to wrap the pipes with mineral wool, twist it with wire and cover it with foil on top. A more complex, but high-quality method is to use a casing made of galvanized steel.

After placing the casing on the pipe, the gaps are filled with insulating material.

How to embed a tee

This event is carried out when an additional boiler, stove or fireplace is installed in the house. The simplest solution is to remove a section of pipe from the main. A tee is installed on the cut of the lower edge, to which the chimneys are connected. The removed section is shortened and inserted into the chimney.

The joint is insulated with a heat-resistant cord and secured with a coupling.

Is it possible to line an asbestos pipe?

The idea of whether it is possible to fix such products in a chimney is initially a failure. Yes, it is faster and cheaper than carrying out major repairs. But it is worth remembering the difficulties with maintenance and operation of asbestos-cement pipes and the possible consequences.

Construction technology

The great popularity gained by this material when arranging a chimney is explained by its fairly simple installation, which is not difficult to do yourself. Installation requires strict compliance with all standards and fire safety requirements, including SNiP requests.

The first step is to ensure reliable fixation, heat and waterproofing. When pipes crack, they try to prevent flue gases from penetrating into the room. The following describes the most common errors and ways to eliminate them, taking into account the features that asbestos-cement pipes have.

Fire safety measures and risks

Asb chimneys can last for decades if you follow the rules of their operation and maintenance.

Fire safety measures are as follows:

- use of fuel with low heat transfer;

- installation of sections in places where the exhaust temperature drops to the optimal value;

- regular cleaning of combustion product exhaust channels;

- use of high-quality thermal insulation.

However, the risk of cracks due to chemical corrosion is always present. It is necessary to regularly check the chimney for leaks.

Types of products

There are 2 types of asbestos pipes: free-flow and pressure.

And 2 subtypes of installation applications: ventilation and intake. Having studied the characteristics and purposes of the products, you can decide which type of pipe to use in one direction or another. For construction, a non-pressure cement pipe is purchased 35% more often than a pressure metal pipe for the following reasons:

- 1/3 lighter than iron.

- High temperature resistance.

- Do not freeze at low temperatures.

- The internal cavity is not overgrown with moss and mold.

- They are not afraid of groundwater.

- They do not pass current.

- Service life is 40−60 years.

- The strength of the material increases with the simultaneous interaction of cold and hot water.

- Minimum costs for thermal insulation.

- Resistance to mechanical loads.

Builders choose asbestos-cement pipes for plumbing communications and installation of fences or ventilation. Pressure models are used to supply water with high pressure. Scope of application: sewers of multi-storey buildings, water supply systems and heating mains. The joints will not tear because they are sealed with special couplings for the passage of water under pressure. For strong water pressure, steel types of pipes are used.

For chimneys in bathhouses and houses, asbestos pipes with a cross-section of 10 cm and a length of 300 cm are used. They are safe to carry on the roof because they are lightweight. Two advantages: they do not burn out and will not collapse during prolonged use in rain and snow.

For fences, asbestos products with a cross-section of 15 cm are used. They are mounted in holes, concreted and slate, wooden boards or profile sheets are attached to the posts. The service life of such supports is 35% longer than that of metal square models, and 90% longer than that of wood logs. The disadvantage of asbestos-cement materials is that the work area becomes dusty when cutting the workpiece with a grinder.