At the point where the chimney exits onto the roof, a gap forms between them, which, if not eliminated, will lead to moisture getting under the roof. The size of such a gap can be 3-5 cm. Traditionally, bitumen, cement or various sealants were used to eliminate it. However, such protection is short-lived and not reliable enough. To eliminate all these shortcomings, a master flush for the chimney is used. Another name for this device is rat or otter.

The master flush for the chimney plays an important role when passing through the roof

Choice of shape and material

The chimney cap was invented quite a long time ago . It solves several practical problems:

- protects the chimney from external factors: rain, snow and wind;

- acts as an additional roof decoration.

It is important to provide, first of all, protection from wind and precipitation, otherwise the walls of the chimney will be destroyed under the influence of weather conditions.

The cover should be selected in accordance with:

- channel type;

- hole diameter.

Based on these indicators, select:

- a cap made of chrome and nickel if the house is heated with gas;

- a removable product if the apartment is heated by a fireplace, solid fuel boiler or wood stove.

The main types are models with a round and square base, stationary or folding, made of tin - chromium-nickel or black. Many modifications are unfounded. They are fixed directly to the chimney duct.

Today, chimneys made of galvanized or stainless steel and copper have appeared. It is also possible to select modifications so that the shade of the cap matches the color of the roof. The selected option must correspond in functionality to the specific type of pipe. It should also match the style of the building.

How to choose

The question of choosing the material and shape of the cap, as a rule, comes first for the potential owner of such an accessory. This is understandable, appearance and the desire to be different from others do their job, but whether these criteria are so important when choosing is something that needs to be sorted out.

Considering all the types and forms in the booklet of manufacturers, it is worth asking about the functionality of the device. After all, not only the correct operation of heating or heating devices, but also the safety of the home owners themselves largely depends on the functionality of the hood.

For example, for certain types of heating installations, installing such devices on chimneys is not only not recommended, but is also strictly prohibited.

For example, according to the regulatory framework of the Russian Federation, the installation of such caps on chimney pipes serving gas boilers is prohibited; for chimneys of such heating devices, it is provided only in the form of a nozzle with a necessarily open top.

This ban is due to the fact that when the temperature drops, the metal chimney freezes and becomes covered with ice, preventing the removal of combustion products, which can lead to the release of carbon monoxide in the combustion chamber and possible poisoning of people.

The fact is that the temperature of the smoke from gas boilers is slightly lower than that coming out of heating devices operating on solid fuel. If the temperature of the smoke from gas boilers varies from 70 to 100 degrees, then the smoke from a solid fuel boiler using conventional fuel or a simple heating stove is already 150-250 degrees.

Thus, the most ideal option for installing a canopy are pipes from conventional solid fuel boilers or stoves.

The next important issue is the installation of such an accessory, because the chimney pipe is not the most easily accessible place in the house. And the chimney, like the pipe, will have to be cleaned periodically, because combustion products contain, in addition to smoke, a lot of impurities that very quickly settle on the surface of the visor. Therefore, when choosing, you should also take into account the fact that quite quickly the cap will be covered with a layer of soot.

In the case where the chimney pipe is not too high and does not provide sufficient draft, it is recommended to pay attention to caps such as deflector or deflector-vane. Such special devices will not only provide protection to the chimney, but will also significantly increase draft by almost 20%, and this is a very important fact.

Architectural form

As for the architectural shape of the cap, a multi-slope weather vane can perfectly protect against precipitation and snow. This chimney looks very impressive, especially if you place figures of any animals made of metal on top.

Models with a flat surface are more often used. There are caps with an opening lid, which are also popular. They are convenient for preventive maintenance and unhindered maintenance of the chimney. The deflector, which has a ventilation hole in its body, significantly improves traction.

But the smoker is not always used. There is virtually no need for it in areas where there is rarely precipitation and virtually no wind. But for Russian latitudes it is a necessity.

Chimney umbrella

A chimney hood can be installed for several reasons:

- it is capable of partially closing the mouths from blowing wind, due to which the draft is prevented from overturning;

- the chimney prevents small debris from getting inside;

- mesh design provides protection from nesting birds;

- such a product extends the service life of the head of a brick pipe, which can be destroyed under the influence of precipitation;

- A weather vane of this type has good decorative qualities, and therefore is able to complement the architectural appearance of the building.

Installing the hood

Here you should focus on safety and practicality. The last thing you need to think about is the external attractiveness of the structure. It is important to consider the following recommendations:

- Round steel pipes cannot be covered with traditional shaped structures. They remove smoke from highly efficient boilers whose efficiency exceeds 85%. It is better to use conical nozzles made in the form of an open nozzle. They will not become covered with a crust of ice in freezing temperatures.

- A brick chimney, devoid of inserts, connected to a high-efficiency heat generator, can be equipped with a cap-shaped nozzle. A pipe passes through it.

- It is advisable to install an umbrella on stoves with vertical channels. This shape performs a protective function on the chimney. But to make this possible, it is advisable to place a stainless steel plate inside.

It is recommended to install hip or gable hoods on smoke exhaust blocks made of brick and equipped with side vents. Due to this, the upper part of the masonry will be protected from precipitation and wind. In this case, contact with the gas duct openings on the sides will be excluded.

To protect a brick block, where chimney and exhaust pipes are open at the top, you can make a box with several through pipes. They, in turn, are inserted into the specified channels. Conventional mushroom-shaped caps are installed on top of the ventilation terminals, while conical nozzles must be installed on gas terminals.

Why do pipes smoke?

- Wrong

pipe diameter is selected.

- Incorrect pipe length as well as height.

- If the wind increases, cold air enters the chimney. The draft becomes less as wind pressure acts on the smoke, the smoke stops leaving the chimney and, as a result, the smoke remains in the chimney.

- The chimney is clogged with soot. You cannot use any chemicals when cleaning the chimney; to clean the chimney, you must invite a specialist.

- Perhaps a brick fell from the masonry. When strong winds rise, there are cases when bricks fall from the masonry. It is necessary to remove the brick and seal the hole with clay.

- The masonry begins to crack and cold air gets into the cracks, the draft decreases, and the fireplace will smoke. All cracks must be sealed with clay mortar.

- Condensation is released, causing the oven to become damp . Reason: when the temperature of the gases released during fuel combustion decreases. Due to the soot that accumulates on the pipe walls, it reduces the thermal insulation.

- If the chimney was built incorrectly.

- If the walls of the chimney are uneven and the cross-section of the chimney is small.

- If the chimney is installed below the roof.

- When installing a chimney near tall trees and houses.

- If the chimney passes air through the brickwork.

- If the room is poorly ventilated.

- Rain, snow.

- When it's warmer outside than in the building.

- When you light it for the first time when the chimney is frozen.

Making a visor

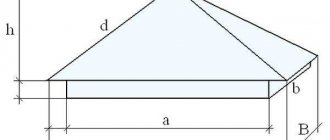

You can make a cap for the chimney pipe with your own hands. The drawings will help you navigate this, but it is important to follow all the parameters specified in it. First of all, you need to determine the external dimensions of the head. The umbrella will be attached here. Following this, you need to sketch a sketch depicting the future structure. To do this correctly, you need to consider the following points:

- the diameter of the product must be 10 cm larger than the dimensions of the pipe so that the edges protrude on all sides up to 50 mm;

- slope angles should vary from 30 to 45 degrees;

- from the chimney cut to the fungus, the minimum height should be 100 mm.

An umbrella is a traditional solution . There are other design options:

- rotating weather vane;

- deflector.

The latter makes it possible to increase traction through wind pressure. Thanks to it, a vacuum is created in the cylindrical body, into which the smoke channel passes. In calm weather, this device retains all its positive qualities. At the same time, it reduces the traction force in the pipe, which results in increased resistance at the exit of combustion products.

A semi-cylindrical weather vane is often popularly called a “sycophant” because it turns with the wind. It is mounted on a special bearing and consists of several components. This is one of the best options, but there are doubts about the reliability of the bearing, and the price of this design is high. It is especially good to install such a model on a round chimney, as it protects the mouth of this device from precipitation and blowing out.

To make a chimney for a canopy with your own hands, it is better to use painted or galvanized metal, the thickness of which is at least 0.5 mm.

The principle of operation of weather vanes

The operation of the deflector is based on the following actions:

- Air flows, bending around the walls of the upper cylinder, hit it. Sliding along its surface, they turn upward and suck in the gases coming out of the pipe.

- After installing the chimney, the air inside the pipe moves more intensely and thus increases draft.

- With a vertical or oblique wind direction, the visor provokes a further increase in thrust. Air flows penetrate through the gap of the device into the upper cylinder and suck in the smoke coming out of the pipe.

- If the wind blows downward, vortices appear under the top of the visor, which slow down the exit of smoke.

Making a Simple Round Umbrella

To perform such work, you need to prepare tools: a drill, metal shears, a hammer and equipment for installing rivets. Once the size of the fungus is determined , work is performed in the following order:

- Screw two self-tapping screws into a wooden plank, maintaining a distance between them equal to the radius of the product + 15 mm. It turns out to be a homemade compass, with which you can make a mark on the metal, marking the central part of the circle. Its outline is also drawn.

- The workpiece is cut with scissors, after which a sector is drawn, the arc length of which is 120 mm. The resulting figure is somewhat reminiscent of a piece of cake.

- The indicated wedge is cut out, and then the outer edges of the figure are aligned with force. Fix them with a vice.

- Drill three holes along the resulting line and connect the ends of the part with screws or rivets. The upper part of the weather vane can be considered ready.

Using steel strips, legs for the fungus and a clamp encircling the pipe are created. They take thin sheets that are bent several times. These parts are similarly secured to the umbrella with rivets.

Installation technology

The main requirement of building codes is that the cap should not impede the exit of flue gases from the pipe .

To comply with it, you need to follow a number of principles:

- When the pipe is removed from the roof ridge by 1.5 meters or less, the top of the cap should rise above the ridge by at least 50 centimeters .

- When the pipe is removed from the ridge by 1.5-3 meters, the head should be on the same horizontal line .

- When the pipe is 3 meters or more away from the ridge, the head should not be below a straight line drawn from the top of the roof at an angle of 10 degrees .

- If the height of the external chimney masonry is 1.2 meters or more, then before installing the cap you need to secure the pipe with roof braces .

Most head models are prefabricated, which simplifies their installation. The general installation algorithm is standard for all additional elements: first, the main product and its additional parts are fastened, then all joints are sealed.

The head should not impede the exit of flue gases from the pipe

The lower part of the cap is installed first; it must be attached to the top of the chimney. Screws or rivets are used as fastening elements.

Next, intermediate elements and the top of the structure are installed, which are connected to each other using brackets. Rubber or silicone-based compounds are used to seal joints. Particular attention should be paid to insulating the joints of the head and chimney.

Gable model

To make a gable weather vane, you need to use a machine called a sheet bender.

Just as in the previous case, first measure the outer surface of the brick chimney. Calculate the pattern and make the corresponding diagram. Next, the cap is assembled using a simple algorithm.

You need to cut the metal and bend it following the dashed lines. The resulting parts must be connected with rivets. The function of rigid racks is performed by ready-made corners made of painted metal , the thickness of which varies from 0.5 to 0.7 mm.

European cap

This model is more designed to prevent the formation of condensation and has a rounded appearance. A chimney of this type can be made independently using a steel sheet and hand-made holders.

How to make a European cap:

- Take a standard metal sheet and carefully bend it around the pipe, or directly along the contour of the chimney.

- They remake the spoons that will hold the cap directly on the pipe. It is best to do this with a special machine or ask a welder you know. You can also make transverse cuts that do not go all the way and carefully bend the strips using pliers.

- These cuts do not have to be transverse. It is permissible to use longitudinal strips if the piece of metal is quite long. A rectangle is cut out along the edges and the tails are left in the center. After this, roll the sheet in the shape of a semicircle and press the tails with a clamp.

- Gently bend the legs.

It is permissible to use a regular chimney pipe clamp to mount such a cap on the pipe.

To make a European cap, all you need is a piece of sheet metal and a grinder disc.