Chimney of horizontal design

With a horizontal chimney there are many nuances during construction; you need to take into account not only the length, as you know, it is limited to certain limits for each channel. You need to take into account the level of inclination, the degree at which the pipe will lie. These are features that must be adhered to to ensure the normal functioning of the oven.

Please note under what conditions the need to install a “lying” pipe arises:

- A classic case when it is necessary to connect a boiler to a channel located at a distance. This could happen, for example, when the stove is inside and the outlet is outside. Then the segments pass through the walls.

- When you need to improve the heat transfer characteristics of the furnace. To do this, they create a so-called “snake” so that the smoke does not just escape in a straight line, but overcomes a winding path, thereby transferring a larger percentage of thermal energy to the house.

Number of stoves per chimney

The main rule of SNiP for chimneys: each stove must have its own chimney. If the stoves are located on the same floor of the same house, their chimneys can be combined into a common channel. In this case, a cut of one meter in height is used inside the channel.

According to the requirements, on one floor one stove can heat no more than three rooms and it must have one chimney.

For a two-story house, you can use a two-tier oven. In this case, the stove must have two fireboxes, each firebox with its own chimney.

If you are using a two-tier oven, the house should not have wood floors between floors.

For two-story apartments, a different rule applies. The stove can be used with one firebox on the ground floor.

Verticality is not always justified

The vertical channel is not always optimal, especially when it comes to boilers, the dimensions do not exceed the classic dimensions and the heating area is not large. In this case, additional “benefit” from the removed hot air is required. That is why long sections of horizontal position are designed. In addition, for some types of boilers, such as gas boilers with a closed operating mode, a standing chimney is, in principle, superfluous. His configuration itself requires a horizontal section, that is, a coaxial image. The principle of its operation is clear.

Double layer steel chimneys

The Russian market is offered by companies Schiedel, Jeremias, Raab and Rosinox (Germany), Fineline (Hungary), Camin Wierer (Italy) and others. Among Russian manufacturers of similar products, Elites can also be mentioned.

For apartment-by-apartment heating in multi-storey buildings, leading chimney manufacturers recommend the LAS (air-gas) system. In this case, flue gases are removed through an internal pipe, and the air required for fuel combustion is supplied to the boiler through a channel between it and the walls of the shaft. The use of LAS makes it possible to operate gas heating units in a mode independent of the air exchange in the room, that is, this approach is most consistent with the requirements of SNiP 41-01-2003 (clause 6.2.2), which require the installation of heat generators in apartments exclusively with closed combustion chambers. These products, made from polymer materials, are offered on the Russian market, in particular, by the Viessmann company.

Condensing boilers, which are becoming increasingly popular, make good use of the latent heat of flue gases, the temperature of which drops to such an extent that condensation cannot be ruled out in the chimney even if the chimney is well insulated. As a means of combating corrosion of the internal walls of chimney pipes, Fineline recommends using a Furanflex polymer liner, which has a one-piece structure. This device is suitable for protecting brick and steel channels of any length, and its installation is carried out without breaking the wall. At the same time, polymers cannot withstand high temperatures, which is why they cannot be used to remove flue gases from stoves and fireplace inserts.

When installing a steel chimney at the exit of the structure from the wall, it is necessary to install additional fastenings, and elbows and bends are not supporting elements; they cannot be pressed against the external surfaces of the building

Resistance to humidity and chemically aggressive environments is the main advantage of modern ceramic chimney systems, which are suitable for working with any type of heating equipment. Made from high-quality technical ceramics, the chimney is impervious to moisture, acids and temperature changes, withstanding up to 1250°C. Such chimneys are mounted from ceramic blocks, and a reliable gas-tight connection is ensured by the design of the channel itself in combination with a special sealant. The disadvantages of such systems are their relatively large mass, volume, and high cost.

Swirls - methods for solving the problem

The only correct solution in terms of combating turbulence from the furnace to the pipes and vice versa is considered to be smoothing the corner joints. That is, watch the angle at which your joints are located. There should be no sharp turns, otherwise reverse flows will always form, thereby worsening traction.

Swirls inside the chimney

This applies not only to “lying” pipes; standing channels often encounter similar problems. Considering that metal corrugation and stainless steel are often used to construct horizontal channels, be careful when choosing the diameter. It should not be small; pipes with a small cross-section form almost a 90-degree angle at turns.

Chimney tee: 45 or 90?

A chimney tee is a very useful thing. We see two types of tees on sale: with an angle of 45 degrees and 90 degrees. Which one should you choose? Alexey TELEGIN, director of SPP Rubin LLC, tells the story.

Director of SPP Rubin LLC Alexey TELEGIN tells how to choose a tee for a chimney.

Why connect the chimney through a tee?

Why do you need a chimney tee? Connecting a chimney through a tee has a number of advantages over a direct (attached) connection. Firstly, debris does not accumulate in the pipe; it falls below the connection area into the resulting pocket, from where it can be easily removed. Secondly, the system becomes independent: the stove can be disconnected from the chimney, cleaned and even replaced without destroying the building. In general, the chimney tee is a wonderful thing, you can’t argue with that!

What kind of chimney tee do we need?

To understand which chimney tee we need: with an angle of 45 degrees or with an angle of 90 degrees, we need to weigh all the pros and cons of the first and second. Let's do that!

Tee 45: advantages

- Less soot and debris accumulate in the resulting inclined section of the pipe. True, this “plus” does not eliminate the need for periodic cleaning of the chimney. And also the need to provide access to cleaning along the entire length of the smoke channel.

- The rotation of the pipe and the horizontal section are at a safe distance from the ceiling. This means higher safety and easier and cheaper installation. Less fire protection is needed and the costs for it are correspondingly lower.

Chimney tee with 45 degree angle

That's all the undeniable advantages. And there are also those with whom you can argue.

Tee 45: controversial benefits

Thus, it is widely believed that a 45-degree chimney tee creates less turbulence than a 90-degree chimney tee. And does not create resistance to the flow of flue gases. But my experience shows that on a gas-tight horizontal section of a chimney made without narrowing the cross-section, at especially low speeds at which gases move in the chimney (2-5 m/s), we cannot use any instruments to determine the presence of the mentioned resistances, even if they there really are. This means that they can and should be neglected, especially when choosing a tee. And one more thing: if we accept as true that an angle of 45 degrees does not prevent the free exit of smoke, then it turns out that it cannot create barriers to the reverse flow of cooling gases and a sharp gust of wind, provoking reverse draft.

And it turns out that tee 45 does not have any special advantages.

Connecting the fireplace through a 45 degree chimney tee.

Tee 45: disadvantages

- When connecting a fireplace (stove) to a chimney at an angle of 45 degrees, the most thermally loaded area will be the area in the upper part of the tee insert and on its rear wall , located opposite the connection point. Overheating of this area occurs, causing rapid and premature wear of the entire part. And due to the complexity of replacing a tee, its overheating and wear are extremely undesirable.

- When connecting at an angle of 45 degrees, we lose a section that compensates for the linear temperature expansion of the heating unit and the smoke exhaust pipe . In this case, a lifting force of the pipe arises, exerting upward pressure on the insertion of the tee. While the weight of the chimney presses down on the tee. Due to the multi-vector direction and the displaced center of mass, a breaking load occurs with curvature of the structure and the risk of cracks. This can lead to depressurization and destruction of the tee at the insertion site. Don't forget that this is the most overheated area. At the same time, responsible and difficult to replace.

- When passing a wall at an angle of 45 degrees, to ensure fire safety, we will need to make a hole of a much greater height than at an angle of 90 degrees, which will lead to a weakening of the load-bearing capacity of the enclosing structure and a deterioration in its thermal insulation . To restore the wall after the opening has formed, we will have to spend more effort, time and materials. At the same time, the appearance of the intersection of the pipe and the wall will still be worse.

- The amount of condensate flowing into the smoke pipe and heat-generating apparatus increases. Modern products provide grooves, curtains and inclined sections in tees that significantly reduce this phenomenon. But the fact remains: through a 45 degree tee, the likelihood of condensation entering the fireplace is much greater than through a 90 degree tee.

- The pipe tends to “slip” from the tee. Which requires fixing the pipe. And it makes installation less reliable and more complicated. Because of this, the pipe is often placed “opposite” to the tee. Clamps are used on metal chimneys. But there is no holding device that secures the steel to the inclined ceramic. The process of “sliding” is inherent in both metal and ceramic pipes. But more often this happens in 45 degree ceramic tees.

- The process of connecting a chimney at an angle of 45 degrees is more complex. This is due to the fact that it is necessary to simultaneously align the pipe both vertically and diagonally, trying to fix it at an unknown point.

- Replacing and removing for cleaning a connection pipe with an angle of 45 degrees is more problematic. Of course, you can lift and tilt the chimney tee, but doing this while working at heights in hard-to-reach places is problematic. And with the chimney assembled, it’s almost impossible.

- Complexity of calculations and design. You might think that all problems are provided for in the design data and the customer should not care about them. But I will give you inexorable statistics. Currently, more than 90% of chimneys are installed without a design, and 90% of them are installed independently by the customer, and (or) with the involvement of low-skilled workers. That’s when you have to solve such “fun” questions as:

Where to install the consoles if they fall on the opening?

Are pipes needed below the tee or will this do?

How far should the pipe extend from the wall and at what level should it end?

How to simultaneously lift the chimney, fix the consoles and the platform with the tee, tilt and level?

Will the tee or bend hit the building structures?

How to raise the pipe: together with the firebox or separately?

The questions, of course, are far from funny, idle or trivial. Installation is complicated, expensive, inconvenient and difficult to visually control. Yes... With an angle of 45 degrees, everything is somehow sad... It is expensive, unsightly, and has difficulties in execution.

What about a 90 degree angle?

Chimney tee with 90 degree angle.

Tee 90: advantages

- The majority of the heat load will be borne by the 90-degree rotation and the horizontal section. This will protect the chimney tee from overheating. The elbow located on the smoke exhaust pipe is an easily replaceable and not very expensive part.

- When connected to the chimney at an angle of 90 degrees, a section is formed that compensates for the linear elongation of the heat-generating unit and the vertical branch pipe , preventing “fracture of the tee insert.”

- The opening needs to be smaller. This means that the wall is less disassembled and the thermal insulation suffers to a lesser extent.

- The design of the passage is more neat. And the amount of materials and time to seal the opening is significantly less than when connecting at an angle of 45 degrees.

- In a tee with an angle of 90 degrees, the condensate goes into the condensate collector, and not into the pipe and not into the heat-generating apparatus .

- Connecting and disconnecting a 90 degree pipe is much simpler and more reliable than a 45 degree pipe.

- The calculation is simpler and cheaper than in the case of a 45 degree tee.

Drawing conclusions

As is already becoming clear, there are more advantages to connecting at an angle of 90 degrees. To summarize: in most cases, a 90 degree connection is the most preferable.

PS: I would like to note that I am not an adept and fanatical follower of the “Teaching of 90-degree tees” and do not call for anathema to all tees with an angle of 45 degrees. I am happy to listen to all reasonable objections. Perhaps, with your help, we will find the truth together faster. Write in the comments!

Watch a video on choosing a tee for a chimney:

Chimney snake

Scheme of gas movement.

Unlike vertical chimneys, the “snake” has a larger heated area and is capable of giving off more heat. These are the so-called multi-turn ones, and can even exceed the length of the classic vertical “riser”. Provided that the same volume of fuel is used, the heat transfer from horizontal ones is much higher. It is also necessary to take into account the peculiarities; they require very good traction, perhaps even of a forced nature.

Hot topic

In stoves and fireplaces, the temperature of the exhaust gases is quite high, and therefore it is most reasonable to use brick or concrete chimneys with them, which, of course, does not exclude the possibility of using steel or clay structures. In principle, asbestos-cement analogues are also suitable, but in accordance with the standards, the flue gases in this case should not be heated above 300°C. It is advisable to provide a separate smoke exhaust channel for each stove, but you can connect two stove fireboxes to one chimney if they are located on the same floor. When connecting chimneys, cuts should be provided in them with a height of at least 1 m from the bottom of the joint.

If stoves are allowed to be placed only in one- or two-story buildings, and each floor must have its own chimney for heat generators, then solid fuel fireplaces with closed fireboxes can be installed even in multi-story residential and public buildings. In this case, they must be connected to a collective smoke exhaust system through an air seal at least 2 m long, which prevents the spread of combustion products.

Chimneys made of technical ceramics are resistant to moisture and acids, as well as temperatures up to 1250°C

Errors in the construction of brick chimneys may also relate to the quality and features of the masonry or the choice of brick. In this case, you cannot use its lightly fired wall or partition varieties. The thickness of masonry joints should not exceed 5 mm, and installation of bars on edges is not allowed. Significant miscalculations include the stepped shape of the inclined sections of the channel, which leads to the formation of turbulence and a decrease in thrust. Inaccurate splitting of bricks, improper preparation of the mortar, the presence of voids in masonry joints and double vertical joints - all this causes problems when operating brick chimneys.

When constructing such structures, the use of hollow or porous bricks is not allowed. For laying furnaces of stoves and fireplaces, as well as chimneys, only fire-resistant ceramic products are used. Their production technology involves firing at a temperature of 1300–1350°C, and the color of the finished product varies - from almost white to light brown, more often straw with brown inclusions. Taking into account the design features of various types of furnace fireboxes, straight and wedge-shaped (end and edge) refractory bricks are produced.

The condition of a brick chimney must be periodically monitored: to simplify this task, the structures are whitewashed, since black soot, indicating the presence of cracks and leaks of flue gases, is clearly visible on a light-colored surface.

Features of brick and concrete chimneys

A brick chimney must be vertical in all areas, and its walls, according to standards, must be at least 120 mm. thick.

For a concrete chimney, this figure is half as much - 60 mm.

Also, chimneys made of brick and concrete should have pockets up to 250 mm deep, with holes for cleaning.

|

Why you shouldn’t make a stove chimney at an angle

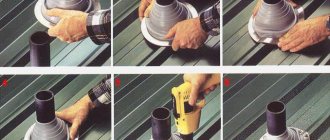

The chimney is often made of tin pipes. This design is easy to assemble. You just need to correctly calculate its dimensions, assemble it and reliably insulate it.

The chimney is an important element of any stove; it allows you to remove combustion products from the room. When the stove is burning, a draft is formed in it, thanks to which the flue gases escape into the street.

When purchasing material and installing a chimney, you must first pay attention to its shape. Experts advise preferring cylindrical pipes; this shape improves smoke removal.

Important! Efficiency depends on the number of angles and turns of the pipe. They cause a lot of soot to settle on surfaces.

It is better to make a smoke channel vertically, but you can place the pipe at an angle if it is no longer than 2 meters.

If you place the channel at an angle of about 45 degrees, you will find several disadvantages:

- If the chimney is installed at an angle, the top of the elbow will heat up the most, which can cause premature wear of this area.

- In a pipe located at an angle, there is no section capable of compensating for thermal expansion. At the same time, a lifting force appears, affecting the upper connection, and the mass of the chimney at this time presses down. Due to different vectors of pressure and weight, the structure may bend or the chimney material may collapse, increasing the risk of cracks. This causes depressurization.

- An inclined smoke channel when passing through a wall requires a large hole, this weakens the enclosing structure and leads to increased heat loss.

- Please note that you will still have to spend money on restoring the wall; if the hole is large, then the cost of sealing the hole will increase proportionally.

- The amount of condensate formed in the smoke channel increases.

- Connecting a chimney at an angle is more difficult than installing it at 90 degrees or vertically. The reason is that you need to simultaneously combine elements in 2 planes.

When assembling the structure, you have to tilt and lift the knee in order to correctly install the pipe, and this is inconvenient to do at a height.

This design has few advantages; in a chimney connected at an angle, little debris and soot collects on an inclined section. But this does not eliminate the need to remove contaminants, and the ability to clean a straight or horizontal pipe is no worse. Therefore, this will not be an advantage of an inclined chimney.

With this connection, the good thing is that the turning point is not close to the walls or ceiling. This simplifies the heating protection device.

They claim that in an inclined chimney, no turbulence is created and no obstacles appear due to which there is resistance to the flow of gases.

It must be said in conclusion that even a beginner can install a chimney on his own, only when working at height you need to think about insurance. It is advisable to perform this work with an assistant.

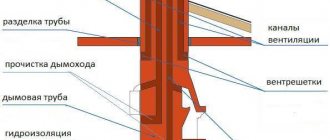

Ventilation in the house

The house must use forced exhaust ventilation and forced supply ventilation. This is due to maintaining a normal draft level and preventing combustion products from entering the room.

It is also forbidden to combine a chimney with a ventilation duct and use the chimney as ventilation.

|

SNiP requirements for chimneys to the ceiling

According to the standards, the top of a brick kiln is laid with three rows of bricks. However, the ceiling also needs to be protected. If it is made of flammable materials, it can be protected with a layer of plaster, which is applied to the metal mesh. The second option is to use a metal sheet laid over thick asbestos cardboard. In this case, the distance between the top of the stove and the ceiling is reduced. It must be at least 250 mm. for conventional stoves, and for long-burning stoves at least 700 mm.

If the ceiling is not protected by fireproof materials, the distance between it and the stove increases from 350 to 1000 mm.

If the top of the stove is covered with only two layers of brick, then all distances must be increased by one and a half times.

For metal furnaces, different conditions apply. If the ceiling is protected and the stove has a thermally insulated ceiling, then the distance between it and the ceiling should be at least 800 mm. If the ceiling is not protected and the ceiling is not insulated, this distance increases and must be at least 1200 mm.

In some cases, a layer of four rows of brick can be laid between the ceiling and the stove. Two holes with an area of 150 cm2 are made in the wall.

What is the difference from a coaxial chimney

In order to understand the distinctive characteristics of horizontal chimneys from coaxial ones, you should understand their structure and operating principle.

The first device combines 2 pipes of different diameters: the inner one removes smoke and combustion products, and fresh air is supplied into the cavity between it and the outer wall of the outer pipe.

A prerequisite for the functioning of coaxial type chimneys is the presence of a turbine in the heating equipment, which will push out smoke and suck in oxygen. This system is the easiest to install, because... does not require natural traction.

Wall and floor safety

If walls and partitions are made of flammable materials, their areas adjacent to the stove must be protected with a layer of plaster at least 25 mm thick. Also for these purposes, a metal sheet with a base of eight-millimeter asbestos cardboard is used. The height of the reinforcement depends on the height of the firebox. The wall is protected from the floor and reaches at least 250 mm above the firebox.

To protect the floor from fire, the space around the stove is protected with a metal sheet of sufficient size. The sheet must be mounted on asbestos cardboard with a thickness of at least 8 mm.

In places where the stove is adjacent to walls or partitions made of flammable materials, they are protected by indentations and grooves.

Cutting

This is a thickening on a stove or chimney with a width of 380 to 500 mm. The thickness of the cutting depends on the wall material adjacent to the furnace. If it is a flammable material, the groove should be wide - 500 mm, if the wall is protected by plaster or metal - 380 mm.

Retreat

It is a gap between the wall and the adjacent part of the stove. There are two types of withdrawal - open and closed. For a closed retreat, holes are made at the top and bottom, each with an area of 150 cm2. The offset does not come into contact with the floor; it is fixed at 70 mm. above the floor of the room.

Depending on the thickness of the walls of the stove and chimney, the closed and open ledge have different widths.

|