In order to move substances in liquid and gaseous states, a profile pipe is rarely used. Their main and important task and function is to reduce the weight of the erected frame structure of the proposed structure. Thanks to several available pipe ribs in square and rectangular cut versions, it has a high level of strength and reliability.

In tandem with its low weight, this ensures minimal impact of the load part on the base of the structure, and reduces the danger and life-threatening moments when creating load-bearing partitions. Installation work when creating a structure made of straight pipes is not difficult. But, with regards to arched structures made of profile pipes, in this case you will need to work hard, taking into account some of the nuances of construction. Professional firms provide assistance in creating bends of both rounded products and profile pipes. Professional workshops are equipped with special devices and tools. Of course, such services are not cheap, therefore, knowing some of the features of the bending process, as well as having basic experience, you can do all the necessary deformation processes yourself.

Where can I use the created arch from a profile pipe?

People who have their own plot of land always try to bring it into a noble appearance, decorate it and decorate it.

Arches made of metal profile pipes can be used for:

- hinged roof and canopy;

- outdoor recreation areas, for example, gazebos;

- greenhouse structures;

- garage buildings;

- fence;

- creating decor, for example, crossing through an artificial pond on the site;

- various ladders and other devices.

By using a profile pipe to create frame structures, the time and effort spent on the creation process itself will be significantly reduced. In addition, curved products perform a decorative function, decorating the structure itself, and also perform a practical function, minimizing the impact of snow and wind gusts, reducing their negative consequences.

In order to obtain the expected result in the process of creating a structure and in the process of using it for appropriate purposes, when creating an arched product, you need to take into account and follow three elementary principles that follow from one another. To begin with, the arched product must be made from profile pipes of the appropriate size. Further, the already created product should have no breaks or waves. The more accurately the work is done, the more beautiful the geometric component of the structure will be. And lastly, deformed profile metal pipes, which are parts of one element, must be absolutely identical. If you do not follow this principle, you may end up with a skewed structure, so it is not advisable to use profiles of different sizes.

We recommend: Do-it-yourself gate made from a profile pipe: how to weld correctly

Template arch details

This method guarantees a high-quality and undamaged metal pipe. On the outside of a rigid product, for example, a concrete base or a metal plate, markings are made of the contour elements of the future arched part. On the surface of a rigid base, in the direction of a straight line in a vertical plane with a distance of 5 cm, pieces of corners or other profile products are mounted using a welding machine. The height of the pipe sections must be greater than the cut of the profile product. If a concrete base is used for a rigid base, it is necessary to drill holes in it to firmly attach metal rods, the diameter of which will be about 15 mm. The created blank will serve as a template product for repeated use. In order to secure one end of the future profile product, you will need at least 4 firmly fixed rods. Some experts in bending pipes from profiles strongly argue that to ensure strength, it is necessary to fix the end of the metal pipe to a rod or corner, which is located at the very edge, by welding. The profile pipe, which has already been fixed to the template, begins to deform by applying manual force. You need to be vigilant, as you can easily overdo it and break the product. There is no need to rush; everything needs to be done slowly. Auxiliary devices can be various levers or mechanisms with chains or ropes. This method of creating a bend in a profile pipe is suitable for pipes with a small cut.

Read also: Rules for working with a hand jigsaw

Creating an arched element using a grinder

In addition to the grinding machine, you will need to work with welding. It should be borne in mind that this method is recommended to be used only when the already created frame base is sheathed with decorative materials or it is not intended to create a beautiful appearance of the structure. This is due to the fact that even carefully created and polished joints will be visible to the naked eye after welding. The initial stage of the upcoming work is marking activities. This concerns the length of the section that will subsequently bend and the place in which it will be located. Along the entire length line, at the same distance from each other, it is necessary to use a grinding machine to make three-sided cuts of the pipe, while trying not to touch its outer surface. It is after this process that you can begin to bend the pipe, creating it in the form of an arch. The bending radius is determined purely individually. Places that were previously sawn must be patched using a welding machine. After this, the connecting places need to be sanded.

Creating an arched element from profile pipes using high temperature

This method of creating bends involves the use of clean sand mass in its dry form. First, you need to close one of the ends of the profile pipe with a barrier cover made of wood, and then the sand mass must be poured into the profile product. Having filled the entire internal space of the product, it is necessary to fix a pointed wooden stick at its second end. Of course, when using this method of deforming profile pipes, you need to have a blank or template product with the required radius. The area that will be subject to deformation is marked with chalk or a marker. Then, the marked area must be heated with a heating device, and the profile product must be fixed into a template blank. After this, you need to start bending it slowly and without sudden movements, reaching the desired radius. The sand mass, in this situation, serves as a protective shield against various damages and loss of its original shape. Having obtained the desired result, one of the barrier covers is eliminated, and the profile product is cleaned of sand mass. The considered methods for creating arched elements from profile pipes will help you install small buildings on land without the help of professional persons, but with your own hands.

Profile pipes often become a material for the manufacture of various crafts for the garden, in particular, they are used to make arches. The attractive aspects of this material are the low weight of the product, the ability to apply paint to the surface of the pipes if it is necessary to restore the color or if you want to give the product a brighter shade.

Content:

How to use an arch made from a profile pipe

Note that the scope of application of metal profile products does not entirely coincide with their direct purpose; pipelines for the transmission of gas or liquid are extremely rarely assembled from them. Most often, they serve as material for assembling lightweight building structures, in particular, quickly erected structures. A positive characteristic of this type of pipe products is the increased strength obtained due to the presence of additional stiffeners.

Among the undoubted advantages is low weight, which allows minimizing loads on the foundation or supports, reducing risks during the construction of load-bearing structural elements. If the structures have rectangular shapes, then the installation work does not cause any difficulties. The question is completely different if arches from a profile pipe are required. It is very difficult to do without special knowledge, skills and tools.

Of course, if you wish, you can use the services provided by specialized companies and order bends on profile pipes or round tubular products. But if you wish, you can try to do this difficult work yourself.

Features of arched structures

Often, landscaping a site involves the construction of several useful facilities for the economy:

- garages and greenhouses,

- gazebos and canopies,

- tables, benches,

- temporary buildings and fences.

A pergola or just an arch made of a plastic pipe will look picturesque against the backdrop of lush greenery; making it with your own hands is not so difficult.

Profile plastic pipes are available for sale in a wide range, with different cross-sections, and their assembly is easy.

If profile pipes are used when creating the frames of the above-mentioned structures, the installation process can be significantly simplified and accelerated. But again the question arises with the use of bent elements. In addition to the fact that they give structures attractiveness and visual lightness, they are also able to reduce wind loads on the structure. If we are talking about the winter period, then we should remember that snow masses do not accumulate on an arched roof.

Read also: How to cook a barbecue from a gas cylinder video

The calculation of an arch from a profile pipe can be performed using a special program or using an online calculator; to get an accurate result, you will need to specify the length and height of the chord. As a result of the calculations, the depth of profile deflection will be determined, which will need to be obtained as a result of processing the pipe with a manual hydraulic pipe bender or bending machine.

What are the requirements for pipe structures?

In order for the construction process to end with the creation of a durable and reliable structure, the following rules, which are closely interrelated, should be remembered:

- To create an arched structure, pipes of a suitable diameter should be used.

- Bent products should not have kinks, waves, or other defects on the surface. The beautiful appearance of the product largely depends on the correct geometry of the arches included in its design.

- If the bent profiles used in the structure are not absolutely identical, then ultimately this fact can lead to the structure being skewed, i.e. The possibility of using different sized products in one design should be excluded.

Arc manufacturing options

Experts question the possibility of high-quality completion of a task using a manual pipe bender. Difficulties in obtaining a satisfactory result usually arise due to the fact that a pipe bender, although a special device, is designed to give a certain shape to short and small-diameter pipes.

Making an arc using a manual pipe bender, watch the video:

The chance of giving the same shape to several high arches on such a device is negligible. Of course, craftsmen can achieve good results, but it will be too difficult for an inexperienced worker to cope with such a task, and there is little point in gaining experience in such a process - a pipe arch can be made with your own hands in another, simpler way.

For example, you can bend a pipe and trim it. The main drawback of this option for making an arch is the sloppy appearance; the method followed by welding can be used if the aesthetics of the product is not of particular importance.

Profile Bending Machine

Pipe bending machines are specialized industrial equipment; their use cannot be called justified if the work is performed one-time and its volume is far from large-scale. Naturally, in the conditions of a summer cottage, the use of such equipment will look at least ridiculous.

The second important point is that it is simply irrational to carry out single orders on such equipment, because for the production of each single product it will be necessary to make a rather complex set-up of the machine. Typically, the result of such processing is arches with an insufficiently accurate profile and side planes turned by the propeller.

If the volume of work is large enough, it is easier to order the production of arches on a bending machine for a profile pipe from a specialized company.

How to make an arch from a profile pipe with your own hands

Of course, the methods that will be discussed further will not arouse either interest or high appreciation among specialists working on the manufacture of numerous structures.

However, these are the good old methods that will help home craftsmen make several correct arches and use them to build a support for growing climbing ornamental plants, a greenhouse, or a house shed.

We make arches according to a template

The first advantage of the method is that there is no threat of damage to the bent pipe. They begin work by drawing the calculated contour on a thick sheet of metal, in full size. Next, vertical sections of the profile are welded along the drawn line; the height of these fragments should exceed the cross-sectional size of the pipe by at least 4 or 5 cm. The spacing of the profile sections should be about five centimeters.

Instead of a metal sheet, you can use a concrete slab to make a template; you will need to make the required number of holes in it and secure strong metal rods with a diameter of about 12-14 mm in them. This design can also be used as a template as many times as necessary.

To securely fix the end of the arch you will need at least 3 or 4 securely fixed pins. Experienced craftsmen advise welding the end of the profile pipe to the rod.

You can bend the pipe manually; the work should be done slowly and carefully; sudden movements may cause the product to break. To reduce the physical effort required, you can use a winch or lever. It is possible to bend a high-quality arc in this way if it has a small cross-section.

We make an arch, use a grinder and a welding machine

This method of making an arch is suitable if the pipe structure is hidden behind the finishing material - any welding seam, even if it is performed by a master, will be noticeable on the finished product. Careful sanding will not hide it.

The work is performed in this order:

- Mark the segment on the pipe where the bend will be made,

- in the marked area, cuts are made at regular intervals, only the outer section of the wall is left intact,

- the sawn profile pipe is bent to the desired radius, this is very simple to do,

- The cut points are welded and carefully ground.

Hot method of making an arch from a profile pipe

To use this method you will need to stock up on clean sand. One end of the pipe is hammered with a peg, sand is poured into the other, as much as will fit. Then close the other end. For this method of making an arch, you will also need a template or blank with a calculated radius. Having outlined the area where the bend will be made, begin heating it with a blowtorch.

Then, using the template, bend the pipe. A pipe filled with sand is guaranteed not to burst, and deformation when bending it will be minimal. Next, the plugs are burned out, and the sand is poured out of the pipe.

Let's watch a video on how to bend a pipe:

Using the simple devices described above will help you independently bend arches from profile and round pipes, and build small original buildings on the site with your own hands, without involving specialists in the work.

What is better not to do?

Using a manual pipe bender to create an arched element from a profile, in most cases, the result is of insufficient quality and the desired result. All this happens because such a device is suitable for deforming small pieces of profile products with small cuts. Unfortunately, large and identical arched parts cannot be completed. Although there are such skilled workers who, even in such a difficult way, create the necessary details. But for a beginner in this business, it’s better not to take risks. For those who have never encountered this type of work, there are more suitable, understandable and high-quality ways to create an arched metal part. In addition to the described deformation option, there is another one that involves a trimming process. The disadvantages of this method include the fact that after such work the deformed product becomes not very neat. Only because of this, the method of cutting and bending profile pipes followed by the welding process is used when the appearance of the finished part is absolutely not important. A special machine for bending profile pipes belongs to the technical equipment of production. Even he sometimes cannot reproduce everything he has planned. In addition, such a machine can only be used in an industrial environment. In the private sector, located on a plot of land, such a machine is simply inappropriate. In addition, a one-time order may not turn out to be of very high quality, since it is quite problematic to configure the device for each part with absolute accuracy. In this case, the radius parameters of the profile arched element may turn out to be unequal, and its sidewalls may be turned in different directions. If it is necessary to create metal arches in large quantities, it is recommended to use the help of specialized companies by ordering the service of bending profile products using special equipment.

Creating profile deformations yourself

You can find a way out of the situation with creating profile arched elements by using some familiar methods. Of course, professionals who deal with massive bending of profile pipes every day will not appreciate them. But in order to improve the local area and greenhouse structures, such options for creating arched parts are acceptable and appropriate.

What to give up

Unfortunately, when using a manual pipe bender to make arches from profile metal pipes, good results are rarely achieved. The fact is that this tool is suitable for bending short sections of pipes of small cross-section. But it is impossible to make long and identical arches with its help. Although some craftsmen are capable of this process, it is not worth gaining experience in such work. There are simpler and higher quality options for manufacturing metal arched elements.

Another method of bending a profile pipe is with trimming. Its disadvantage is the sloppy appearance of the curved pipe, therefore metal profiles are cut and bent with further welding only in cases where the aesthetic side of the finished product does not matter at all.

A roll forming machine, which is classified as industrial equipment, also does not always pay off. Firstly, it can only be used in large-scale production. It will look ridiculous on a personal plot. Secondly, single orders are not always fulfilled with high quality due to problems with precise adjustment for each product. As a result, the radius of the arch from the profile pipe is inaccurate, and its side planes are turned by a “propeller”.

If there is a large volume of work, it is more reasonable to produce metal arches on roll forming machines, placing an order in specialized companies.

Calculator for calculating the radius of the arched arch - with the necessary explanations

Agree, arched structures look very elegant in the interior or in the design of the site. They are widely used in the laying of stoves and fireplaces, outdoor barbecue complexes, in the design of passages between rooms, in the construction of fences, gazebos and other structures. But laying out a high-quality arch is a very difficult task, requiring considerable skill and mandatory verification of each action performed.

Arch radius calculator

To prevent the arch from becoming weak or skewed, it is necessary to strictly control its dimensional parameters. Deciding on some of them is not a big problem: for example, the width of the opening can be easily measured or set in advance, the height of the arch is usually chosen based on the design idea or the availability of free space. But how can we accurately determine the radius of the arc that will define the lower arch of the arch? There is no problem if the arch is semicircular, that is, it is exactly half the circle - its radius in this case is equal to half the width of the opening. But what about the archery?

We suggest that you do not search for geometric formulas on the Internet, but use the calculator for calculating the radius of the arched arch located in this publication. Some explanations will be given below.

Explanations for the calculation

To erect an arch, a template is usually prepared in advance - the so-called circle. In order for it to exactly correspond to the required “geometry”, it is impossible to do without knowing the radius of the arc that forms the vault of the arch. In addition, it is necessary that the seam lines between the bricks creating the arched vault converge at exactly one point - in the center of the circle of which the arch is a part. To do this, a nail is driven into this center, a thread is tied to it, and the correct direction of each masonry seam is verified using it. But in order to accurately mark this center, you again cannot do without the radius value.

All seams between the bricks forming the arched vault must “look” at one central point, and this is necessarily controlled during laying by a thread stretched from this center

So, usually the master has two “starting” values at his disposal:

A diagram that will help you correctly determine the initial dimensional parameters of the arch

L is the so-called length of the arch, that is, the horizontal distance between its extreme points. Usually this will be the width of the doorway or, for example, the width of the fireplace window.

H – the height of the arch, that is, the vertical distance from the horizontal line (chord) connecting its lowest points and the highest point of the arch.

There is a geometric relationship by which, based on these two quantities, the radius of the arc that defines the lower vault of the arch (R) can be accurately calculated. This formula is included in the proposed calculator.

You just need to sequentially indicate the length and height of the arch on the sliders - and the program will immediately give the answer with an accuracy of a millimeter.

Attention - the initial data is also indicated in millimeters. Is it difficult to build a fireplace for your home yourself?

Is it difficult to build a fireplace for your home yourself?

Of course, this is a task of an increased level of complexity, but if you have the skills to perform high-quality brickwork, then why not try it? Take, for example, the simple ordering diagram that is given in the article on our portal dedicated to the selection and construction of wood-burning fireplaces for the home.

What's the result?

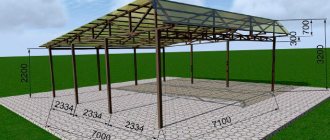

Calculation of arched canopies is rarely done in full - trusses are calculated only for critical or large objects, but not for small buildings in the courtyards of private houses. For such buildings, it is enough to calculate the snow and wind loads. This is necessary to choose the appropriate brand of corrugated sheet or type of cellular/profiled polycarbonate.

In addition, calculations are made of materials for arched canopies made of metal profiles. It is not as simple as for conventional single-pitch and gable roofs, since the rounded surface needs to be “unfolded” onto a plane. But this is not an impossible task: you just need to substitute the values into the formula or use our online calculator.

Useful article? Save it on social networks so you don’t lose the link!

Top ↑

Team oprofnastile.ru

Read on topic:

Single-pitch canopy made of corrugated sheets

Detailed instructions on how to make a free-standing lean-to canopy from a metal profile - with drawings, diagrams and step-by-step installation instructions.

Carport made of metal profiles

We tell you in detail how to build a carport from metal profiles and corrugated sheets: from choosing the brand and coating of corrugated sheets to drawings and step-by-step instructions for installing the structure.

Choosing plastic: five convincing reasons

Plastic garden arches are noticeably superior to analogues made from classic materials. Indeed, against the backdrop of short-lived wood and corroding metal, this practical and modern material boasts a number of advantages:

- high moisture resistance, and as a result – immunity to mold and fungi;

- durability - the product is designed for a 50-year period of intensive use;

- color fastness that will not fade over time;

- resistance to low temperatures;

- no unpleasant odor.

Arches made of plastic pipes as a support for roses

The attractiveness of a portal constructed from plastic pipes lies not only in its stylish and laconic design, but also in its relatively low cost. And the ability to quickly install the structure makes it the best option for a garden or cottage.

In order to make an arch from a plastic pipe with your own hands, you do not need to be an experienced construction specialist or a professional landscape designer. It is enough just to follow the basic rules and recommendations.

Assembly of the structure

Assembly of side and rafter trusses can be done on the ground if there is a crane or other lifting equipment. In their absence, this work is carried out separately, that is, first the side trusses are attached to the supports, and then the rafters.

First, fixation occurs on several spot tacks, after which it is imperative to check the geometry of the planes and completely weld the joints.

Trusses can be assembled on the ground

After assembly, the frame is cleaned and thoroughly primed with an anti-corrosion compound. The durability of the structure depends on the quality of this processing.

Calculation of polycarbonate point fastenings

It would seem that something unprecedented is polycarbonate. Just screw it on with self-tapping screws for corrugated sheets and that’s the end of it! Cheap and cheerful, especially if special thermal insulation at the joints is not required. However, polycarbonate sheets torn off during strong winds suggest that this is not an entirely correct approach to solving the problem and polycarbonate sheets need to be secured at least with fasteners specially designed for this, and even in this case, the pitch between fastenings should be selected not by eye, but by calculation.

There are two main types of fastenings for polycarbonate sheets - tape and point. When a hole is drilled in polycarbonate and a self-tapping screw is screwed into the sheathing, this is a point fastening. Fastening polycarbonate using corner and joining profiles can be considered as strip fastening. When fastening a sheet using various kinds of corner and joining profiles, the load on the sheet is transferred more evenly and such fastenings usually do not require additional calculations. But when using point fastenings, quite large local stresses can arise in the area of contact between the fastening and polycarbonate.

How to weld a frame with your own hands

The simplest canopy design is a lean-to one based on simple purlins, since in its manufacture there is no need to bend profile pipes. They are assembled using trusses with parallel chords, mounted on supports at an angle.

A lean-to canopy is the simplest design

Next you need to take several steps:

- First you need to measure and cut all the structural elements from the profile pipe.

- To assemble the frame, you need to lay out the elements on a horizontal plane and, if possible, secure them with clamps to protect them from unnecessary movements. Seal the joints by welding, making sure that the dimensions correspond to the drawing, and weld the joints completely.

Frame assembly is carried out in several steps

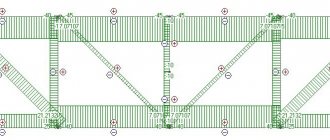

Manufacturing of trusses

A metal truss is a load-bearing structure with zigzag-shaped load-bearing elements between the chords. There are various designs of trusses used when constructing a canopy from a profile pipe.

The truss design of a specific canopy may vary

Farm manufacturing sequence:

- These elements are welded according to the drawing on a horizontal plane. In this case, you need to press them with clamps first onto the tacks. Then, after making sure that the dimensions are correct, the joints are completely welded.

- The first truss produced will be the template for welding the rest.

- After finishing the work, you need to clean the seams with a grinder, then drill holes for fastening the roof along the top side of the truss.

Trusses from a profile pipe are made according to a template

How to bend pipes

For arched trusses it is necessary to bend profile pipes. To do this, you can use a manual or electric bending machine. If there is none, then you can do this work manually in one of several ways.

Notching

The bend is carried out as follows:

- First you need to make cuts with a grinder on the upper edge of the pipe in increments of 10–15 cm (depending on the radius of the planned arch).

- Now you can bend the pipe from the middle, after first clamping the workpiece in a vice.

- At the end, it is necessary to weld the widened cuts, and also clean the seams with a grinder.

Notching is one of the ways to bend a profile pipe

Packing with sand

A method that does not require special tools. This work is performed as follows:

- First you need to weld or plug one end of the pipe.

- Now you can pour sand into the cavity and hammer in the plug from the other end.

- Heat it with a cutter and bend it to the desired radius.

Video: how to bend a pipe without a pipe bender

Installation and fastening of canopy supports

This stage of work is carried out according to the following plan:

- First you need to clean the area and mark the location for installing the canopy.

- Next, you need to dig holes (50*50 cm, 70 cm deep) for the columnar foundation.

- Now you can prepare concrete by mixing cement, sand and crushed stone (fractions 5–20) in a ratio of 1:2:2.

- Pour it into the holes, compact it, insert the mortgages. The foundation should be left for 4–5 days, covered with plastic film on top. In this case, you will have to water it every day.

- Now you can begin installing the supports. They need to be cut with a margin of 5–10 cm, since slight unevenness of the site is possible.

- They must be placed one by one, checking the vertical position using a level. Now the supports can be welded to the mortgages.

- Now, using a laser level or hydraulic level, you need to find the lowest point on the supports and place a mark at the desired height. It must be “transferred” to the remaining supports. This way you will ensure that all marks are in the same horizontal plane.

- At the end of the support, you need to cut it using a grinder according to the marks.

The diagram will help you get the job done efficiently

Metal trusses for canopies ↑

This design consists of two belts. The upper and lower chords are connected through braces and vertical posts. It is able to withstand significant loads. One such product, weighing from 50–100 kg, can replace metal beams three times larger in weight. If calculated correctly, a metal truss, unlike beams, channels or wooden beams, does not deform or sag when exposed to loads.

A metal frame experiences several loads at the same time, which is why it is so important to know how to calculate a metal truss in order to accurately find the equilibrium points. This is the only way the structure can withstand even very high impacts.

Lathing and coating thickness

Let's start by calculating the snow load.

Before we figure out how to calculate a polycarbonate canopy, we will formulate a couple of assumptions on which the calculation is based.

- The data given is relevant for high-quality material without signs of destruction by ultraviolet radiation. Polycarbonate without a UV filter becomes fragile after 2-3 years of operation in the light.

The absence of an ultraviolet filter causes accelerated destruction of polycarbonate.

- We deliberately neglect the limited deformation resistance of the sheathing, considering it absolutely durable.

And now - a table that will help you choose the optimal polycarbonate thickness and lathing pitch.

| Load, kg/m2 | Dimensions of the sheathing cell with polycarbonate thickness, mm | |||

| 6 | 8 | 10 | 16 | |

| 100 | 1050x790 | 1200x900 | 1320x920 | 1250x950 |

| 900x900 | 950x950 | 1000x1000 | 1100x1100 | |

| 820x1030 | 900x1100 | 900x1150 | 950x1200 | |

| 160 | 880x660 | 1000x750 | 1050x750 | 1150x900 |

| 760x760 | 830x830 | 830x830 | 970x970 | |

| 700x860 | 750x900 | 750x950 | 850x1050 | |

| 200 | 800x600 | 850x650 | 950x700 | 1100x850 |

| 690x690 | 760x760 | 780x780 | 880x880 | |

| 620x780 | 650x850 | 700x850 | 750x950 | |