Choosing rolled metal allows you to make strong and durable sashes with your own hands in a short time. At little expense, the owner receives a gate made of corrugated pipe on a rigid, stable frame. He can choose the material for lining the doors at his discretion.

We recommend that you read other articles:

- Standard garage door sizes

- How to make a garage door

Advantages and disadvantages of profiled pipes

Among the main advantages of profile products used in the production of gates, experts highlight:

- low price;

- high strength with light weight;

- possibility of self-assembly (metal profiles are easily cut, welded and connected with self-tapping screws).

Location on

The disadvantages of profile products include:

- susceptibility to rust when interacting with precipitation, which causes the formation of corrosion;

- inconvenience in priming and painting the surface of rolled pipes, which entails an increase in time spent on pipe installation.

Figured metal picket fence

As can be seen above, the advantages of profile pipes more than compensate for their disadvantages.

How to weld a fence gate from a profile pipe with your own hands

The manufacturing technology of the structure is quite simple. To weld gates from profile pipes, you need to select the type of product that best suits the design of the doors.

Installation of locks

Pipe selection

It is preferable to choose a corrugated pipe for the gate with a square or rectangular section. Pipes of this shape are easier to install and transport to the site. The most durable profile pipes are made from the following types of steel:

- stainless steel;

- galvanizing;

- carbon

The photo shows metal doors.

Forged elements

The price of pipe blanks depends on the material from which they are made. The most budget option is carbon steel products. However, when choosing carbon alloy pipes, the low strength and short service life of such products are taken into account.

Welded cold-rolled and galvanized profiles are the best option for sashes, but their cost is higher. Pipes of the same diameter can differ twice in wall thickness.

Pipes of square or rectangular cross-section are used for the sashes. It is possible to do the job correctly and with your own hands if you have a welding machine and auxiliary tools.

The photo shows the structure after installation.

After installation

Site preparation

At the preparation stage, the dimensions of vehicles entering the gate opening are taken into account. The total area occupied by swing or sliding doors is determined. Standard gate sizes are:

- overall width – 2.5–3.5 m;

- height (gates and gates) – 1m 50 cm;

- the width of the gate is 0.75–1 m.

The photo shows a gate at the dacha.

Metal picket fence on a professional pipe

Taking into account the gate, the total width of the area under the gate should be 3.5 or 4.5 m. The structure mounted on the previously installed fence is placed at the appropriate height of the fence. Sometimes a lower height of the valves is acceptable, but not less than 40 centimeters.

Drawings and calculations

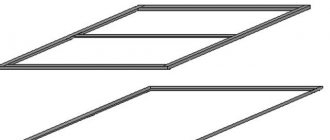

Before carrying out work, a drawing is drawn on paper. A rectangular opening is depicted with a smaller rectangle inside, indicating a profile frame indicating the length and width of the future structure. The financial costs for purchasing the necessary materials and a set of tools for the job are also calculated.

Installation diagram with dimensions

Gates made from corrugated steel pipes are assembled from various elements that differ in cross-section. The diameter of the steel pipe for the supporting wings of the support is 80x80 or 100x100 mm. The frame of the gate made of corrugated pipe is made of 50x50 mm products.

Jumpers and longitudinal strips are welded from profile sections of 20–40 mm.

In addition to the main values, the drawing shows the dimensions of the gaps between the doors, the ground and the supports. On hinged sides the approximate gap width is 5mm. Taking into account the possible sagging of the gate and its jamming in the future, a gap of 10 mm is left on the side with locks.

Sketch of a metal frame

In an area not exposed to snow and debris, clearance is taken into account at the bottom of the sashes, but not less than 20 mm. When taking into account the negative impact of external factors, the gap height is provided at 50–150 mm (decided individually).

Design Features

The gate frame, welded from metal, usually has considerable weight, so swing gate leaves must also be secured by welding to strong, rigid, stable supports.

Swing

This requirement can be easily met by manufacturing garage doors. They are attached to existing walls made of stone, concrete or other material that is highly durable and resistant.

After all, it makes no sense to make metal gates for a wooden garage or barn. The only complication is that the opening in this case needs to be welded with a steel angle in order to weld hinges or canopies to it.

If the gate is installed in a fence opening, care must be taken to ensure that the pillars that serve as supports can withstand its weight.

If the gate is swinging with a leaf width of up to 1.5 meters, filled with light material, for example, corrugated sheeting, then a round or square steel pillar made of a pipe with a diameter of 100 millimeters or more can be used as a support for each leaf.

It is enough to concrete the pillar into the ground in such a way that the lower end is necessarily deeper than the freezing level, otherwise in winter the swelling soil can push out and tilt the pillars. In this case, the gate leaves will shift from the design position.

Recoil

Sliding gates welded from metal will require the construction of a fairly serious foundation. Being a cantilever in the closed position, they will exert a large load on the support, and this load can be directed both downward and upward, that is, to be pulled out of the ground.

It is desirable that the foundation of the sash be connected together with the foundation of the supports. This will prevent them from moving relative to each other during any ground movements, which is possible from heavy vehicles passing along a nearby road.

Sliding gates are typically suspended on rollers from a beam connecting the top of the supports. The connection is made by welding and there are no special requirements for the stability of the supports.

Manufacturing of sliding gates

The sliding type of gate is highly wear-resistant and is sheathed with most durable materials (except forging). The high cost of their installation is compensated by the strength and reliability of the sliding system.

Fence of a private house

The complex design of the doors of the sliding model is welded according to a scheme identical to that of the swing model. First, by welding the required size profile pipes, a frame is created. There are various sliding gate mechanisms:

- suspension;

- rail;

- cantilevered.

How to sheathe a gate frame

Upon completion of the installation of the frame, finishing of the sashes follows. The cladding technology depends on the material used. It is advisable to use sheathing identical to the fence. Otherwise, the gate will not fit into the overall picture of the fence.

At the summer cottage

To fill the frame of the profile sashes, various variations of material are used:

- forged elements;

- sheet metal (galvanized);

- profiled sheets;

- edged and tongue and groove boards treated with primer, antiseptic or paint and varnish compounds.

Sheathing made of corrugated sheets

This is the most practical option for finishing this structure. The material is low in price and easy to install. It can be combined with forged elements (bolts, trim). Often sheets are purchased with a painted and galvanized coating. The corrugated sheeting is attached to the frame of the sashes with self-tapping screws.

Types of profiled sheets

Wood paneling

It wins in presentable appearance, but loses in durability. Wood is susceptible to rotting and mechanical damage. To improve strength and extend service life, the lumber used is treated with fire inhibitors and anti-fungal agents.

Forged elements

Often the cladding of the structure frame is made of forging elements made from metal that is heated to forging temperature and amenable to high-temperature pressure treatment. The implementation of original design solutions is possible by cutting and welding such products.

Forged doors

If you have a welding machine and a blowtorch, you can forge a metal pattern on the doors yourself. However, it is easier to buy ready-made forging elements, but they will cost much more. For example, the price for 1 m2 of finished products will be at least 1 thousand rubles.

Tools for work

When all the main parts of the gate are ready, you should decide on the lock and handles. If necessary, you will need to weld brackets to attach the handle from the inside.

Next, tools and additional materials are prepared for welding. You will definitely need:

- welding machine;

- electrodes for welding steel grades MP-3 or ANO-21;

- hammer, sledgehammer;

- protective clothing and welding mask;

- building level or simple plumb line;

- trowel or spatula;

- several sections of pipe, 1000 mm long, for lintels when concreting pillars;

- concrete solution;

- For installation and welding of hinges, embedded parts are prepared to provide gaps between the gate, hatch and floor.

Having prepared all the materials and tools, we begin to manufacture and install the gate.

Garage doors made of profile pipes

If, in addition to installing fence gates near a private house or cottage, you plan to build a garage, the frame for the garage doors can also be made from profile pipes. The most common options for garage door systems are tilt-up and swing.

Installation and welding

Creating a lift-and-turn structure

When opened, the overhead gate rises horizontally, extending outwards and creating a semblance of a canopy. The operating principle of this design is the movement of the canvas mounted on the frame around its axis. This allows you to change the horizontal and vertical position of the sash using a roller mechanism and metal guides.

Hanging on poles

After allowing the concrete to cure, they begin to install and secure the street door. Remove the spacers from the tray. Using mortgages, set the position of the gate between the pillars, maintaining the gaps.

At the bottom, to prevent rubbing when the structure sag, a gap of 100 mm is made. This will provide ventilation to the yard and prevent scuffing. Check the correct installation in all planes and begin welding the hinges.

The plates on the mating part of the loop are placed on the pole. Now you should weld the hinges on all sides of the plate. We remove the embedded parts and check the operation of the gate. It should work easily without scuffing.

Additional Information

To create gates of any design, it is more rational to buy new pipe profiles. If funds are insufficient, previously used products may be used. In this case, additional time will be required to clean the pipes from rust. If the corrosion is too deep, the use of such products is not recommended.

In a private house

New steel pipes can be purchased at a metal warehouse or online. For example, on Avito. Using the price list presented on the resource, you can find both new and inexpensive used products. Additional information on selecting and assembling profile gates can be found on specialized forums.