The production of all types of pipes made of aluminum and aluminum alloys is regulated by only three regulatory documents. They determine the production method, range and dimensions of aluminum pipes, quality characteristics, labeling rules, alloy grades, etc. Here is a list of these regulatory documents:

- GOST 18475-82 , regulating the production of cold-deformed pipes of round, square and rectangular profiles;

- GOST 18482-2018 , according to which extruded round pipes are produced;

- GOST 23697-79 , regulating the production of straight-seam welded round pipes made of aluminum alloys.

Each of the listed documents contains a section on testing of finished products, including mechanical strength indicators. Please note that aluminum pipes do not pass hydraulic tests, which means that they are not intended for pipeline construction.

Aluminum pipe

For the installation of heating systems and pipelines, aluminum pipes are often used, which is one of the types of non-ferrous metal products. Various welded structures can also be made from it. Low weight and high strength have made these products in demand in various fields of activity.

To make the pipe, aluminum strip is continuously welded. Products without heat treatment are produced from annealed billets. To produce cold-worked pipes, sheets H1, H2 and H3 are used from cold-worked aluminum, and the same products, but from the D16N grade, are produced from annealed semi-finished products using reduction technology.

Features of application for air conditioning systems

Copper is considered the traditional material for the production of air conditioner tubes, and for many consumers it may be a discovery that there is an alternative in the form of aluminum. Aluminum is approximately 2 times cheaper than copper; its use can significantly reduce the cost of connecting air conditioners. Why do many professionals still avoid using aluminum pipes for air conditioners?

Aluminum pipe after the necessary processing is used for air conditioners

The fact is that copper and aluminum react and corrosion occurs, which does not allow the use of aluminum products. However, modern technological solutions make it possible to cope with this problem. Aluminum tubes for air conditioners with copper tips have now become available for purchase. During their production, pieces of copper are welded to an aluminum tube using modern high-tech equipment using the intermolecular welding method.

The result is a reliable material for installing air conditioners at minimal cost. The attitude towards aluminum tubes for air conditioners is still quite skeptical, but users who decided to try them note the quality and significant savings.

GOST standards for aluminum pipe products

Features of the production of aluminum pipes must take into account GOST 18475-82 and GOST 22233-2001. The content of chemical elements in the alloy is determined according to the adopted GOST 4784-97. Pressed pipes are produced under the control of GOST 18482-79. Rolled pipes produced by cold deformation comply with GOST 18475-82. Straight-seam pipe products are produced by welding the strip, which is determined according to GOST 23697-79.

THE FINAL PRICE FOR AN ALUMINUM PIPE DEPENDS ON THE TERMS OF DELIVERY (QUANTITY, TERMS OF PAYMENT, DELIVERY), THIS PRICE LIST IS FOR INFORMATIONAL NATURE ONLY!

PLEASE CHECK PRICES by calling (812) 931 5252 and (499) 390 5252

Dear customers! To avoid waiting for shipment at the warehouse, we ask you to pick up the selected goods only after receiving a notification to your email!

We try to save your time.

sells round aluminum pipes from warehouses in Moscow and St. Petersburg. To buy round aluminum pipes, as well as other products, please use the search by brand and size on our website or call

in Moscow

in St. Petersburg, 322-95-91.

From us you can buy aluminum round pipes of various sizes. The price for a round aluminum pipe is presented on the website. We carry out cutting of aluminum pipes to any size, retail sale, delivery to the address.

Duralumin pipe D16t, aluminum pipe AMG2, AMG3, AMG5, pipe AD31 is a hollow profile of different sections, made of aluminum and its alloys.

Aluminum pipe is distinguished by high performance characteristics: long service life, resistance to the destructive effects of corrosion and chemically aggressive substances, low weight and high strength.

The scope of application of aluminum pipes is quite wide - from road construction and oil production to public utilities. They are indispensable in the construction of ships, aircraft, cars and industrial equipment. They are successfully used in the manufacture of radiators, gas tanks, pipelines for fuels and lubricants, gas pipelines, water pipelines, heating systems, drainage systems and air ducts.

Aluminum pipe is made from the following grades of alloys: AMg2, AMgZ, AMgZS, AMg5, AMg60, AD31, AD35, AB, AD00, AD0, AD1, ADS, AD, AMTs, AMTSS, D1, D16, AK6, V95, the chemical composition of which must comply GOST 4784 and GOST 11069

You can buy aluminum pipes from us:

1.

Duralumin pipe D16. In another way, the material used to make this pipe is called duralumin or duralumin. This aluminum alloy with alloying substances (copper, magnesium, manganese, etc.) is particularly durable;

2. Aluminum pipes D16T. These pipes are made from the same duralumin, only heat-treated.

3.

Duralumin D16T is a material that is subject to heat treatment, hardening and aging. The popularity of pipes made of D16T duralumin is explained by their high strength (including static and fatigue strength) and fracture toughness. High levels of corrosion resistance are achieved by cladding pipes with pure aluminum;

4. Aluminum pipe AMg2M - has such characteristics as high ductility, thermal conductivity, resistance to aggressive environments and easy weldability.

Aluminum pipe is classified according to production method:

- pressed pipes made of aluminum and aluminum alloys in accordance with GOST 18482-79; cold-deformed pipes made of aluminum and aluminum alloys in accordance with GOST 18475-82; longitudinally welded pipes made of aluminum alloys in accordance with GOST 23697-79.

The standard provides for the following cross-sectional shapes of aluminum pipes (round, square, rectangular and profile). Moreover, round aluminum tubes can be thick-walled or thin-walled.

Another criterion for the classification of aluminum pipes is the type of heat treatment, according to which the pipes are divided into: annealed (m); hardened and artificially aged (T1); hardened and naturally aged (T); without heat treatment.

Aluminum tube has high ductility, corrosion resistance and thermal conductivity. The material used can be easily machined and welded in various ways. It is hygienic and can be successfully used in a wide temperature range when exposed to aggressive environments.

Can you tell which aluminum sheet is used in each picture? Are you at a loss? Let’s try together to understand the main aluminum alloys and their applications.

First, let's look at the condition of aluminum sheets.

GOST 21631-76 defines 7 possible states of the sheet, we will focus only on the most common ones:

1) annealed - M;

Soft aluminum sheet, easy to deform.

2) semi-hardened - H2;

The aluminum sheet is more rigid than in the “M” state and is also easily deformable (withstands bending up to 90 degrees). It holds its shape well, its rigid state prevents the formation of dents, therefore it is most often used in thermal insulation of pipes.

3) cold-worked - N;

Cold hardening is a method of hardening metal using cold deformation (additional rolling on a machine).

4) hardened and naturally aged - T;

Solid aluminum sheets. More difficult to process (it breaks when bent at 90 degrees). Used in parts and assemblies with high loads.

Alloys 1105, VD1.

Technical aluminum sheet is used as an insulating and finishing material.

The low weight of the sheet and its flexibility ensure low costs and convenience when carrying out insulation work. The most commonly used alloys are 1105AN2, VD1AN2. AD1N2 alloy is also used for thermal insulation.

Alloys of the aluminum-magnesium group: AMG2, AMG3, AMG5, AMG6.

Acid-resistant aluminum sheet is made from aluminum alloyed with magnesium and manganese.

The AMg2M, AMg3M, AMg5M, AMg6M grades have high anti-corrosion characteristics and are perfectly weldable. Therefore, they are widely used in the production of welded containers, fuel tanks and other parts in aircraft construction. Excellent for both industrial shipbuilding and private production of boats, boats, catamarans.

Alloys AD1, A5.

Food grade aluminum sheet is made from grades of primary aluminum - cold-worked (A5N, AD1N), semi-hard-worked (A5N2, AD1N2), annealed (A5M, AD1M).

AMC alloy.

Sheets made of aluminum grade AMts have increased ductility and are easily deformed. They are used in a semi-hardened and cold-worked state in the automotive industry for the manufacture of radiators, frames, and rivets. Can also be used in food production, but without direct contact with food.

Alloys D16, D19, V95.

D16AM is annealed duralumin with normal cladding.

D16AM is a high-strength type of duralumin and is resistant to external influences. D16AM does not become brittle in the cold, therefore it is used in conditions under which the use of other types of steel becomes impossible. D16AM alloy sheets are most widely used in the production of various parts manufactured by stamping.

D16AT - made from an aluminum alloy with alloying elements, the main of which is copper. The alloy is used for the manufacture of bent profiles. The advantage of D16AT is that a part made from such an alloy is immediately hard, without additional heat treatment.

D16T – duralumin, made from an alloy of aluminum with copper and manganese.

D16T has good ductility and increased fatigue characteristics. The range of applications of the alloy is wide. D16T is used in construction, aircraft manufacturing, shipbuilding, furniture production and other industries.

B95 is a durable aviation alloy. It is used for wing top skins (plates, sheets), stringers (bent sheet and pressed), beams, struts and other elements of the fuselage and wing of modern aircraft (TU-204, Il-96, Be-200) and other highly loaded structures operating in mainly for compression.

Alloys D16, V95 cannot be welded by argon-arc and gas welding. Therefore, rivet joints are most often used for joining semi-finished products (thick sheets, profiles and panels).

Aluminum pipes have many advantages, including high resistance to aggressive substances, long service life and ease of installation. An important advantage is the low cost of the products. Due to these advantages, pipes are used in various fields.

Aluminum is a popular metal that has many advantages and is used in various fields. Aluminum pipe was used to construct sewer and water supply systems back in the days of the Soviet Union.

Aluminum products have created quite serious competition with their cast iron and steel counterparts. The main advantage of pipes is their high resistance to corrosion. As a result, their service lines increase significantly.

Recently, the popularity of aluminum pipes has increased. Today, the market offers a wide range of such products from various manufacturers.

Varieties

Depending on certain characteristics, aluminum pipes are divided into several types. Depending on their purpose and shape, products can be round or shaped. If the wall thickness is no more than 5 mm, then these pipes are considered thin-walled, and if the wall is thicker than 5 mm, they are considered thick-walled. Metal processing technology determines the following types of pipes:

- without heat treatment (no designation);

- annealed (marked with the letter “M”);

- hardened and naturally aged (designated as “T1”);

- hardened and artificially aged (o).

The manufacturing method affects the strength and other parameters of aluminum pipes, which may determine their scope of application.

Design Features

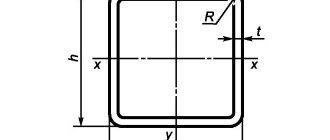

Square and rectangular pipes have no special features compared to steel products. But shaped products are found in very unusual and interesting cross-sectional shapes: in the shape of a semicircle, triangle, semi-oval, rhombus, complex shape, with external ribs - they are used to make stairs and stepladders. The plasticity of the material makes it possible to obtain interesting products for decorative finishing of premises.

Assortment

Aluminum pipes are produced in both regular and unmeasured lengths. In the second case, their length is 1.5-11.8 m if the diameter is in the range of 10-75 mm, and with a diameter from 76 to 220 mm, the length will vary from 5 to 12.5 m. Products with measured lengths have the following the same extreme parameters as unmeasured pipes. The difference is that rolled products have certain dimensions, the difference between which can be 100 mm.

The production of products of multiple measured lengths takes into account an allowance of 5 mm when cutting. The maximum length error for measuring aluminum pipes with an outer diameter of 10-75 mm is no more than 30 mm. Pipe products with a diameter of 76-220 mm may have a deviation in one direction or another of no more than 20 mm.

The weight of 1 meter of aluminum pipe depends on the diameter and wall thickness, and the alloy grade can also affect this indicator. Typically, to calculate the theoretical weight of 1 meter of rolled pipe, the default density of B95 aluminum is 2.85 g/cm. To more accurately calculate the weight of aluminum pipes from other grades of aluminum, you need to use already known coefficients, which can be found in a special reference book.

Tips for choosing

When choosing aluminum products, you should carefully consider the future design and determine the required dimensions, wall thickness, and profile finish. When purchasing, you should carefully inspect the purchased material. The pipes should not have cavities, cracks, non-metallic inclusions, delaminations, sink marks, looseness, bubbles, or strong dents.

When purchasing, require a certificate - otherwise you can buy a soft aluminum pipe instead of a durable alloy. Scratches and shallow scratches, small stains, tarnished colors, and residues of technological lubricant are allowed on the surface. If you buy material with a decorative coating, you should carefully inspect the coating.

Approximate price and best manufacturers

The best producers of rolled aluminum in Russia are Samara Metallurgical Plant, Kamensk-Uralsky Metallurgical Plant, Stupinskaya MK, Agrisovgaz, Belokalitvinsky MPO. Prices for common pipe sizes for small metal structures (per linear meter):

- 25x25x2 mm from ADZ1 T1 alloy - from 150 rubles/m.

- 30x30x2 mm from ADZ1 T1 alloy - from 170 rubles/m.

- 40x20x2mm from ADZ1 T1 alloy - from 170 rubles/m.

These are prices for inexpensive pipes; pipes from other manufacturers can cost twice as much, imported ones are even more expensive.

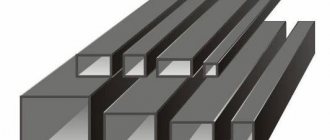

Aluminum profile pipe

Profile rolled aluminum pipes usually have a rectangular (PR) or square (KB) cross-section, but there are also shaped (FS) products. They may differ in length, diameter and wall thickness. Such aluminum pipes are often used to create various structures with low weight but high strength. Profile products are widely in demand in the construction sector, agriculture and various industries. They have anti-corrosion properties and resistance to aggressive environments. Due to its beautiful appearance, the profile is used as design elements for interior design.

Profile-type pipe products have the following advantages:

- the weight of finished structures is reduced because less material is required to manufacture the profile;

- Thanks to the shape and weight, the transportation and storage of metal products is simplified;

- the profile section makes aluminum pipes more rigid, due to which they can withstand high loads;

- To create certain structures, profile pipe rolling is often required.

Installation and connection of aluminum pipes with a profile section can be carried out by welding or using fittings that are selected for a specific case.

Depending on the cross-section, profile products are of the following types:

- Square. Such aluminum pipes withstand the same load, regardless of which side it acts on; rectangular. Typically used when one side is subject to a higher load;

- Shaped. These products are necessary in special situations when a profile with a section of a certain shape is required.

Profile products are used to create communications not only indoors, but also outside. Communications made from these aluminum pipes are lightweight, reliable and have a long service life. The use of rolled profiles allows us to achieve a reduction in the overall price of a ready-made structure.

Depending on the manufacturing method, profile products are divided into the following types:

pressed pipes obtained through the action of a press; cold-formed. To produce such pipes, an aluminum circle is required to act as a blank. Then, through certain actions (drawing, firmware, calibration), the desired profile is obtained; welded These products are made from aluminum strips by welding. After welding the sheet metal, hot tempering is performed, which is intended to relieve stress on the resulting seams.

Seamless products have no joints or welds, due to which all loads on the aluminum pipe are distributed more evenly. Even a small profile, the edges of which do not exceed 20 mm, can withstand serious loads. The most common profile-type pipes are square products, with each side measuring 40 mm. They are used in various fields of activity to create reliable and lightweight structures.

Installation Tips

Welding aluminum requires a highly qualified welder, and this method is usually not used at home. But it is possible to fasten using crab systems, fittings and bolts - the most popular methods of assembling metal structures. It is advisable to install using crab systems.

To fasten with crabs, you will need two wrenches, M8 bolts, and a crab connection. The corrugated pipes are cut to size and the burrs are removed.

The blanks are inserted into the crab all the way, lightly tightened with bolts, the angles are checked, the bolts are tightened tightly. If you are assembling a large structure, it is better to “bait” the entire structure, measure the verticality and horizontality of the pipe blanks, the squareness of the corners, and then tighten all the bolts, starting from the bottom. This type of work is best done together.

You can assemble part of the structure on a flat horizontal platform, and then lift it and install it. Having installed two walls of a canopy, gazebo or greenhouse, install and attach all the transverse pipes, measure, assemble the other walls, measure again, tighten the bolts completely.

When assembling structures using bolts, it is imperative to use connecting plates. Before assembly, holes should be drilled in the bolts and plates, then assembled and tightened.

Round pipe made of aluminum and its alloys

One type of rolled metal product is an aluminum pipe with a round (CR) cross-section. These products vary in length, outer diameter and wall thickness. Round rolled metal can be made from aluminum and from its various alloys, for example, V95, AD00, AMg2, AB, AMts, D1 and other grades. By using certain alloys, it is possible to make an aluminum pipe with the required characteristics of strength, softness, corrosion resistance, etc. This opportunity expands the scope of application of pipe products.

The following parameters are typical for round aluminum pipes:

outer diameter varies between 8-160 mm; wall thickness is 1-15 mm; the length of the product is unmeasured; the level of manufacturing accuracy can be either normal or high; strength characteristics are normal, high or increased; goods are stored and transported in coils or in the form of lengths.

The presence of contamination and various damages on the surface of the material is not allowed, and there should be no burrs at the cut site.

One of the best alloys for the manufacture of such aluminum pipes is considered to be the AD31T1 grade. Pipe products made from this alloy are the most common and are needed in various fields of activity. Most often these products are used in the plumbing field. They are used for laying water pipes, both hot and cold. Such aluminum pipes are also needed to connect heating systems (they are connected to batteries). To install a “warm floor” in a room, you should choose pipes from other materials, because aluminum does not have sufficient flexibility for this purpose.

Depending on the wall thickness, aluminum pipes are divided into thin-walled and thick-walled. Their variety is also influenced by the method of heat treatment, according to which round rolled metal is divided into annealed (M), hardened and artificially aged (T1), hardened and naturally aged (T), as well as products without heat treatment.

The material of aluminum pipes has plastic properties, anti-corrosion resistance and good thermal conductivity. The metal is easy to process and has excellent weldability. Also, the metal does not emit harmful components, remains chemically neutral to many substances and can be successfully used under conditions of temperature changes.

Features of operation

It should be remembered that the connection using bolts or crab systems is serviceable, and periodically - 1-2 times a year - it is necessary to check the connection and tighten the bolts.

Possible problems

It should be borne in mind that the strength of aluminum is still less than that of steel, and a large rack loaded with preparations for the winter is not the best use for duralumin structures. But all kinds of awnings and canopies, enclosures and light shelving are exactly what aluminum corrugated pipes are intended for. In addition, such pipes do not like large lateral loads - the pipe may bend.

Packaging, transportation and storage

Aluminum profiles can be scratched and even bent during careless transportation or storage. Therefore, when transporting, they should be laid in such a way that heavy objects do not put pressure on them (or fall!). A couple of pieces of wood or a bag of putty weighing 25 kg will not do much damage to large pipes, but a fallen door, window, or steel corner may well leave a dent or bend the pipe.

It’s a good idea to pack products in cardboard and polyethylene, especially if the pipes have a decorative coating. There are no special requirements for the storage of aluminum and alloys. But if you know that this alloy is not resistant to corrosion, store collapsible structures under the roof, or even better, in a garage or shed, and not on the street or in the basement.

Pipe sizes

Thin-walled aluminum pipes are those whose wall thickness does not exceed 5 mm. Most tubular manufacturers produce such products. Thick-walled pipes include products with a wall thickness of at least 5 mm.

All dimensions and estimated weight of 1 meter of cold-deformed steel are specified in GOST 18475-82. For welded pipes, GOST 23697-79 is provided, and the parameters of extruded products can be found in GOST 18482-79.

According to GOST 18475-82, the outer diameter can be 6-120 mm and 130-150 mm. The wall thickness ranges from 0.5-5 mm. The theoretical weight of 1 meter of aluminum pipe varies from 0.023 to 4.948 kg. In accordance with accepted GOST, the length can be either measured or unmeasured. For small rolled pipes, the length is in the range of 1-6 m, and with a larger outer diameter, the length of the products will be no more than 4 m.

GOST 18482-79 involves the production of rolled pipes with a round cross-section, the diameter of which can vary between 18-300 mm, while a wall thickness of 1.5 to 40 mm is allowed. The estimated weight of one meter of aluminum pipe can be 0.222-93.116 kg. The length of pipe metal products according to this GOST can be measured, unmeasured, and also a multiple of measured. All pipes, taking into account the accepted standard, must have a length in the range of 1-6 meters. In GOST 18482-79 you can find tables of sizes and weights for aluminum pipes of different brands.

Mechanical properties according to GOST 18475

According to GOST, an aluminum pipe has the mechanical properties that are given in the table.

Table 3

| Alloy grade | Wall, *10 mm | Material condition | Pipe side, *10 mm | Relative elongation, * 10, % | Yield strength, *10-1 GPa | Tensile strength, MPa |

| Not less | ||||||

| AD0, A5, A85, A8, AD1 | All thicknesses | Annealed | All sizes | 2 | — | 60 (for AD1 60-110) |

| Up to 0.2 | Hardened | 0,4 | — | 80 (for AD1 110) | ||

| 0,2-0,5 | 0,5 | — | 80 (for AD1, 100) | |||

| AMtsS, AMts | All thicknesses | Annealed | 1,5 | — | 90-135 | |

| Hardened | — | — | 135 | |||

| AMg0.7, AD31 | Annealed | 1,2 | — | No more than 155 | ||

| Hardened | — | — | 155 | |||

| AMg1 | Annealed | 1,0 | — | 120-175 | ||

| Hardened | — | 165 | ||||

| AD31 | After hardening, cold-hardened and naturally aged | 0,4 | 2,45 | 265 | ||

| After hardening, cold-hardened and artificially aged | 0,8 | 2,75 | 315 | |||

| Naturally aged and tempered | 1,3 | — | 174 | |||

| Artificially aged and hardened | 0,7 | — | 245 | |||

| AB | Annealed | 1,7 | — | No more than 145 | ||

| Naturally aged and tempered | 1,4 | — | 205 | |||

| Artificially aged and hardened | 0,8 | 2,25 | 305 | |||

| Hardened | — | — | 145 | |||

| D1 | Annealed | 1,0 | — | No more than 245 | ||

| Up to 0.10 | Naturally aged and seasoned | Up to 2.2 | 1,3 | 1,95 | 375 | |

| 0,10-0,50 | 1,4 | 1,95 | 375 | |||

| Up to 0.10 | 2,2-5,0 | 1,2 | 2,25 | 390 | ||

| From 0.10 to 0.50 | 1,3 | 2,25 | 390 | |||

| All thicknesses | More than 5.0 | 1,1 | 2,25 | 390 | ||

| All thicknesses | Hardened | All sizes | — | — | 245 | |

| 1955 | All thicknesses | Annealed | All sizes | 1,0 | — | No more than 245 |

| From 0.10 to 0.15 | Naturally aged for 30-35 days. and hardened | Up to 4.0 | 1,0 | 1,95 | 335 | |

| 0,15-0,50 | 1,0 | 1,95 | 335 | |||

| 0,10-0,15 | Naturally aged for 2-4 days. and hardened | 1,0 | 1,75 | 235 | ||

| From 0.15 to 0.50 | 1,0 | 1,75 | 235 | |||

| 0,15-0,50 | After hardening, it is hardened and aged naturally for 30-35 days. | 1,2-4,0 | 0,6 | 2,25 | 355 | |

| After hardening, it is hardened and aged naturally for 2-4 days. | 0,6 | 1,75 | 265 | |||

| After hardening, cold-hardened and artificially aged | 1,0 | 2,55 | 375 | |||

Aluminum pipe production

Aluminum pipes can be produced by pressing, welding or cold forming. Each of these methods is relevant and allows us to produce high-quality products of different sizes. For the production of aluminum pipes, aluminum alloys of different grades are used, for example, AMts, AMg1, AD31, etc.

There are several production steps involved in the production of extruded pipe. First, the semi-finished product is heated to the required temperature, after which it is subjected to a special press to obtain a round shape. Next, pressing is carried out with a stamp, due to which a through hole appears. At the next stage, the product is hardened. The final stage must be agreed upon with the buyer. It involves additional treatment of the surface of the aluminum pipe with a special coating, due to which the material is endowed with increased protective properties.

Welded pipes are made from aluminum strip. The blanks are sheets of alloy grades AMg2, VD1, AMg3, D16, etc. To produce straight-seam products, the continuous welding method is used. Stress on the seams is removed using a hot tempering procedure. The outer diameter of such aluminum pipes is determined by GOST 23697-79, according to which it must be at least 10 mm and no more than 220 mm.

Seamless rolled tubular products obtained by cold deformation are made from aluminum grades AMg2, AMg3, AMg5, AMg6 and D16. To produce cold-deformed aluminum pipes, round blanks are drawn, pierced and calibrated at reduced temperatures. Seamless products are in demand in various industries.

Finished products must have a clean and smooth surface. In accordance with quality standards for aluminum pipes, the presence of any burrs and roughness is not allowed. There should be no signs of rust or burnout. Defects such as cracks, holes or chips are also unacceptable. All requirements apply not only to the surface of the product, but also to the place of cut.

Dents and scratches that do not affect the minimum permissible size of the aluminum pipe are not considered a defect. Spots, round streaks and lubricant residues are also acceptable.

How are they produced?

The technology for manufacturing aluminum profile pipes is fundamentally no different from the technology for manufacturing steel professional pipes. The ductility of aluminum and its alloys facilitates manufacturing. Pipe manufacturing methods: welding, cold deformation, pressing. Heat treatment after manufacturing is mandatory; it relieves stress in the metal.

Production technology

Welding is carried out as follows - cutting the sheet into strips, bending the strips and electric welding. Then the workpiece is molded (rolled) into the desired profile. The plasticity of aluminum allows this to be done without intermediate heat treatment. Then the pipe is released - heated and cooled, while internal stresses in the metal are relieved. As tempting as this method is, it also has its drawbacks - the metal in the area of the weld is not as strong as the rest of the pipe, and it is in this place that leaks or cracks may appear over time.

Welding aluminum is a rather complex process and requires a highly qualified welder. Therefore, it is recommended to install these pipes in unloaded structures that do not require special tightness, and mainly in everyday life.

Pressing - a heated workpiece is passed through a special press and the sleeve is squeezed out, as it were. Pressing allows you to obtain a durable pipe of good quality.

During cold deformation (drawing), the pipe is pulled out in a cold state, a profile is formed (circle, square, oval) and calibrated. Then subjected to heat treatment. This method produces pipes of the highest quality, with high dimensional accuracy, with a thin wall, and minimal dimensions. The disadvantage is the high cost.

Aluminum products can be subjected to heat treatment: hardening, annealing, artificial or natural aging.

Scope of application and properties

The Resurs company provides aluminum pipes of different diameters, the cost of which can be found on the website. If necessary, the rolled pipe is cut into any lengths. Both retail and wholesale purchases of goods are available. Aluminum pipes are available from the alloy AMg2, AMg3, AMg5, AD31 and D16t, which differ in properties and scope of application. Our specialists will help you choose the most suitable option for a particular case.

All aluminum pipes have many positive qualities. They are characterized by high reliability, strength and durability. The material has anti-corrosion properties and resistance to aggressive environments. Light weight makes it much more convenient to use.

The scope of use of aluminum pipes is very diverse. They are in demand in the agricultural industry, construction and oil production. These products are used in ship and aircraft construction, as well as in the production of vehicles and industrial plants. They are necessary in the manufacture of heating systems, fuel tanks and pipelines for certain chemicals. Rolled aluminum pipes are used for laying water pipelines, ventilation and drainage systems.

Pipe classification

For the production of aluminum pipes, many different alloys can be used, for example, AMg2, AMg5, AD31, ADS, AB, AMts, D16, V95 and others. GOST 4784 and GOST 11069 determine the composition and proportions of the content of certain elements in these alloys.

The Resurs company offers aluminum pipes from the following popular materials:

D16. These duralumin pipes are made from an aluminum alloy with additives such as copper, magnesium and manganese. The products are characterized by increased strength; D16T. For the manufacture of this rolled pipe, the same material is used as for the D16 brand. The difference lies in the presence of additional heat treatment. Duralumin has high strength characteristics and good impact strength. The use of cladding technology gives aluminum pipes additional resistance to corrosion; AMg2M. Metal products made from this grade of aluminum are characterized by good ductility and thermal conductivity. It is easy to process, has excellent weldability and can be used under the influence of aggressive substances.

Advantages and disadvantages

If we compare the pros and cons of aluminum profile pipes, there are many more advantages:

- Low weight - three times less than that of steel structures - this makes construction, transportation and installation easier.

- Variety of profile shapes and colors for decorative products.

- Great strength.

- Plasticity - pipes bend easily.

- Resistance to corrosion - even alloys that are susceptible to it still corrode much slower than steel.

- Resistance to high and low temperatures.

- Aesthetic appearance.

- Durability.

- Easy to maintain.

- Manufacturability – professional pipes are easy to install; You can use welding, crab systems, fittings, bolts.

- Low thermal expansion.

- Wide operating temperature range from -80° to +120° C.

- Complete and fairly harmless recycling - aluminum is completely melted down and used to produce other products.

The disadvantage is the relatively high price and softness of pure aluminum. In addition, it should be borne in mind that aluminum pipelines are not used for drinking water (and food products).

What affects pipe quality

A high-quality aluminum pipe should have a smooth surface, without chips, dents or other damage. The cut of such a product will be smooth and without burrs. It is also important to have a deformation tolerance for each meter of pipe. The degree of quality of rolled pipes also depends on the composition of the material, which is determined chemically or spectrally.

The outer diameter and wall thickness are measured using a micrometer, which can provide sufficient measurement accuracy. To check the straightness of an aluminum pipe, certain steps are performed. First, the product is placed on a test plate, and then a special meter ruler is attached to it. Next, feeler gauges are used to measure the largest gap between the ruler and the surface of the pipe.

The outer surface of the rolled metal product is inspected without the use of any devices. Aluminum pipes supplied in coils are checked during winding. Inside, the product is viewed through an illuminated screen. If the products are packaged in coils, then the inner surface is checked on small sections of pipes, for which a sample of at least 100 mm in length is cut from one of the edges.

Cracks, swelling, chips, traces of corrosion, burns and other defects of various origins are not allowed on both the internal and external surfaces of products. There should be no longitudinal burr on the outside of the aluminum pipe, and on the inside this defect is allowed only if its height does not exceed 2 mm. The depth of damage and defects is checked using special instruments in accordance with accepted standards.

The following minor defects are allowed on the metal surface of an aluminum pipe:

small sunsets, scratches, abrasions, nicks and other defects, the depth of which does not violate the permissible error limits for wall thickness; displacement of the edge by no more than 10% of the original wall thickness of the pipe; tarnish, spots and ringing; lubricant residues; traces of deburring; small dents.

The last defect must be within the diameter tolerance if the aluminum pipe has a diameter of no more than 75 mm and a wall thickness of 2-3 mm. For products of the same diameter, but with a wall thickness of 0.5-1.5 mm, a dent with a depth of no more than 1.5 mm is allowed. If the diameter of the rolled pipe is more than 75 mm, then, regardless of the wall thickness, a defect of up to 5 mm is allowed.

Product standardization

The characteristics and production of rectangular profile pipes are regulated by several documents. The range of products is certified in accordance with GOST 22233 and standard 8617-81. Document 22233 gives the characteristics of profiles made from aluminum alloys by hot pressing, which are intended for use in translucent structures of structures and buildings.

Also an important document, which contains the classification of aluminum products, technical requirements, assortment, maximum dimensional deviations, conditions for acceptance and testing of pipes, is GOST 18475, approved in 1982. This standard applies to cold-formed structures intended for export and the national economy.

There are thin-walled (with a wall up to 0.05 * 100 mm) and thick-walled (with a wall more than 0.05 * 100 mm).

Features of packaging, transportation, storage and labeling

All aluminum pipes with a diameter of no more than 60 mm are bundled. They should have a label attached with markings that provide information about the grade of metal, batch number and other nuances.

On the edge of any thick-walled pipe with a diameter greater than 60 mm, it is necessary to extrude or mark with paint such data as alloy grade, metal condition, batch number and quality control mark from the manufacturer.

Thin aluminum pipes that are wound into coils must be fixed with wire in at least three places. An icon with exactly the same information as in previous cases is attached to already packaged products. You should know that bobbins are returnable containers.

Characteristic advantages of seamless pipes

Having considered the classification of aluminum pipes, it is worth citing the significant advantages of seamless structures, which are as follows:

- In fact, there are no seams on the surface, which makes it easy to use them under high pressure without the risk of breakthrough and loss of tightness. This is the best option that everyone who makes a decision regarding the installation of utility lines with similar materials must pay attention to;

- For thick-walled pipes this is the most relevant solution, because it ensures a uniform appearance of the anodized surface itself. This definition is especially in demand when laying main pipelines, for which extruded aluminum pipe is widely used;

- The absence of welds is still relevant taking into account those features when coolant is distributed. In this case, divergence and flattening may occur in the seamed pipes during deformation. For example, a 28 mm pipe B95T1 GOST 1882-79 will be an ideal solution for installation in such communication lines;

- Much greater structural strength is also noted, which makes it possible to expand the scope of application of the pipe range and guarantee the fulfillment of all functional responsibilities assigned to them.

Order aluminum pipes from the Resurs company

Resurs employees are qualified specialists. They can advise on cooperation issues or provide information about a product the client is interested in. To do this, just call or use the website, where you can also familiarize yourself with our metal products.

The Resurs company offers an aluminum pipe with a round cross-section, which is in demand when laying water supply, gas pipelines and ventilation. You can also purchase from us a profile with a square or rectangular cross-section, which is actively used in the construction industry for the construction of lightweight and durable structures.

We are engaged not only in the wholesale and retail sale of aluminum pipes, but also provide additional services. We can cut rolled pipes into the required lengths, and you can order the pipes to be coated with paint or a special protective layer. There are also other services that can be found on the website or call + 7 (495) 215-50-72

The Resurs company has in stock aluminum pipes made from various alloys. The warehouse has round and profile metal products of various diameters and lengths. You can also always choose the required wall thickness.

To order aluminum pipes or other products, just select the desired product on the website and fill out the contact information. After this, our employee will call to clarify some points and coordinate delivery. It is also possible to place an order by phone.