A pipe saddle is a separate element of the pipeline, with the help of which a branch of the main line is quickly and efficiently arranged (sometimes it is called a clamp). Saddles can be installed on domestic and industrial water supply, sewerage, heating and gas systems. You can select the most optimal device for certain conditions and install it yourself.

Devices for branching pipeline systems

Description of elements

A saddle for a HDPE pipe is a special part that consists of two parts that compress the pipe on both sides. That is why the element has a second name - a clamp for insertion. With the help of a saddle, branches are created on irrigation, sewer, gas and water mains. In addition, these may be private pipelines.

Some types of saddles have a design that allows the elements to be used for tapping into pipelines operating under high pressure. This greatly simplifies the installation of individual sections in sewer and water supply networks.

The saddle is installed so that the integrity of the low-density polyethylene pipe is not compromised. Most models have their own cutter that allows you to drill holes of the required diameter. This allows the device to be used in hard-to-reach places such as mines, collectors and wells. You can install the saddle on a new or already functioning network. It is possible to use the device when laying open communications from HDPE. Using a saddle, you can make a tie-in on any section of the pipeline (about

Do-it-yourself saddle installation

How to install a tie-in clamp? The installation diagram depends on the type of fitting used.

Installation of crimp and flange saddles

A threaded crimp or flange saddle is mounted according to the following scheme:

- the section of the highway on which it is planned to install a branch is blocked;

- the installation site of the fitting is cleaned of dirt, corrosion if the pipe is metal, and degreased;

- The saddle is fastened and the fitting is tightened with bolts;

Installation of fitting on the main line

- a hole is drilled to connect an additional line;

Preparation of a secondary highway branch

- a secondary pipeline is connected using a threaded or flanged connection.

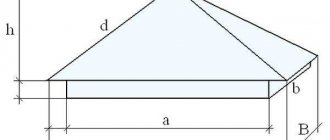

Characteristics and design of the crimp clamp

The saddle, made in the form of a crimp clamp, is considered the most accessible element, as it has a low cost. The main material for the manufacture of the device is PP-B polypropylene. The minimum diameter of this type of saddle is 2 cm, the maximum is 31.5 cm. The operating temperature of the element should not exceed 450C. An important characteristic of the saddle-collar is its protection from ultraviolet radiation.

Installation of a saddle of this modification on a pipe is carried out by tightening two curved halves, one of which has a threaded outlet. This makes it possible to install various bends, tees, ball valves and adapters with external threads.

In addition, there is a place inside the outlet where a rubber O-ring can be installed. The installed clamp for HDPE pipes and the maximum tightened bolts ensure reliable tightness at the insertion point. In this case, the permissible operating pressure of the connecting unit can reach 10 atmospheres. The thread of the outlet has a standard size, which allows you to install the saddle on a metal pipe in parallel with other connecting elements made of plastic or steel.

The saddle for a pipe made of low-pressure polyethylene in the form of a crimp clamp has a fairly simple design, which allows you to easily and quickly install the element by attaching the HDPE pipe to a wall or other base. In addition, the device is resistant to various chemical elements, making it possible to use in any environment.

Benefits of using a saddle

The saddle consists of two halves. This will allow the pipe to be pressed tightly on both sides. The purposes for using devices may be different, it all depends on the situation. At the same time, they can be embedded into the system without disconnecting communications.

When choosing a saddle for a polyethylene pipe, you should take into account its dimensions

Saddles are actively used in industry. They are also used to equip sewers with a pipeline size of 110 mm. Products are rarely used for gas and heat pipelines.

There are compression and electric welded models. Compression options are used for steel water pipes. There will be no difficulties during installation, but more effort is required than when equipping an electric-welded model.

The popularity of saddles is due to a number of advantages:

- Practicality;

- Affordable price;

- Simple and quick installation;

- High quality connection;

- Reliability.

But the clutch also has negative sides. It should be noted that the device has high performance characteristics. But modern tees are still superior to this connection method.

Saddle pad: description and types

For installation on HDPE pipes, a special device was developed - an electric-welded saddle for polyethylene pipes. Its installation is carried out using electric diffusion welding, so the device has an additional name - electric welded saddle. The main application is water and gas products made of low-density polyethylene. The lower part of the device is equipped with a heating element, which is installed during the manufacturing stage of the part.

An electrodiffusion welding machine is used to bond the saddle and HDPE pipe. This is a modern device with a function that allows you to automatically set the voltage and operating time depending on the type of fitting. To do this, the manufacturer applies a barcode to the electric welded saddle, allowing you to select the desired operating mode. As a result, the possibility of erroneous selection of parameters for welding is eliminated. At the bottom of the lining saddle there is a belt that secures the device to the pipe in a certain place immediately before welding.

In the process of heating the spiral with an electric current of a given power over a certain amount of time, part of the pipe and saddles become soft, that is, melted. When cooled, these parts form a cast system. A connection using a saddle-plate on a water pipe can withstand a pressure of 16 atmospheres, on gas pipes – 10 atmospheres. When using the necessary equipment, saddles equipped with a special valve can be used to insert into the line under pressure. Thanks to the monolithic joint of the saddle with the pipe, a particularly strong connection is achieved. This gives the device a great advantage, despite its high cost.

According to the design, saddle pads can be of the following types:

- With head swivel part . This is a prefabricated structure, the elements of which have a cross-section of at least 4 cm and no more than 40 cm.

- With a head fixed part . For this design, the cross-section range is no less than 6.3 and no more than 22.5 cm. In this case, a branch perpendicular to the main pipeline is possible.

The saddles are attached to the head part using bolts and nuts followed by welding. In addition, a saddle wrench is required, with which the cutter located in the head part is inserted into the pipe. This creates a suitable degree of tightness.

- Without head part . In these types there is either a welding outlet or a cast pipe. In the first case, the simultaneous installation of both the saddle and the outlet pipe is assumed. In the second, the saddle is installed on the pipe by butt welding or using an electric welding coupling.

- In addition, the saddle for HDPE pipes can have a mating part , or it can be made without it. When using the second option on large-diameter pipes, special straps are required that will prevent the saddle from moving during the welding process.

Conclusion

We examined the design and operational features of the main types of saddle bends, which can be used on both domestic and large pipelines for various purposes. The instructions for using these devices with your own hands are simple, and therefore you can cope with this task yourself.

If you still have any questions that require comprehensive answers, watch the video in this article.

Did you like the article? Subscribe to our Yandex.Zen channel

Prices for equipment and services

The average price of a simple pipe welding machine is 3,000 rubles. There are examples that cost 50,000 rubles, but this is a technique for professionals.

A polypropylene pipe costs from 20 to 100 rubles per linear meter. The price depends on the diameter of the product and the presence or absence of a reinforced layer. The cost of fittings is from 10 to 300 rubles.

Prices for plumbing work vary slightly. On average, a comprehensive pipe layout 12 meters long with tees and other connections will cost you at least 11,000 rubles.

The complexity of the work and the presence of hard-to-reach areas significantly increases the final cost.

Main characteristics

A saddle or saddle branch is a part that provides a secondary branch. This element is indispensable for gas and water supply, as well as sewer systems. Essentially, it is a type of compression fitting . It is divided into 2 main subtypes: pad and clamp.

In general, the saddle is considered a universal device, since it can have different diameters depending on the type of pipe used. Accordingly, it will be possible to find a branch on sale intended exclusively for polyethylene or steel pipes.

When purchasing, you need to remember that some saddles allow you to insert into the line under pressure, which means that installation of the units will be simpler and cheaper.

What do SNiPs say?

The active use of plastic pipes became possible thanks to official permission:

- SNiP 2.04.05–91 “Heating, ventilation and air conditioning”;

- SNiP 2.04.01–85 “Internal water supply and sewerage of buildings.”

The main requirement is that the manufacturing company must have a license, and the material itself must fully comply with the sanitary standards of the Russian Federation.

When starting welding work, practice first. Don't skimp on a piece of pipe and the cheapest coupling - it's worth it.

]]>

Advantages of polypropylene pipes

The main advantages of this material:

- heat resistance from + 95 °C (regular pipes) to 175 °C (reinforced);

- low thermal conductivity;

- long service life;

- anti-corrosion properties;

- environmental friendliness of the composition;

- absence of salt and lime deposits.

Another undoubted advantage is the strength of the connections.

The use of materials from the same group in the installation of structures allows you to create a monolithic connection.

The light weight of polypropylene (PP) products and the simplicity of assembly make it possible for even a beginner to quickly and quietly weld with his own hands.

Saddle installation technology

The type of design or fastening of the saddles affects the process of their installation. Among the stages of installation of crimp elements are:

- blocking of a pipeline section;

- cleaning the pipe from dust and dirt, degreasing its surface;

- mounting the saddle on the surface and adjusting its position;

- securing the part with bolts;

- re-checking the correct installation and final tightening of the bolts;

- drilling a hole in a pipe.

Installation of electric welded samples includes:

- shutting off the pipeline (if necessary);

- scraping the outer layer of the pipe 1-2 mm at the site where the saddle is installed;

- degreasing and cleaning the sanded surface;

- installation of the part using belts;

- adjusting the position of the saddle and tightening the belts;

- mark on the pipe the start time of welding (if necessary);

- connecting the welding machine wire to the fitting terminals;

- waiting for welding to complete;

- drilling a hole in a pipe.

At the last stage, belts and other auxiliary equipment are removed. This installation of saddles on HDPE pipes is fast (the work takes a few minutes) and very effective.

A saddle for a polyethylene pipe is a universal element, which is a type of compression fitting. It greatly simplifies and reduces the cost of installing pipeline components.