The American is a universal and indispensable device that is used in domestic and industrial construction of pipelines of various configurations. Almost all craftsmen have to face the need to create a quick-release connection on a line to replace a section of it, insert an insert, or clean it. Thanks to this useful invention, plumbers have at their disposal a variety of practical fittings for American plumbing, allowing them to do the job quickly and efficiently.

What is “American”: why is it called that and what is it used for

The “American” connection owes its name to the country where the technology for threaded connections of materials of different sections and compositions was developed. GOST USA The American thread standard does not coincide with the standards in force in Europe and Asia. But quite often there is a need to create a unified system of pipes and plumbing fixtures of different origins. In order to adapt their products to the standards of importing countries, American designers came up with a technology for quick and reliable joining of plastic, copper and steel pipes.

American couplings are used to perform the following tasks:

- inserts into the system of tees, taps and other devices;

- replacing the damaged section of the highway;

- installation without the use of electric and gas welding.

To understand what an American is, it is necessary to consider the design features of this category of fittings, study their properties, advantages and scope of application.

Joining of metal components

Metal pipelines for various purposes are still widely used in plumbing. Therefore, the installation of metal pipes is widely used in a wide variety of options.

For simple joining, you need to cut threads at the ends of the assembled elements using a standard thread-cutting tool. The American thread is screwed onto the prepared ends, and the threads need to be sealed by winding FUM tape or strands of flax fiber.

The final connection is made by tightening the nut and installing the gasket. When reusing the connecting assembly, the gasket must be replaced. The joint turns out to be reliable and repairable. What are the American types for metal components:

- direct connection of metal pipes;

- installation is carried out at right angles, as well as at angles of 30 and 45 degrees;

- installation of cantilever elements of a water supply system with a pipe, such as taps, mixers, air vents;

- threaded connection for changing to another diameter;

Connecting pipes using an American allows you to get a sealed joint in pipelines of any configuration.

What types of fittings are there?

The assembly of water supply, heating and gas pipelines requires the presence of many branches, branches and intermediate devices. At the same time, it is necessary to provide connection options for heated towel rails, toilet tanks, radiators and many other devices.

The detachable connection of pipes must be tight, strong and durable.

Particular attention is paid to the aesthetic side of the issue. To achieve these goals, various types of American women are used.

Gusset

It is used at the joints of pipeline sections at a certain angle. If earlier adapters were welded into the system, now this need has disappeared. American corners have different diameters and degrees of bending. Products available for sale are curved at angles of 45º, 60º, 90º and 135º.

The main advantage of such fittings is that the transition from one direction to another is smooth. The connection with the union nut ensures a tight fit of the joints and optimal pressure on the rubber gaskets. At any time, it is possible to remove the fitting for inspection or cleaning of the line.

coupling

The combined detachable coupling is used to connect straight sections of the main line. American inch thread allows joining of pipes made of PVC, non-ferrous and ferrous metal.

Despite the simple-looking device, these fittings are capable of ensuring tight joints throughout the entire period of operation of the system. An undoubted advantage of using a coupling is the ability to unscrew and remove it. The product is reusable and can be used many times without loss of quality characteristics.

Cranes

Ball valves have become a successful and worthy replacement for valves, which were previously used everywhere. Installing an American faucet, what does it give? This question arises due to the high cost of this product in comparison with standard squeegees. The stainless steel body and brass inserts are durable, corrosion-resistant and reliable. The absence of rubber and silicone gaskets eliminates abrasion and premature failure of fittings.

Ball valves are installed under sinks, waste tanks, water heaters, at the entrance of the main line to the apartment, in front of heating radiators.

Other types of American

When repairing pipelines, you may need removable tees, crosses and plugs. You can complete installation tasks without the use of welding, soldering and thread cutting tools using American fittings. Connectors have different configurations, sizes and materials of manufacture. For joining, fittings with one or another connection option are used.

Cone or flat?

Conical “American” ones, supplemented with a rubber seal, ensure tightness due to internal pressure; in this case, the union nut can even be tightened by hand. As for flat seal options, it will be necessary to ensure the required contact pressure.

Mandatory tightness of the connection can be ensured by either a conical “American” or a flat one. At the same time, flat ones make it easy to change gaskets, which are not in short supply. And for conical ones, special gaskets with a non-standard size are needed. In turn, conical ones without gaskets should not be chosen, since to create a tight connection, you need to tighten the nut very tightly, which is unacceptable if the pipes are, for example, plastic.

Types of threaded connections and options for connecting to a pipe

Novice plumbers are interested in what American fittings are available for connecting pipes. Quite a lot of them have been developed to solve any issue when laying or repairing pipelines. Let's dwell on what kind of fittings and fittings there are, the shape and cross-section of products.

Cone and flat

The American cone is rightfully considered the most reliable, dense and durable device for joining materials of the same and different configurations. The conical connection assumes the absence of gasket material. Contact density is achieved by tightly pressing the joints being connected.

Experts recommend using sealing tape when installing an American brass straight coupling to prevent even the slightest chance of leakage. Cone fittings are usually installed in heating and hot water supply systems, as these products are resistant to high temperatures.

Flat fittings use a flange nut on the flange and a flat gasket to provide a seal. It is easy to install cylindrical inserts; you can use gas wrenches for this. The disadvantage is that the gasket decreases in size over time, changes shape and begins to leak water.

It is not recommended to hide such varieties of Americana in walls or under decoration. A leak will definitely occur, it’s a matter of time.

With threaded fitting

A similar device with external thread allows you to join polypropylene pipes without welding. In some cases, the distance between the wall and the connection point is so small that the issue can only be resolved by installing an American fitting with a threaded fitting. For work it is necessary to use special tools with a fixed application of force.

With internal thread

When working with steel and brass pipelines, durable and reliable fittings with internal threads are used. The use of plastic in such joints is not recommended.

The tubes are pre-carved to match the American style.

To do this, there is no need to dismantle or cut off part of the system. After this, no matter how many inches the internal thread is, the union nut is screwed onto the pipeline.

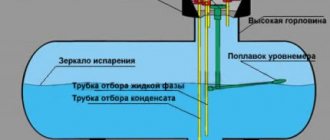

Area of use

The area of use of American pipes for polypropylene (PPR) pipes is home and main pipelines transporting non-aggressive liquid media, steam and gas. Thus, products of this kind can be found in heating systems (at the radiator connection point), sewer septic tanks, plumbing fixtures, and gas inlets. They are used as adapters, shut-off valve elements, and plugs.

We recommend that you read: Review of fittings for connecting metal-plastic pipes

Fitting diameters range from ½ to 2 inches. The maximum pressure is 30 bar. The operating temperature range of water and other transported media ranges from – 20 to + 150°.

Materials

American fittings are made from materials that have different strength, resistance to temperature changes and corrosion. Each pipeline has its own characteristics, for which its own version of connections and inserts is selected.

Steel (stainless)

Stainless steel products are characterized by high strength, ease of use and long service life. They do not change their appearance throughout the entire service.

The cost of steel weld fittings is in the average range, which makes them popular among amateurs and professionals.

Galvanized

They belong to the budget category of goods of this class. The availability of products attracts craftsmen when carrying out large-scale construction work. However, the service life of galvanized fittings is limited. Over the course of several years, their geometry is disrupted due to corrosion, which destroys the black iron. The zinc itself moves away from the body of the product after a maximum of a year, exposing unsightly rust.

Brass

A review of the types of couplings for polypropylene pipes allows us to conclude that brass American ones meet all the requirements regarding reliability and safety.

The alloy is durable, elastic, resistant to heat and chemically active liquids. The disadvantage is the high cost and change in color of brass during operation. The appearance of products is improved by chrome plating or powder coating.

Copper

American copper products are produced in limited quantities due to low demand and high cost. Fittings made of this metal are in demand only when they are attached to products made of a similar material. Copper is difficult to care for as it darkens and develops a greenish patina.

The metal is susceptible to electrolytic corrosion, which is impossible to combat.

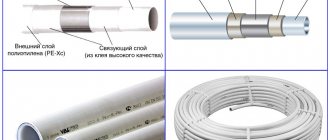

Plastic

American women are not produced in their pure form from polypropylene. This plastic does not have sufficient strength for connecting pipes and plumbing fixtures. A polymer is used as a base into which metal threaded inserts are fused. As a rule, plastic American ones are used in systems where there is high temperature and pressure.

Advantages and disadvantages

Having examined the features of American plumbing and answered the question of what it is, we can dwell on the advantages and disadvantages of these devices.

First, let's look at their advantages:

- reliability and strength of the connection, absolute tightness of the connection;

- simplicity and high speed of installation, which involves tightening one or two nuts;

- a dismountable connection that can be easily removed and put back;

- the ability to join pipes made of materials of different structures;

- a wide range of products of different configurations with seals included;

- long service life of a structure assembled using American steel.

Fittings in this category have no technical disadvantages. The high cost confuses craftsmen with low incomes, but it is justified by the high quality of the product. As for changing the color of products made of non-ferrous and ferrous metal, they are installed in technological channels, covered with panels and boxes.

Keys for American women

To work with American women, it is recommended to use a special tool. The use of improvised tools and devices can lead to deformation and breakage of fittings.

The recommended kit for installing American plumbing fixtures consists of the following products:

- adjustable wrench;

- open-end wrench;

- spanner;

- dies for making threads;

- internal keys with 6, 12 and 34 edges;

- round spacer key.

It is better to buy tools in a set, which is cheaper and helps solve any problems with installing the American one.

How to install correctly

Depending on what material you have to work with, different methods of installing fittings are chosen.

At the joints of metal pipes

Steel lines are used to transport hot liquids under high pressure. Threaded connections are used to connect their sections.

First you need to take a die of the required size and make 7 turns of thread at each joint. After this, the fitting is inserted between the joints, and the union nuts are screwed onto the threads until the required degree of pressure on the gasket is achieved.

In plastic joints

Threads are not made on polypropylene pipes, since they are not intended for this. Adapters with metal fragments with internal or external threads pressed into them are welded or glued to the ends of the pipes (this depends on the operating conditions). And American women are already attaching themselves to these elements.

Dear reader, if you have experience in this field, share it with those who are taking their first steps in the repair business. We will be very grateful to you.

( 1 ratings, average: 5.00 out of 5)

By type of assembly method

In addition to differences in materials of manufacture, the threaded connection differs in the design of the docking units.

They are threaded, with different cutting directions, having internal or external threads on the sides. Samples with a conical joint are also used, with the help of which an American connection is made using a thrust ferrule under the nut.

American connection

Such a variety of fittings creates certain difficulties when choosing them for an inexperienced person, but gives real pleasure to professional performers.