When the column that holds the well walls in an unchanged state ceases to perform its functions, the question inevitably arises of how to pull the pipe out of the well with the least amount of effort and money. Several methods are used in this matter. All of them involve the use of specialized equipment.

The article we presented describes in detail the practice-tested methods for removing casing from a water intake excavation. Problems that can be encountered when pulling a pipe string out of a shaft are given. Taking into account our recommendations, the problem will be solved with the least amount of effort and time.

What are casing pipes?

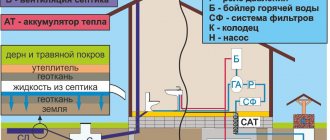

A well is the same well, only very deep and of small diameter. To strengthen the walls and ensure the tightness of the well structure, casing pipes are used. If there are several layers of water in the soil that are unsuitable for consumption, then the casing will not allow them to mix with clean drinking water.

Pipes made of metal, plastic and asbestos cement are used as casing. The first of them are durable and resist mechanical loads well. They are produced with a diameter from 114 to 508 mm. They are equipped with threads, which facilitates both their installation and dismantling.

The main disadvantages are the tendency to corrosion and high cost. They are used mainly for deep mines with large water resources.

A well with a steel casing can be restored if necessary. If the string is made of a different material, restoration using a drilling tool is not possible

Plastic products do not have the disadvantages inherent in steel pipes. The internal diameter of PVC pipe is from 80 to 200 mm. The products also have threads, are chemically resistant, and lightweight. Plastic pipes are buried no more than 60 m.

The strength characteristics and cost of plastic siege columns have an optimal ratio. Disadvantage: low resistance to mechanical stress. Ideal for constructing a well in a private yard

Asbestos-cement pipes have a diameter of 10–50 cm and a length of up to 500 cm. They are used less and less. They are fragile and unsafe for health.

Advice from professionals

Oleg Stepanovich Vekshin, driller: Removing parts of the drill string is also possible by other methods, for example, by immersing a threaded tool, which, when rotated counterclockwise, causes the string to seat.

Evgeniy Sychev, driller: As for the asbestos-cement pipe, it is practically impossible to remove it from the well without damage.

So this point should be taken into account when choosing material for installing the casing pipe.

When is casing removal necessary?

There are basically only three reasons for removing the casing from a well:

- The trunk has depressurized, which happens due to poor-quality connections of the casing string links or corrosion of the pipes by rust.

- A tool or equipment is hopelessly jammed in the barrel, making it impossible to remove the old pump and install a new one.

- A change in the design of the tube well is required: deepening, transforming the well filter, etc.

Other cases are not a reason to remove the structure. Sometimes you can save the situation by installing a polymer liner of a suitable diameter. If the break occurs at great depth, dismantling is simply impossible. Then it is easier to drill a new source than to spend a lot of money on restoring the old one.

Image gallery

Photo from

Removing casing during development

Dismantling an old water well

Removing the two upper links

Using blocks to pull out pipes

Possible alternatives

A specialist who is approached with a question about how to get a pipe out of a well will definitely ask a counter question: why? Some owners of private houses think that this is the only way to restore the operation of an old, abandoned or improperly installed well. Sometimes the desire to dismantle a pipe is dictated by the need to repair or replace a failed structure.

Since the dismantling process is labor-intensive, troublesome, long and expensive, you should definitely look for alternative solutions. For example, a smaller diameter production structure can be driven into a damaged casing pipe. The crack will be reliably closed and the well's operation will be restored.

Consultation with experienced specialists can be useful. Sometimes it is enough to properly clean the well and dismantling is simply not necessary.

In some cases, it turns out that it is cheaper and easier to drill a new well than to restore an old one.

What factors need to be taken into account?

Usually a well on a site is drilled to a great depth, so removing the casing pipe from it is not an easy task.

Before deciding on such an event, you need to clearly know the answers to the following 6 questions:

- what is the casing pipe made of?

- product weight;

- at what depth is its base located;

- how much time has passed since its foundation;

- under what conditions it was used;

- Is there a good enough reason why it needs to be dismantled?

It is possible that the dismantling work will turn out to be so complex, labor-intensive and financially expensive that it would be more rational not to solve the problem of how to get the pipe out of the well more easily and quickly, but to abandon this idea in favor of deciding to install a new water source.

Alternative method

It is often not possible to remove the pipe without damage.

For this reason, an alternative method for updating and repairing pipes has been developed that does not require dismantling them. It consists of placing a special liner made of polymer material inside the pipe, the diameter of which is slightly smaller than the main pipe.

To work with a polymer liner, it is necessary to install a winch with a block designed for 1.5 tons. The weight of the polymer is not very large and even a mechanism with low power can cope with lifting such a repair pipe.

The work is carried out in the following order:

Using a deep pump, all the water is pumped out. A waterproofing solution is injected into the main pipe (anti-corrosion liquid can be used). Then the polymer pipes are lowered using a winch.

The sections are fastened together with threads as the liner moves deeper into the shaft. A homemade filter is installed in the lower section of the liner. Several holes are made using a drill or perforation (a grinder is used). The top of the filter is wrapped quite tightly in geotextile.

After completion of the work, water is supplied into the pipe under pressure to slightly expand the sandy bottom of the well and create a cavity below for collecting water.

It is also necessary to remove waste so that your site is clean and all sanitary and hygienic standards are observed.

Drilling a water well is a rather complex and time-consuming task in itself. But even greater problems await site owners if dismantling of the device is necessary. The most difficult question that arises in this regard is: how to pull the pipe out of the well?

List of related problems

In the process of removing the casing from the ground, you may encounter a number of unpleasant surprises. You must be prepared in advance for the fact that the prepared block and winch will not cope with the task due to insufficient traction force. Then you will have to order a crane, and this will add more problems: you need a visit, which will inevitably damage the landscape.

It should also be taken into account that the pipe may be so “tight” with soil that it will be necessary to reduce the coefficient of friction by drilling holes around the head and pouring a large amount of water into them. The pipe will come out of the wet ground much easier. A side effect of such actions is the likelihood of the mine walls collapsing.

When removing the casing structure, you cannot do without special equipment. A durable flooring is built under it from rails, rolled metal or beams

Insufficient rigidity of the extracted pipe. If it is made of asbestos cement, then removing it without damage is out of the question.

It will simply fall apart and come to the surface in the form of separate fragments, and the fragments will end up at the bottom of the well. It is better not to reuse such a shaft if an asbestos pipe has been removed from it, given that this material is far from safe.

Caprice or necessity?

The only truly valid reason for removing the pipe may be complete dismantling of the well.

But in most cases, the owners are not satisfied with the quality of the water, which has dropped due to pipe wear, and they tend to throw away the old communication, replacing it with a new one. Be prepared to have to do the well repair yourself. Because finding a good specialist can be quite difficult.

In any case, this work is not easy and cannot be done without the help of professionals and heavy equipment. The financial investments and consequences for the site are also almost global in nature. The main difficulties are:

The reluctance of the pipe to be removed to the surface is as if it had grown together with the surrounding soil.

That is, we are not talking about careful pulling with a winch! You will have to drive a heavy crane into the site, which will certainly damage the beds and the landscape as a whole. Increased friction. The unfortunate pipe often cannot be removed even with the help of a crane. The soil creates strong friction and this slows down the structure.

In this case, several not very deep holes are built around the mouth using a drill, into which water is pumped. In total, several tons of water will enter the pit. The moisture will serve as a natural lubricant and it will be easier for the crane to remove the structure from the soil.

However, such water-saturated soil becomes too plastic. After lifting the pipe, a serious collapse may occur. Not only will the mine itself be filled with earth from the inside.

The surface layers of soil closest to the well will move into the failure. The rigidity of the pipe frame will be violated. Over time, everything decays. Casing pipes are no exception to this rule.

An old pipe, especially one made of asbestos, will easily break into pieces if disturbed. The crowbar will fall to the bottom of the shaft, making the water unsafe to drink. And it is simply impossible to remove all the fragments.

Before carrying out work, it is advisable to consult with professionals involved in drilling wells.

They will make an accurate calculation of the weight of the pipe, take into account the coefficient of friction and assess the degree of wear of the structure. After such an assessment, the owners will know exactly what awaits them in the event of dismantling.

Preparing to dismantle the wellbore

Knowing about possible difficulties, you should prepare for the process thoroughly.

The first step is to determine the weight of the product, for which:

- measure the well depth, pipe diameter, wall thickness;

- open the directory and, focusing on the diameter and wall thickness, find the weight of 1 linear meter. m;

- multiply the found value by the depth of the shaft and obtain the required mass of the pipe.

This value will be the basis when choosing a winch based on traction force. If the figure turns out to be significant and there is no winch with such a traction force, then the only option is to order a crane. When deviations from the calculated value are insignificant, a conventional winch will do.

Cost of the project and work to abandon wells

Before the liquidation of a water well , a project must be drawn up.

Drawing up a project for liquidation plugging is estimated at 70,000 rubles.

The cost of work during which the well is abandoned depends on the scope of work for cleaning the wellbore, a set of geophysical studies, the depth of the well and the diameter of its production casing. Approximately, the cost of liquidation plugging of a well ranges from 1,400 to 1,800 rubles per 1 meter of well.

Methods for removing pipes from a well

Professionals have their own methods for pulling out casing pipes: stretching followed by breaking, flushing with walking, twisting.

Tension method for column extraction

To use this method you will need a traveling system or a jack. The force generated during tensioning is above the critical plasticity limit of the casing material. Therefore, the structure may not withstand and burst.

The process algorithm is as follows:

- A trench about 1 m deep is dug around the mouth of the pipe.

- A clamp is put on the pipe, and cables are attached to it, after which the structure is slightly tensioned.

- The clamp to which the cable is attached is moved lower and the same actions are repeated. This ensures smooth pulling.

- The upper edge of the casing structure is pulled out until a break appears. The fragment is removed from the shaft, and the remaining part is captured with a special fishing tool and the process is continued, or after replacing the damaged part of the shaft, the casing is installed in its original place.

It is advisable to use this option for dismantling pipes with a large diameter and thick walls.

It is almost impossible to extract the entire line using this method. Most often the pipe will not be suitable for further use

If the well axis has a vertical deviation, this extraction method cannot be used. For such complex work, it is better to hire a drilling crew.

This is what a mechanical grip looks like - a clamp with which the pipe is fixed. The removal process can be complicated by breakage and jamming of the riser, so the plasticity of the material must be taken into account

The hoist used for lifting must have a large load capacity. The best option is to use jacks. You should know that you cannot count on further use of the removed pipe.

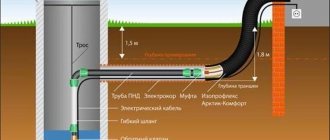

Removal by washing

If the casing pipe does not come out of the ground due to the formation of a sand plug, a relatively simple method is used to remove it - washing and stretching. To do this, you need a pump with a special flushing device. The pressure part of the pump is connected to the top of the pipe.

The pressure should be minimal, but sufficient for water circulation. The column is washed, and after the sand flows out, the pressure is increased. The body of the pipe is walked around, turning it with the help of a rotor and loosening it. All this is done in parallel with washing. Thus, the coefficient of friction is reduced, and the string will come out of the well more easily.

The ideal option is when the diameter of the pipe allows not only to fix the pump in the upper part, but also to lower the second one to the base of the column. The reverse supply of water is started as soon as the edge of the flushing hose drops 300 cm below the shoe-coupler of the sedimentary column. The process is continued until the sand blockage near the pipe is completely eliminated.

Sometimes when the pipe is lifted up to 10 m, it becomes impossible to remove it due to the strong compaction of the plug. In this case, there is only one way out - to remove individual fragments. Separately, we should dwell on the process of removing the pipe.

First, a piece of reinforcement with a diameter of about 18 mm is welded onto her body. This element is needed to secure the winch slings and begin lifting the casing riser.

To lift, it is necessary to apply a vertically directed draft force. To do this, a block is installed at the highest point of the pipe being removed, and a cable is thrown through it. When the winch drum rotates, torque is converted into traction force.

A light weight pipe can be lifted using a lever. Its end is brought under the welded reinforcement and, applying force, the riser is gradually pulled out of the ground.

Application of the unwinding method

Using this method allows you to unscrew the casing elements and remove them from the well.

To apply the method, you need a supply of tools:

- fishing bit;

- rotor;

- perforator;

- cumulative torpedoes.

A special fishing bit with a left-hand thread and a steel drill pipe are lowered into the shaft. The rotor turns the pipes counterclockwise.

Having completed approximately 20 revolutions, the casing string is walked, increasing the load to the maximum. If the fished pipe does not break, the pacing and unwinding is repeated. The result of these efforts should be incomplete unscrewing of the connections.

Devices for catching pipes are equipped with spiral or collet grips. The diameter of the fished pipe must be less than the diameter of the pipe body

If the thread cannot be loosened even after a number of cycles, a special tool is used, rotating which causes the pipes to vibrate due to friction and transmission of torque to the removed riser.

Result: After rotating the tool for 1 hour, the connection becomes loose. At the next stage, grab the upper rim of the column and unscrew its fragment. To remove the unscrewed part of the pipe outward, a tensile force is applied. The steps are repeated until the entire column is dismantled and all its elements are at the top.

The unscrewing process is based on a combination of torque and tension loads. The casing riser is first untwisted and then pulled out. To prevent the column from breaking, the torque and tension force must be constantly monitored

When all efforts do not lead to success, a radical method is used - violating the integrity of the structure by using cumulative torpedoes. As a result of their explosion at a given depth, ring cuts appear on the body of the pipes. All that remains is to cut off the individual elements using a hammer drill or other cutting tool.

All this work can be done by specialized organizations. Their cost is considerable, so the owners of country houses are looking for other ways to remove the pipe themselves.

How to remove a stuck pump

There are many ways to free pumping equipment from wells. They depend on the degree of suction or jamming of the pump in the casing, as well as on the suspected cause of the problem. Unfortunately, it is not always possible to solve it due to insurmountable difficulties. But it’s still worth trying to remove the equipment.

The cable is in the way

The most common cause of device jamming is a sagging electrical wire. It can be quite difficult to remove a pump wrapped in cable from a well. When lifting the equipment, also with force, there will only be an additional sealing of the gap between the casing and the pipe. In this case, you should not use jacks or winches, otherwise the cable may break under significant loads.

You should try to push the pump down with rotational movements, either clockwise or counterclockwise. Scrolling is carried out using a water intake pipe. Any slack in the cable is tightened and the lifting begins again. The main thing here is to be patient and not overdo it.

Siltation

The pump, overgrown with silt, is released by “swinging”, raising and lowering it many times. Start with a minimum step, which is increased as necessary. In this case, you should use only a cable or both a cable and a hose. As a result of the reciprocating movements, the hardened sludge will gradually begin to liquefy and eventually weaken the position of the pump.

No one can predict in advance how long it will take to “boost” the pump. This depends on the length of the well's non-operational period, the thickness of the silt layer above the pump and the density of the sediment.

Vertical deformations or deviations of the casing

A slight rise of the pump to a certain point, knocking and a sharp stop indicate that there are deformations inside the well that impede the upward movement of the equipment. But there may not be a knock - it all depends on the nature of the defect.

In this situation, you can try to get around the obstacle by simultaneously lifting and rotating the pump by the hose. This should be done smoothly and slowly. If the circumstances are successful, the casing will eventually “slip”, but if it’s unsuccessful, you will have to part with the equipment or the well.

Foreign objects

Jamming of the pump can be caused by a small object or pebble, since the gap between the wall of the casing pipe and the casing of the device is, as a rule, minimal. In most cases, independent attempts at extraction only lead to cable breakage. But the situation can be controlled by professionals with experience and diagnostic equipment.

Specialists have underwater cameras in their arsenal, with the help of which the cause of jamming is determined. The experts will analyze the situation and offer an option for saving the well. But we should immediately make a reservation - the services of such companies will be expensive. It is recommended to contact them if there is expensive equipment in the well.

Factory and homemade equipment

To remove casing from a deep well, professionals use factory-made equipment.

It is characterized by such nominal parameters as pressure in MPa, stroke force - forward and reverse in force, maximum torque in kN/m, maximum clamping or extraction force in force, angle of rotation of the clamps, weight in kg, dimensions in mm, range of diameters of the pulled out pipes

The installation consists of a base plate with a stationary gripper and two hydraulic power cylinders installed on it, an upper plate, a movable gripper with which pipes are clamped

The hydraulic return cylinder rods are combined with supports equipped with a crossbar on which the top plate rests. To clamp the support column, this plate has a special movable gripper. Both fixed and movable grips are 3-wedge jaws, internally threaded and placed in a cage.

Hydraulic cylinders are connected to the pumping station. In the event of an emergency situation when there is not enough force to remove the pipe, use a clamp wedging device. The tension may not be enough if, due to unforeseen circumstances, additional friction forces appear between the pipe body and the walls of the well.

The equipment is installed on the casing stand and the latter is clamped using a movable gripper, and then lifted. The lift is equal to the stroke of the pistons. The next step is to fix the pipe with a fixed grip and return the top plate to its original position. The pipe is removed by repeating these steps. While the riser is being drawn out, it is supported by a crane.

With the help of such equipment, casing pipes are pulled out of the ground, the top of which is almost invisible, since the installation has a low pick-up. Another advantage of the mechanism is the ability to lift steel pipes, the standard sizes of which are in a wide range.

To dismantle small-diameter pipes on your site, you can make suitable equipment yourself. For this you will need 2 channels for the racks, a drum for the cable, a bearing with an internal diameter of 40 mm, a cable, and a handle.

Two supports are made, about 1 m high and approximately 0.6 m wide. They are shaped like the letter T when tilted. A bearing is attached to the uprights at the top, and an axle is passed through it. The drum and handle are attached to the axis.

The cable is wrapped around the pipe and the drum begins to rotate. The pipe gradually emerges from the ground. If a plastic product is to be dismantled, a special clamp is used.

As the pipe is removed, the cable is lowered lower. When the structure has a significant length, a special device is used - a jig - to hold the column while moving the cable to a new position.

Organization of liquidation activities

The instructions on the procedure for liquidation and conservation of wells require the transfer of drilling facilities to a state that will ensure environmental protection, safety of the population, and safety of the subsoil. In this regard, their users are instructed to: ensure the safety of the well (mothball it), if it can still be used, or take measures for complete liquidation.

The project and its implementation

The liquidation of a water well, like any other drilling facility, is initiated by the individual or legal entity that owns it. He also exercises control and is personally responsible for the rational use of extracted resources.

A well abandonment project can be standard; developed during the process of exploratory drilling; or created immediately before performing work.

Its structure includes the following sections:

- An explanation justifying the reasons why the well should be abandoned;

- List of technical solutions related to this process;

- Organizational nuances and procedure for well abandonment;

- List of measures to ensure environmental safety and subsoil protection;

- Estimate.

If the well is mothballed, then the explanatory note must present options for carrying out work during the construction process or at its completion, as well as during operation, including seasonal ones.

The project should present methods for equipping the wellhead and its conservation. Items for ensuring security measures and estimate calculations are carried out in a similar way.

Liquidation to come

When any changes are made to a previously developed project, they are subject to additional assessment and approval by Gosgortekhnadzor. At the same time, the developer of such documentation is obliged to exercise supervision during the course of work. Its conditions are necessarily stipulated in the subsoil user agreement with the designer.

The liquidation of a water intake well is considered completed only when the corresponding act is signed and registered. When it comes to conservation, the project sets a deadline. If for some reason they are exceeded, and there is a threat of harm to nature or the population, regulatory authorities have the right to demand liquidation measures.

Categories of abandoned wells

There are several categories of drilling objects that must be eliminated. The main criterion for this division is the reasons for the abandonment of wells.

And they can be like this:

Category I

These are mainly wells that have expired. And the well's flow rate has already reached its lower limit, and the facility has simply become unprofitable.

Category II

This category includes wells that were drilled to the design level, but encountered unfavorable conditions during the work. For example: we were looking for water, but discovered gas on a non-industrial scale.

This also includes wells that were not brought to the design depth due to a discrepancy between the design and actual structure of the formations, or due to the occurrence of insurmountable obstacles.

Category III

Problems also arise when various force majeure situations arise. Elimination of accidents in a well that occur both during construction and during operation or major repairs is often not economically feasible.

This is a break in a technical or production string, cable, drilling tools getting into the barrel, poor-quality cementing (see Cementing wells: methods and technologies). Sometimes not the entire trunk is destroyed, but only part of it. However, this only makes sense if there is a productive horizon above the emergency area.

Force majeure situation: ground collapse

Category IV

This includes all wells that must be abandoned for environmental or technological reasons. For example, when the construction of a well is completed, but it cannot be operated due to non-compliance with actual conditions.

The fourth category also includes previously mothballed wells, but not put into operation; illegally drilled; located in areas where the geological situation has changed.

Options for clearing jams

How to get a pump out of a well if it is stuck is a very reasonable question for homeowners who are faced with a similar problem for the first time.

By correctly identifying the probable cause of an accident, you can choose the most effective way to eliminate it.

Lifting when the cable is slack

If, when lifting to the surface, the equipment does not move even with considerable effort, the sagging cable is to blame.

Removing a stuck pump is quite simple. To do this, you need to lower the device down and select the place where the cable sag in order to free the case from the loop.

Important! All movements must be smooth to prevent the power cable from breaking and the pump hose from sagging.

To avoid such an accident in the future, the electrical cable must be connected to a water hose and secured with clamps. When removing, the hose and cable must come out at the same time, this will prevent them from possibly sagging.

Extraction when the bottom silts

How to get a hose out of a well when the bottom is heavily silted? In such a situation, you can pull out the equipment from the bottom by smoothly swinging from side to side. Translational movements contribute to the rapid erosion of silt by water that has accumulated around the device.

To properly lift the pump from the bottom, you should not make sudden movements, which could lead to jamming or breakage of the cable. 15 minutes are enough to lift the device to the surface of the structure.

Important! If the bottom is regularly silted, it is recommended to carry out timely prevention, which will allow the well or well to be cleared of soil deposits. Cleaning frequency is every three years.

Extraction during reverse siltation of the bottom

Excessive deepening of equipment can lead to reverse silting of the bottom of the hydraulic structure. Then salt deposits in the water are deposited on the body of the device and on the internal walls of the casing, thereby reducing the diameter of the structure. Lifting equipment in such conditions becomes increasingly difficult and dangerous.

It is worth noting that washing the mine with water will not give the desired result and will not allow you to get rid of lime deposits. In this case, you can get the pumping baby out by rocking, making translational movements up and down.

The algorithm for removing enabled equipment is performed as follows:

- Lifting the pump using a fastening cable to the level of the narrowing of the casing.

- Lowering the device to the starting point. Repeat the lifting/lowering procedure until lime deposits do not interfere with removing the pump.

- Carrying out preventive cleaning of the mine with periodic removal of pumping equipment.

Lifting when casing is damaged

Excessive soil pressure, as well as the use of low-quality installation materials when constructing a well, can lead to damage to the casing and failure of the tightness of the joints. If the pump is stuck in the well, how to get it out if the column is destroyed? The device is removed to the emergency level using a clockwise circular motion. All movements must be smooth so as not to aggravate existing damage to the well.

Useful recommendations from experts

To successfully solve the problem with a stuck pump and prevent it from recurring in the future, experts recommend:

- Install a small-diameter pump in the hydraulic structure, which will provide the required technological gap between the column and the device body.

- Install a submersible pump using a reliable cable made of stainless steel. This design can withstand extreme loads.

- Homemade devices - hooks and crampons, securely fixed to a metal cable. This will avoid a broken structure, which will complicate the process of removing the pump.

- When operating a hydraulic structure, use strong and durable lifting mechanisms that will prevent possible breakage of the pumping equipment.

- Install the protective cap with a tight fit to the inner walls of the casing. This will prevent the well from clogging with debris and foreign objects.

- Carry out timely prevention and maintenance of the mine independently or with the involvement of special services.

Any homeowner can solve the problem of stuck pumping equipment in a private well. In case of serious accidents, it is recommended to use the services of professionals, because cleaning the mine and raising the equipment will cost much less than drilling a new well.