Gas, due to its cheapness and availability, is the main source of fuel used for cooking in public housing and the private sector. To use it, you only need to connect a gas stove with a hob to a pipeline leading from the main line.

Typically, such work is carried out by highly qualified specialists from state gas services at a price affordable for all segments of the population - this helps reduce the number of incorrect unauthorized connections that can cause accidents with serious consequences. But gas services are not always located in close proximity to the owners’ place of residence; sometimes the property is located in a remote area and the arrival of a specialist will take a long time and cost a considerable amount.

In this case, connecting the stove to the gas main, due to the simplicity of the work carried out, can be done independently if you know the installation technology and the basic safety rules that require working with gas.

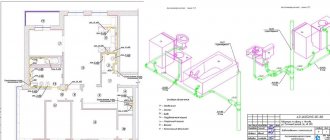

Rice. 1 Options for installing a stove in the kitchen

Choosing a chimney for a gas boiler

Any wall-mounted gas boiler needs a chimney. Depending on the model, this can be either a traditional chimney or a small horizontal chimney that can be led outside directly through the wall of the house.

Photo 4: Installation of a coaxial chimney for a turbocharged boiler

In double-circuit boilers with an open combustion chamber, the combustion process occurs with the help of air from the room in which the heating device is installed. Typically, such models are installed in specially equipped boiler rooms. To remove combustion products, they are connected to traditional chimneys for gas boilers made of ceramic or stainless steel.

Wall-mounted boilers with a closed combustion chamber (turbocharged) use outside air in their operation. It is supplied inside the device through one of the channels of the coaxial chimney. The second channel is used to discharge flue gases into the atmosphere. A coaxial chimney is very easy to install and you can connect a gas boiler to it yourself.

When is it better to use polyethylene pipes?

If you plan to lay a gas pipeline in the ground, then in this case you cannot do without polyethylene pipes. Steel pipes in this case are not the best option, since, when laid in the ground, they are vulnerable to corrosive processes.

In theory, both cross-linked and regular polyethylene can be used to make gas lines. However, cross-linked polyethylene is hardly used as there is no benefit from it being more durable and heat resistant. But its price is higher when compared with ordinary low-density polyethylene.

In a store, identifying polyethylene pipes that can be used for gas supply is quite simple. A yellow line is drawn along their entire length.

It is worth noting that polyethylene compression fittings are not used on gas connections. Their mechanical strength is limited, and it is not worth completely excluding the possibility that no external influences will be exerted on the gas pipe.

Sleeve connections, for which either rubber seals or glue are used, are also not suitable. Most often, this method is used when it is necessary to connect PVC pipes intended for sewage. They are not suitable for gas because they do not guarantee complete tightness.

All that remains is to use three types of fittings:

- brass, which provide both tightness and mechanical strength;

- fittings for welding, which are connected with a soldering iron at low temperatures (it is recommended to set the temperature to 240 degrees Celsius);

- electric welded, on which spirals have already been applied, intended for melting contact surfaces. They are expensive but can guarantee a high quality connection.

What is a bellows eyeliner and what are its advantages?

A bellows gas hose is a corrugated pipe made of stainless steel. Special fittings are installed at the ends of the hose to create a strong and safe connection. The connection to the pipes and equipment is secured using union nuts made of the same material. To increase the level of tightness, metal or plastic sealing rings are installed at the joint.

As a rule, sealing gaskets are included in the flexible hose kit.

Eyeliner kit

The advantages of a bellows hose over other types of flexible hoses designed for connecting gas equipment are:

- strength and rigidity. According to manufacturers' requests, the service life of the bellows is up to 25 years;

- possibility of correct operation at different temperatures;

- not exposed to direct sunlight;

- ability to withstand high pressure;

- possibility of stretching, and when the length increases to 50%, the strength of the liner does not decrease.

The disadvantages include the cost of the equipment, which is 2–3 times higher than the price of rubber analogues.

The best hoods for kitchens with a width of 90 cm

Replacing bathroom faucets: how to change them yourself

Wide hoods are installed above large stoves so that the equipment can completely remove steam, smoke and drops of grease.

Apelson Apolo 900 inox

4.9

★★★★★ editorial assessment

94% of buyers recommend this product

The hood has two operating modes – exhaust and circulation. Three speeds allow you to choose the desired performance up to a maximum of 600 cc. m/h. The kit comes with a carbon filter. Two 40 W incandescent lamps provide good illumination of the work area.

Pros:

- electronic and push-button control;

- two operating modes;

- stylish modern design;

- low cost.

Minuses:

The glass arch requires careful handling. Apelson Apolo is suitable for those who want a stylish hood in their kitchen on a limited budget.

Apelson Apolo is suitable for those who want a stylish hood in their kitchen on a limited budget.

Elikor Modern Quadra 90

4.8

★★★★★ editorial assessment

90% of buyers recommend this product

A quiet motor is specially installed in the hood so as not to distract household members with unnecessary noise. With a capacity of 650 cc. m/h the motor produces no more than 54 dB. A clear advantage of Elikor Modern is the use of two types of control - push-button and mechanical.

Pros:

- low noise level;

- three suction speeds;

- stainless steel housing;

- two halogen lamps of 20 W each.

Minuses:

- Only a grease filter is installed;

- 1 year warranty.

The hood is suitable for those who do not like noise - for example, for families with small children.

Installation of gas supply

Installation of the bellows gas hose is carried out in compliance with the following rules:

- it is unacceptable to hide the liner in the wall, since any leak that is not detected as soon as possible can lead to emergencies, damage to property and loss of life;

- Do not install a hose with a large number of kinks;

- condensation on the equipment will help reduce the service life of the liner.

Installation diagram:

- choosing an installation location in accordance with the recommendations given above;

Optimal connection diagram for a gas stove

- turning off the gas supply to the premises. To make a temporary shutdown, you can use the tap installed in the apartment, and if it is missing, you need to contact the management company;

Individual gas shut-off valve

- dismantle the old eyeliner (if any);

- if the supply line and tap are missing, then before connecting the equipment, it is necessary to cut a thread on the pipe and install a tap that allows you to shut off the gas supply directly in the living room. For example, to troubleshoot equipment;

- dielectric installation;

- A flexible hose is connected to the tap. As a rule, in this situation, the “nut” connection method is used;

When connecting the liner, special attention is paid to installing the sealing gasket. A connection without a gasket will not be completely sealed

To increase the tightness, you can additionally use FUM tape or other similar material.

- connecting the supply to gas equipment using an o-ring. All nuts and fittings must be fixed using an open-end wrench without unnecessary effort. Even slight overtightening can lead to damage to the seal and rapid depressurization;

Connecting the liner to the equipment

- examination. To identify a leak, you can use a soap solution and an ordinary brush (sponge). If soap bubbles appear on the surface when applying the solution, then the connection is not airtight.

Leak detection with soap emulsion

How to connect a gas stove yourself, watch the video.

If you cannot install the equipment yourself, it is recommended to contact gas service specialists. Replacing the eyeliner will cost approximately 300 - 500 rubles.

Stages and problems encountered

With rare exceptions, every home owner, when purchasing it, does not have the opportunity to choose which equipment to use for cooking: gas or electric. This is due to the fact that already at the design stage, residential premises acquire an energy system that will be used in the kitchen. The equipment is installed according to the developed project.

Accordingly, before making a decision to abandon gas in an apartment, it is important to study the design of this apartment or other residential premises. You should carefully, including involving professionals, study the capabilities of the electrical network of the premises

In an apartment building that was originally designed to use gas, as a rule, the design load on the electrical networks does not allow installing an electric stove instead of a gas one. Therefore, it is imperative, if you act legally, to install and arrange new electrical wiring that corresponds to the new equipment used.

The prepared project with the signatures of the residents is sent to the appropriate authorities in order to approve the redevelopment, since this redevelopment is considered just a redevelopment. Mandatory organizations when coordinating refurbishment are the management company, the housing inspection, and organizations involved in the sale of gas and electricity. Only after all the necessary permits have been obtained can you proceed to the next stage - dismantling the gas stove and, if possible, the pipe supplying gas to the room.

In our country, work with gas equipment is subject to mandatory licensing. The peculiarity of this stage is that removing the “blue” fuel supply pipe in a gasified apartment building is very difficult and, as a rule, impossible

Therefore, when deciding to change the energy source, you should pay attention to this aspect. Professionally performed dismantling of gas equipment means no problems in the further operation of the premises

If the gas supply pipe remains in the room, it must be inspected at least once every six months to detect gas leaks, which only a licensed organization has the right to carry out. Each locality has its own, determined by local authorities.

The next stage is the arrangement of electrical wiring, if required by the developed and agreed upon project, and installation of electrical equipment. Installing an electric stove, replacing the wiring - this is the type of work that must be carried out by specialists

This is very important because electricity, if used improperly, can cause harm to human health, even death.

Accordingly, when choosing a contractor that will install electrical equipment, you should pay attention to whether it has a license to carry out electrical work, as well as whether its employees have permission to work with electricity of the corresponding category

What is common to the stages of dismantling and installation of new equipment under consideration is that upon completion, a certificate of completion must be drawn up, which indicates the contractor, the types of work performed, the contractor, the warranty period, and the signatures of the parties handing over and accepting the scope of work. Attached to the act are copies of licenses to carry out this type of work and specialist approvals certified by the contractor.

The documents discussed in the previous paragraph will be required for the next stage of re-equipment, namely contacting the appropriate authorities to commission the electric stove and wiring. Such authorities are Rostechnadzor, an organization involved in the sale of electricity, a technical inventory bureau of local governments, and a management company. At this stage, the state supervisory function in the field of energy supply to the population ends. The further method of payment for electricity and the refusal to consume gas fuel is also determined.

Other types of gas hoses for gas stoves: sizes, prices

A gas rubber hose in a metal braid has an internal part made of polymer materials, which is covered with a layer of vulcanized rubber on top. On the outside, the hoses are braided with special steel threads, creating a so-called reinforced layer.

The main disadvantage of using hoses is considered to be the high ability of steel to transmit electricity, as well as the susceptibility of the internal polymer material to destruction, which may not be noticed due to the presence of upper layers. If the stove is not in use, it is recommended to shut off the gas hose during this time, which will increase its service life. The price for a finished product 60 cm long starts from 140 rubles.

When using this type of connection, you additionally need to install dielectric inserts, which are installed at the junction of the hose and the gas pipe. The presence of a dielectric will protect the gas stove and the hose itself from the effects of stray current, which can cause a fire.

A gas rubber hose in a metal braid has a disadvantage - it is the high ability of steel to transmit electricity

Advantages of using rubber reinforced hose:

- affordable price;

- ease of installation;

- operation in a wide temperature range: from -35 to +50 °C;

- wide choice of length and diameter.

Reinforced PVC hose is considered more modern than the options listed above due to the fact that the characteristics of the material do not allow the product to conduct electric current. In addition, polyvinyl chloride does not break down as easily as rubber. Additional strength to the hose is provided by the presence of two layers of PVC. Inside the sleeve there is a black material, and the top layer is most often distinguished by a yellow color. It is used for supplying various types of gas mixtures: acetylene, propane and butane.

The PVC gas hose for a gas stove is designed for operating pressure up to 0.63 MPa, and the temperature at which gas can be operated varies from -20 to +90 °C, which is a significant advantage. Another positive aspect of using PVC products is the wide range of sizes, with the maximum length of a gas hose for a gas stove being 5 meters and the minimum length being 0.4 m. Galvanized steel is used for the manufacture of fittings, and dielectric properties are ensured due to the presence of a paronite gasket. Other advantages of the product:

- does not collapse upon contact with a hot stove;

- affordable cost, price per meter of product starts from 170 rubles;

- not subject to destruction when exposed to hot drops of oil;

- suitable for use under high load conditions;

- long service life: minimum – 12 years, maximum – 20 years.

The PVC gas hose is considered more modern and is used for supplying various types of gas mixtures

Connection tools and parts

In most cases, the master has the necessary parts. All you have to do is pay the cost of the installed elements. But you can buy everything yourself, after specifying exactly what you need.

For installation you will need:

- Flexible hose.

- Ball valve.

- Sealant: FUM tape or Loctite 55.

- Pad.

- Dielectric coupling (if the stove needs to be connected to electricity and a metallized hose is installed).

The hose with which the device is connected to the gas pipeline must be made specifically for gas. They are always marked in yellow. If there is a blue or red mark on it, then such an element will not fit, since they are intended for water. The following types of hoses are distinguished:

- Rubber – made of high-strength vulcanized rubber reinforced with textile thread. It is flexible and durable, withstands temperatures from – 35 to + 50 °C. At the same time it is inexpensive.

- In a metal braid - a modification of the previous version, where the strength is increased due to the presence of a metal casing. The price for it, of course, is also higher.

- Bellows - is a corrugated pipe made of metal-plastic. It is wear-resistant, withstands pressure changes, bends and stretches well. Of all those presented, it has the highest cost.

Before purchasing, check with a specialist which hose is best to purchase.

A ball valve will be needed if the shut-off element has not been replaced for a long time. Some houses still have paddle taps, which is unacceptable under the latest regulations. The new valve should be made of nickel plated brass.

FUM tape or Loctite 55, which are complex synthetic sealants, are used as a sealant to create a safe connection. Previously, flax thread was used for these purposes, however, it does not always provide a tight connection. These products are much more reliable and durable.

The gasket is installed between the hose and the stove itself. It is needed to prevent small debris from entering the device from the gas supply system. This significantly increases the operating time of the equipment. The gasket has a diameter of 3 mm and is usually supplied with the device.

A dielectric coupling is needed if the stove has an electric oven or ignition, i.e. it is connected to electricity. This is necessary so that if you accidentally touch the hose while the oven is on, electrical potential does not accumulate, which could damage it.

It would also be useful to prepare a container with soapy water and a brush or sponge. They will be useful for checking whether there are any leaks anywhere.

If you are connecting the plate to the cylinder, you will also need a pressure stabilizer. It is absolutely necessary, since the pressure in the cylinder is much higher than in the pipes. And to reduce it, a special part is used.

The employee has the rest of the tools: keys, screwdrivers, and you don’t need to prepare anything additional.

If you don’t have a meter, you can immediately ask the master to do this work too. Of course, you need to pay for the additional service of installing a gas meter, but you won’t have to issue a call in the future. Just discuss this point in advance, buy a meter and all the components. We have already talked about which gas meter is better.

Bellows Gas Hose: Best for Gas Stove

If you ask a specialist what type of hose for a gas stove should be, most likely he will suggest purchasing a bellows version for installation. This type of hose is considered the most reliable for connecting the hob to the central gas supply. In addition to gas stoves, it is used to connect water heaters and gas boilers used for individual heating. A bellows is an elastic corrugated shell that protects the inner layer from mechanical and other types of damage.

The great demand for bellows hoses is due to the high technical characteristics and reliability of the devices. The products easily withstand the high pressure created by the gas flow in the pipe. Ease of connection is provided by two fittings designed for connection to a gas pipe and directly to the device. All hose components are made from high-quality stainless steel, which guarantees maximum service life.

Helpful advice! For a safer connection when connecting the hose, a special gasket made of plastic or soft metal is additionally used.

The bellows gas hose is considered the most reliable for connecting the hob to the central gas supply

The price of a gas hose for a gas stove of this type is significantly higher than the cost of other product options, but the service life is at least 10 years longer than the service life of other devices. So, the minimum time during which you can safely use a bellows hose is 25 years, although some companies give a 30-year warranty. The final price is usually influenced by the manufacturer and size of the product.

You can find out how much a gas hose for a gas stove costs (depending on the characteristics) from this table:

| Connector diameter, inch | Length, m | Price, rubles |

| 1/2 | 0,4 | from 250 |

| 0,8 | from 290 | |

| 1 | from 320 | |

| 1,5 | from 400 | |

| 3 | from 780 | |

| 4 | from 950 | |

| 5 | from 1150 | |

| 3/4 | 0,6 | from 350 |

| 1 | from 450 | |

| 2 | from 700 | |

| 2,5 | from 900 | |

| 3 | from 1050 |

Tips for choosing

One of the factors influencing the choice of a particular model of tabletop stove is often the presence or absence of a stationary gas pipeline. It depends on this whether it will be a stove for main gas or for bottled liquefied gas.

The number of burners on the stove is determined by the volume and frequency of food preparation, as well as the specific use of the device. For 1-2 people or for travel use, a one- or two-burner stove is sufficient, but for a larger family, a three- or four-burner model will be required.

When choosing a stove, you also need to pay attention to the technical characteristics

Dimensions and weight. Tabletop stoves generally have standard dimensions within 55x40x40 cm. Weight does not exceed 18-19 kg. Such small-sized devices do not take up much space. Burner size. If there are 3-4 burners on the stove, let them be of different sizes. Coating

This is especially important for the hob. It must be durable, so it is preferable to choose a plate coated with stainless steel

In addition, such material is easier to wash off contaminants. Enameled coating is cheaper, but it is not durable. In addition, chips often form on it. It is advisable to choose a model with a lid. This will protect the stove from damage during transportation and keep it clean during storage. A stove with electric ignition (piezo ignition) is easier to operate. Availability of gas control. This option prevents gas leakage and makes the stove safe to use. An electric oven is more powerful and gets hotter, but it also consumes a lot of electricity. The safest oven is with double-layer heat-resistant glass in the door (there is no risk of burns). It’s good if the design of the model for main gas allows it to be connected to a cylinder. In this case, the kit must include a special adapter-jet. Imported models often have more additional options, but their cost is higher.

The design of the slab and its color are chosen taking into account personal taste. However, it is worth considering that coatings made in shades of brown look much more impressive. In addition, dirt is not so noticeable on them.

The main advantages and disadvantages of using bellows hoses

Simple models of bellows hose are presented in the form of corrugated products, which are distinguished by the presence of a round cross-section. If you choose a more expensive option, then in addition there will be a metal sleeve or polymer coating for protection. The modernized version of the bellows hose has a built-in thermal protection valve, which, when the temperature rises critically, independently shuts off the flow of gas. Of course, this option will also affect how much the hose costs, but the losses that can be incurred in the event of a gas leak will be much higher. Other advantages of bellows hoses:

- easily bend and stretch;

- can withstand loads up to 6 atm;

- are operated in a wide temperature range from -50 to +200 °C;

- are made of high-quality materials that comply with all GOST standards;

- meet the technical requirements for domestic use;

- maximum possible service life - up to 30 years from the date of installation;

- withstand the influence of electric current up to 1.5 kW;

- a large selection of hose lengths for connecting a gas stove - from 0.4 to 5 m;

- compatibility with most types of gas equipment and various accessories;

- the presence of a coating that protects the base of the hose from the effects of various household chemicals used for cleaning and disinfecting the kitchen.

Simple models of bellows hose are presented in the form of corrugated products

Additional safety for the hose is provided by an electrically insulating polymer layer, which protects not only from mechanical stress, but also from high-frequency currents that are created by some household appliances, for example, a microwave oven. Due to the strength of the hose, manufacturers guarantee the integrity of the connection even in the event of natural anomalies, such as an earthquake, when the stability of the building is compromised.

The only relative disadvantages include the price, which is several times higher than the cost of similar products from other groups. However, the presence of a large number of positive characteristics, which include a significant service life, covers this drawback.

Helpful advice! When installing a stove or hob with a built-in electric ignition function, experts recommend additionally installing a dielectric insert between the gas supply tap and the bellows hose to ensure greater safety.

Hose rating

We do the heating of the bathhouse with our own hands: an overview of water and gas heating supply

Based on the above, we can conclude that you should not purchase a rubber gas hose for your stove; the best option is a bellows hose. To connect equipment, it is better to buy a connecting element with a maximum length of no more than 1.5 meters. The connection of the slab with a flexible hose must be carried out by professionals and ensure absolute safety during operation of the entire system.

For a long service life of the eyeliner, it is necessary to choose the right not only the product itself, but also its manufacturer, who guarantees the quality of their products. These are companies such as:

- Italian EMIFLEXp.a. – its products are certified by Rostest and approved by Gostekhnadzor, hoses can be used at temperatures up to +100°C and a pressure of maximum 7 atm;

- Chinese Tuboflex produces high-quality eyeliners, but their cost is lower than their Italian counterparts;

- Turkish G-BEKA - products have a low cost, a large margin of safety, can be used at temperatures reaching +250°C and operating pressures up to 6 atm.;

- Chinese OSCAR-M - cheap products with good quality for installation at home.

Main manufacturers of bellows gas line

The market leader in the production of bellows hoses is considered to be the Italian company Emiflex, which has also been certified in Russia. After some research, approval for the use of hoses from this company was given by the state organization Rostest. In addition, the manufacturer received the appropriate permit from Gosgortekhnadzor, which approved the use of products for connecting household gas in residential premises.

The Emiflex gas hose has the following technical characteristics, which make the company a market leader:

- the product is designed to work with natural and liquefied gas;

- the maximum gas pressure for which the product is designed is 7 atm;

- the device can be operated without loss of properties at temperatures from -20 to +100 °C;

- thickness of the metal bellows hose – 2.1 cm;

- it is permissible to stretch the product twice its original length;

- Hoses are available in various cross-sectional diameters - 1, 1/2, 3/4 (in inches);

- Among the types of fastenings, options such as nut-nut and nut-fitting are available;

- The outer coating of the bellows protects the product from exposure to chemical detergents.

The maximum length of the Emiflex gas hose, which is certified in Europe, is 2 meters. For the production of devices, stainless steel is used, marked AISI 316 L. In addition, the hose comes with an aluminum gasket, which is used during installation. The manufacturer draws attention to the fact that lengthening the sleeve is possible only during installation. It is unacceptable to stretch the hose during operation.

Another certified Italian manufacturer in the Russian Federation is Idrosapiens SRL, which also has a European quality certificate confirming the product’s compliance with standards for household use.

The gas hose from Idrosapiens SRL has excellent technical characteristics

Gas hoses from this company guarantee high-quality and safe operation for 15 years. At the same time, longer use is not excluded, but without providing a warranty from the manufacturer. Below is a table indicating the price of gas hoses from Italian manufacturers.

| Size, inch | Length, m | Manufacturer and price, rubles | |

| Emiflex | Indrosapiens | ||

| 1/2 | 0,5 | 1350 | 1300 |

| 0,75 | 1700 | 1500 | |

| 1 | 1850 | 1650 | |

| 2 | 3800 | 3450 | |

| 3/4 | 0,5 | 1700 | 1550 |

| 0,75 | 2000 | 1750 | |

| 1 | 2500 | 2150 | |

How to choose?

To begin with, it should be clarified that statements about the maximum length of the eyeliner are not entirely correct. Such myths are diligently spread by gas service employees. They are quite understandable - for increasing the length of a rigid pipe, a substantial fee is taken. Naturally, connecting using flexible hoses is unprofitable for monitoring services. At the same time, in Russia there are no restrictions on the length of the gas hose established at the state level.

In the EU there is a 2 m limit, but whether to take it into account is up to you to decide. European standards do not have legal force in our country, and internal instructional documents of gas services are valid only up to the home tap. In practice, however, it is not so easy to decide which sizes are better. Measuring the required area with a tape measure is only half the battle.

But the distance may vary. For example, when rearranging furniture, making major repairs, or simply while cleaning the stove. All this should also be foreseen in advance, otherwise problems will be inevitable

You should immediately note that hoses 3 or 5 meters long are equally reliable and can withstand high pressure. Of course, only if other indicators are carefully taken into account. All gas hoses must be purchased strictly at specialized retail outlets

And even there you should definitely ask for a certificate. If you refuse to present it or have the slightest doubt, it is advisable to refuse the purchase. It is not advisable to purchase Chinese products

All gas hoses must be purchased strictly at specialized retail outlets. And even there you should definitely ask for a certificate. If you refuse to present it or have the slightest doubt, it is advisable to refuse the purchase. It is not advisable to purchase Chinese products.

The hose must be braided with a yellow symbol. If it is absent, we can confidently assume that the hose is not suitable for pumping gas. In most cases, hoses with a length of 1 to 2 m are used. The predominant thread diameter is ½ or ¾ inch. But gas boilers and water heaters that consume more blue fuel than a conventional stove must be connected through a 1-inch hose.

It is also important how the hose is connected to the consuming equipment. There are two connection formats: with a pair of nuts or with a nut and a fitting at the ends. Since you cannot bend the home pipeline too much, you must immediately decide whether an angular or straight connection will be used

Of course, you can’t skimp on a gas hose.

Since you cannot bend the home pipeline too much, you must immediately decide whether an angular or direct connection will be used. Of course, you can’t skimp on a gas hose.

What is a dielectric insert for gas: main purpose

The dielectric insert (coupling) is a cut-off fitting that prevents failure of gas equipment, which can be caused by stray current. These currents are formed in the ground due to a violation of the integrity of a household or industrial electrical line. In addition, their source is a railway or tram line. Stray current enters the gas pipeline due to the difference between the resistance of the soil and the metal parts that make up the gas pipeline. It is through the main line that the current enters the household gas pipeline.

Another reason for the occurrence of stray current in the gas system may be poor-quality grounding of household appliances that come into contact with the gas pipe. In general, we can say that there are many reasons for the appearance of stray currents, and the consequences from them will only be negative. To avoid this problem, a dielectric is used for the gas hose, which is inserted between the gas tap and the bellows connection to the gas appliance.

The coupling is installed in order, firstly, to prevent failure of gas equipment, especially if it is modern equipment equipped with a large number of electrical functions. Secondly, the presence of a dielectric prevents the occurrence of a spark, which can cause a fire or even an explosion. For these reasons, according to the rules of the gas service, a dielectric must be used to connect gas equipment, be it a bellows or rubber liner. It comes in two types:

- dielectric couplings - attached between the gas pipeline and the hose that fits the device;

The thread of the fitting can be cut both outside and inside the end part

- dielectric bushings - are non-conducting bushings mounted in the place of dismountable mating of gas pipe elements.

Like bellows hoses, inserts are classified by size, which vary depending on the diameter of the threaded part - 1/2, 3/4 and 1. Therefore, for any type of flexible bellows gas line, you can select a product of the appropriate size. The thread of the insert can be either external or internal. Both bushings and couplings have the same strength characteristics and are designed for a pressure of 6 atmospheres.

Interesting information! The dielectric material used in the production process of the bushing is polyamide, a non-flammable polymer characterized by a significant resistance of approximately 5 million ohms.

Dielectric couplings are special fittings with threaded ends, mounted between the gas pipeline and the fuel-consuming device.

Instantaneous water heater repair prices

No. Name of work Unit of measurement Price, rub. (VAT included)

| 1 | Dismantling an instantaneous water heater with installation of a plug | water heater | 970 |

| 2 | Connecting an instantaneous gas water heater | water heater | 2750 |

| 3 | Replacement (or repair) of an instantaneous water heater burner | burner | 440 |

| 4 | Replacing the block tap | block crane | 1760 |

| 5 | Replacement (or repair) of the gas part of the block tap | detail | 1110 |

| 6 | Replacement (or repair) of the water part of the block tap | detail | 670 |

| 7 | Replacing the heat exchanger | heat exchanger | 1060 |

| 8 | Replacing inlet and outlet pipes | a tube | 420 |

| 9 | Replacing the solenoid valve | valve | 460 |

| 10 | Replacement of draft sensor, microswitch, thermocouple | sensor/microswitch/thermocouple | 300 |

| 11 | Replacing gaskets (eliminating water leaks) | pad | 510 |

| 12 | Replacing the handle | pen | 100 |

| 13 | Cleaning the fitting, water nozzle | fitting/nozzle | 470 |

| 14 | Cleaning (replacement, repair) of the igniter nozzle | nozzle | 300 |

| 15 | Cleaning the tube, adjusting the draft sensor | tube (traction sensor) | 230 |

| 16 | Burner cleaning | burner | 710 |

| 17 | Removing and cleaning the supply tube | supply tube | 440 |

| 18 | Cleaning the radiator (heat exchanger, heater) from soot | radiator | 1760 |

| 19 | Replacing batteries | battery | 170 |

| 20 | Replacing a corrugated outlet | corrugated outlet | 500 |

| 21 | Lubrication of block valve plug (rod) | operation | 310 |

| 22 | Packing the oil seal (replacing the gasket) of the water part of the valve block | operation | 400 |

| 23 | Replacement (repair) of flame sensor, spark plug | sensor, spark plug | 300 |

| 24 | Installation (adjustment) of a new steel structure | operation | 2000 |

| 25 | Mounting an instantaneous water heater without drilling holes | operation | 1490 |

| 26 | Fastening instantaneous water heater with drilling holes | operation | 1660 |

How to properly install the dielectric when making bellows connections

According to the state safety standard, a dielectric insert must be installed between the gas tap and the bellows connection. Basic steps to be taken when installing the bushing:

- Turn off the gas valve. It is important to leave the gas on the stove so that it all burns out.

- Take 2 adjustable wrenches: with one you need to hold the valve body, and with the second, you need to tighten the nut of the bellows connection that connects the pipe to the gas appliance.

- Screw any seal onto the free ends of the coupling (a polymer version is best for this), and then manually screw the dielectric into the gas pipeline.

- Again, using 2 keys, one of which holds the valve, and the second holds the coupling, the product is screwed in until it stops. It is important not to overdo it here, so as not to strip the threads and deform the valve body.

- Screw the nut from the bellows hose onto the other end of the coupling, holding the dielectric with an adjustable wrench, and tighten the connection firmly.

After completing all the steps, you need to check the joint for leaks. To do this, use either a small brush or a shaving brush, which is first lathered generously. A soap solution is applied to all joints and inlets, after which the gas tap is slowly opened. If even small bubbles or foam suddenly appear, the tap should be turned off and the quality of the joints should be additionally checked. You can use a gas appliance only if the soap solution does not bubble. Neither matches nor lighters should be used to check leaks, as in the event of a leak they can cause a tragedy.

Any sealant must be applied to the free ends of the dielectric coupling

Requirements that must be taken into account when working with gas pipelines

Before connecting gas to the stove and boiler, it is necessary to find out what features should be taken into account when carrying out this type of work.

As a rule, gas does not differ in pressure from atmospheric pressure. However, a typical excess gas in the pipe may be 0.005 MPa or 0.05 atmospheres.

Since neither gas nor its propane-butane mixture are chemically aggressive substances

, they do not cause corrosion of steel pipelines.

In addition, the minimum viscosity of the gas allows it to be transported through a pipe with a small internal diameter. Therefore, it is quite possible to install a pipe whose diameter does not exceed 1/2 inch.

It must be remembered that most often when installing gas boilers with high power ratings, pipes with a large cross-section are used. As a rule, the recommended parameters are indicated in the instructions that accompany any gas equipment.

Gas pipelines must be completely sealed.

This also applies to pipe connections. A gas leak, unlike a tap water leak, is a very serious problem that can lead to a fire or explosion.

How to make a safe gas connection: connection features and safety precautions

Regardless of which hose for the gas stove is chosen: bellows or any other flexible hose option, the connection will be made according to the same pattern. Before connecting the hose, you need to unfold the gas device and inspect the back wall of the product. On some models, the gas pipe is marked “Output”. Depending on the configuration, the product must be placed straight or at a slight angle.

In any case, it is important that the hose does not bend too much. To avoid this, additionally purchase corner adapters that allow you to change the angle of direction of the sleeve. In advance, before carrying out all work, it is necessary to think about the location of the stove and calculate the length of the hose.

Important! Before starting work on installing or replacing a gas hose, you must turn off the gas valve and do not open it until measures have been taken to identify a possible leak.

The riser is most often located in one of the corners of the kitchen, and a pipe extends from it, connected by welding, with a gas tap attached to it, to which a flexible bellows gas supply will be attached. If the faucet has an external thread, then a union nut is used to connect the hose. If there is an internal thread, the sleeve is screwed directly into it.

Before you begin work on installing the gas supply, you must turn off the gas valve.

It is imperative to install a paronite gasket between the entrance to the gas equipment and the hose, which comes complete with the tap. Some experts recommend purchasing a gasket equipped with a metal mesh yourself. If a high-quality faucet has been chosen, then you can be sure of the reliability of the gasket.

After installing the paronite gasket, the bellows hose is screwed to the outlet of the plate, and then all connections are tightened using a wrench. At the last stage, it is necessary to conduct an inspection for the possible presence of leaks, using a soap solution, as in the case of installing a dielectric. If no bubbles appear, the cooker or other device can be used safely.

Typical connection instructions

Ideally, it is better to invite a specialist to install gas and gas-electric stoves, but if you are still determined to make the connection yourself, then the installation instructions will help with this. By following it in detail and carefully observing the mandatory points, it is quite possible to cope with this task yourself.

The standard sequence of actions is as follows:

- Free the “object” from packaging materials and all components (baking tray, tray, dividers, etc.), leaving only the protective film, which must be removed after completing all repair work.

- Install the stove in the intended place, maintaining the distance from the wall specified in the attached documentation.

- Using a level and adjustable feet, the working surface is leveled horizontally.

- A flexible hose is connected to the gas pipeline. To do this, the threaded connection is wrapped with a sealant (FUM tape) and tightened with the appropriate wrench.

Then the gas hose is connected to the device in the same way, using a seal and tightening the locknut with two open-end wrenches. It often happens that the thread at the outlet of the plate has a pitch of 3/8′, then an adapter is installed that comes with the device.

- The last step is to check both connections for leaks, which is carried out using a soap solution. In this case, thick foam is generously applied to the joints (with a brush or hand) and the gas supply valve is opened on the lower side. If bubbles appear at the joint, the tap is turned off and the defective connection is redone. If the surface remains level, then there is no gas leak, which means the new stove is installed correctly.

- At the end, the functionality of the burners and oven is checked.

The video will help you understand more clearly how to properly install a gas stove yourself.

Installation recommendations

Experts advise following several rules when attaching gas hoses:

- to avoid kinks, tension or twisting, in order to connect the hose to the plate without compromising its integrity, you should select a bending radius of the part equal to three diameters of the hose used;

- the length of the part is selected taking into account the required distance, so that it is possible to move the equipment if necessary, and the type of product that was chosen, with some supply of hose for the gas stove, so that unnecessary stress is not created in the structure;

- the place must be accessible for inspection of parts;

- there should be no extraneous connections on the device;

- the product cannot be painted to prevent surface cracking;

- connections are made using metal tips;

- parts should be protected from condensation causing oxidation.

Regardless of which hose you connect to the gas stove, you should use the electric ignition very carefully.

Unapproved connection to the gas pipeline after the gas meter

Connection to main gas: permitting documentation

Stage 1. Collection of the necessary documentation to be submitted to the interdistrict gas trust (MTGH) for the issuance of specifications. List of necessary documents for connecting gas at the first stage: At this stage, you will only have to spend money on thermal engineering calculations (about 3,000 rubles), the preparation of which will take up to 10 working days.

To obtain the technical specifications, it is necessary to pay a bill for the permitted connected power in the amount of 159 rubles/kW of the capacity of the gas equipment noted in the application.

Gasification of a private home: what is needed for this

A copy of the BTI technical passport for the house. 1.4. Topographic survey with planting of the house and gasified buildings and premises on the owner’s property.

1.5. Permission to connect to the gas pipeline, if it is laid in neighboring areas, from its owner (usually the owner is GorGaz). 2. Obtain from GorGaz the technical conditions for gasification, and, if necessary, for electrochemical protection of the designed underground gas pipeline.

Replacing gas pipes in an apartment: features of the work

Therefore, if a replacement is necessary, you will need to contact the appropriate institution and wait for the technician to arrive.

Work on replacing a gas pipe Having arrived at the installation site, the technician must remove unauthorized persons from the site and ensure that there are no smokers or sources of open fire.

Before entering the work site, a warning sign “Caution! Gas!”, “Smoking is prohibited!”, “No entry!” etc

There is a great desire to supply gas to the house, but there is no 300-500 thousand.

rub. There is a neighboring house that has gas installed.

The third part of the old house belongs to the owner of the new one; an agreement can be reached with the remaining owners, as long as there is no danger of an explosion. Is it possible to make an illegal transfer? What does this mean? The new house is planned to accommodate one person year-round, while the old house will accommodate 3-5 people in the summer.

And the consequences can be quite severe. If you want to find out how to solve your specific problem, please contact the online consultant form on the right.

It's fast and free! Or call us at 8(800)-350-30-02 (the call is free for all regions of Russia)!

Unauthorized gas connection should be understood as an illegal connection to gas mains and gas pipelines using gas-using equipment without obtaining permission from the enterprise providing gas supply to the territory in which such a connection was made.

Fine for unauthorized connection of gas and equipment: stoves, water pumps

No. 549 “On the procedure for supplying gas to meet the household needs of citizens.”

The main provisions of this regulation are: Thus, the use of gas and gas equipment must be under the constant supervision of competent specialists. Such actions actually qualify as gas theft.

Administrative

Every technical specialist: builder, designer, power engineer, occupational safety specialist.

At home, in the office, on the go: your reliable legal support, anytime, anywhere.

Every technical specialist: builder, designer, power engineer, occupational safety specialist.

At home, in the office, on the go: your reliable legal support, anytime, anywhere.

Questions and answers

Sosenskoye, village Nikolo-Khovanskoye, (Novomoskovsky administrative district of Moscow), reviewed by JSC MOSGAZ. First Deputy General Director I want to buy an apartment in an apartment building on the attic floor.

There is no gas in the attic. Is it possible to install gas into the attic (based on what law)?

Is this legal? Do you need the consent of the home owners? Thank you. Dear Lyubov Sergeevna!

First Deputy General Director Good afternoon! I want to connect gas to a house in...

an existing low-pressure gas pipeline. They will not reduce or completely shut off the supply. What - a torch, cutter, electric welding to cut holes in an existing pipe. To be honest, I’m in a stupor. Author, could you please explain? Or is it an inert gas?

>

What to consider for connection security

To safely connect and use the equipment, you should follow some rules:

- whatever the hose is to connect the gas stove, its location must be freely accessible so that it is not blocked by foreign objects;

- You should not replace the hose on a gas stove with your own hands; it is better to invite a gas specialist;

- connecting equipment with a flexible hose must be carried out in strict compliance with safety requirements;

- after connecting, the hose should sag slightly, without tension;

- the element must not be bent or twisted;

- the part cannot be painted;

- It is worth replacing the element a little earlier than the time for which it was designed; you cannot wait until a gas leak begins at the stove and then change the hose.

Replacement of the liner must be carried out by specialists licensed for such activities. They also periodically check the functionality of the equipment.

If the jets are installed incorrectly

Applying decorative plaster with your own hands: video, methods and rules for performing the work

It is quite simple to determine that the wrong jets are installed on the slab.

This will be noticeable by the following signs:

- the burner ignites with a bang, goes out, burns with a hum and is unstable;

- the flame is low and hisses, extinguished;

- The color of the fire turns yellow and soot is formed.

All this indicates incomplete combustion of gas, which means there is a high risk of an emergency. Therefore, you need to replace the injectors with those provided by the manufacturer.

You can do this yourself, taking all precautions, or invite a specialist. But no matter how easy this work may seem, in the absence of basic knowledge about the structure of the stove, you should not take it on

Rules for connecting a stove in a private house

If in a city apartment the duties of gas supply service specialists, with whom the owner has entered into a voluntary-compulsory agreement, include mandatory inspection of gas equipment at least once every six months for the safety of the entire house, then in the private sector the situation is different.

Here the homeowner independently makes a decision on gas supply; he can connect to the central gas pipeline and enter into an agreement with the relevant services, similar to apartments, or use an autonomous gas supply from cylinders and gas holders.

With the latter options, you will most likely have to connect the gas stove yourself or with the help of hired specialists without any guarantees. Therefore, you should approach the matter with full responsibility and carefully study the technologies in order to choose the right components and carry out high-quality installation.

Installation of gas hoses

Where to contact?

To officially change the stove to a more modern model, you will need to:

- buy a unit;

- contact a gas company that has an SRO certificate, that is, permission to install gas equipment in a residential building.

Private gas services most often offer their services at affordable prices. After installing a new stove, it will be necessary to register it with Gosgaz. Employees from licensed companies are also authorized to make entries in the passport of the new gas unit

It is most rational to call a gas specialist from the municipal gas organization, because the fewer intermediaries in this important matter, the better

There is a certain procedure for replacing slabs in private households. In megacities, there are city programs according to which all gas stoves must be modernized. Often such operations are implemented at the expense of municipal budgets (Moscow, St. Petersburg, Nizhny Novgorod).

- if the slab is on the balance sheet of municipal or state organizations;

- if the homeowner has benefits, being a hero of Russia or the Soviet Union, a participant in the Great Patriotic War;

- slabs are also changed for elderly people who do not receive any subsidies;

- poor citizens whose income is below the minimum wage;

- citizens who live in non-privatized households under a social tenancy agreement.

Before starting operation of the stove, you should draw up a document “On technical inspection”. It is also called a “defective statement”. It is usually compiled in several copies. It should contain the following entries:

- about existing faults;

- operating time of this device.

After analyzing the annual preventive inspections of the slab, a final document is drawn up. Then an application is made to the DEZ, which indicates the request for a replacement. The DEZ employee must put the homeowner in line to replace the gas appliance.

To make the replacement yourself, you need to take the following steps:

- submit an application to the REU of the city gas service, where you should indicate a request to replace the unit;

- a specialist will arrive from this organization, who will assess the amount of work to be done and issue an invoice;

- if the homeowner installed the stove himself, he is obliged to write a request for permission to connect it;

- after the invoice is received, it should be paid and an agreed time for the master to come and do his work;

- After installation, a corresponding mark must be placed in the gas stove passport.

Rules for connecting a stove in an apartment

When using a stove in an apartment, it is better to entrust its connection to specialists from gas supply services and organizations, with whom you must first conclude an agreement for the supply of natural fuel with the opening of a personal account to pay for services. An agreement is usually necessary when purchasing a new apartment; the list of documents that are generally needed to connect a gas stove in compliance with all standards is as follows:

- Certificate of ownership of the apartment and a certificate confirming state registration of housing.

- Registration certificate for the apartment.

- An old contract for the maintenance of the stove and a subscriber's book, if available.

- Passport for the installed stove and gas meter.

The documents collected by the homeowner are submitted to the gas service, after which its specialists issue forms for filling out a gas supply contract. After filling out the papers and receiving instructions on the operation of gas installations, the contract is signed by both parties with the issuance of permission to connect the equipment.

Pipes for gas stoves and panels

What you need to know before moving the kitchen into the living room

A typical kitchen is convenient for cooking, but absolutely not suitable for a large family dinner, not to mention the most solemn occasions that bring together both relatives and numerous friends.

A spacious kitchen is the dream of most families in a panel or brick apartment building. Wanting to increase comfort, owners sometimes decide to combine the space of the kitchen and the adjacent room, creating a studio (a hybrid of kitchen and dining room).

Factors affecting transferability

Obtaining a permit for redevelopment in a building is much more problematic than in your own home in the private sector; It is easier to coordinate the future kitchen-dining room if the stove and sink are not moved into the room.

The fundamental possibility of reconstruction is influenced by the following circumstances:

It is allowed to move the kitchen into the living room:

- those living on the first floors or higher, if there is a non-residential premises below (shop, warehouse, office, parking) or an apartment with a similar redevelopment. The exception is a one-room apartment, in which the only residential space is thus converted into non-residential space;

- owners of multi-level apartments on the second floor.

Redevelopment is impossible if the mortgage agreement expressly prohibits such changes.

Coordination and preparation for kitchen relocation

Remodeling an apartment without approval is an easy but short-sighted decision. Mistakes made can have a negative impact on the technical condition of a residential building and lead to malfunctions of individual systems; An apartment redesigned without approval cannot be sold or exchanged.

Gas pipe transfer

When moving a kitchen into a living space, work with the gas pipe is most strictly regulated. Building codes prohibit:

- place the gas pipe next to the electrical wiring; the optimal distance is considered to be 10 cm;

- install a gas pipe fork; hide gas pipes under trim or screed, or deepen them into walls.

Relocation of water supply

An important task is the technically correct location of the sink and dishwasher, as well as the competent installation of water supply and sewerage pipes.

Plastic pipes are preferred for water supply (due to their long service life). They are hidden in the walls, under the ceiling, behind plasterboard trim or in the floor screed.

Ventilation transfer

During installation it is important to remember:

- the exhaust ventilation will have to be pulled to the main ventilation duct in the kitchen, which cannot be dismantled; you cannot connect to the ventilation duct of the bathroom;

- if the new ventilation pipe is long, it is necessary to install a fan with a silencer

- the pipe (due to its large cross-section) cannot be placed behind a suspended ceiling; You will have to punch a hole of significant diameter in the wall.

Lighting transfer

When drawing up a project, it is worth calculating the possible increase in load on the electrical network and considering the convenient location of sockets and lamps.

Relocating household appliances

The location of the sink and stove is entered in the apartment passport. The rest of the household appliances can be placed at your own discretion.

Connection using a pipe

Connecting a gas stove with a metal pipe is used quite rarely in households - this technology is complex, economically unprofitable and obsolete, and it does not allow installing the stove in another place. To connect, it is necessary to manufacture and bend a pipe of a given size, cut threads at its ends and connect it to the main line and equipment using couplings.

- When carrying out work, several options are considered: in the first case, the supply pipe is welded to the main pipeline, and the second end is connected to the slab using a surge coupling with a fixing nut.

- In another option, couplings with lock nuts are installed at the edges on the supply pipe section (threads are pre-cut on both sides), which is then screwed to the main pipeline and the outlet pipe of the slab.

You can do without couplings with nuts to implement a collapsible connection if you have a welding machine - for this, American adapters are welded to the two ends of the pipe.

One of the rather rare connection options is the use of copper pipes - in this case, the workpiece is bent as required with a pipe bender and fittings with union nuts are soldered to its ends.

Connection diagram for a pipe section using couplings

The main advantages and features of stoves with electric ignition

Naturally, not everyone needs such a function as electric ignition. Many people still use matches or a lighter to light the burners. At the moment, it is unlikely that you will be able to find a stove that does not have an electric ignition function. But there's nothing wrong with that. Prices for stoves with and without electric ignition are practically the same.

In fact, a stove with electric ignition has several advantages:

- You don't have to run around looking for matches or a lighter to turn on the gas. Moreover, this technique is very easy to use.

- There is no way you can get burned while lighting the burner.

- If you have used an electric stove for quite a long time, then the process of getting used to gas appliances will be more painless for you. You simply need to press a button or, as in the case of automatic electric ignition, turn a switch.

Safety Rules and Tips

You must adhere not only to the step-by-step instructions, but also to the requirements for a secure connection, which include the following recommendations:

- The connections and flexible hose make them accessible in case of a sudden gas leak.

- The maximum permissible length of 1.5 m cannot be exceeded by a centimeter.

- Twisting, bending, pressing, and contact with hard surfaces is not allowed.

- Normal use is permitted only after inspection by a gas service inspector.

- Before starting work, stop the gas supply and check that the valve is sealed in the closed position.

- During the installation process, only special equipment, fasteners, tools, and seals are used.

- The use of uncertified components and sealing materials is prohibited.

- After depressurization, the pipes are plugged with a damp cloth and released immediately before connection.

- For half-inch pipes, a regular cap from a PET plastic bottle is used as a stopper.

After assembly, each connection is coated with a soapy water solution to detect leaks. Bubbles indicate that the connection needs to be unscrewed, the seal removed, a new one applied and re-twisted. After this, the verification procedure is repeated. At the end of the activities, the tap is turned off, and a master from Gorgaz is called, who must carry out an inspection and make a corresponding note in the log. Even if you have to wait several days for an inspection, do not use the oven as it is unsafe even if everything is done correctly. Only a specialist will identify a defective slab if the manufacturer allowed it.

Connecting a gas cylinder to a stove at the dacha, where can I go myself?

This question makes you wonder where to go for help, whether you can make the connection yourself, whether this is a difficult process.

Like the connection of any gas equipment, the connection of the gas cylinder and the stove in the country must be supervised by a representative of the gas service. If it is not possible to promptly call a specialist or the application was not responded to as quickly as we would like, you can handle it on your own. But after this, you still need to call a specialist to evaluate the work of the amateur and correct any shortcomings if any are discovered.

First you need to make sure that the stove is in order, as is the gas cylinder (there should be no obvious damage, severe wear, etc.).

You should also stock up on tools:

- gas tube;

- gas reducer;

- cabinet for storing the cylinder.

The algorithm of actions will be as follows:

- The cylinder should be placed at a distance of 5 meters from the stove.

- The place for installing the cylinder must be prepared: you need to install a special cabinet and prepare fastenings.

- Now you need to connect the hose by screwing it onto the hose of the stove.

- Tighten the clamps as much as possible.

- Install the gearbox on a special adapter with wrapping tape.

- Connect the cylinder.

- Open the valve and check for leaks. To do this, use a regular soap solution: there are no bubbles, which means everything went well.

Gas line service life

After installing the hose, you should check its service life and remember the installation date. The product, depending on the type, is designed for a period of 5 to 15 years. It is important not to forget to replace it on time.

Guaranteed service life is indicated in the product passport and in the certificate of conformity.

- rubber hoses (with and without sheath) – 5-year warranty, service life up to 10 years;

- PVC eyeliner – 12-year warranty, lasts up to 20 years;

- bellows gas hose - 15 year warranty, does not require replacement up to 30 years.

Kinds

Having familiarized yourself with the basic requirements that a flexible gas channel must meet, you can now take a closer look at its individual varieties. There are four main types of hoses:

- rubber, reinforced with polyester thread and other materials;

- pure rubber;

- made of rubber and special fabric;

- bellows format.

Rubber fabric hose is quite cheap. Textile threads are used to strengthen it. It is easy to install such a product, it is highly flexible and, moreover, quite functional. At any retail outlet you can find a product that is suitable in length and internal cross-section.

That is why they are actively used to connect household appliances to sources of liquefied gas. The only problem is the insufficient safety of the structure. Gradually, the rubber will become covered with small cracks. This threatens the gas escaping. As a result, rubber hoses of the classic type are now used only for connecting end devices to cylinders.

It should be remembered that rubber gas hoses are not rigid enough. Their normal period of use is 24 months. After this period expires, no one will undertake to guarantee the serviceability of the system. However, the most modern brands of rubber (due to special additives) can last up to 5 years. An improved option is a rubber hose with a reinforcing layer.

Externally, such a product resembles an ordinary water hose. The outer weaving is made of stainless steel (in the form of threads). Inside there is a polymer hose in direct contact with the gas. It is not difficult to distinguish a product for gas supply from a water supply one - its braiding contains yellow fragments.

However, such hoses can only withstand temperatures no higher than 50 degrees. In most industrialized countries such designs are not used at all. Domestic gas services also consider their use undesirable. Some exceptions are made for cases where security restrictions are observed as strictly and strictly as possible.

We must also remember that steel inclusions transmit electric current. Therefore, the use of insulating gaskets is a prerequisite for normal operation. They also make the home gas pipeline somewhat more complicated and more expensive. To supply gas under high pressure to the Russian Federation, only a bellows (corrugated metal) hose can be used.

It easily tolerates:

- high heat;

- squeezing;

- mechanical impact;

- high internal pressure.

This product has at least two layers. The outer layer, predominantly made of PVC, increases the safety of the products. The fact is that the polymer layer helps prevent electric shock to the gas pipeline and reduces the risk of corrosion processes. There is another type of bellows gas channels that use steel braiding without insulating material. Regardless of this difference, the internal passage must be at least 1 cm in diameter.

A high-quality bellows hose can last 20-30 years. Therefore, its increased cost is completely justified. Carefully selected polymers provide reliable protection against aggressive substances. Even in the most ordinary kitchen such substances are sometimes found.

Documentary question

Connecting a gas stove begins not with preparatory work, but with purchasing the stove itself and carefully unpacking it. But even after the most thorough inspection, do not rush to start work. After all, you still need to get a list of documents from the gas service. To do this, you must provide local gas workers with your passport with a certificate of family composition, a title document for housing, a passport for the meter, a maintenance agreement, gas receipts, a subscription book, and a certificate of registration of ownership.

Only after this Gorgaz will issue you a subscription book with notes on instructions on how to behave with gas for you and all members of your family, forms for an agreement on the supply of gas to your home, as well as a contract for this same gas supply.

Advice: after receiving the necessary documentation, try to connect the stove as soon as possible. After all, the warranty period extends from the date of purchase of this household appliance, but not connection. Therefore, if you decide to put your new stove in the garage or pantry for an indefinite period of time, this is not the best idea.

Choosing a location for kitchen equipment

It is placed where appropriate, based on comfort requirements. But there are a number of other mandatory requirements. The floor surface must be perfectly flat

This is important not only from a safety point of view

If there is a misalignment, the dishes are cooked unevenly. To prevent this from happening, use the adjusters on the legs. Most modern modifications of household gas stoves are equipped with them. This will allow you to install the stove correctly even on an uneven floor.

When connecting gas stoves, but without adjustable legs, place pieces of chipboard, plastic, plywood, etc., selecting them according to thickness

It is important that all connections and hoses are within reach

In the event that repairs or replacement are required, it is important to be able to perform the actions without dismantling and in cramped conditions. Ventilation is also important

Therefore, the meter, tap and pipes are not “sewn up”. And the stove itself is not placed close to the wall. See the manufacturer's instructions for the gap size. This requirement cannot be violated. This is the safety of your family and property.