Those who decide to renovate a new building apartment will not have to change communications, because the pipes in new houses are made of polymer materials that meet all modern requirements. But if you live in an old house, then replacing the plumbing in the apartment is a necessity. After many years of use, they have reached a high degree of wear and tear, and their appearance leaves much to be desired. If you prepare well, you can replace the pipes in your apartment yourself.

When do you need to change pipes?

There are two main reasons to replace your home's plumbing system.

- Wear and tear of pipes: Steel products rust over time and become unusable. To avoid their complete destruction, it is necessary to replace communications.

- Planned repairs: if the apartment owner is renovating the bathroom, then it makes sense to change the pipes at the same time, even if there is no serious damage.

In both cases, it is necessary to completely remove the old pipes, inspect the risers, and, if necessary, cut them off. The new system is installed according to a pre-developed scheme.

Worn steel pipes

Reasons for installing a new riser

The need to replace a vertical pipeline arises in two cases: after the expiration date of the metal structure and when performing a complete renovation of the bathroom.

Depending on the conditions, its replacement is performed in one of two modes:

- planned - when water pipes are worn out;

- emergency - when a malfunction occurs and a leak occurs.

In old houses, the “original” apartment risers are made of galvanized or cast iron pipes. Metal structures are susceptible to corrosion and therefore require replacement.

Corrosion is the main enemy of cast iron and steel pipelines; it “corrodes” and corrodes risers with hot water supply faster than with cold water

It has been noticed that pipes wear out the most in interfloor ceilings. Therefore, the joining of the new pipe to the old one should be done outside the ceiling: in the bathroom of neighbors living on the floor below or above.

For metal pipes, the service life is about a quarter of a century. In reality they last much longer. But after forty years of service they fall into disrepair.

The use of metal pipes after the warranty period is not recommended for the reason that they can break at the most unexpected moment

Even if the pipes look intact after the end of the operational period, it is still recommended to replace them. This is explained by the fact that a pipe worn out over time can burst at any time, which will lead to great material damage both for the owners of the apartment and for neighbors affected by flooding.

As planned, it is recommended to replace pipes at the stage of major repairs. When arranging modern interiors, it is customary to “hide” the pipeline in the wall, and therefore getting to it in the event of an emergency will not be easy.

If you dream of installing a new jacuzzi or purchasing auxiliary equipment for the bathroom, then moving the vertical pipeline cannot be avoided

Cast iron pipes are usually replaced with polypropylene analogues. And this choice is fully justified by a number of undeniable advantages that the polymer has.

These include:

- resistance to corrosion and aggressive influences;

- smoothness of the inner walls, preventing the accumulation of limescale on the inner surface of the pipeline;

- high strength;

- environmental Safety.

For arranging a pipeline with cold water, ordinary metal-plastic and polypropylene pipes of the appropriate diameter are suitable, and for supplying hot water, pipes intended for heating systems are suitable. They are characterized by higher strength and increased resistance to deformation.

Manufacturers of polypropylene pipes claim that the service life of products is about 50 years, and those used to supply cold water are about 100 years.

The internal surface of polypropylene pipes, which is in contact with drinking water, meets all sanitary standards, and the internal diameter of the products does not change during operation

Compared to metal structures, installation of polypropylene pipes takes much less time. The use of welding technology makes it possible to obtain a strong and reliable connection with minimal effort.

Types of pipes for an apartment

Modern materials from which water pipes are made are divided into three groups.

Table 1. Types of pipe materials

| Type | Description |

| Metal | Steel (galvanized or uncoated), copper |

| Plastic | Polypropylene, PVC |

| Composite | Consist of metal and plastic |

Steel pipes are installed quite rarely, although their service life reaches 50 years. Firstly, there are problems with installation: it is difficult to do without special equipment (welding, pipe bender). Secondly, steel (even with a zinc coating) rusts quite quickly and requires painting.

Steel pipes

Copper pipes are more durable, but they are also the most expensive. Collecting them on your own is also not easy.

Copper pipes have a beautiful appearance and can be an excellent decorative element.

Most often, metal-plastic and polypropylene pipes are installed. The reasons for their popularity: simple installation, durability, favorable appearance without additional processing. Plastic pipes during assembly will require the use of a special device - a soldering iron. But its cost is quite low, and if necessary, you can rent the device.

Plastic pipes

Prices for water pipes

Water pipes

Metal-plastic is also durable (pipes can last up to 40-50 years). But due to the use of different materials (their coefficients of thermal expansion are different), threaded connections are weakened during temperature changes, and during water hammer, the seal may also be damaged.

The main stages of replacing a water supply system

Residents of apartment buildings must, first of all, purchase all materials, including consumables. Only after delivery of everything necessary can you turn off the water on the riser; this will shorten the period of lack of water for other residents; by the way, do not forget to warn them about this. For dismantling you will need an ordinary grinder; with its help you can remove all old pipes with the least effort and in the shortest possible time.

Replacing shut-off valves

Before replacing the water supply in the apartment, check the serviceability of the valves at the entrance to the apartment. Most often, the performance of this device is impaired, so repairs should begin with replacing the faucet.

It will be better if you entrust this stage to a professional plumber, and you should officially contact the housing office. This approach to replacement can save you from many difficulties.

First of all, there will be an additional guarantee that none of the residents will independently turn on the water supply in the basement.

Dismantling old valves very often ends with the threads on the supply pipe breaking. In this case, it will be a plumber's problem.

When choosing a faucet, do not try to save on cost; the device will have to last quite a long time, so a lot depends on its quality.

Filter installation

Requirements for the design of water supply systems stipulate the installation of special filters. Modern mixers are very sensitive to the presence of various mechanical impurities in water. Scale, sand, and metal scale disable such devices very quickly, and besides, it will not improve your health.

The choice should be made on the simplest coarse filter; it includes a metal mesh and a regular settling compartment.

By the way, install the filter so that the sump faces down, otherwise scale will not collect in it.

Threaded connections

Replacing water supply pipes involves making threaded connections of various elements. This applies to installing taps, filters, and connecting various devices.

The threaded connection is sealed in a simple way:

- You will need a simple linen wrap and some paint. Fluff the flax fibers and wrap them around

thread in such a way that it is not tightened when connecting parts (along the thread). Cover the surface of the linen with a layer of paint. This method has been used for many years and shows quite reliable results. - If you are a supporter of modern materials, then use fum tape or similar materials. It is easily wound onto the thread and does not require the use of paint.

For connection, you can use special detachable fittings - American ones; they will simplify the process if dismantling is necessary in the future. Compaction and hermetic sealing of such units is carried out using rubber gaskets.

Selection of pipe diameter

For installation in apartments and houses, two types of pipelines are used: metal (3/4 and 1/2 inches) and plastic (25 and 20 mm).

Table 2. Pipe sizes for different types of wiring

| Type of wiring (diagram) | What diameters are used? |

| Tee | The mains are assembled from 3/4-inch (25 mm) pipes, and the bends to the consumer devices are 1/2-inch (20 mm) |

| Collector | The line from the riser to the distributor is 25 mm, and after it - 20 mm |

Dismantling old pipes

Dismantling an old pipeline is a process that needs to be approached individually. Some elements of the system may be able to be dismantled using a screwdriver or an adjustable wrench, while in other situations a grinder will be required.

The general set of tools required for dismantling comes down to the following list:

- Hammer;

- Bulgarian;

- Hammer;

- Chisel;

- Scrap;

- Sanding discs;

- Screwdriver Set;

- Knife;

- A pair of adjustable wrenches.

It will be ideal if the replacement of pipes with plastic ones is carried out together with the renovation of the home - firstly, you will not have to remove the garbage twice, and secondly, during the renovation it is much easier to hide communications in the walls, if such a desire arises.

Installation of water pipes

Installation of a water supply system begins with opening the wall (if the pipes are behind it), removing old elements, planning what the new connection diagram will look like (it’s better to make a plan). At this time you will have to decide what types of pipes should be used. You can use different ones: for example, replace the steel riser with the same one, and replace the remaining elements with metal-plastic ones.

Assembly is the most labor-intensive process. It is important to connect the pipes carefully to prevent leaks. After installation is completed, a check should be performed. Water pressure is gradually supplied to the risers. Inspection and troubleshooting are carried out.

System check

The last step is sealing the meters and painting (if necessary).

Sealing hot and cold water meters

TOP 5 mistakes when installing plastic water pipes

In this section we have collected the most offensive and popular mistakes when installing plastic pipes.

- Incorrectly marked boundary of the pipe entrance to the electrical fitting. It will force you to lose one fitting and two pipes, but overall nothing fatal.

- Too much force when butt welding. Again, there are two pipes on the list of losses, but you lost them not because of inattention, but because of your own zeal.

- Loosely fitting bevels during cold welding. The result will be a weak connection that will only be held in place by glue.

- Pipes not cleared of dust and grease during welding. The result will be a weak connection that will simply fall apart after a few years.

- Incorrectly measured fitting size before cutting pipes. Will force you to ruin all the material. There is no solution, and the process itself is characterized by large financial and time losses, for which this error receives first place. As the saying goes: “Measure twice, cut once.”

We sincerely hope that this article will help you avoid mistakes and make the process of replacing pipes enjoyable! And if you can share your experience in installing water pipes, or know some interesting secret - write in the comments and we will definitely discuss your information!

Pipe routing: diagrams

Before design begins, you should determine:

- how many plumbing fixtures will be installed in the apartment and where;

- location of the main node with meters;

- installation points for shut-off valves.

It should be taken into account that a number of sanitary installations will require special equipment to reduce pressure (reducers).

Water reducer

At the same time, you need to choose the type of materials that you plan to use. It is important to accurately calculate their number by drawing up an estimate. This is necessary so that during the process you do not need to be distracted by frequent trips to the store.

Pipe routing can be done according to one of three schemes:

- tee (or series). This is the simplest method. A pipe is connected to each riser of the apartment, from which all water consumers will be supplied. Pros: Doesn't require a lot of pipes. Cons: in a large apartment at the end of the main line, the water pressure will be much lower than near the riser, and any plumbing work will require completely shutting off the water;

- collector This is a universal scheme, suitable for both large and small-sized housing. Water from the risers goes first to the distribution unit - the collector, and from it is supplied to each of the consumer devices. The supply is more uniform in terms of pressure in each circuit. But assembly will require more material (pipes);

- combined. This is a combination of the two mentioned assembly methods. Example: one common line is sent from the collector to the kitchen. All consumers in the room are connected to it: sink, dishwasher and other devices.

Main types of wiring

Additional elements in the water supply system are required to improve its performance or to ensure adequate operation of devices. These are reducers for increasing/decreasing pressure, shut-off valves, filters, various sensors and couplings for connecting pipes without welding. There are entire separate systems that can shut off the water supply in the event of a water leak.

Choosing the installation method

There are two methods of normal installation of plastic pipes - welding and press fitting. Welding is divided into two types - cold (using epoxy glue) and hot (using a welding machine).

Cold method

Cold welding is not only a method, but also the name of the main consumable when using it. Nowadays, almost every hardware store sells fast-hardening, reliable glue that allows you to firmly connect plastic pipes together. This method is more resource-intensive than hot welding, but does not require an expensive welding machine. It will also require a little more time - the glue needs to harden, and money, since the material, although inexpensive, requires a lot of it.

On the other hand, it prevents the appearance of sagging inside the pipes, which increases their normal service life. We recommend using this method, since durability and reliability are more important than immediate savings in time and money.

Welding

The classic method of joining pipes, not only plastic, but also metal. Requires a powerful power source, as well as a set of equipment - a welding machine, a protective mask, etc. This method is faster than cold welding and is traditionally considered more reliable. But, as studies have shown, cold welding is not inferior to hot welding in terms of speed and reliability. On the other hand, improper use of hot welding can lead to the formation of beads on the pipes, which is guaranteed to lead to pipe clogging in the next few years.

Press fittings

Another option for connecting pipes, this time purely mechanical. This method is characterized by the use of fittings made of plastic material, which, after installing pipes in them, are pressed with force by a special press machine. This leads to their deformation and fixation of the joints. The result is a strong connection.

Copper pipes: installation

Installation will be expensive, but the system will be more aesthetically pleasing, even when assembled externally, and will also be durable.

What will you need?

- Materials: fittings, angles, ball valves.

- Tool:

- equipment and consumables for soldering (torches, fluxes and solders);

- tool for crimping fittings;

- cutter for copper pipes;

- a set of wrenches for tightening nuts (plus a gas one).

Soldering torch

Prices for various types of gas burners and blowtorches

Gas burners and blowtorches

How to assemble a copper pipeline with your own hands?

- Work planning: creating a diagram, calculating the number of linear meters required for assembly.

Plumbing wiring diagram - Connecting lines (or manifold - if you select the appropriate type of assembly) through adapter couplings. Most often, the riser is made of steel, and it is problematic to securely weld copper to it.

- Assembling the remaining components of the system. Soldering is used to create permanent connections. But if possible, you should avoid it and use threaded connections with flax and sealant, since without the skills it is difficult to solder tubes with an open flame.

Soldering process - Checking for leaks. Pressure should be gradually applied to the system to avoid water hammer. At the same time, inspect connections and joints. There should be no leaks.

Video - Soldering copper pipes

Pipe condition assessment

An assessment of the current condition of the pipes will have to be carried out in any case, even if they are completely replaced. If you have an accurate idea of them, you will be able to choose the most optimal dismantling option. For example, sometimes it’s quite simple to deal with old connections - just rocking the pipes at the joints is enough to simply disconnect them . If you can’t just pull out the pipes, then a chisel will come to the rescue, which is used to process the joints - the seal is removed from them. If the case is very severe, you will have to use a sledgehammer and a grinder to completely disassemble the entire system. It is also worth purchasing a gas burner for dismantling work - some elements will have to be heated thoroughly in order to disconnect.

Old cast iron sewer pipe

On a note! If we are talking about replacing cast iron pipes in old apartments, then you don’t have to waste time going through the methods and immediately settle on the third option. Despite the decrepitude of the entire sewer system, the connections of such pipes are usually very strong and will not simply give way.

Metal-plastic: installation

One of the simplest ways to arrange a home water supply. Composite tubes hold pressure well, bend easily during assembly, and are reliably connected if the installation rules have not been violated. The most popular diameters are 16 and 20 mm. Both open and closed wiring will look good. It is recommended to use a collector circuit.

What will you need?

- Materials: special fittings, pipe fasteners (clamps, ties), flax and sealant.

- Tool:

- pipe cutter and pipe bender for metal-plastic products;

- special press jaws;

- adjustable and Swedish (gas) keys.

How to assemble a pipeline with your own hands?

- Assembly (as in other cases) begins with the creation of a circuit. When planning, it is recommended to provide as few tees and adapters as possible. They reduce water pressure.

- It is important to carefully calculate the lengths of all elements (pipe sections). Cut them and prepare them for installation: bending and cleaning the ends. Using a gauge, trim the ends of the workpieces.

- Using collet or compression fittings, connect the systems into a single whole.

This is what the connection looks like

Installation differences:

- using collets: first a threaded union nut is put on the tube, and then a split ring. All this is inserted into the fitting and tightened tightly;

- using compression fittings: here the role of the ring is played by a wider split sleeve. It is also placed after the nut. When fixing it in the fitting, it is necessary to apply force;

- Push fittings: no tools are needed to create the connection. The tube is inserted into the element and it is fixed. Preventing leaks is achieved thanks to water pressure, which acts on the wedge and reliably presses the edges of the tube;

- Press fittings are used to create permanent connections (without the possibility of disassembly). The pipe must be cut evenly and calibrated. A special sleeve is put on it, and a fitting is inserted inside. Using pliers they press everything together.

Assembling press fittings

When assembling threaded connections, you need to use fum tape or flax.

Video - Metal-plastic assembly process

Connection of polypropylene and metal-plastic pipes

Here's what you need to know before replacing water pipes with metal-plastic ones - compression fittings have a not very pleasant feature.

Under the influence of constantly changing fluid pressure and temperature, the fitting ferrule may become loose.

After some time, you may have to tighten the connection a little with a wrench. Therefore, you should not bury pipes in the wall; access to the fittings must be provided. As a solution, you can use press fittings, they provide higher reliability. For installation you will need press pliers.

Polypropylene pipes are installed by welding. The heating temperature and duration must be strictly maintained. After connection, it is necessary to ensure that the joint remains motionless until it cools. Pay attention to the correct relative position of the parts.

As you can see, there are no particular difficulties in the process of replacing water pipes, and the quality of modern materials will ensure a long service life. So it’s worth thinking about replacing the water supply systems in your own apartment.

How to replace the coil?

Even a beginner can do this. To replace a worn-out water heater, you need to follow a number of steps:

- Shut off the water - turn off the valves on the stopcocks of the risers or use the manifold to turn off the coil.

Shut off water - Using an adjustable wrench, disconnect the union nuts securing the product to the system and carefully remove the coil.

Unscrewing the heated towel rail - Install the new product in the same place using adapters (if necessary). Seal the threads with fulente or flax.

- Gradually increase the pressure to the nominal pressure and check for leaks.

Tip: it is recommended to purchase products with a minimum of welds. They are considered more durable.

Removal of old structures

Replacing the old water supply pipes in an apartment or house with plastic ones begins with dismantling the previously installed pipeline. Structures with a long shelf life are usually assembled from metal parts. Accordingly, for work you will need an angle grinder. If there is a need to change the riser or taps, you will have to shut off the water supply. To do this you will need to:

SF-mix manual up to 0.8 m3/h

AMETHYST - 02 M up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

- Coordinate the implementation of work with the service organization that is responsible for intra-house communications.

- Notify residents from neighboring apartments connected to the common system with you about the upcoming closure.

- Do not delay implementation, but do everything as quickly as possible. In this regard, it would be advisable to turn to professional specialists who will quickly and efficiently perform all the necessary manipulations.

After you change the riser, you can take your time and continue dismantling the pipeline calmly. First of all, you need to drain the liquid and only then start working with the grinder. Some owners who dismantle communications themselves unscrew the existing fittings using a wrench without cutting them. However, this takes up too much time, which could be used to do more important things. Of course, the use of special equipment is not always appropriate (if you are only changing pipes, but not touching the plumbing and tiles). After all, sparks from a saw wheel can cause serious damage to them.

Possible problems and solutions

Most common mistakes relate to incorrect assembly of the plumbing system:

- errors in calculations. The assembler forgets to add to the length of the pipe blank the length of the section that will be inside the fitting (or adapter), and this is up to 15-20 mm per side;

- low quality of permanent (welded) connections. There are defects in the seams through which water leaks out. Eliminated by forming a new seam on top. In some cases, it is necessary to completely digest the pipe. It is important to understand that even a small leak will eventually turn into a larger one;

- Water drips/oozes from threaded connections. It might need a little tightening. If the defect cannot be eliminated, you will have to disassemble the assembly and carefully examine the condition of the threads - if the damage is severe, the element will have to be replaced completely. If everything is in order. then you need to wind more flax, apply another layer of sealant and try to properly tighten the connection again;

- improper soldering of polypropylene. As a result, the pipe connections are not very strong and can break when pressure is applied. During operation, you should follow the recommendations of the manufacturers of the soldering iron and the plastic products themselves. This applies to both the depth of edge penetration and the temperature of the device;

- choosing unreliable plumbing fixtures. Buying cheap devices on the market can lead to difficulties: constant breakdowns, broken fittings and flooding, and incorrect operation. It is recommended to use products from trusted Russian, Belarusian or European manufacturers;

- ignoring the requirement for the slope of the sewer line. Craftsmen do not maintain the required parameter (3 cm/m for a pipe diameter of 50 mm), this leads to difficulties in moving wastewater. To eliminate it, it is easier to redo the connecting point with the riser, otherwise the apartment owner will constantly encounter blockages;

- the features of the pipe materials used are not taken into account - linear expansion, different behavior under temperature changes, reaction to water hammer;

- Mistakes made when installing the system are often due to the lack of experience of the apartment owner. There must be ball valves on each riser - for shutting off the water, points for connecting meters. It is important to check the system before it is shut down.

Important: care should be taken when assembling pipelines in areas where stationary electrical appliances are located: meters, lighting lamps, junction boxes. It is necessary to exclude the possibility of water leaks and contact with exposed wires.

Pipe burst in an apartment

Schematic layout of the wiring

After dismantling the structures, it is necessary to calculate the layout of the new pipeline. Of course, it can be installed exactly as the previous system was installed. But, as a rule, upon closer examination it is possible to find a more rational way. For clarity, first draw a schematic drawing with chalk directly on the surfaces of the walls and floor, where the pipe elements will be located. This will make it much more convenient to record the calculations being carried out.

Be sure to provide places for installing water purification filters. As a rule, they are installed in a designated hidden niche behind the toilet or bathtub. When choosing an installation location, make sure that in the future you can easily change filter units in water treatment devices. After all, you will have to do this at least once or twice a month. When installing cleaning devices, keep in mind that mesh units are installed with the removable tank down (one of the most common mistakes of novice plumbers and even experienced professionals). It is advisable to install water meters immediately after the filtration medium.

Installation of steel products

To assemble the water supply, it is necessary to weld bends to the risers. Other pipe parts will subsequently be connected to them. As an assembly diagram, you should choose a simpler budget option - a tee. When installing a common line, take the pipe and bend it at an angle that allows it to pass through the bathroom. In the areas where the consumer system is connected, threaded drains must be fixed using a welding machine.

Next, you need to connect ball valves to the risers and bring bent communication elements to them. The joints should be sealed with sealant and linen thread. After that, the tightness will be tested. Even minor defects made when making welds must be corrected immediately.

Copper pipeline

This material is very different from common options in terms of technical characteristics. It is much easier to replace water pipes in an apartment with the same polypropylene ones during renovation. The fact is that in apartment buildings the risers are made of steel, which makes it quite difficult to weld copper elements to them.

If you are able to cope with the task yourself, then you know very well that soldering is used to form permanent connections. However, in this case it should be excluded if possible. You should try to connect elements on the thread using sealant and flax. Only a professional can successfully solder parts with a torch. Without the appropriate skills, you will simply waste time and effort, but will not achieve the desired result.

Installation of metal-plastic

This material is best suited for home water supply installations. It is relatively easy to work with; metal-plastic tubes are pressure-resistant and bend well during assembly. Of course, with strict adherence to installation techniques.

As a basis, it is worth considering the collector circuit. When composing it, try to avoid having a large number of adapters and tees. Because of them, the liquid pressure in the system will be significantly lower.

Thoroughly calculate the parameters of the design details. Cut them in advance and prepare them for installation. Connect all communication elements using compression or push-in fittings.

How to replace pipes in an apartment with polypropylene

This material lends itself well to soldering, allowing you to form permanent connections. Using this method, you can connect parts of different sizes, solder corners or connecting tubes.

Main table dispenser AquaPro 919H/RO (hot and cold water)

Main table dispenser AquaPro 929CH/RO (cooling/heating)

Floor dispenser AquaPro 311 (empty, without cooling)

Threaded joints should be treated with sealant and linen thread. To connect polypropylene parts with communications made of another material, special fittings (adapters) are used.

At the end of the work, the system must be checked for leaks using the pressure of the supplied fluid. Of course, this is not particularly relevant for residential premises. However, it is important to consider that when heated to 100 degrees, the length of the polypropylene pipe increases at the rate of 1.5 cm per 1 m. That is why hot water supply requires the installation of compensators.

Is it possible to replace pipes yourself?

If the owner of the property has registered it as property, then he (by law) is responsible for the condition of communications inside the premises. But it should be understood that since the pipes are under pressure, replacing them with your own hands without the appropriate experience is highly not recommended. Utility services have the right to prohibit the operation of systems assembled by amateur plumbers, because most likely at least one of the rules of SNiP (building codes and regulations) will be violated and there is a danger of a water breakthrough at any moment. It is almost impossible to visually determine the quality with which the assembly was carried out, with the exception of some cases.

Poor quality welding

Replacement of risers is carried out only with the knowledge of the engineering and operating company that controls the entire house. In some cases, the work will be carried out not only by plumbers, but also by welders. The same applies to the installation of meters. They are placed under the supervision of certified masters and sealed.

conclusions

Independent replacement of water supply pipes in an apartment or house with plastic is only available to those who have the appropriate knowledge and experience. Without professional training, it is impossible to achieve high-quality work. Any mistake, even a minor one, can result in serious problems for the homeowner (in the worst case scenario, you will flood several floors down). Faced with the need to pay for repairs to your neighbor's living space, you will spend much more money than you would pay for the services of a master.

Heating main repair

Despite the apparent simplicity of the design of engineering systems, repairing heating networks almost always becomes a rather complex task, requiring the involvement of specialized specialists. One of the most effective methods of preventing emergency situations is the timely implementation of repair and restoration work and regular preventive maintenance. With this approach, as practice shows, complete replacement of heating systems will be required much less frequently, due to the increase in service life several times.

The specifics of repairing heating networks in Moscow are determined based on the parameters of the system itself. First of all, the method of laying pipelines is taken into account. When using an open (“air”) path, the technology for performing work, as a rule, is significantly simplified, which leads to a reduction in maintenance costs and the time required for troubleshooting, performing urgent emergency repairs of the heating main.

For pipelines laid in the ground today, the most relevant method is trenchless repair and restoration. Using it, major repairs of heating networks will be carried out as efficiently as possible, even taking into account the difficulties of performing any such work in the capital. Its essence will be to destroy the old pipeline using a pneumatic punch, and then, advancing the polymer pipe, destroy the worn out old structures.

Metal-plastic pipes

Metal-plastic pipes are a structure of three layers of inner and outer plastic and metal between them. The pipes are connected to each other using fittings. Press fittings or collet fittings are used. For installation you will need a pipe cutter, a press, an adjustable gas wrench, or better yet, a set of reamers (reamers) for the diameter of the pipes and then you will not be afraid of leaks.

Plastic pipes vary in size (in inches): 1/2\ 3/4\ Iх, 11/2\ Pipes are flexible, easy to install, and rust does not form in their internal space.

This option is by far the most common.

Metal-plastic pipes are more durable and environmentally friendly. A metal-plastic pipe is a solid, laser-butt-welded or ultrasonic-welded aluminum pipe, protected from the inside and outside with polyethylene layers. Metal-plastic pipes have gained popularity due to the following positive properties:

- not subject to corrosion;

- sanitary and hygienic indicators are higher than those of steel;

- high throughput.

- ease of assembly

- You can always cut into a finished pipeline.

.The disadvantage of installing metal-plastic structures can be considered the high cost of fittings, they are afraid of water hammer, as well as the need for regular maintenance of pipes every two years, the tightness of the connections must be checked, they need to be tightened. . Therefore, it is not recommended to bury metal-plastic in walls. Place metal-plastic pipes in open areas where minimal resistance to water flow is important, to a washing machine, sink, etc. To connect two types of pipes, use metal-to-plastic adapters.

Tools

Areas of application

Metal-plastic pipes can be used in the following systems:

domestic and drinking cold water supply; hot water supply, radiator heating at a coolant temperature not exceeding 95ºС; built-in heating systems:

water underfloor heating or cooling (“warm floors”; “cold floors”);

water wall-mounted radiator-free heating or cooling (“warm walls”; “cold walls”); soil heating of soil in greenhouses, greenhouses, winter gardens, flower beds and greenhouses;

biological treatment stations, etc.

Street

Small-diameter pipes have to be replaced on the street only by owners of private houses. Everything is simple: take a shovel, dig a trench, cut off a piece of old rusty pipe with a turbine and install a new one in its place. What about apartment buildings, neighborhoods and neighborhoods?

Typically, the replacement of communications in these cases is carried out not by private individuals, but by organizations armed with heavy equipment. There are two main ways to repair pipelines:

Digging a trench

Does it make sense to describe what makes us happy in our hometown many times a year? Traffic is blocked, an excavator and a team of intellectuals of unknown age with shovels are brought in, after which a flowering lawn or smooth asphalt turns into a sinkhole with a dirty puddle at the bottom.

Occasionally, the landscape is decorated with a car flying into a hole due to lack of lighting and its happy owner, who is in a hurry to share his knowledge in the field of folklore with others.

Familiar to everyone

HDD and other bloodless methods

Recently, especially in large cities, trenches have begun to be replaced by special horizontal drilling units.

Trenchless pipe replacement also requires heavy equipment, but there is no need to block traffic and dig up the street: the soil is pierced with a special drill under the surface, after which the pipe is pulled through a horizontal channel.

There are two ways to replace an old water supply:

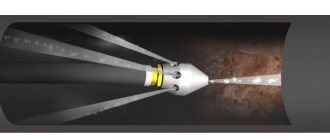

- The injected air powers a pneumatic, self-contained breaker that breaks up the old pipe, widens the channel around it, and compacts the surrounding soil. A pipe of the same or larger diameter is then pulled through such a channel. This method can replace a pipeline made of concrete, asbestos cement or cast iron.

- Overgrown old steel pipes are cleaned of accumulated deposits, after which a plastic pipe of smaller diameter is pulled through the gap. Considering the lower resistance to water flow of smooth plastic and the lack of overgrowing, this is often more than enough.

And no holes in the middle of the road