19 July 2021, 08:43 Flanges

They are a disk-shaped part with a central hole for the passage of the internal environment.

There are equidistant holes for fastening along the perimeter. The flange design is marked: Fig.

1: Flange markings, location of versions Historical information.

Until 2021, there was a series of GOSTs of group 12815-12822 and all types of flanges had different GOSTs. Currently, flanges are manufactured according to GOST 33259-2015. Main differences.

Flange connection

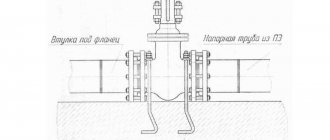

So what is the flange for? And its purpose is to organize a flange connection. Suppose there are two sections of pipe and they can, of course, be welded together, but then it will be a rigid one-piece connection, and in order to organize a quick-release flange connection, flanges are used, which are welded onto the ends of the pipes and tightened with bolts with nuts or studs with nuts, as in photo below.

The flange itself is a flat ring or sometimes made in the form of a square or rectangle with a hole in the middle for inserting the end of the pipe and several evenly spaced holes closer to the outer diameter into which bolts or studs are inserted, nuts are screwed onto them and the two flanges are tightened together. To seal the connection between the flanges, a gasket made of special rubber or other material for this purpose, such as fluoroplastic, is placed. By the way, depending on the type of gaskets, there are different designs; it would be more correct, of course, to use different types of gaskets.

The pipes themselves are often connected to each other, but more often it is necessary to connect some apparatus or devices, for example, heat exchangers with a section of the pipeline through which some kind of medium is supplied. For example, look at the photo below there is an oil cooler MB 25-37 and at the ends two flanges number 1 are clearly visible, which are welded to the pipes and on them there are additionally counter flanges number 2 screwed with bolts and nuts, this is the delivery kit for the manufacture of the heat exchanger. The customer needs counter flanges to organize the connection of the device with the pipeline section.

Let’s say a customer ordered the production of a heat exchanger, brought it to the site, installed it, and needs to connect it. To do this, pipelines are connected to the device, flat steel mating flanges supplied in the kit are welded onto the ends of the pipes and the flange on the cooler and at the end of the pipe are connected with bolts or studs, not forgetting, of course, to put a gasket between them for tightness. Comfortable! Because Periodically, for example, for repairs or preventive maintenance, the need to stop the operation of the device and disassemble it arises. This oil cooler has four flat steel flanges. Two for inlet and outlet of cooling water and two for inlet and outlet of cooled oil.

In the same way, sections of pipelines are connected to various technological tanks. Flanges 1 and 2 refer to the type of flanges of fittings, connecting parts and pipelines.

Thus, we can say that flanges are needed to organize the connection or connection of a pipeline section

to various technological devices and devices: heat exchangers, containers, etc., for supplying and discharging media, as well as for connecting pipe sections to each other.

Go ahead. The number 3 in the figure indicates the same flange, but this one is of the type for vessels and apparatus. This is where the differences begin to appear.

Differences, types and types of flanges

What type, where to use, what material it is made of, under what conditions this or that flange should work is regulated by state standards or simply GOSTs. Two significant types of flanges can be identified: for fittings and for vessels and apparatus

.

Flange types

- for fittings, connecting parts and pipelines. Ru from 0.1 to 20 MPa (from 1 to 200 kgf/cm2). GOST 12815-80 download -, .

- for vessels and apparatus. GOST 28759.1(2,3,4)-90. Download GOST 28759.1, 2, 3, 4.

Those. the former are used to connect parts of pipelines with branch pipes, as in the example above with MB 25-37, simply for connecting pipes, and the latter for the manufacture and joining of parts of apparatus. For example, in photo mb 25-37 you can see flanges 3 that connect the water chamber of the oil cooler to the body. An oil cooler specifically refers to heat exchangers and pressure vessels.

Go ahead. We found out that the first difference between flanges is what they are intended for by considering the two above-mentioned standards. And then within each GOST there are different types of flanges depending on many factors of their application, purpose, and manufacture. Let's see.

Types of flanges depending on GOST

GOST 12815-80 contains types of flanges

:

- cast from gray cast iron according to GOST 12817-80 - flanges of cast fittings, connecting parts, machines, instruments, pipes of devices and tanks made of gray cast iron for a nominal pressure Ru from 0.1 to 1.6 MPa and a medium temperature from minus 15 to plus 300 °C.

- cast from ductile cast iron according to GOST 12818-80 - flanges of cast fittings, connecting parts, machines, instruments, pipes of devices and tanks made of ductile cast iron for a nominal pressure Ru from 1.6 to 4.0 MPa and a medium temperature from minus 30 to plus 400 °C.

- cast steel according to GOST 12819-80 - cast steel fittings, connecting parts, machines, instruments, pipes, apparatus and tanks for a nominal pressure Ru from 1.6 to 20.0 MPa and a medium temperature from minus 253 to plus 600 ° C. GOST 12819-80 free download - , .

- steel flat welded according to GOST 12820-80 - standard for steel flat welded flanges of pipelines and connecting parts, as well as for connecting flanges of fittings, connecting parts of machines, instruments, pipes of devices and tanks for a nominal pressure Ru from 0.1 to 2.5 MPa (from 1 to 25 kgf/cm2) and medium temperature from 203 to 573 K (from minus 70 to plus 300 °C). GOST 12820-80 free download - , . The price of flanges according to this GOST 12820-80 can be found in the price list for pipeline fittings. Additionally, I will say that blind steel flanges are manufactured according to the same standard. You can see what it looks like in the photo above in the upper left corner or just below. Essentially it is a flange plug.

- steel butt-welded - collar according to GOST 12821-80 - steel welded flanges of pipelines and connecting parts, as well as for connecting flanges of fittings, connecting parts of machines, instruments, pipes, apparatus and tanks for a nominal pressure Ru from 0.1 to 20.0 MPa (from 1 to 200 kgf/cm2) and medium temperature from 20 to 873 K (from minus 253 to plus 600 °C). GOST 12821-80 can be downloaded in the following format: or . There you can also see drawings and all flange sizes. If you need to see the price and buy flanges according to GOST 12821-80

or contact our sales department. Here I note that, unlike the above, it is possible to use a flange connection at a higher pressure and at lower and higher temperatures. These are their main differences in application. - steel loose on a welded ring according to GOST 12822-80 - steel flanges loose on a welded ring of pipelines and connecting parts of machines, instruments, pipes of devices and tanks for Ru from 0.1 to 2.5 MPa (from 1 to 25 kgf/cm2) and medium temperature from 243 to 573 K (from minus 30 to plus 300 °C).

If necessary, you can download GOST 12822-80 in word or pdf format. The price of flanges is in the price list.

For more detailed information, you must, of course, go to the appropriate guest house.

GOST 28759.1-90 - flanges of vessels and apparatus:

- steel flat welded according to GOST 28759.2-90 - for vessels and apparatus with a diameter from 400 to 4000 mm with a nominal pressure from 0.3 to 1.6 MPa at a working environment temperature from minus 70°C to plus 300°C, intended for operation in chemical, petrochemical, oil refining and other industries.

- steel butt welded - collar according to GOST 28759.3-90 - flanges for vessels and apparatus with an internal diameter from 400 to 4000 mm and an external basic size (bottoms, pipes) from 426 to 720 mm with a nominal pressure from 0.6 to 6.3 MPa , at a working environment temperature from minus 70°C to plus 540°C, intended for work in chemical, petrochemical, oil refining and other industries.

- steel butt welded for octagonal section gasket in accordance with GOST 28759.4-90 - flanges of vessels and apparatus with a diameter from 400 to 1600 mm with a nominal pressure from 6.3 to 16.0 MPa at a working medium temperature from minus 70°C to plus 540°C, designed for use in chemical, petrochemical, oil refining and other industries.

Now it becomes clear what types of flanges there are and what types they are divided into depending on their purpose. All technical characteristics, drawings, designs and dimensions of flanges can be viewed by following the links at the top or selecting the corresponding GOST at the bottom of the article. Let's go find out further.

Marking

Let's look at the alphanumeric codes that manufacturers use to mark flanges. For example, let's take this entry:

10 40 02 1 F GOST 33259-2015

Here 10 - DN , nominal diameter, 40 - PN , nominal pressure, 02 - type, 1 - size range from the table, F - type.

We have sorted out the flange sizes according to the state standard. They talked about the types and types of connecting nodes. Readers are left to make the right choice.

Flange versions

Flange version

this is essentially the design or type of the end surface of the flanges between which a flange connection is created. And here, too, the geometry of surfaces is regulated by GOST. Let's look at an example.

GOST 12815-80 contains 9 versions:

- version 1 - there is a connecting protrusion at an angle of 45 0 as a chamfer, by the way the most common.

- version 2 - also with a projection but at an angle of 90 0.

- version 3 - with a projection at 45 0 plus a depression, sampling from the inside.

- version 4 - flange with a spike, the same as the previous one, only a projection of 90 0.

- version 5 - with groove. It looks like a ring sample.

- version 6 - for lens spacer. Has an internal chamfer.

- version 7 - for an oval gasket. Oval groove on the end surface.

- performance 8 and 9 - performance 8 is the same as the 4th, and the ninth is the same as the 5th. How they differ I don’t understand the difference. I would be glad if anyone writes in the comments to this article.

GOST 28759.2-90 contains 15 versions, and 28759.3-90 - twelve. There is no point in listing them, so I ask you to follow the links to these GOSTs and see everything in detail, what they look like, etc.

Where are flanges used?

*

This type is used for pipeline assembly; installation of any flange occurs only if there is a pipe of the appropriate diameter. There are several areas of application for the part:

- assembly of civil central pipelines;

- gas pipeline assembly;

- installation of domestic water supply systems;

- installation of heating mains;

- assembly of industrial systems and communications.

Flange connection

These parts can be pipe, shaft, fitting or body parts. This is a universal product that, when connected to another part, can provide a tight seal. The element can withstand high temperatures and pressure, so this type of fastening can be used in gas and water pipelines. The parameters by which they are selected are the dimensions, shape of the sealing surface, as well as the method of fastening.

Geometric dimensions and weight of flanges

Very important parameters, both at the stage of designing devices, containers, etc., and at the stage of operation and repair, including procurement, because you need to know which part to buy. Therefore, it is very important to know what connection and overall dimensions

available on certain flanges. There are a lot of sizes, but the main one is a nominal bore. The choice of flange when purchasing and during design is based on it. Let's go into a little more detail.

Nominal size of flanges

Let's say there are two pipes that are connected to each other or a pipe on a heat exchanger or some container. The pipes and the nozzle have an outer diameter and it is sometimes believed that it should correspond in the designation to the inner diameter of the flange, but this is not the case. For example, DN100 corresponds to an outer diameter of the pipe of 108 mm or 114 mm, by the way, according to Yandex statistics, the flange most often searched for is DN 100, and for DN 125 the pipe diameter is 133 or 140 mm, for DN 150 they choose a pipe with a diameter of 152, 159 or 168 mm, depending on execution and from the letter A, B, B indicated in the GOST table. When an order is placed, a letter must be indicated next to the flange designation; if it is not there, then it is considered that the letter A is selected.

This dependence exists for flat flanges and flanges with a welded ring, but for collar flanges - butt joints do not have this. If you go to GOST, you will see everything in detail.

The nominal diameter of the flanges is a fundamental parameter on which all basic geometric dimensions depend. Those. knowing the nominal diameter of the flanges

all the rest are assigned automatically, except for one nuance called a row.

Rows of flanges

There are only two of them, 1st and 2nd, but they affect the overall dimensions. Depending on which row of flanges 1 or two

Dimensions depend on:

- diameters D3, D4, D5, D6.

- d - diameter of holes for studs or bolts.

- n is the number of these mounting holes.

- h1 is the height of the protrusion and the depth of the tenon.

- h2 is the depth of the groove.

- h3 is the depth of the oval groove.

- nominal diameters of bolts or studs.

Rows of flanges

All other connection or overall dimensions depend only on the nominal diameter. In accordance with GOST, flanges must be manufactured according to the preferred row 2 if 1 is not specified.

All dimensions in the drawings and tables, depending on the nominal diameter and row, can be viewed in GOST.

Weight or mass of flanges

Another important quantity is the mass of the flanges

, rather from a practical point of view, for example, to determine the weight of the entire batch, if there are other options, please put your comments at the end of this material, I will be very grateful. This value can also be found in the tables of the required GOST.

So we got acquainted with the basic, from my point of view, geometric and conventional dimensions and sizes of flanges. And all the rest can be found and viewed on site, they have already been determined by various strength calculations of strength materials. The dimensions are clear, but since the flange is steel and made from some kind of metal, of which there are a lot of brands, the question will accordingly arise: “What metal or grade of steel are the flanges made of and how to choose the right one if necessary, or how to choose the grade of steel, cast iron and alloy flanges"?

Manufacturing technologies

The production technology and choice of flange connection design depend on the conditions under which a particular element will be operated and the operating parameters of the pipeline system.

Today there are several technologies that are used to produce compounds. For example, casting, forging, flame cutting, steel bending and hot stamping.

In accordance with the current GOST, there are nine options that can be used when choosing a flange design. Each one is different depending on the shape or size of the joint surface. The simplest design and installation is for flat welded steel flanges. Other types have special requirements, which are determined by their scope of application.

Materials or grades of steel, cast iron or alloys of flanges

In order to select the material from which the flanges are made

There is GOST 12816-80 and it has one wonderful table, once you see it, everything becomes clear. Let's say we are interested in a collar flange or, in other words, a steel butt weld in accordance with GOST 12821-80. The first thing we pay attention to is the conditional pressure at which it operates. Let's say it is 150 kgf/cm2 or Ru 15MPa. We look where it is located, we find that in the second column and the second part it is in the range from 0.1 to 20 MPa, because the first part does not suit us 0.1 to 10 MPa.

Next, we look at the operating temperature conditions, for example, from -40 0C to +450 0C and find that a stainless steel flange 12x18n9t is suitable for us, although 12x18n10t is currently used as the most common grade of stainless steel, and studs, bolts and nuts and steel grade 20x13 are corrosion-resistant heat-resistant, used in power engineering. That's all science is.

There are many different grades of steels and alloys, but the most popular are st20, st3, 09g2s, 12x18n10t and 15xm, as they are most often used for the manufacture of flanges because There are many more such working conditions. There are, of course, specific brands, but there are very few conditions under which they should work. It is worth noting that there are many fittings made of cast iron or ductile iron, therefore flanges are used from the corresponding grades of cast iron SCh 15 and KCh 30. All other materials, if necessary, look at GOST 12816-80. You can also download it.

What is the part made from?

The industry uses steel flanges, but the steel from which the part is made also varies. The marking of steel flanges will determine in what conditions it is best to use this part:

- Steel 20 is the most commonly used raw material. This is carbon steel, parts made from it are used for assembling fittings on highways, where the external temperature is not lower than –40 degrees, and the internal temperatures are not higher than +475 degrees.

- Steel 09g2s is a steel made of nickel, chromium and molybdenum alloys, intended for welding. Products made from this material can be used at external temperatures from –70 degrees.

- 12Х18Н10Т – cryogenic steel. Parts made from this material can be used in aggressive environments, such as alkalis and acids. Permissible temperature from – 196 degrees to +350 degrees.

- 10Х17Н13М2Т – corrosion-resistant ordinary steel. Fasteners made from it are used in particularly extreme conditions, because it remains resistant to stress corrosion. Operating temperatures from -196 to +600 degrees.

- 15Х5М – low-alloy heat-resistant steel. Such products have high resistance to oxidation at +600-650 degrees.

These brands are the most used, but in addition to them, manufacturers use other raw materials. There are polypropylene models - they are designed for joining polypropylene pipes with metal shut-off valves. The operating temperature of this material is much lower - +80 degrees. They can be supplied with a flange collar - a special part for creating a flange connection made of polypropylene.

Features of connecting pipes or pipes with a flange

Here I will talk about the features of connecting the pipeline or pipes of devices or containers directly to the flange itself. Because the most common are steel welded flat, steel butt welded or collar and steel free on a welded ring, then we will focus on them.

Connection of steel flat welded flanges to a pipe or pipe

During installation, the pipe is inserted into the flange and welded with two seams, one inside and the other outside along the end surface. The most labor-intensive connection, because you need to make two welds and to align the holes you will have to twist the pipe.

Connection of steel butt welded flanges - collar

For installation, the end of the pipe is leaned against the end of the flange or the so-called collar, which is why they are called collar collars, the one that is cone-shaped and is welded with just one weld. Much faster and easier.

Connection of steel loose flanges on a welded ring

Here a pipe is taken, the flange itself is put on it, then the pipe is inserted into the ring and scalded. The other part of the connection is exactly the same. It turns out that only the rings are welded to the pipes, and the flanges rotate freely on the pipes or pipes. Next, the ends are brought to each other, rotating the flanges until the holes match along the contour and studs or bolts are inserted and everything is tightened with nuts. Extremely convenient, because... there is no need to rotate the pipe or ensure exact alignment of the holes before welding, which is not always possible. Very practical in hard-to-reach places or where frequent inspection of flange connections is required, for example in the chemical industry. It may be cheaper because... It is allowed to use only a stainless steel ring, and the flange itself is made of ordinary carbon steel 3 or steel 20.

So we looked at how the most common types of flanges are joined and now I would like to show how to correctly designate them.

Flange designation

Designation of flat weld flanges

Flange 1-450-10 st. 20 GOST 12820-80 - this is the designation for a conventional flat flange of version 1 (with a connecting projection) with a nominal bore of 450 mm, designed for a nominal pressure of 10 kgf/cm2 or 1 MPa, made of steel 20.

And if the flange is square, with DN 1200 made of steel 3, then: Square flange 1-1200-10 st. 3 GOST 12820-80.

When ordering flanges with a nominal diameter of DN 100, 125 and 150 m, the letter of the corresponding pipe diameter is indicated.

When ordering tongue-and-groove flanges for fluoroplastic gaskets, the letter F is placed after the nominal pressure numbers.

Designation of collar flanges - butt welded

Flange 1-1000-100 st. 12x18n10t GOST 12821-80 - collar flange version 1, nominal diameter DC 1000 mm, PN 10 MPa or 100 kgf/cm2, made of stainless steel.

Square flange 1-800-10 st. 12x18n10t GOST 12821-80 - if square. And here Du is 800, and Ru is 1 MPa.

And if the design is tongue-and-groove, then the letter F is added.

Designation of loose flanges

Flange 125-6 st. 3sp GOST 12822-80 - DN 125, Ru 0.6 MPa, steel 3 sp.

Square flange 400-6 st. 15khn GOST 12822-80. Here the nominal diameter is 400 mm and the steel is 15ХМ.

Because When a welded ring is used in a pair, it is designated as follows:

Ring 1-400-6 st. 15ХМ GOST 12822-80 - version 1, DN 400 mm.

When ordering diameters 100, 125, 150, you need to add the letter you need. And when ordering a flange for tongue-and-groove fluoroplastic gaskets, the letter F is added.

So we looked at how the main types of flanges are designated

and we can move on to the next question, which I think is very important. And he’s talking about how to buy flanges, where to look at the price, and maybe look at the price list with the range, availability and prices.

How to buy steel welded flanges, prices and price list

In order to see the price for any flange, flat, collar, loose or mating, you can request a price list from the sales department by phone +7(351)735-95-75 or by email This e-mail address is being protected from spambots, for You must have Javascript enabled to view it. You can also send a request to the specified coordinates and get the best prices

, since the cost changes and the price list is not always updated quickly, issue an invoice and buy. You can arrange for the goods to be shipped. The price of flanges can be viewed by visiting the price list page for pipeline fittings. You can download it in a format convenient for you to your computer and keep it always at hand. There is also the cost of gate valves, valves, bends, taps and other fittings.