Plastic pipes have become widespread; they are used for water and gas supply, installation of sewerage, storm drains, etc. You can find pipes of various types on the market, so the consumer may have understandable difficulties in choosing a specific pipe option for the task he is solving.

Some of the most popular pipes currently are polypropylene (PP) and polyvinyl chloride (PVC). Each option has its own advantages, so when choosing pipes, you should first consider the purpose for which they are purchased. The main difference between PP and PVC pipes is the materials used in their manufacture, which determined their properties and areas of application.

PVC pipes - main characteristics

Polyvinyl chloride (PVC) is a chemical product containing up to 57% combined chlorine . As a result, the material does not ignite and practically does not burn, it is insoluble in water and is highly resistant to strong and weak alkalis and acids. Due to its characteristics, PVC is widely used in industry for the production of film, cable insulation and, of course, pipes.

Pros and cons of PVC pipes

The undoubted advantages of PVC pipes include:

- Increased rigidity and resistance to deformation and impact.

- Resistant to salts, acids and alkalis.

- Corrosion resistance.

- Durability and reliability - the useful life with proper operation reaches up to 50 years .

- Light weight and easy installation.

There are very few disadvantages to PVC pipes:

- With a sharp temperature change or temperatures exceeding +60°C, the pipes are destroyed.

- When exposed to extreme heat, they may release chlorine and dioxins.

Considering these properties of PVC pipes, they are most often used for the installation of sewage systems, cold water drainage, in drainage systems and irrigation systems.

What is the difference between internal sewerage and external sewerage?

The answer here is quite simple - the difference is in the increased rigidity of pipes for outdoor use!

Sewage systems that are laid outside homes must withstand long-term exposure to a thick layer of soil and the pressure of cars passing from above.

External sewerage is produced mainly from two materials - uPVC (unplasticized polyvinyl chloride) and PP (polypropylene).

PVC-U pipe for external sewerage: characteristics

- Effluent temperature up to 60°C.

- The pH of the effluents is in the range of 2-12.

- Flammability is a self-extinguishing material.

- The design pressure of connections and joints is 0.5 bar.

- Service life >50 years

PP (polypropylene) pipe for sewerage: characteristics

- Effluent temperature up to 80 °C.

- The pH of the effluents is in the range of 2-12.

- The design pressure of connections and joints is 0.5 bar.

- Service life >50 years.

Polypropylene pipes - main characteristics

Polypropylene is a solid polymer (melting point +170°C ). This heat-resistant material has dielectric properties, is resistant to acid-base environments even at elevated temperatures, and to mineral and vegetable oils and aqueous salt solutions at temperatures above +100°C. Polypropylene is little susceptible to cracking under the influence of aggressive environments.

Low frost resistance - only up to -30°C - is one of the important disadvantages of polypropylene. To improve this characteristic, polypropylene is modified with rubber. Frost-resistant polypropylene is somewhat inferior to unmodified polypropylene in rigidity, but surpasses it in frost resistance, which for this material reaches -50°C .

Today, polypropylene is the safest type of polymer , so it is used in industry for the production of pipes that can be used for the installation of cold and hot water supplies, for transporting compressed air, gas and various aggressive liquids.

Polypropylene pipes - advantages and disadvantages

Polypropylene pipes have many advantages:

- Durability - products last up to 50 years.

- Low thermal conductivity - there is no loss of hot water temperature inside the pipes, and condensation does not form on the surface.

- The smooth surface of the pipes inside and outside prevents the accumulation of various deposits.

- Environmental safety - this is especially important when transporting drinking water.

- Easy to install and light weight.

The disadvantages of polypropylene pipes include:

- Reduced service life at constant high temperatures of the transported liquid.

- Loss of shape when heated due to high linear expansion coefficient.

These disadvantages are eliminated by reinforcing polypropylene pipes with aluminum foil, fiberglass or composite materials.

However, polymers are not without significant disadvantages:

- When heated, the strength of polymers decreases. Like all organic substances, they burn, and under the influence of ultraviolet rays they age (become brittle and collapse);

- Disadvantages include a large (10 times more than steel) coefficient of thermal expansion; however, the elasticity of polymers partially compensates for this disadvantage.

Technologists producing products from polymers are trying, and not without success, to enhance their advantages and reduce their disadvantages. In the second half of the 20th century, the chemical industry mastered the production of dozens of polymers, but 5-7 of the most important ones found mass application, including in the production of pipes. The undisputed leaders are polyethylene (PE)

,

polypropylene (PP)

and

polyvinyl chloride (RUS)

. These polymers belong to the group of thermoplastics. They are capable of transforming into a plastic-viscous state when heated, and hardening when cooled. Pipes from such polymers are produced by extrusion (extrusion) using a heated screw (an example of a simple extruder, but without heating, is a home meat grinder). The pipes are obtained with a very smooth surface (the roughness of polymer pipes is approximately 10 times lower than that of steel pipes).

General advantages of plastic pipes (PVC and polypropylene)

Advantages of plastic pipes over aluminum, steel and other metal pipes:

- Low cost . Polymers are one of the most technologically advanced materials, because in one production cycle a finished product, for example, a pipe, is immediately obtained. There is no need to perform further operations to modify the product. This significantly reduces the final cost of the plastic pipe.

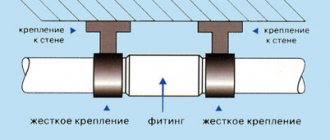

- The low weight of plastic pipes makes it possible to easily install the entire system using various fittings (couplings, adapters, manifolds and plugs) for connection.

- The corrosion resistance and durability of plastic pipes, unlike metal ones, reduces the cost of pipeline repair and replacement.

- When used correctly, plastic pipes are environmentally friendly : due to their resistance to various external environments, they do not change the quality and characteristics of liquids passing through them, for example, they do not affect the color and smell of water. due to the smoothness of the inner surface, salts do not accumulate on the pipe walls and bacteria do not survive, which means plastic pipes are not susceptible to contamination and clogging.

Selection of pipe stiffness class depending on soil type

Stiffness class of external sewerage pipes External

sewerage can be of different ring stiffness classes - for example, SN4 (4 kN/sq. meter) or SN8 (8 kN/sq. meter).

The ring stiffness class is selected depending on the depth of the pipe and the intensity of vehicle traffic above the pipes.

If you are going to bury pipes in your garden plot to a depth of no more than 3 meters, then the SN4 pipe is suitable for you.

If you need to lay a sewer through a busy highway, where heavy trucks are constantly moving, or bury a pipe to a great depth, then an SN8 pipe is needed.

Distinctive properties of PVC and polypropylene pipes

The main differences between PVC pipes are their increased rigidity and the inability to use them when transporting hot (more than +60°C) liquid. Polypropylene pipes are more resistant to high temperatures and are therefore suitable for transporting both cold and hot water.

These qualitative characteristics determine differences in the areas of their application.

Application of PVC pipes

| Scope of application | Qualitative characteristics of the PVC pipes used |

| Cold water supply system in apartment buildings and private buildings. | Pressure pipes made of unplasticized gray PVC are used, as they are strong, rigid and durable and can withstand strong water pressure. Wall thickness is up to 3.2 mm, and diameter is from 50 to 160 mm. |

| Separate areas of cold water supply or internal sewerage. | Gray plasticized PVC pipes are used; they are less durable with a wall thickness of 1 to 2 mm and a diameter of 30 to 50 mm. |

| Dishwasher or washing machine drainage system. | Gray corrugated PVC pipes are used - the simplest and cheapest, not durable, but they can be easily replaced. |

| Protection of electrical wires in internal and external electrical networks. | Corrugated PVC pipes are used; during their production, a self-extinguishing additive (anti-peren) is added, which ensures fire safety. They are very flexible and durable, which makes it possible to lay electrical cables inside wooden or concrete walls, in wet rooms or in swimming pools. |

| External sewer system. | Rigid orange PVC pipes with a wall thickness of 3 mm and a diameter of 100 to 500 mm are used. These pipes easily withstand weather temperature changes and soil loads at shallow depths. |

| External sewer system at a depth of up to 15 m. | Corrugated multilayer PVC pipes of orange color are used. Due to the large number of stiffening ribs, they can withstand soil loads at a depth of up to 15 m. |

| Septic tanks and drainage wells. | PVC pipes of the largest diameter and orange color are used. |

Application of polypropylene pipes

| Scope of application | Qualitative characteristics of the polypropylene pipes (PP pipes) used |

| Internal cold and hot water supply system in apartments and houses. | White PP pipes are used, they are easily connected by welding or through fittings, can withstand high pressure and are the cheapest of PP pipes. |

| Centralized and individual heating system. | Gray PP pipes are used; they are chemical and thermal resistant and airtight. |

| Drainage and watering system on the street. | Black PP pipes are used, which have the highest resistance to ultraviolet radiation, drying out and exposure to aggressive weather conditions. |

| Summer irrigation system for a personal plot. | Green PP pipes are used - the most unstable to internal water pressure, but the cheapest. |

| Internal floor heating system. | To resist high temperatures and water pressure, three-layer PP pipes reinforced with aluminum or fiberglass are used. |

When producing plastic pipes, an information line with technical characteristics must be applied to them using a laser for ease of use and installation.

The choice between PVC and polypropylene pipes depends entirely on the scope of their application and can be based on the quality characteristics given above.

Repair and constructionComment

Scope of application

On an industrial scale, pipes made of cross-linked polyethylene are of little use, since their diameter is limited to a maximum of 250 mm and limited ability to operate under increased loads. In individual construction, the use of cross-linked polyethylene is widely used in installation:

- heating communications;

- in cold and hot water supply.

Pipes made of cross-linked polyethylene are popular for installing heated floors. This material is easy to install, does not require special skills or complex equipment, is durable and reliable. For heating systems, only pipe materials with a protective layer are used.

When choosing pipes and fittings for installing water supply communications or heating systems, you should be guided by the manufacturers' recommendations, since the documentation always indicates the direction of use and acceptable operating parameters.

Note! All pipe products are marked in detail on the outside. The label indicates:

The label indicates:

- mode of production;

- release date (up to a week);

- wall thickness and diameter;

- acceptable operating parameters;

- quality control mark.

Each manufacturer offers fittings for mounting their products. The use of native materials is the key to reliable connections and long-term operation, since the production of pipes and fittings uses the same process.

Performance comparison

These materials are neighbors in the alkene group, so they have a lot in common in terms of physical properties. But propylene still has generally higher strength characteristics. For example, on the Brinell hardness scale, polyethylene has an indicator of 1.4-2.5 kgf/mm², and polypropylene – 6.0-6.5 kgf/mm². For other indicators, the differences are not so noticeable. The areas of application of both materials also have many similarities.

They are used in the production of packaging materials, plastic dishes, and pipes. Foamed polymers are in demand as a thermal insulation material. They are widely used for the production of copolymers (they contain various structural units, for example, polyethylene and polypropylene or some other polymer). Production of dielectrics, household items, decorative items - the list of areas where you cannot do without them would take a long time.

One of the modifications of polyethylene - ultra-high molecular weight high-density polyethylene - has very high strength characteristics. In this regard, the material is used where special strength is required. For example, when creating body armor, helmets, armor panels. In a number of parameters, its characteristics are higher than those of Kevlar, which is also used for the manufacture of body armor.