From this article you will learn:

- What are the technical characteristics of different types of couplings for polypropylene pipes

- In what areas are couplings for polypropylene pipes used?

- What types of couplings exist for polypropylene pipes?

- What is an “American” coupling for polypropylene pipes?

- How to install couplings for polypropylene pipes

A coupling is a fitting that connects individual pipes that make up a pipeline. Couplings for polypropylene pipes must create an airtight and reliable connection that can withstand high temperatures and exposure to aggressive environments.

Straight coupling for polypropylene pipes

For connecting pipes of equal diameter

Intended for joining pipelines with the same diameter (for example, for extending one pipe segment onto another). White or gray polypropylene is used as the base material in such couplings. Such couplings can be used in any engineering systems (heating, hot water supply, water supply) in which the operating temperature does not exceed +95⁰С and the pressure does not exceed 2.5 MPa. This is made possible by the increased wall thickness in straight couplings compared to the wall thickness in standard pipelines.

The standard range of diameters of straight couplings for polypropylene pipes is represented by the following values: 20mm, 25mm, 32mm, 40mm, 50mm, 63mm, 75mm, 90mm, 110mm.

By the way, the technique for soldering plastic pipes can be found here.

What is PP coupling

A coupling is a connecting part for installing various types of pipes into a single pipeline. This is a universal type of fitting that is suitable for all types of pipe products.

The item became widespread due to its versatility and low cost. Installation does not take much time, and the work is not particularly difficult, so even a non-professional can handle it.

Products made from polypropylene have a number of undeniable advantages:

- Light weight.

- The melting point is 160–170 °C, which makes it possible to use them for working with hot water.

- The product is highly durable: it will take considerable effort to damage the coupling.

- With proper use, the service life is about 50 years.

- The material is soundproofing, so the sound of liquid movement will not be heard.

- Does not conduct electric current.

- It is highly resistant to active chemicals.

- The material is harmless to people and the environment under normal operating conditions, but it is worth considering that during combustion toxic substances are released in large volumes.

- Not subject to corrosion.

Disadvantages include:

- The vulnerability threshold of the material starts from -10 °C. At low temperatures, elasticity is lost, the walls of the pipe become brittle and unstable to mechanical damage, and accordingly, it is not suitable for outdoor use.

- The material is highly flammable and not resistant to open fire and high temperatures, so you should not place polypropylene products, for example, next to the stove.

- Polypropylene is a material that also does not withstand high temperatures.

We recommend that you read: Which gas torch to choose for soldering copper pipes - a review of the best

Note! It is not recommended to use polypropylene in systems with temperatures above 95 °C. Under high temperature exposure, polypropylene loses strength and becomes less resistant to any mechanical damage. In addition, leaks may occur at pipe joints.

Transition coupling for polypropylene pipes

For connecting pipes of different diameters

Designed for joining pipelines with different diameters and has technical characteristics close to direct analogues. The only difference is that the permissible operating temperature in the transition couplings should not exceed +80⁰С, and the pressure should not exceed 2.0 MPa. These features are due to the physical design features of such products.

Very often the need for such couplings arises when forming branches from the central riser to the consumer.

The standard range of diameters of adapter couplings for polypropylene pipes is represented by the following values:

- 110mm with transition to 63mm, 75mm, 90mm;

- 90mm with transition to 50mm, 63mm, 75mm;

- 75mm with transition to 20mm, 25mm, 32mm, 40mm, 50mm, 63mm;

- 63mm with transition to 20mm, 25mm, 32mm, 40mm, 50mm;

- 50mm with transition to 20mm, 25mm, 32mm, 40mm;

- 40mm with transition to 20mm, 25mm, 32mm;

- 32mm with transition to 20mm, 25mm;

- 25mm with transition to 20mm.

Moreover, if it is necessary to transition from the maximum diameter to one of the smallest, several couplings can be installed sequentially (for example, 110x63mm + 63x25mm).

Compound

The coupling is made from reliable and high-quality materials in order to ensure the best performance properties:

• Cast iron metal.

• Stainless steel.

• Thick plastic.

The material for the manufacture of the connecting element is selected depending on its purpose. The main criteria are:

• The type of fluid that will flow through the pipes.

• Her temperature.

• Pressure level.

It is important to know: today you can find many combination couplings that are suitable for various scenarios of its use. So, regardless of the type of work being done, you can choose the most suitable coupling.

Combined coupling with internal thread (MRV)

Internal threaded coupling (MRV)

is an assembly product consisting of a polypropylene bushing, inside of which a metal insert with a pipe (internal) thread is pressed. This design allows you to connect plastic water supply elements with standard engineering communications products that have a metal base (faucets, heated towel rails, metering devices, filter elements, valves, etc.).

Additionally, the design of MPV couplings provides external ribbing, which provides convenience when screwing the coupling onto a threaded connection. When installing couplings of this type, it is highly undesirable to use a mechanic’s tool, since excessive clamping force can damage the coupling structure and it will leak. Therefore, screwing the coupling is best done manually, using additional sealants (fum tape, tow, etc.).

The technical characteristics of MPV couplings are identical to transition couplings for polypropylene pipes and are +80⁰С and 2.0 MPa.

The standard range of diameters of combined couplings with internal threads (MRV) for polypropylene pipes is represented by the following values:

- 20mm x 1/2in,

- 20mm x 3/4in,

- 25mm x 1/2in,

- 25mm x 3/4in,

- 32mm x 3/4in,

- 32mm x 1in.

The first value is the diameter of the workpiece (for soldering to a polypropylene pipe), the second value is the nominal value of the pipe internal thread in inches (for threaded connections with standard elements of engineering communications).

Installation features

The versatility of the material allows you to make connections of any complexity without tricks. When installing a polypropylene fitting, you need to take into account a number of certain rules that will save time and material.

- It is necessary to use suitable equipment when welding at a certain temperature, which should not exceed 260 °C: in this case, the inner walls quickly melt without heating the outer part of the product. For high-quality welding, you need a special welding machine for soldering polypropylene products with a set of heads of the required diameter.

- It is advisable to mark before clipping. This is especially true for triple connecting fittings or pipe sections with bends. Marking will allow you not to lose the direction and order of welding.

- The coupling must be pressed onto the welding mandrel with force, since contact between the inner wall of the coupling and the mandrel is required for melting. If the inner wall does not touch the mandrel, it means that the wrong head diameter was selected or the product is defective.

- You cannot make carvings on polypropylene yourself. It will not provide a sealed connection.

- It is recommended to cut pipes with special scissors for polypropylene or a ring cutter. It is advisable to cut it evenly, this will ensure a more reliable connection to the coupling during welding.

- When connecting, polypropylene products must not be rotated relative to each other, so as not to move the elements and break the tightness.

- If the work is carried out with reinforced polypropylene pipes, then for welding it will be necessary to remove part of the reinforcement with a shaver, otherwise a high-quality and tight connection cannot be ensured.

Note! It is better to choose a welding machine with a removable leg; without a leg it will be easier to work with weight. And for working on a table, you can again equip it with a leg and securely fix it on the surface.

Combined coupling with external thread (MCN)

External threaded coupling (MRN)

Its characteristics are completely similar to the previous version. And the main difference is that the metal sleeve pressed into the structure of the polypropylene coupling is equipped not with internal, but with external pipe-type threads.

That is, just like for MPV couplings, MPH couplings are used to create a transition from a plastic pipeline to standard utility products with metal terminals (valves, mixers, bends, etc.).

The standard range of diameters of combined couplings with external threads (MPN) for polypropylene pipes is represented by the following values:

- 20mm x 1/2in,

- 20mm x 3/4in,

- 25mm x 1/2in,

- 25mm x 3/4in,

- 32mm x 3/4in,

- 32mm x 1in.

The first value is the diameter of the workpiece (for soldering to a polypropylene pipe), the second value is the nominal value of the external pipe thread in inches (for threaded connections with standard elements of engineering communications).

Which connection method to choose

Using the information presented above, you can quite objectively evaluate the use of the mentioned solderless connection methods for installing such communications as:

- cold water supply;

- hot water supply;

- heating;

- sewerage

Cold water supply

Fittings are most suitable for installing cold water supply systems in houses and apartments. Their advantage is that they serve well as connections between polypropylene pipes and with pipes made of other materials. Just like fittings for domestic water supply networks, couplings are used. Both are designed for pipe connections with a diameter of ½ to 3 inches. The disadvantages include the high cost of docking points.

Polymer pipes and fittings for cold water withstand gluing with epoxy compounds and cold welding well. The advantage of adhesive methods is the speed and ease of installation. The disadvantages of such connections are the high demands on precise execution of the gluing technology. The slightest violation leads to water pipeline leaks.

Hot water supply

Just like cold water pipes, hot water pipes can easily withstand connections using fittings and couplings.

If anything can be classified as a disadvantage, it is the impossibility of gluing them with glue and cold welding. These compounds cannot withstand strong heat and are completely destroyed under its influence.

Heating

For heating systems of houses and apartments, threaded and detachable connections of polypropylene pipes are most suitable. American type couplings are especially in demand.

They play the role of adapters from polymer pipes to heating radiators made of aluminum, steel and bimetal. There are no particular disadvantages of this connection method.

Sewerage

This refers to a non-pressure system for draining contaminated water from household plumbing fixtures such as a bathtub, sink, sink, toilet, bidet and floor drain. Pipes with a diameter from 32 to 100 mm are used. They are installed section by section. Each section, on the one hand, expands in the form of a watering can (socket).

When one section enters another, tightness is achieved thanks to a rubber sealing ring. The undoubted advantage of socket connections is their ease of installation, which does not require virtually any excessive physical effort. No deficiencies were found.

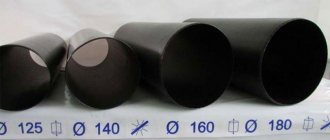

Combined couplings with internal and external threads on a turnkey basis

Turnkey external threaded coupling (MRN)

They are a special case of the two options described above. And they differ from MRV couplings and MPH couplings only in that they are equipped on the metal thread side with an additional protrusion for gripping the key. This feature allows the use of this type of coupling for pipelines of large diameters, as well as in all other cases where additional force is required to thread the coupling.

The standard range of diameters of couplings with internal and external turnkey threads is represented by the following values:

- 32mm per inch;

- 40mm by one inch and a quarter;

- 50mm by one and a half inches;

- 63mm by two inches;

- 75 by two and a half inches;

- 90 by three inches;

- 110 by four inches.

Classification of devices by thread type

1. The external thread coupling has the same purpose as the standard coupling, the only difference is the installation process. An element with an external thread is much more convenient to screw in.

2. With metal thread. Unlike previous products, this coupling has a metal base, which makes it much stronger. The principle and method of use remains the same.

3. The threaded coupling at the base is ideal for connecting different types of pipeline systems.

4. American type dismountable coupling is used to connect rigid and flexible structural elements together. High strength is ensured by a massive metal cap. Also, such a design solution can be used to connect parts of the pipeline, which will later be dismantled for replacement with more advanced devices (for example, a pump).

5. The coupling with a union nut is designed to connect different water pressure systems with increased strength. For example, these could be pipe connecting elements.

It is important to know: it is necessary to choose the appropriate type of coupling design depending on the type and types of structural elements that need to be connected.

Combined split type couplings (American)

Detachable couplings

are products for joining plastic and metal pipes. Moreover, the design of such couplings allows for subsequent separation of the joined sections without their deformation. American cables are very convenient to use for connecting consumers that require periodic maintenance (heating radiators, electric water heaters, etc.).

The process of connecting and disconnecting in such couplings is carried out through a threaded connection on the metal section of the coupling (using a key). Moreover, just like the MRV and MRN couplings, the “Americans” can also be equipped with various types of threads (internal and external).

The technical characteristics of dismountable couplings are +95⁰С and 2.0 MPa.

The standard range of diameters of American collapsible couplings is represented by the following values:

20×0.5; 20x0.75; 20x1; 25x0.5; 25x0.75; 25x1; 32x0.75; 32x1; 32x1.25; 40x1.25; 50x1.5; 63x2; 75x2.5; 90x3; 110x4,

where the first value is the diameter of the workpiece (for soldering to a polypropylene pipe), the second value is the nominal value of the external or internal pipe thread in inches.

Operating classes

There are couplings for various operating conditions. The product class shows which ones specifically. You need to pay attention to this when purchasing shaped parts. For the installation of pipelines with hot or cold water, as a rule, class 2 fittings are used. They are optimally suited for this purpose.

The characteristics of the classes are as follows:

- 1 - temperature up to sixty degrees (service life 50 years);

- 2 - temperature conditions up to seventy degrees (service life 50 years;

- 4 - intended for use in low-temperature radiator systems for fifty years (2.5 years at twenty, twenty years at forty, twenty-five years at sixty and 2.5 at a temperature of seventy degrees);

- 5 - used in high-temperature radiators with the expectation of operation for 50 years (14 years at twenty, 25 years at sixty, 10 years at eighty, one year at ninety degrees).

These classes are regulated by the international standard ISO 10508.

Watch the video:

Couplings for polypropylene pipes with union nuts

Suitable for frequent inspections of certain segments of utility lines. So, for example, such couplings are very convenient to use for connecting a replaceable water filter (to dismantle such a filter it will be enough to unscrew the union nuts).

The technical characteristics of the presented products and their overall dimensions are completely identical to the collapsible type couplings, the description of which is proposed above.