A pipeline is a system of interconnected metal or plastic pipes and fittings. To connect individual elements, there is always an uninsulated section (technological indent) at the ends of the pipes. This could be a section of a steel pipe not covered by a shell or a stripped section of a plastic product.

Technological indentations are left in order to make a high-quality weld, which then, however, must be insulated in the same way as the rest of the pipeline. And for these purposes, a heat-shrinkable pipe coupling (THUM) is used.

Heat-shrinkable couplings for insulating joints of polyurethane foam pipes

Our company presents modern thermal insulation materials of its own production, which can be ordered and purchased in any required quantities.

The advantage of this product is the combination of high quality and optimal prices. Quality is based on the use of the latest technologies and materials with strict control at all stages of production. And low prices are possible due to the absence of intermediaries between the manufacturer and the buyer.

Our products are designed to provide effective insulation for a variety of pipelines.

note

It meets all required standards and has optimal characteristics for the climatic conditions of Russia.

Today, installation and maintenance of heating mains requires not only a professional approach, but also the use of materials that effectively perform their function over a long period.

This is especially important for two reasons:

- firstly, work on installing heating mains and eliminating deficiencies during operation is costly;

- secondly, in the absence of proper pipe insulation, heat loss increases significantly, and the pipelines themselves quickly wear out, being exposed to the destructive effects of external factors.

We produce and sell a Joint Sealing Kit, which allows you to correctly and successfully insulate the joints of polyurethane foam pipes. Avoiding unnecessary costs and unforeseen losses in the process of insulating polyurethane foam pipes.

The range of joint sealing kits includes modern insulating materials:

Heat-shrinkable sleeve

, radiation-crosslinked couplings The heat-shrinkable coupling is made from the same shell that the PPU pipe insulation has, but is specially stretched at the factory. This allows you to put the coupling on the joint, after which it is given its original size through heat treatment.

Foam assembly package

The foam assembly package is indispensable for insulating joints using a heat-shrinkable sleeve. The assembly foam package contains packaged liquid components A and B, the volume of which is calculated for each standard size of pipe, which are mixed and fill all the cavities that have arisen between the pipe and the heat-shrinkable coupling. This ensures high-quality sealing.

TIAL-M tape

Heat-shrinkable tape TIAL-M is designed for reliable protection of pipeline joints from corrosion and waterproofing protection of seams used in heat supply networks. Heat-shrinkable tape carefully covers the surface of the joints.

To insulate a pipe joint in polyurethane foam insulation, the following materials of the TIAL brand are required:

- Locking plate TIAL-ZP for fixing a heat-shrinkable sleeve on a pipe;

- Heat-shrinkable tape TIAL-M for waterproofing pipe joints;

- Hot melt adhesive TIAL-Z for better adhesion of heat-shrinkable materials.

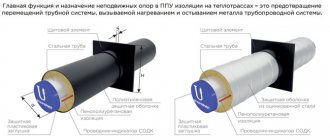

An excellent material for waterproofing, thermal insulation and sound insulation is polyethylene foam. It is also lightweight and chemical resistant. Special damping mats are made from this material.

Their function is to ensure that pipes can move in the ground when their temperature changes (heating and cooling). They are placed in places of branches and turns.

We also produce a wall bushing (wall bushing) - a special rubber seal that protects the pipeline shell from friction and damage at points of contact with reinforced concrete structures.

Galvanized casing for pipe insulation in polyurethane foam insulation in an OC sheath

The galvanized casing is used as a protective layer for above-ground installation of pipelines with a thermal insulation layer made of polyurethane foam shell or cast polyurethane foam. It can be mounted on a pipeline insulated with polyurethane foam shells or serve as an outer shell if it is installed at a joint and then filled with liquid insulating polyurethane foam.

The protective casing for pipes in polyurethane insulation is made of galvanized steel 0.5 mm thick with rolled stiffeners. The OC casing is manufactured without rollers, as a result of which clamps or ordinary self-tapping screws for thin sheets can be used for fastening.

Advantages of protective galvanized casings:

- products completely ready for installation,

- ease of installation on already laid pipelines,

- aesthetic appearance and high quality products,

- protection of polyurethane foam pipe insulation from mechanical damage and atmospheric influences,

- durability of the structure.

PPU shell

PPU shell is a prefabricated segmental insulation made of rigid polyurethane foam, which is mounted from ready-made elements - “shells” directly on the pipes.

These products are made in the form of elongated hollow semi-cylinders in a wide size range corresponding to the outer diameters of the pipes.

This pipe insulation is easy to use, quick to assemble and provides effective thermal protection.

Polyurethane foam shell for pipes has strength and moisture protection sufficient for use on pipelines located indoors and closed channels. To expand the range of application of this type of insulation, the production of polyurethane foam shell segments with protective coatings made of durable sheet materials resistant to moisture and ultraviolet sunlight has been launched.

Currently, the Joint Insulation Plant can offer you 5 types of prefabricated insulation:

- PPU shell without protective coating . Standard products, which are produced in a variety of standard sizes, and are designed to insulate intra-house communications, as well as sections of pipelines protected from moisture and ultraviolet radiation.

- With a protective coating of bitumen paper . This type of protection provides reliable insulation from moisture, therefore it is used when installing underground pipelines - both duct and non-duct type.

- Covered with fiberglass . This is one of the most commonly used types of shells and can be used successfully outdoors. Fiberglass is resistant to mechanical loads and the ultraviolet component of solar radiation.

- Foiled with thin metal . The use of an outer coating of metal foil allows you to protect the PPU insulation from mechanical influences, ultraviolet radiation, mold and rodents - all factors that may arise when operating an insulated pipeline in open spaces.

- Coated with galvanized steel . Like polyurethane foam insulation of pipes, shell parts made of polyurethane foam need protection from mechanical stress and significant moisture. Galvanized steel is the most durable coating, giving the PU shell anti-vandal properties, providing effective protection from UV and moisture.

Our company offers not only favorable prices and excellent quality, but also a lot of interesting offers for the purchase, payment and delivery of manufactured products. Each Client will receive from us maximum information about the product and its application, will be able to take advantage of a flexible system of discounts and will be satisfied with the communication with our specialists.

Source: https://mufta-ppu.ru/

Heat shrink sleeve for heating networks

There is an unpleasant factor in systems with hot pipe surfaces. This is a deformation increase or decrease in the length of the pipe due to its heating and cooling. Due to this, friction of the insulation on the ground occurs, followed by a decrease in its layer, right down to the metal. This usually happens at branch sites. Damping mats made of foamed polyethylene, which ensure safe movement of pipes, help eliminate such effects.

For places where the heating main comes into contact with reinforced concrete structures, a wall entry collar is used. But all this is a topic for a separate article.

When giving preference to one or another type of waterproofing, calculate the amount of effort, time and money spent. We assure you that you will choose heat-shrinkable sleeves made of radiation cross-linked polyethylene.

| Price list for heat shrink sleeve | |

| Name | Price |

| Heat shrink sleeve 110 * 600 | 300 rub. |

| Heat shrink sleeve 125 * 600 | 330 rub. |

| Heat shrink sleeve 140 * 600 | 420 rub. |

| Heat shrink sleeve 160 * 600 | 480 rub. |

| Heat shrink sleeve 180 * 600 | 530 rub. |

| Heat shrink sleeve 200 * 600 | 610 rub. |

| Heat shrink sleeve 225 * 600 | 680 rub. |

| Heat shrink sleeve 250 * 600 | 850 rub. |

| Heat shrink sleeve 280 * 600 | 940 rub. |

| Heat shrink sleeve 315 * 600 | 1200 rub. |

| Heat shrink sleeve 355 * 700 | 1600 rub. |

| Heat shrink sleeve 400 * 700 | 2050 rub. |

| Heat shrink sleeve 450 * 700 | 2500 rub. |

| Heat shrink sleeve 500 * 700 | 3000 rub. |

| Heat shrink sleeve 560 * 700 | 3400 rub. |

| Heat shrink sleeve 630 * 700 | 4000 rub. |

| Heat shrink sleeve 710 * 700 | 5100 rub. |

| Heat shrink sleeve 800 * 700 | 6300 rub. |

| Heat shrink sleeve 900 * 700 | 7800 rub. |

| Heat shrink sleeve 1000 * 700 | 9300 rub. |

| Heat shrink sleeve 1200 * 700 | 14000 rub. |

Insulation of joints using heat-shrinkable sleeves

One of the effective ways to insulate joints when installing pipes and heating networks is to use heat-shrinkable couplings.

Insulation of pipes and insulation of pipeline joints are needed in order to save fuel for the production of heat and money when paying for utilities.

This becomes possible because insulated PI piping retains heat and keeps heat loss to a minimum.

Important

Before welding the pipes, one coupling is placed on the pi-pipe, after which the pipes are installed and butt-welded.

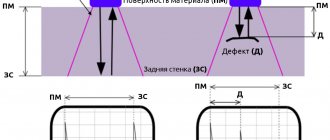

After welding, but before insulating the joints using heat-shrinkable sleeves, it is worth checking the following parameters:

- technical inspection of the quality of metal pipe welding seams;

- connection of conductors of the UEC system;

- quality control of conductor connections.

Insulation of pipeline joints as protection of pipes using heat-shrinkable couplings consists of the following steps:

- insulation of joints is carried out using the following materials: heat-shrink sleeve 600 or 700 mm long, polyurethane foam components, thermal applicator 40x2.5 mm, mounting plug, conical polyethylene plug, tinned copper wire holders and sleeves for installation of wires of the UEC system of pipeline systems in polyurethane foam insulation;

- a coupling is placed on the pipe, which, after connection, moves to the middle of the joint and is released from the protective shell;

- after heating the coupling with a propane torch until it shrinks completely, it acquires a barrel-shaped shape;

- then it is necessary to check the tightness of the coupling covered with polyurethane foam by injecting air into the hole at a pressure of 0.05 MPa (0.5 atmospheres);

- After this, you need to make sure that the pressure is maintained without significant change. If it decreases, you need to check the quality of the shrinkage of the coupling again and perform additional shrinkage (if required);

- if the pressure readings are normal, you can safely remove the plug and fill the coupling with liquid polyurethane foam with its further foaming and polymerization;

- after this, the internal holes must be closed with polyethylene canonical plugs, which are welded to a heat-shrinkable sleeve.

Insulating pipe joints using heat-shrinkable couplings is reliable protection against many external negative influences, such as moisture penetration into PI pipes, mechanical damage, etc.

Liquid polyurethane foam contains polyol and polyisocyanate components, which, when mixed, form a special mass that can expand to the required volume, polymerize and turn into rigid polyurethane foam.

produces heat-shrinkable couplings that can withstand 2000 production cycles, can be used for sealing joints at temperatures from -20 to +30°C, and are made of high-density polyethylene PE-100, which ensures high quality joints during insulation, durability of couplings and reliability operation.

Installation technology

The coupling is installed in parallel with welding work, in a certain sequence:

- The product is removed from the packaging immediately before installation, the inner surface is freed from contamination.

- The thermal cuff is placed in the middle of the joint, its edges are marked on the pipes with a marker.

- Before welding, a coupling is put on one of the pipes and moved about half a meter from the edge.

- The pipes are installed in the same plane; a gap is provided for the welding seam.

- Welding can be carried out using a torch, electric or manual gas, or an automatic welding complex.

- After welding is completed, the joint requires time to cool. The tightness test is carried out depending on the welding technology used.

- After making sure that the seam is tight, the heat-shrinkable sleeve is moved, completely covering the uninsulated section of the pipe.

Important! Heating begins from the bottom of the pipe in such a way that thermal energy is distributed from the middle of the cuff over its entire surface. Exceeding the temperature above 90-110º C is unacceptable, as it will destroy the coupling. Overheating is indicated by a bluish sheen appearing on the surface.

In order for the coupling to “sit” tightly on the pipe, it is heated from bottom to top.

When the pipe insulation is crimped, the void is filled with polyurethane foam from the kit through the hole provided in the coupling. Air is removed through another hole. After half an hour, the holes are sealed using conical plugs, which should not protrude above the coupling.

If the work is carried out correctly, a visual inspection will confirm:

- protrusion of a layer of glue around the circumference of the product;

- no gap between the coupling and pipe insulation.

PPU coupling | Butt joint insulation kit, coupling

To ensure tightness, strength and reliability, various couplings are used at pipe connections. One of the most modern varieties, widely used both in our country and abroad, is heat-shrinkable couplings.

Their peculiarity is that when heated, they change size (compress), adapting to the diameter of the pipe. In this case, the shape of the part is completely preserved. This greatly simplifies and speeds up the process of sealing joints during pipeline installation.

When the part shrinks due to heating, the released polymer fills all the voids and irregularities in the pipe, which ensures a more reliable connection.

Joint sealing kits available in stock

All sizes, fair prices.

Performance qualities of heat-shrinkable couplings

Heat-shrinkable couplings have the following performance qualities:

- possibility of complete sealing of the joint;

- long service life;

- outstanding strength and reliability;

- environmental friendliness, biological neutrality, absence of any harm to human health;

- resistance to chemical attack;

- resistance to negative environmental influences.

| Standard size | Foam assembly package | dmm | PE coupling | Heat-shrinkable tape (dimensions of one piece) | Locking plate (dimensions of one segment) | Adhesive glue (sizes of one piece) | ||||

| Dmm | Lmm | hmm | Lmm | Lmm | hmm | hmm | Lmm | |||

| 32x110 | 32x110 | 32 | 110 | 500 | 150 | 445 | 150 | 100 | 50 | 395 |

| 32x125 | 32x125 | 32 | 125 | 500 | 150 | 490 | 150 | 100 | 50 | 442 |

| 38x110 | 38x110 | 38 | 110 | 500 | 150 | 490 | 150 | 100 | 50 | 395 |

| 38x125 | 38x125 | 38 | 125 | 500 | 150 | 490 | 150 | 100 | 50 | 442 |

| 45x125 | 45x125 | 45 | 125 | 500 | 150 | 490 | 150 | 100 | 50 | 442 |

| 57x125 | 57x125 | 57 | 125 | 500 | 150 | 490 | 150 | 100 | 50 | 442 |

| 76x140 | 76x140 | 76 | 140 | 500 | 150 | 540 | 150 | 100 | 50 | 490 |

| 89x160 | 89x160 | 89 | 160 | 500 | 150 | 605 | 150 | 100 | 50 | 552 |

| 108x180 | 108x180 | 108 | 180 | 500 | 150 | 665 | 150 | 100 | 50 | 615 |

| 133x225 | 133x225 | 133 | 225 | 500 | 150 | 810 | 150 | 100 | 50 | 756 |

| 159x250 | 159x250 | 159 | 250 | 500 | 150 | 885 | 150 | 100 | 50 | 835 |

| 219x315 | 219x315 | 219 | 315 | 500 | 150 | 1100 | 150 | 100 | 50 | 1040 |

| 273x400 | 273x400 | 273 | 400 | 700 | 225 | 1360 | 225 | 100 | 100 | 1336 |

| 325x450 | 325x450 | 325 | 450 | 700 | 225 | 1520 | 225 | 100 | 100 | 1493 |

| 426x560 | 426x560 | 426 | 560 | 700 | 225 | 1860 | 225 | 100 | 100 | 1838 |

| 530x710 | 530x710 | 530 | 710 | 700 | 225 | 2400 | 225 | 100 | 100 | 2309 |

| 630x800 | 630x800 | 630 | 800 | 700 | 225 | 2700 | 225 | 100 | 100 | 2597 |

| 720x900 | 720x900 | 720 | 900 | 700 | 450 | 3000 | 450 | 100 | 100 | 2926 |

| 820x1000 | 820x1000 | 820 | 1000 | 700 | 450 | 3300 | 450 | 100 | 100 | 3240 |

| 920x1100 | 920x1100 | 920 | 1100 | 700 | 450 | 3650 | 450 | 100 | 100 | 3554 |

| 1020x1200 | 1020x1200 | 1020 | 1200 | 700 | 450 | 4000 | 450 | 100 | 100 | 3868 |

Example of a symbol:

Set isol. joints_muftovy_57x125

Components of the coupling joint insulation kit:

— ODK wire holders — 4 pcs. (6 pcs. for pipes Ø530 mm and above)

— sleeves for connecting the UDC wire — 2 pcs. (3 pcs.)

— drainage plug — 1 pc. (2 pcs. for shell Ø400 mm and above)

— conical plug — 1 pc. (2 pcs. for shell Ø400 mm and above)

— foam assembly package — 1 pc.

— heat-shrinkable PE coupling — 1 pc.

— heat-shrinkable tape — 2 pcs.

— locking plate — 2 pcs.

— adhesive glue — 2 pcs.

Note:

Dosed PU foam components (A and B) are supplied in the form of foam packages or special containers

Source: https://www.sktk-ppu.ru/production/ppu/komplekt-izolyatsii-stykovogo-soedineniya-muftovyy/

Heat-shrinkable sleeves for polyurethane foam insulation

Heat-shrinkable sleeves for polyurethane foam insulation

The use of heat-shrinkable couplings for hydrothermal insulation of joints that meet the requirements of PJSC "MOEK" allows for long-term trouble-free operation of pipelines in PPU insulation in accordance with the requirements of GOST 30732 - 2006 "Steel pipes and fittings with thermal insulation made of polyurethane foam with a protective sheath." The service life of a pipeline in PPU insulation is at least 30 years. Heat-shrinkable couplings must ensure the durability of the joints equal to the service life of the pipeline.

We produce couplings:

- heat-shrinkable for pipes in PPU insulation (in a polyethylene shell) with a diameter from 110 to 1600 mm, with a standard length of 500, 600, 700 mm. If necessary, the length can be changed

- heat-shrinkable for insulating joints of flexible pipelines with PPU insulation, D=100-250mm, L=800mm.

- heat-shrinkable for repair work, arbitrary (on request) length, max. L=2800mm, D=110-315mm.

- made of sheet steel with galvanized coating for pipes in a galvanized shell with a diameter of 110 to 1600 mm.

For the production of couplings, polyethylene shells are used, manufactured in accordance with GOST 30732-2006.

All heat-shrinkable couplings produced by PC STiM LLC are delivered to the customer’s site with kits for thermal and waterproofing of joints (KZS) packaged in boxes.

Prices are indicated in rubles, excluding VAT.

from 02/20/2018

| № | Pipe diameter x shell diameter, mm | Coupling length, mm | Cost of coupling, rub. | Cost of KZSL(T), rub. | Cost of KZS(T), rub. | Cost of KZS(ES), rub. |

| 1 | 38 x 110 | 500 | ||||

| 2 | 38 x 110 | 600 | ||||

| 3 | 57 x 125 | 500 | ||||

| 4 | 57 x 125 | 600 | ||||

| 5 | 76 x 140 | 500 | ||||

| 6 | 76 x 140 | 600 | ||||

| 7 | 89 x 160 | 500 | ||||

| 8 | 89 x 160 | 600 | ||||

| 9 | 108 x 180 | 500 | ||||

| 10 | 108 x 180 | 600 | ||||

| 11 | 108 x 200 | 500 | ||||

| 12 | 108 x 200 | 600 | ||||

| 13 | 133 x 225 | 500 | ||||

| 14 | 133 x 225 | 600 | ||||

| 15 | 159 x 250 | 500 | ||||

| 16 | 159 x 250 | 600 | ||||

| 17 | 159 x 280 | 500 | ||||

| 18 | 159 x 280 | 600 | ||||

| 19 | 219 x 315 | 500 | ||||

| 20 | 219 x 315 | 600 | ||||

| 21 | 219 x 355 | 700 | ||||

| 22 | 219 x 355 | 600 | ||||

| 23 | 273 x 400 | 700 | ||||

| 24 | 273 x 400 | 600 | ||||

| 25 | 325 x 450 | 700 | ||||

| 26 | 325 x 450 | 600 | ||||

| 27 | 377 x 500 | 700 | ||||

| 28 | 377 x 500 | 600 | ||||

| 29 | 426 x 560 | 700 | ||||

| 30 | 426 x 560 | 600 | ||||

| 31 | 426 x 630 | 700 | ||||

| 32 | 426 x 630 | 600 | ||||

| 33 | 530 x 710 | 700 | ||||

| 34 | 530 x 710 | 600 | ||||

| 35 | 630 x 800 | 700 | ||||

| 36 | 630 x 800 | 600 | ||||

| 37 | 720 x 900 | 700 | ||||

| 38 | 720 x 900 | 600 | ||||

| 39 | 820 x 1000 | 700 | ||||

| 40 | 820 x 1000 | 600 | ||||

| 41 | 920 x 1100 | 700 | ||||

| 42 | 920 x 1100 | 600 | ||||

| 43 | 1020 x 1200 | 700 | ||||

| 44 | 1020 x 1200 | 600 | ||||

| 45 | 1220 x 1425 | 700 | ||||

| 46 | 1220 x 1425 | 600 | ||||

| 47 | 1420 x 1600 | 700 | ||||

| 48 | 1420 x 1600 | 600 |

Prices may vary depending on order volume and payment terms!

Heat-shrinkable couplings are manufactured according to TU 5772-001-16878992-2014, comply with STO SRO NP "MSK" 1.12-2013, and exceed the requirements of EN-489, GOST 30732-2006, SP 41-105-2002

Composition of KZSL (T) : polyurethane foam components in PE containers, sealant (applicator), weld-in and drainage plugs, wire holders, crimp sleeves, solder.

Composition of KZS (T) : polyurethane foam components in PE containers, sealant (applicator), heat-shrinkable fabric, locking plates, weld-in and drainage plugs, wire holders, crimp sleeves, solder.

Composition of the KZS (ES) : polyurethane foam components in PE containers, electric welded tape, welded and drainage plugs, wire holders, crimp sleeves, solder.

Source: https://www.pkstim.ru/pages/mufta.html

Heat-shrinkable sleeves (THUM) in St. Petersburg

Pipes in polyurethane foam insulation from "TIZ" :: Heat-shrinkable couplings

Heat-shrinkable (heat-shrinkable) coupling (TUM)

The heat-shrinkable coupling (THUM) is used in heat supply for sealing pipe joints on the heating main, ensuring a hermetically sealed connection of the butt joints.

PPU pipes do not have a layer of polyurethane foam at the ends.

When connecting pipes, it is necessary to additionally insulate the welding points. For these purposes, heat shrink sleeves are used. The couplings are securely fixed at the joints of the pipes and allow polyurethane to be poured to protect the pipelines. Coupling Length Wall thickness, mm Coupling weight, mm PRICE D L MM RUB 110 125 140 160 180 200 225 250 280 315 355 400 450 500 560 630 710 800 900 1000 1100 1200

| 500 | 3,0 | 0,6 | 337 | DISCOUNT |

| 500 | 3,0 | 0,7 | 356 | DISCOUNT |

| 500 | 3,0 | 0,7 | 430 | DISCOUNT |

| 500 | 3,0 | 0,8 | 460 | DISCOUNT |

| 500 | 3,0 | 0,9 | 495 | DISCOUNT |

| 500 | 3,2 | 1,1 | 555 | DISCOUNT |

| 500 | 3,5 | 1,3 | 640 | DISCOUNT |

| 500 | 3,9 | 1,6 | 730 | DISCOUNT |

| 500 | 4,4 | 2,0 | 870 | DISCOUNT |

| 500 | 4,9 | 2,5 | 1080 | DISCOUNT |

| 500 | 5,6 | 3,3 | 1600 | DISCOUNT |

| 700 | 6,3 | 5,8 | 1700 | DISCOUNT |

| 700 | 7,0 | 7,2 | 2170 | DISCOUNT |

| 700 | 7,8 | 1,1 | 2550 | DISCOUNT |

| 700 | 8,8 | 11,2 | 2950 | DISCOUNT |

| 700 | 9,8 | 14,0 | 3700 | DISCOUNT |

| 700 | 11,1 | 17,9 | 4400 | DISCOUNT |

| 700 | 12,5 | 22,6 | 5600 | DISCOUNT |

| 700 | 14,0 | 28,5 | 6400 | DISCOUNT |

| 700 | 15,6 | 35,2 | 7500 | DISCOUNT |

| 700 | 17,2 | 42,6 | 10500 | DISCOUNT |

| 700 | 18,2 | 49,5 | 10900 | DISCOUNT |

How to check the correct installation of TUM

The correct installation of a heat-shrinkable sleeve can be determined by several parameters:

- upon visual inspection there should be no gaps between the coupling and the main pipe (at a distance of 200 mm);

- along the entire circumference of the cuff, molten glue should appear on the main pipe;

- plugs in technological holes can rise above the insulation by no more than 2 mm.

Correct and high-quality installation of a heat-shrinkable sleeve provides protection to the main pipe and, accordingly, extends its service life. The use of SODK will help to detect pipeline weaknesses in time and carry out repairs before the pipe collapses.

Heat-shrinkable sleeves

The heat-shrinkable coupling, due to its simple design and installation method, ensures a hermetically sealed joint between polyurethane foam pipes, i.e. the joint is completely insulated.

Polyurethane foam is poured after installation of the coupling into special holes and gradually expands in the closed volume, thereby filling all the empty space of the provided cavity volume.

Advice

The material of heat-shrinkable sleeves is heat-stabilized high-density low-pressure polyethylene, GOST 16388.

Our company supplies heat-shrinkable couplings of standard length (from 500 to 700mm), as well as non-standard (up to 1400mm). They can be used to insulate pipes with diameters from DN100 to DN1200 mm. It is also possible to manufacture according to the Customer’s drawings and special projects. Most importantly, all parameters depend on the length and diameter of the pipeline joint. The warranty period for this type of product is 12 months.

Features of installing a thermal coupling at a joint

The joint of two pipes in polyurethane foam insulation is a steel diameter and a polyethylene pipe diameter. The gap between them needs to be filled with polyurethane foam. The most important thing is to make sure that the pipeline in polyurethane foam insulation becomes one whole.

The thermal coupling is put on the pipeline before installation and welding of individual pipes, and is applied to the joint after the welding process. Using a gas burner (the flame should be at a temperature of 80-100C), special hot-melt adhesive is heated.

The hot-melt adhesive, in turn, connects the heat-shrinkable sleeve and the PPU pipe shell into one whole. As a result, you get a solid pipe, so to speak, “sewn together” from two polyurethane foam pipes, a thermal coupling and hot-melt adhesive.

Next, you need to wait until the steel pipe cools down to a temperature equal to the ambient temperature and you can pour polyurethane foam. The PPU (polyurethane foam) components are poured into the cavity between the steel pipe and the coupling, previously properly mixed and dosed.

It is worth noting that pipes in polyurethane foam most often come with an ODK (operational remote control) system and this point must be taken into account when installing couplings. After welding, the wires of the UEC system are cleaned, degreased and connected.

The quality of the connection can be checked using the ringing method using a special indicator. The ODK cable should not be stretched like a string, this can lead to spontaneous rupture when the temperature changes. But they shouldn’t hang down either.

Manufacturers of polyurethane foam pipes always make a special allowance for the wires of this system, so there is no need to worry that there will not be enough length.

note

The entire installation process of thermal couplings must be carried out by specially trained personnel. If the qualifications of your specialists in this matter are insufficient, then we are ready to train them within two days.

A heating main or technological pipeline system in polyurethane foam insulation can last 50 years or more only with proper qualified installation, as well as the selection of high-quality heat-shrinkable couplings, which we always have in stock.

We provide good discounts and installment plans for regular customers, so working with our company in the area of heat-shrinkable sleeves is especially profitable and pleasant!

Source: https://skyprom.ru/shop/truby-v-ppu-izolyatsii/komplekty-zadelki-styka-ppu-trub/termousazhivaemye-mufty/

Features of storage, transportation and use

The service life of any product will not be reduced if it is properly stored, transported and used. With regard to heat-shrinkable sleeves, it is mandatory to comply with the following rules:

- do not allow overheating above 30 degrees, so organize storage and transportation accordingly;

- storage should be single-tier or using inter-tier spacers;

- for storage and transportation, a vertical arrangement is provided to prevent ovalization;

- it is permissible to use the matryoshka principle, inserting products of a smaller diameter into larger ones;

- Protective packaging may only be removed immediately before installation;

- successful installation is only possible if it is carried out at temperatures above -15º C;

- more than five degrees of misalignment during docking is not acceptable;

- Installation must not be carried out if moisture gets on the surface of the pipes. At least a temporary shelter should protect against the penetration of precipitation, and the surfaces to be joined should be kept dry. Getting moisture under the cuff is strictly unacceptable.

Heat-shrinkable couplings are used when laying trunk lines, where they exhibit excellent performance properties. regardless of the climatic conditions. Economical and easy-to-install products perfectly protect the welded joints of polyurethane foam pipes, eliminating the need to carry out additional hydro- and thermal insulation work.

Heat shrink sleeve for insulated polyurethane foam pipes

sells wholesale and retail heat-shrinkable couplings for polyurethane foam pipes. They are used in the installation of pipelines for various purposes. This element is necessary for reliable insulation of joints between sections of the pipeline.

Displacement, deformation, and therefore the risk of leakage are eliminated. If the pipes are in good condition and there are no leaks, then the consumer receives water/heat and there are no extra costs for maintenance and repairs.

Consequently, such products provide savings and safety in the operation of pipeline systems.

Dimensions of PPU couplings

| Shell | Steel pipe diameter | Coupling inner diameter | Coupling thickness |

| D,mm | d1,mm | d,mm | s,mm |

| 90 | 32 | 105 | 2,0 |

| 110 | 38 | 130 | 2,5 |

| 125 | 57 | 145 | 2,5 |

| 140 | 76 | 160 | 3,0 |

| 160 | 90 | 180 | 3,0 |

| 180 | 109 | 200 | 3,0 |

| 200 | 109 | 220 | 3,0 |

| 225 | 134 | 250 | 3,5 |

| 250 | 160 | 275 | 4,0 |

| 280 | 160 | 300 | 6,0 |

| 315 | 220 | 335 | 5,0 |

| 355 | 220 | 375 | 5,0 |

| 400 | 274 | 425 | 6,5 |

| 450 | 324 | 475 | 7,0 |

| 500 | 324 | 515 | 9,0 |

| 560 | 427 | 590 | 9,0 |

| 630 | 529 | 653 | 11,0 |

| 710 | 529 | 745 | 9,0 |

| 800 | 629 | 840 | 12,5 |

| 900 | 719 | 940 | 14,0 |

| 1000 | 819 | 1045 | 15,5 |

| 1100 | 919 | 1155 | 17,0 |

| 1200 | 1019 | 1265 | 18,0 |

These products are also good for their ease of installation. The coupling is quickly installed on polyurethane foam pipes, and can also be easily dismantled if it is necessary to replace individual sections of the system.

For this purpose, a special hot-melt adhesive is used, which welds the product to the polyurethane foam shell.

The initial diameter of such a nozzle is higher than that of the shell, but after heat shrinking, it decreases, allowing you to obtain the tightest possible connection. When shrinking, the product does not deform.

Heat shrink sleeve for PPU pipes

From us you can order excellent quality PPU couplings for pipes. These are products from leading manufacturers. Products are available in different sizes - length, diameter. If you have any questions, you can ask our staff. This will help speed up and simplify selection and ordering. Also, if you need to purchase a stainless steel sheet, then this is the place for you.