Manufacturers cut external and internal inch threads of different sizes in accordance with GOST.

When working, special tables are used. Products with coarse and fine pitch are designated in the drawing as UNC and UNF.

Why are water and gas products measured in inches?

The system for measuring pipes in inches is called imperial, and in millimeters or centimeters is called metric. The Imperial measurement system was developed by the British. The history of the founding of this system goes back to 1495, when the English king Henry VII introduced an individual standard.

The metric system is more convenient, but in water and gas lines the dimensions of materials are calculated in inches. This is the generally accepted standard GOST 3262-75, which is used in water and gas lines. Going deeper, it should be noted that 1 inch equals 25.4 mm. However, if you take an inch water pipe and measure its diameter, you will get a value equal to 33.5 mm. What does this mean?

This discrepancy is due to differences between the American inch and the British one, which was approved by King Henry. In Britain, one inch was the size of a thumb. That is why today there are such disagreements with the diameters of conventional pipelines and water and gas pipelines.

One inch in the time of Henry VII was measured by the ball of the thumb, and is considered approximate.

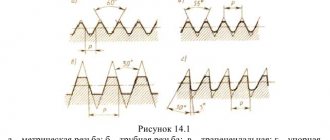

How to distinguish metric threads from inch threads

It is not difficult to distinguish an inch pipe from a metric one. To differentiate, you need to pay attention to the thread notches. It is almost impossible to determine the degree of notch by eye, especially since the difference between metric and inch threads is only 5 degrees.

Metric threads have a cut of 60 degrees, and inch threads have a cut of 55 degrees.

Pipelines can be distinguished by rounded threads, which are visible to the naked eye. It is impossible to make a mistake, but to clarify, a special device is used - a thread gauge. As a last resort, to clarify the thread, you can use an ordinary ruler. The photo below shows a special coupling, which is used to connect a plumbing product to a regular one.

How to determine the step?

To measure the pitch of an inch thread, specialized devices and tables are used. They allow you to accurately determine the distance between turns or grooves.

In cases where special tools and tables are not available, you can approximately determine the inch thread pitch of a bolt. The best way to do this is to select a nut with known parameters. If the threaded element screws on easily, then the bolt dimensions correspond to the fastener with internal threads. If screwing is difficult, select another nut. This way it is possible to determine the pitch without special devices and a table.

It is possible to carry out calculations using a simple ruler. A person with minimal technical knowledge and skills can handle the job. You will need a measuring tool with an inch scale.

To measure, combine the first turn with the zero mark of the ruler. Next, count the number of protrusions within 1 inch. To determine the pitch without a table, the resulting distance is divided by the number of protrusions. Thus, with the help of simple mathematical calculations it is possible to determine the pitch of an external inch thread.

To determine the pitch between turns on internal surfaces without a table and a tool, dye is applied to the protrusions. After this, place a small piece of paper inside the hole and press it against the ridges. Based on the resulting impression, the pitch is calculated using a ruler.

Please note that this can only give an approximate value. For more accurate step measurements, use a special tool and tables.

IMPORTANT: In some cases, cutting according to the American standard is possible. The protrusion profile in the drawing has the shape of an isosceles triangle. Its sides are located at an angle of 60 degrees relative to each other.

What diameter does a ¾ pipe have: features of determination

In Russia, as in most countries of the former USSR, the inch system is used for designation in water supply and gas supply. It follows from this that the outer diameter of the pipe ¾ according to GOST 3262-75 is 26.8 mm. The internal size of the ¾ steel pipe is 20 mm. However, this value for water supply and gas pipeline products represents the value of the nominal diameter Dу. It is also called the pipeline capacity. If the outer diameter of the pipeline corresponds to 26.8 mm, then the diameter of the external thread is approximately 26.4 mm. However, it may not always be equal to this value. It all depends on the wall thickness of the product used. Depending on the thickness of the pipeline walls, the value of the external parameter can reach 28 mm.

In America and some European countries, ¾ sizes do not correspond to the values indicated above (i.e., those used in the former countries of the union). This means that if it is necessary to join such materials, you will need to use special adapters. ¾ pipes are used for laying water and gas pipelines, as well as heating systems.

An important parameter for water and gas pipelines is the number of threads or thread pitch. For ¾ products, the number of threads is 14 per inch. This means that there are 14 threads per unit of measurement. It is important to know that inch pipes are measured by the internal diameter (the nominal diameter), while metric pipes are measured by the outer edges of the threads. Below is a table showing the parameters of pipelines in two units of measurement for different types of products.

The length of the ¾ pipelines can be different, since there are corresponding standards for this. However, experts pay attention to uncut material when there are large orders. This allows you to significantly save on adapters and connectors.

When choosing pipelines, it is important to consider the purposes for which they are planned to be used. If you need to cut a thread, you can use two types of tools: a die or a die. The clamp is more convenient to use, as it can be not only manual, but also electric.

Markings and accuracy classes

There are 3 classes of thread accuracy: first (the coarsest), second and third (the most precise). The choice of one class or another depends on 2 factors: the dimensions of the thread diameter taken from the table, the fluid pressure in the pipeline. The higher the thread class, the greater the fluid pressure it can withstand.

Dimensions are checked for compliance with a certain accuracy class using special gauges. This method allows you to most reliably determine whether the thread matches the required dimensions, but it is more labor-intensive. This method is effective in conditions of multi-batch production of parts that require high precision. When the production volume is not so large and there are no increased requirements for accuracy, the thread sizes are controlled as follows:

- The dimensions of the outer diameter are measured using calipers, micrometers and other mechanical measuring instruments. The readings are then checked against a reference table.

- The pitch dimensions are determined by applying special dies, for example an inch thread gauge. Then the resulting number of turns per inch is correlated with the value of the inch thread size table. The easiest way to measure the thread pitch is to take a ruler, mark 25.4 millimeters on it and count how many turns are included in this segment. Let us immediately note that this is the roughest method and is not suitable for measuring threads with the third and second class of accuracy.

Let's look at the designation of inch threads in technical documentation using an example:

G 2” LH-2-40

The letter "G" means that the pipe thread is cylindrical. According to Russian standards, a conical pipe is designated by the letter “K”.

The number "2" indicates the size of the outer diameter. The unit of measurement is inches. Thread sizes and their options are fully regulated by GOSTs and are listed in special tables.

The letters "LH" indicate that the thread has a left-hand screw direction. The absence of this designation indicates the right direction.

The number “2” characterizes the accuracy class. The table of deviation limits is indicated in GOST. The number “40” is the size characterizing the length of screwing.

Pipe manufacturing materials ¾

Depending on the material used to manufacture the ¾ pipeline, the final product may have different parameters. Only the internal diameter of the materials cannot be changed, which is equal to 20 mm for ¾-inch products. In this case, only the outer size of the product changes.

If you need a ¾ thread on a pipe, then 3 dies are used for this. Using the first die, a roughing pass is made, through which the threads are formed. The second is intended for stripping, and the third die is used for finishing. When connecting ¾ copper pipelines, soldering technology is used. This is due to the fact that the internal diameter of such products is 19.05 mm, that is, less than necessary. The wall thickness of such products is 1.07 mm, so a threaded connection cannot be made.

All connectors, taps and valves for water and gas supply systems are appropriately marked for the diameter of the pipelines they are used for. This marking is located on the outside of factory parts.

It is recommended to cut threads directly using special equipment. Water and gas pipelines are systems that require precision, so when choosing a material, you need to take into account not only the dimensions, but also the quality of the products. After all, how long the structure will last depends on this parameter.

Read also: Field-effect and bipolar transistor difference

Inch

(Russian designation:

inch

; international:

inch

,

in

or

″

- double stroke; from Dutch duim - thumb) - a non-metric unit of distance and length in some systems of measures [1] [2] [3]. Currently, an inch usually means the English inch used in the United States (English inch), exactly equal to 2.54 cm.

The International Organization of Legal Metrology (OIML) in its recommendations classifies the inch as one of those units of measurement “ which should be withdrawn from use as soon as possible where they are currently used, and which should not be introduced if they are not used.”

» [4] .

In the Russian Federation, the inch is allowed for use as a non-system unit without a time limit with the scope of application “industry” [2].

Slicing Methods

To cut inch threads, you can use manual and mechanized methods.

Manual cutting is performed with special tools - dies and taps. The die is used for cutting external threads, and the tap is used for internal threads. Cuttings are performed in the following sequence:

- The part on which the thread is cut is tightly fixed in a vice.

- The cutting tool is fixed: the die is in the die holder, the tap is in the driver.

- The tool is prepared for cutting. The tap is inserted into the inside of the pipe, and the die is put on its end.

- Cutting is performed by rotating the tool with a die holder or a wrench.

The cutting procedure is usually repeated several times to obtain a better result.

Mechanized cutting of inch threads is performed on a lathe. In this case, the following sequence of operations is observed:

- The part is clamped in the machine chuck. The cutting cutter is fixed on the machine stand.

- Chamfer the end of the workpiece.

- Adjust the speed of movement of the caliper. When setting the settings, they are guided by the data in the inch thread tables of the lathe.

- Bring the cutter to the surface of the part and start the machine, turning on the thread feed.

Mechanized cutting of inch threads is characterized by increased productivity and quality of the result. However, this method cannot be used for every pipe. The product must have sufficient rigidity and wall thickness to withstand lathe processing. In addition, thread cutting is a technological operation that must be performed by a qualified turner with the appropriate skills.

History [edit | edit code]

It is generally believed that the inch was originally defined as the width of the thumb [5]. According to other legends, an inch was defined as 1 ⁄36th of a yard, which, in turn, was established as the distance between the tip of the nose and the thumb of the outstretched hand of King Henry I of England (there is also a version that a yard was his sword). Another legend connects the definition of an inch (“legal inch”) with the length of three dry barley grains taken from the middle part of the ear and placed one against the other with their ends, which was determined by the act of King Edward I [6]. In English everyday life, the measure “barleycorn” (English barleycorn) equal to one third of an inch is still used. It is important to note here that inches are usually denoted by whole numbers and fractions (with denominators 2, 4, 8, 16), and not by decimals.

Historically, the width of an adult man’s thumb [5]. Typically, an inch is equal to 1 ⁄12 or 1 ⁄10 (“decimal inch”) foot of the corresponding country (in Russian and English systems of measures, 1 inch = 10 lines (“big line”)). The word “inch” was introduced into the Russian language by Peter I at the very beginning of the 18th century.

In Russia, English inches were best known (including under the name from the original language: insh

(obsolete),

inch

(obsolete, as well as modern jargon) and French inch; the first was more often used in science and technology, the second in typography. According to the old Russian system of measures: 1 inch (equal to English) = 10 lines = 100 points = 4/7 vershka = 1 ⁄12 feet (equal to English) = 1 ⁄28 arshin = 1 ⁄84 fathoms = 1 ⁄42,000 versts, however in everyday life, it was mainly not feet and inches that were used, but arshins (= 7 ⁄3 feet) and tops (= 7 ⁄4 inches) commensurate with them. In parallel with the definition of the Russian inch through English at the beginning of the 20th century, there was a (also legalized) relationship between the inch and metric units of length: 1 inch = 25.39954 mm [7].

After the transition of the USSR to the metric system, inches were used to a limited extent: in water supply and gas pipelines, the inch calculation (using whole fractions of an inch) remained for the diameters and pitch of pipe threads [8] [9] ; Unofficially, some calibers of artillery were expressed (the most famous are “three-inch” - guns of 76.2 mm caliber), small arms (“three-line” - 7.62 mm), the length of nails, the thickness of boards and the size of some other objects, although the actual values of the sizes of various technical products quite often in inches (or other units of the old system) were expressed in rounder numbers than in the metric system.

Usage [ edit | edit code ]

The inch is the commonly used standard unit of length in the United States [10], Canada [11], [12], and the United Kingdom [13]. It is also used in Japan for electronic components, especially screens. In much of continental Europe, the inch is also informally used as a measure for display screens. In the United Kingdom, public sector guidance states that from 1 October 1995, without time limit, the inch (together with the foot) should be used as the base unit for road signs and associated distance measurements (with the possible exclusion of clearance height and width) [14] and may continue to be used as a secondary or additional indication after metric measurement for other purposes [13] .

Inches of different countries [ edit | edit code ]

Vienna inch

= 2.6340278 cm.

English inch

or

imperial inch

(English inch from Latin uncia - 1 ⁄12 part) since 1958 is equal to exactly 2.54 cm. Previously it was converted to the metric system in a different way:

- 1819 - 1000000/393694 cm ≈ 2.5400438 cm;

- 1895 - 2.5399978 cm;

- 1922 - 2.5399956 cm;

- 1932 - 2.5399950 cm;

- 1947 - 2.5399931 cm.

Germany

- Bavaria

: 2.43216 cm or 2.918592 cm ("decimal inch"); - Baden

: 3 cm (1810); - Prussia

: 2.61545 cm (1755), 3.76625 cm ("decimal inch", 1816); - Confederation of the Rhine

: 2.61541 cm; - Saxony

: 2.36 cm.

Spain

1 pulgada = 2.32166 cm.

The French inch was used, but since 1985 the value has been changed: 2.707005 cm.

Read also: How to properly install a car radio

1 pulgada = 2.3278 cm.

Along with Rhine inches (see above, in the section on Germany), the following were used:

- Courland inch

≈ 3.36 cm; - Riga inch

≈ 2.24 cm; - Revel inch

≈ 2.6715 cm.

Polish-Lithuanian Commonwealth, Poland, Grand Duchy of Lithuania

- Old Polish

or

crown inch

(before 1819) ≈ 2.48 cm; - Novopolsky inch

(1819-1849) = exactly 2.4 cm; - Wrocław

(

Bresław

,

Silesian

)

inch

= 2.742 cm; - old Lithuanian inch

≈ 2.7076 cm.

Rio de La Plata

1 pulgada ≈ 2.547 cm.

As in the UK, since 1958 the American inch has been equivalent to 2.54 cm - to distinguish it from the rest, this unit is called the international inch

.

Previously (since 1866) it was equal to 2.54000508 cm (more precisely, 10000/3937 cm); sometimes this old value is still used today under the name geodesic inch

.

The caliber of small arms in the USA is usually measured in hundredths of an inch (in the UK - traditionally in thousandths). For example, the famous 45 caliber is 0.45 inches (or 11.43 mm); The 30th is 0.30 inches (or 7.62 mm); The 50th is 0.50 inches (or 12.7 mm), etc.

French inch

(French pouce - thumb), also known as

the Parisian inch

and

royal inch

, was equal to 75,000 ⁄27,706 cm, that is, approximately 2.706995 cm. In the old Parisian system of measures, 1 inch = 12 lines = 144 points = 1 ⁄12 feet = 72 ⁄3161 cubits = 1/72 toise.

The units of the Didot typographic system, adopted in Russian typography, are based on the divisions of the French inch.

In technology [edit | edit code ]

In recent years, under the influence of American technology and technical terminology, inches are used in Russian much more often. In particular, they express the size of various computer parts, components and accessories: floppy disks, disks, TV screens, displays (monitor), etc. Dots per inch (dpi) and lines per inch (lpi) measure the resolution of various devices graphical input/output. The screen diagonal of household television broadcast receivers, which was measured only in centimeters during Soviet times, is now often indicated in inches.

The diameter of car and motorcycle rims, mountain bike and cruiser rims is also traditionally measured in inches, while tire sizes and fasteners, as well as road, cross and hybrid bicycle rims, are measured in the metric system, although the tire size of Japanese and American SUVs is usually indicated in inches, for example 31*10.5R15 - tire height 31″, width 10.5″, wheel 15″. The diameter of the speakers is also measured in inches.

In modern typography, in addition to French, the English inch is also used, especially in computers. Font sizes are measured in points, 72 fractions of an inch.

Widicon inch [edit | edit code ]

Equal to ⅔ of an ordinary inch or approximately 16.93 mm [ source not specified 1663 days

] . Most often it is used to measure the diagonal of the matrix of digital cameras. Historically, it originated as a designation for the size of the active part of the vidicon target, which has a bulb diameter of 1 inch.

For example, 1/2.7″ is a unit divided by 2.7 and multiplied by 16.93 mm, that is, 6.27 mm.

Pipe diameter [edit | edit code ]

The traditional designation of the diameters of water and gas pipes in inches does not directly express either the outer or inner diameters of the pipes [15]. This designation is closer to the designation of the nominal diameter of pipeline elements, which can be expressed both in the Anglo-American inch and in the metric European system [16]. However, there is no formula for converting "pipe inches" to millimeters or to "regular" inches to determine the actual outside or inside diameter of a pipe. The nominal bore in the metric system is also weakly related to the geometric diameter of the pipes [15]. To unambiguously compare the conventional inch diameter with the standard outer diameter of the pipe and the diameters of the pipe threads, it is necessary to use reference literature and regulatory documentation.

GOST 3262 [17] establishes technical conditions for steel pipes used for water and gas pipelines, but it does not standardize or designate

pipe diameter in inches.

When cutting pipe threads, you must be guided by GOST 6357 [8], which establishes the main dimensions of cylindrical pipe threads in millimeters, but uses the designation

of thread size

in inches

. Thus, to establish correspondence between the inch size of a pipe and its actual geometric diameter, it is necessary to compare the data given in these two standards.

For example, the outer diameter of a ½" pipe in accordance with GOSTs is 21.3 mm, and a 5" pipe is 140.0 mm. When trying to calculate the conversion factor, it is discovered that “pipe inches” are greater than the standard value of 25.4 mm and “different” for different pipe diameters.

The table provided is based on the GOSTs mentioned above, but does not claim to be complete and cannot serve as a replacement for official regulatory documentation.

| Thread size designation [8] | Nominal pipe bore [17] | Outer diameter of external thread (pipe) [8], mm | Pipe outer diameter [17], mm |

| ⅛ | 6 | 9,728 | 10,2 |

| ¼ | 8 | 13,157 | 13,5 |

| ⅜ | 10 | 16,662 | 17,0 |

| ½ | 15 | 20,955 | 21,3 |

| ¾ | 20 | 26,441 | 26,8 |

| 1 | 25 | 33,249 | 33,5 |

| 1¼ | 32 | 41,910 | 42,3 |

| 1½ | 40 | 47,803 | 48,0 |

| 2 | 50 | 59,614 | 60,0 |

| 2½ | 65 | 75,184 | 75,5 |

| 3 | 80 | 87,884 | 88,5 |

| 3½ | 90 | 100,330 | 101,3 |

| 4 | 100 | 113,030 | 114,0 |

| 5 | 125 | 138,430 | 140,0 |

| 6 | 150 | 163,830 | 165,0 |

In cartography [edit | edit code ]

Maps of Russia in the 18th - early 20th centuries had a scale of versts in inches (or in English inches).

Read also: Instruments for determining hardness

Inch map scale:

- 10 versts in an inch (ten versts/ten versts) - 1:420,000, or 4.2 km in 1 cm.

- 5 versts in an inch (pyativerstovka/pyativerstka) - 1:210,000, or 1 cm 2.1 km.

- 3 versts in an inch (three-verst / three-verst) - 1:126,000, or 1 cm 1.26 km.

- 2 versts in an inch (two-verst / two-verst) - 1:84,000, or 0.84 km in 1 cm.

- 1 verst in inch (layout/layout) - 1:42,000, or 0.42 km in 1 cm.

An inch thread is a thread, all parameters of which are expressed in inches, the thread pitch is in fractions of an inch (inch = 2.54 cm). For inch pipe threads, the size in inches characterizes the clearance in the pipe, and the outer diameter of the pipe itself is slightly larger.

Inch threads are used in threaded connections and screw drives. Inch threads come in the following types:

- Inch cylindrical – UTS (Unified Thread Standard). This type of carving is widespread in the USA and Canada. The apex angle of this thread is 60 degrees. Depending on the step, it is divided into: UNC (Unified Coarse); UNF (Unified Fine); UNEF (Unified Extra Fine); 8UN; UNS (Unified Special). The most widely used thread is UNC. This thread conforms to ANSI 1 standard.

- British standard inch thread - BSW. Fine pitch threads are called BSF (British Standard Fine). The apex angle of this thread is 55 degrees.

- Inch tapered NPT or cylindrical NPS. Meets ANSI/ASME 20.1. This thread is used for pipe connections. Has an apex angle of 60 degrees. In Russia, such threads correspond to GOST 6111-52.

Most often in Russia recently you can find fasteners with inch UNC threads (unified coarse thread). Such fasteners are often found on equipment imported into our country (lawn mowers, trimmers, generators, cultivators, American-made cars, etc.) from the USA, China and some other countries. When working with inch fasteners, you must remember that the sizes of the keys for inch fasteners are different from the keys for metric fasteners.

What is carving and its types

A thread is a groove of a special shape and size, applied in a spiral to the inner or outer surface of a pipe or metal rod.

Can be applied to cylindrical or conical surfaces. It is characterized and differs from each other by the shape of the groove, the height/depth of the relief and the distance between the turns - the pitch. In order to connect two parts, they must have the same or compatible threads, with one part having an external thread and the other having an internal thread of the same type and size. In general, threads are divided into fastening and running threads. Chassis are used in machine elements and provide movement. We are more interested in those that are used in everyday life and that we encounter in the process of repair and construction. This is just a mounting thread. In fact, that’s what we’ll talk about.

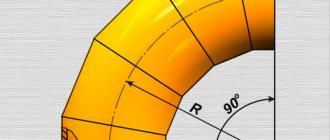

Types of thread according to the direction of turns and surface

It is also worth knowing that in the direction of application of turns, threads there are right and left, and in the direction of the surface on which they are applied - cylindrical and conical.

Types of threads

Pipe threads have their own profile, which provides a tight seal. It is used for non-welded connections of metal pipes in pipelines, installation of various types of fittings, and connection of devices. Recently, threaded connections have also been used on some types of plastic pipes, but there the approach is different - it is cast, although the essence is the same.

Three types of pipe threads and their differences

There are three main types of carving:

- Metric. You can distinguish them by the sharp tops of the turns and grooves. Shape: triangle with 60° angles. It is called so because its parameters are indicated in millimeters, and these are units of measurement of the metric system. Standardized by GOST 9150-81.

- Inch. It is also based on a triangle, but with an apex of 55°. It is present on imported parts. As you can see, the difference between metric and tapered threads is in the corners.

- Pipe. It differs from metric by a slightly smaller angle - 55°, and has the same angle from inch. The main difference is that the edges are rounded. And this is fundamentally important. It can be applied to a cylinder (pipe), and then the word “cylindrical” is added to the name. Standardized by GOST 6357-81. When threaded on a cone, it is called a pipe taper thread.

What type of carving is there? These are connecting ones - for connecting parts

The types of threads that may be on imported fittings and components may also be useful. This is a Whitworth thread, which is designated BSW if it has a coarse pitch and BSF if it has a fine pitch. It was this standard that was taken as the basis for the development of pipe threads in the USSR. So Whitworth threads and standard manufactured pipe threads are compatible.

Types of threads and their areas of application

There are other profiles, but they are common and very specific. Under normal conditions they are not needed. For general development, let's say that there are also rectangular and trapezoidal shapes.

Where is which one used?

Now about where what type of thread is used. Metric is applied to anchors, bolts, studs, nuts and other fasteners. Applied to a cylindrical surface it does not provide a tight seal, so it is not the best choice for pipelines. However, it is used, and for tightness it is “set” on a winding - tow or fum tape. In addition to plumbing, it is used in assembling frames from round pipes with a threaded connection.

What types of threads are there: profiles and standards

The picture changes when a metric thread is applied to a conical surface. This connection has a high degree of tightness. It is the metric conical thread that is applied to caps and is used in industrial pipelines for transporting gas and liquids that emit volatile substances. In everyday life, the use of conical threads is limited, since special equipment is required for its application.

It is not difficult to guess that pipe threads are used in pipelines. Thanks to the smooth profile lines, even without additional sealing, the connection is airtight. It is this type that is applied to elbows, angles, tees, and other devices that are used in the assembly of plumbing, heating and sewage systems.

The main dimensions of inch UNC fasteners are given in the table of inch threads

| Standard size | Outer diameter, inches | Outer diameter, mm | Drilling diameter, mm mm | Threads per inch | Pitch, mm |

| N 1 – 64 UNC | 0,073 | 1,854 | 1,50 | 64 | 0,397 |

| N 2 – 56 UNC | 0,086 | 2,184 | 1,80 | 56 | 0,453 |

| N 3 – 48 UNC | 0,099 | 2,515 | 2,10 | 48 | 0,529 |

| N 4 – 40 UNC | 0,112 | 2,845 | 2,35 | 40 | 0,635 |

| N 5 – 40 UNC | 0,125 | 3,175 | 2,65 | 40 | 0,635 |

| N 6 – 32 UNC | 0,138 | 3,505 | 2,85 | 32 | 0,794 |

| N 8 – 32 UNC | 0,164 | 4,166 | 3,50 | 32 | 0,794 |

| N 10 – 24 UNC | 0,190 | 4,826 | 4,00 | 24 | 1,058 |

| N 12 – 24 UNC | 0,216 | 5,486 | 4,65 | 24 | 1,058 |

| 1/4″ – 20 UNC | 0,250 | 6,350 | 5,35 | 20 | 1,270 |

| 5/16″ – 18 UNC | 0,313 | 7,938 | 6,80 | 18 | 1,411 |

| 3/8″ – 16 UNC | 0,375 | 9,525 | 8,25 | 16 | 1,587 |

| 7/16″ – 14 UNC | 0,438 | 11,112 | 9,65 | 14 | 1,814 |

| 1/2″ – 13 UNC | 0,500 | 12,700 | 11,15 | 13 | 1,954 |

| 9/16″ – 12 UNC | 0,563 | 14,288 | 12,60 | 12 | 2,117 |

| 5/8″ – 11 UNC | 0,625 | 15,875 | 14,05 | 11 | 2,309 |

| 3/4″ – 10 UNC | 0,750 | 19,050 | 17,00 | 10 | 2,540 |

| 7/8″ – 9 UNC | 0,875 | 22,225 | 20,00 | 9 | 2,822 |

| 1″ – 8 UNC | 1,000 | 25,400 | 22,25 | 8 | 3,175 |

| 1 1/8″ – 7 UNC | 1,125 | 28,575 | 25,65 | 7 | 3,628 |

| 1 1/4″ – 7 UNC | 1,250 | 31,750 | 28,85 | 7 | 3,628 |

| 1 3/8″ – 6 UNC | 1,375 | 34,925 | 31,55 | 6 | 4,233 |

| 1 1/2″ – 6 UNC | 1,500 | 38,100 | 34,70 | 6 | 4,233 |

| 1 3/4″ – 5 UNC | 1,750 | 44,450 | 40,40 | 5 | 5,080 |

| 2″ – 4 1/2 UNC | 2,000 | 50,800 | 46,30 | 4,5 | 5,644 |

| 2 1/4″ – 4 1/2 UNC | 2,250 | 57,150 | 52,65 | 4,5 | 5,644 |

| 2 1/2″ – 4 UNC | 2,500 | 63,500 | 58,50 | 4 | 6,350 |

| 2 3/4″ – 4 UNC | 2,750 | 69,850 | 64,75 | 4 | 6,350 |

| 3″ – 4 UNC | 3,000 | 76,200 | 71,10 | 4 | 6,350 |

| 3 1/4″ – 4 UNC | 3,250 | 82,550 | 77,45 | 4 | 6,350 |

| 3 1/2″ – 4 UNC | 3,500 | 88,900 | 83,80 | 4 | 6,350 |

| 3 3/4″ – 4 UNC | 3,750 | 95,250 | 90,15 | 4 | 6,350 |

| 4″ – 4 UNC | 4,000 | 101,600 | 96,50 | 4 | 6,350 |

Tightening torques

Tightening torques for UNC inch fasteners for SAE grade 5 and higher bolts and nuts are shown in the following table.

| Thread size, inches | Tightening torque for standard bolts and nuts | |

| N*m* | Pound-force-foot** | |

| 1/4 | 12± 3 | 9±2 |

| 5/16 | 25 ± 6 | 18± 4,5 |

| 3/8 | 47± 9 | 35 ± 7 |

| 7/16 | 70± 15 | 50± 11 |

| 1/2 | 105± 20 | 75±15 |

| 9/16 | 160 ± 30 | 120± 20 |

| 5/8 | 215± 40 | 160 ± 30 |

| 3/4 | 370 ± 50 | 275 ± 37 |

| 7/8 | 620± 80 | 460 ± 60 |

| 1 | 900 ± 100 | 660 ± 75 |

| 11/8 | 1300 ± 150 | 950 ± 100 |

| 1 1/4 | 1800 ±200 | 1325 ±150 |

| 1 3/8 | 2400 ± 300 | 1800 ± 225 |

| 1 1/2 | 3100 ± 350 | 2300 ± 250 |

*1 Newton meter (N*m) is equal to approximately 0.1 kgm. ** Pound-force-foot is the British and American equivalent of N*m.

Unit conversion table

Conversion of energy unitsConversion of pressure units

| 1 J = 0.24 cal | 1 Pa = 1 N/m*m |

| 1 kJ = 0.28 Wh | 1 Pa = 0.102 kgf/m*m |

| 1 W = 1 J/s | 1 atm =0.101 mPa =1.013 bar |

| 1 cal = 4.2 J | 1 bar = 100 kPa = 0.987 atm |

| 1 kcal/h = 1.163 W | 1 PSI = 0.06895 bar = 0.06805 atm |

Sources

- https://stroychik.ru/strojmaterialy-i-tehnologii/rezba-trubnaya

- https://prompriem.ru/stati/trubnaya-rezba.html

- https://prompriem.ru/stati/dyujmovaya-rezba.html

- https://www.rocta.ru/info/dyujmovaya-rezba-tablica-razmerov-shag-oboznacheniya-gost-i-markirovki/

- https://met-all.org/metalloprokat/metizy/dyujmovaya-rezba-razmery-tablitsa-gost.html

- https://ooo-asteko.ru/sootvetstvie-rezby-v-dyuymah-i-millimetrah/

- https://trubyisantehnika.ru/%D1%82%D0%B0%D0%B1%D0%BB%D0%B8%D1%86%D0%B0-%D1%81%D0%B0%D0%BD% D1%82%D0%B5%D1%85%D0%BD%D0%B8%D1%87%D0%B5%D1%81%D0%BA%D0%B8%D1%85-%D1%80%D0 %B0%D0%B7%D0%BC%D0%B5%D1%80%D0%BE%D0%B2-%D0%B2-%D0%B4%D1%8E.html

- https://DomStrouSam.ru/trubnaya-rezba-razmery-tablicza-osnovnye-vidy/

- https://domxoloda.ru/table-sizes/