Pipelines are used for different purposes: moving gases, different types of liquids, bulk materials. In order for the system to continue to function for a long time, withstanding the influence of external factors, without collapsing from water hammer, it is necessary to use special fasteners. With their help, you can protect the pipeline from physical influences from the outside and vibrations from the inside. On sale there are different types of fixed supports in PPU (polyurethane foam) insulation, which have different features, strengths, and weaknesses.

Purpose

Fixed supports of polyurethane foam insulation are used in the construction of new or alteration of old highways. Suitable for systems with the following technical characteristics:

- maximum liquid temperature - up to 140 degrees;

- permissible pressure - 1.6 MPa;

- The nominal temperature range is from 70 to 150 degrees.

A temperature of 150 degrees is peak. Long-term exposure may destroy fastenings. PPU insulation increases thermal insulation in those places where supports are installed. They are used not only to hold the pipeline stationary. With the help of such fastening elements, compensation is carried out for angular, transverse, and other loads that may arise at different intervals of the heating network.

Normative base

The manufacture and installation of the product is regulated by a number of GOSTs and SNiPs.

When installing parts, we are guided by SNiP 3.05.05 - 84, which clearly states permissible errors and deviations from the design.

In particular, the deviation of the location of the part for a pipeline laid indoors should not exceed +-5 millimeters, and +-10 millimeters for supports installed on external pipe lines. The permissible slope, according to these standards, is 0.001, unless otherwise provided by the project. There are also requirements for the location of supports relative to welded joints - at a distance of 5 centimeters or 20 centimeters for water supply and heating network pipes. https://ohtaspb.ru/articles/krepleniya_truboprovodov_po_sposobu_primeneniya/

Device

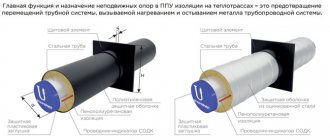

Fixed supports for pipes in polyurethane foam insulation consist of several elements:

- polyethylene body;

- SODK indicator;

- steel pipe;

- centering supports;

- an insulation layer made of polyurethane foam;

- centering support elements;

- fixed supports.

Each element must be firmly connected to each other so that the part remains intact under strong vibrations and physical stress.

Main installation features

Fixed-type elements are attached by welding to the platform, then secured to the pipeline using special fasteners. It is recommended to use metal plates to ensure even greater reliability. They are attached to the end of the clamps.

In the case of clamps, so-called stop strips should be used. They rest against the clamp and prevent the pipe from slipping. If the load on the structure is high, you can use two clamps at once. As for the distance between individual thrust elements, they are determined at the design stage in accordance with existing GOSTs and taking into account the specific operating conditions of the system.

Clamp-type supports are used for mounting above-ground structures. Shield supports are used if necessary to secure the pipe in the channel.

In this case, one important rule should be followed: there must be a certain gap between the clamp and the support itself, usually equal to one and a half millimeters. And in order to avoid corrosion at the points of contact, aluminum sheets can be used.

All GOSTs should be strictly observed, even if they are contrary to the wishes of the customer. In the end, the development of GOSTs was carried out by public service professionals with extensive experience in this field.

Classification

Fixed supports for polypropylene pipes are divided into separate groups depending on what raw materials are used for manufacturing. Kinds:

- With electric welded pipes, which are insulated with polyurethane foam. Manufactured according to GOST 10704, 10705, 10706.

- With seamless pipes and insulated with polyurethane foam.

- Parts used for the manufacture of gas and oil pipelines are produced in accordance with GOST 20295. They have welded pipes and polyurethane foam insulation.

- With seamless heat-deformed and cold-deformed pipes. Manufactured in accordance with GOST 8732, 8734. They have polyurethane foam insulation.

- Parts used for the manufacture of pipelines for the petrochemical and oil refining industries. Manufactured on the basis of GOST 550. Covered with polyurethane foam insulation.

- Parts with welded pipes.

The polyethylene protective shell is the main element, without which the part cannot be put on sale or used.

If there is no protective polyurethane foam layer on the structure, the part will quickly become unusable due to the formation of rust. In addition, parts without polyurethane foam are not used to assemble hot water pipelines.

Support is not just a separate element of the system

It would be a big mistake to consider the support an independent structure. In fact, this is not an independent construction part, but an integral part of the entire pipeline system. Supports perform many useful functions. For example:

- Protection of the pipe from damage where it touches supporting structures;

- Correct position of the entire pipeline on the ground;

- Distribution of loads along the entire length of the route;

- Elimination of vibration disturbances and reduction of stress inside pipes.

Supports are also often called “suspension”. But in reality, this is not always true. After all, pendants, in turn, are one of the types of supporting structures. Therefore, it would not be entirely correct to summarize them under a single name.

Characteristics of pipe supports and their purpose

A fixed support is usually understood as a steel supporting structure that bears the main load of the highway. The support prevents the steel flanges from moving in any direction. Mechanical impacts on the support are softened thanks to a protective shell made of polyurethane foam and galvanization. The barrier to moisture is created using heat shrink tape.

Purchased supports for polyurethane foam pipes must fully comply with established standards.

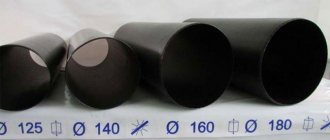

There are various types of fixed structures that comply with GOST. This document regulates the production of non-productive products with maximum diameter values: the minimum value is 32 mm, the maximum value is 1420 mm.

After laying the standardized products in the trench, it is concreted on a reinforced base, thanks to which the fixed supports are called “dead”.

The documents regulating this process include:

- GOST 30732-2006.

- GOST 14911-82.

- GOST 36-94-83.

NOPs can be made from different materials, among which a special place is occupied by:

- Hot rolled steel sheets.

- Pipe steel billets.

- Centralizers.

- Thermal tape.

- Polyurethane foam shell.

- Galvanized shell.

The release of NOP can be carried out with or without thermal insulation.

There are also different ways to lay pipelines. It could be:

- Overhead pipeline. To protect such a system, galvanized sheathing should be used.

- Underground ductless system in a polyurethane foam shell. According to the relevant standard, waterproofing of supports for such pipelines must be done using polyurethane foam or PE sheathing.

In addition, there are regulatory documents that take into account the parameters of compensators. In accordance with these standards, the length of heating main sections is determined. Compensators are designed to dampen temperature changes in the pipe insulation, so they are installed in the spaces between the pipes. Fixation is carried out in several places; reinforced concrete frames are used for installation.

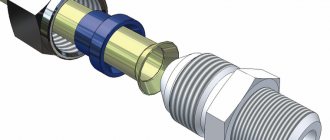

Unit 2.39 Fixed mount to the ceiling for turbos with a diameter from 2 to 10 inches

Description A pipeline without insulation of medium and large diameter is mounted to the ceiling on a fixed support. Its body is secured with 4 fastening kits (bolts, washers and nuts) with perforated consoles. They are placed vertically and pressed to the slab with anchor bolts. There is a clamp on the body that directly fixes the pipe. Depending on the size of the pipe, the load on the fastening unit can be very significant. For this reason, in order to avoid the pipeline system breaking from the base and the subsequent occurrence of emergency situations, the fixed support is additionally connected with guy wires (at an angle of 45°) to the ceiling. They contain threaded rods with special angles and expansion anchor bolts. This fastening unit with a clamped pipeline is used when the temperature of the pumped substance is slightly different from the environment. Now, due to the presence of compensation for thermal compression or expansion, the pipe will not collapse. Therefore, such pipeline fastenings are used in shopping centers, industrial premises for cold and hot water, heating systems or compressed air. Components are manufactured galvanized, which protects them from water and corrosive processes. During operation, they may experience significant vibration loads and exposure to polluted or excessively humid air.

- A traverse with a support heel, in which a pair of holes are made for the correct selection of the length of the console and its angular position. The body of the fixed support is suspended on a traverse.

- Anchor bolts. Firmly and reliably hold stud angles and consoles in the concrete floor. An increase in the load on the pipeline fastening unit is possible precisely due to the use of braces.

- Clamp to a fixed support. It eliminates dangerous pipe displacements and compensates them in the required direction to prevent ruptures. The product is manufactured to be resistant to vibration.

- Support housing. Use only in conjunction with the above clamp for better compensation of temperature deformations in pipeline systems.

- A set of fasteners - bolts, nuts and washers. They provide a strong connection between the support body, traverses and studs. Thus, the forces acting on the pipe fastening unit are completely redistributed to the floors.

- The washer for the mounting rail repeats the letter P in cross-section. It is used for installing pipelines and traverses.

- Threaded rod with thread. It acts as a tension rod to ensure that the pipe fastening unit can withstand the tearing force, which sometimes exceeds the design value for a short period of time.

- Universal installation corner. They are needed for assembling studs and traverses with a support body at an angle of 45 degrees.

There is a table that clearly indicates the technological division of supports in accordance with the norms and standards of their use. This table is used at the design stage, when the pipeline is planned on paper. This ensures rational use of funds, as well as the safety of the entire structure in the future.

Features of installation on the heating main

Fixed stabilizers for heat supply systems are produced in two versions: for underground and above-ground operation. The placement of clamps in underground utilities is necessary to absorb overloads that occur when soil layers are displaced.

The uniform arrangement of support elements along the entire length of the heating main reduces vertical and linear loads on the pipeline branch. Structural components are installed in front of heating equipment, bellows corrugated pipes and fittings for main facilities. They help prevent temperature effects on the above devices.

When installing, the supports are fixed into reinforced concrete frames on those line segments that are marked in the technical design.

Laying systems underground requires placing the pipes and the supporting elements themselves in a polyethylene sheath. It provides thermal insulation protection for engineering structures, reducing heat losses in communications.

The number of clamps is specified in the technical documentation. Calculation of the optimal distance between them is an important step in the design of civil and industrial facilities. At the same time, engineers take into account the throughput and length of the highway, and take into account the instructions of building codes and regulations. Thus, SNiP 2.09.03.-85 defines a minimum step of 6 meters (a multiple of three) when designing industrial communications, including stabilizers for pipeline branches. These dimensions change when the route crosses railway and road communications and approaches different buildings.

Advantages and disadvantages

- Ease of fixation: sliding support elements for pipelines are characterized by quick installation, which can significantly reduce financial costs for production.

- Reliability: both clamp and welded sliding bearings are not only more functional than fixed ones, but also safer. They reduce the risk of pipeline damage due to thermal expansion.

- Lightweight design, which can significantly reduce the final cost. Its price is reduced, since “dead” fasteners are heavier and require more installation and operation costs.

- Durability.

- A significant selection of products on the market.

The only drawback of sliding supports is the high market cost.

Accessories